Method and device for recycling high-pressure dissolved steam exhaust of diluting tank in alumina production

A technology of spent steam recovery and dilution tank, which is applied in heating devices, steam/steam condensers, and other non-combustion heat generation, etc., can solve the problems of low spent steam recovery rate, large spent steam waste heat loss, and environmental pollution, etc. Achieve obvious recycling benefits, reduce production energy consumption, and avoid environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

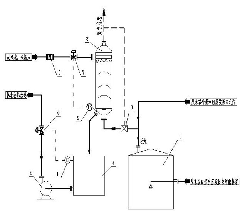

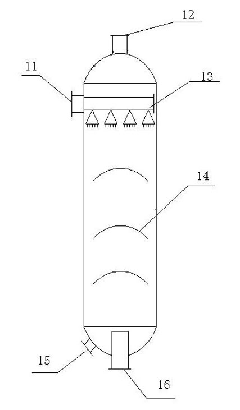

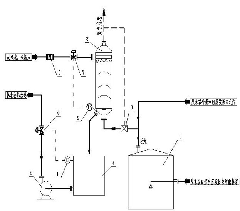

[0019] Embodiments of the present invention: as figure 1 As shown, in the method of the present invention, a exhaust steam recoverer 2 is arranged on the upper part of the dilution tank 1 to recover the stripped exhaust steam. The exhaust steam produced by the high-pressure dissolution dilution tank 1 and the exhaust steam of the final stage condensate are mixed with the exhaust steam from the evaporator, and then introduced from the bottom of the exhaust steam recovery device 2, passing through the multi-layer arc-shaped plate of the exhaust steam recovery device 2, and mixed with the exhaust steam from the exhaust steam recovery device 2. The cold water sprayed on the upper part of the recovery device 2 performs heat exchange, and the exhaust steam condenses and heats the cold water. After the two are mixed, hot water comes out from the bottom of the exhaust gas recovery device 2 and enters the hot water tank 4 . By adjusting the flow of fresh water, the temperature of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com