Process for recycling excessive methyl alcohol in biodiesel production process

A biodiesel and production process technology, applied in the field of chemical engineering, can solve the problems affecting the conversion rate of esterification, waste product quality of methanol, waste of environmental protection pressure, etc., and achieve high energy utilization efficiency, thorough and reliable recovery, and complete recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

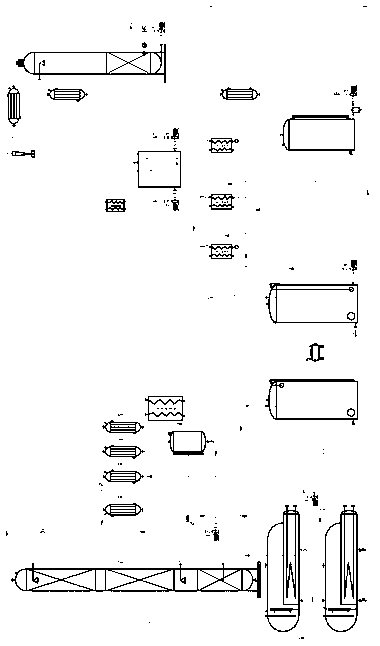

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, and the percentage concentration involved is the mass percentage concentration. The main equipment contacting methanol is all made of 304 stainless steel; the rectification section of the rectification tower is made of high-efficiency structured corrugated packing 250Y, made of 316 stainless steel; the stripping section of the rectification tower and the negative pressure flash tower are made of DN40 Pall ring packing, made of 316 stainless steel .

[0025] Such as figure 1 Shown, specifically, processing step of the present invention is as follows:

[0026] In the first step, the waste methanol produced by the biodiesel production line is condensed into a liquid phase and stored in a dedicated waste methanol storage tank 7;

[0027] The gaseous methanol leaving the reactor with water in the esterification reaction turns into a liquid phase after exchanging heat with the feed metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com