Alkyl-substituted pyridinamine iron-based catalyst and preparation method and application thereof

A pyridine amine iron series and pyridine amine iron technology are applied in the pyridine amine iron series catalyst, the application in the polymerization of isoprene, and the field of catalyst preparation, which can solve the problem of unclear catalyst structure active center, low molecular weight of synthetic polymer, Problems such as poor selectivity, to achieve the effect of small temperature dependence, good industrialization value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

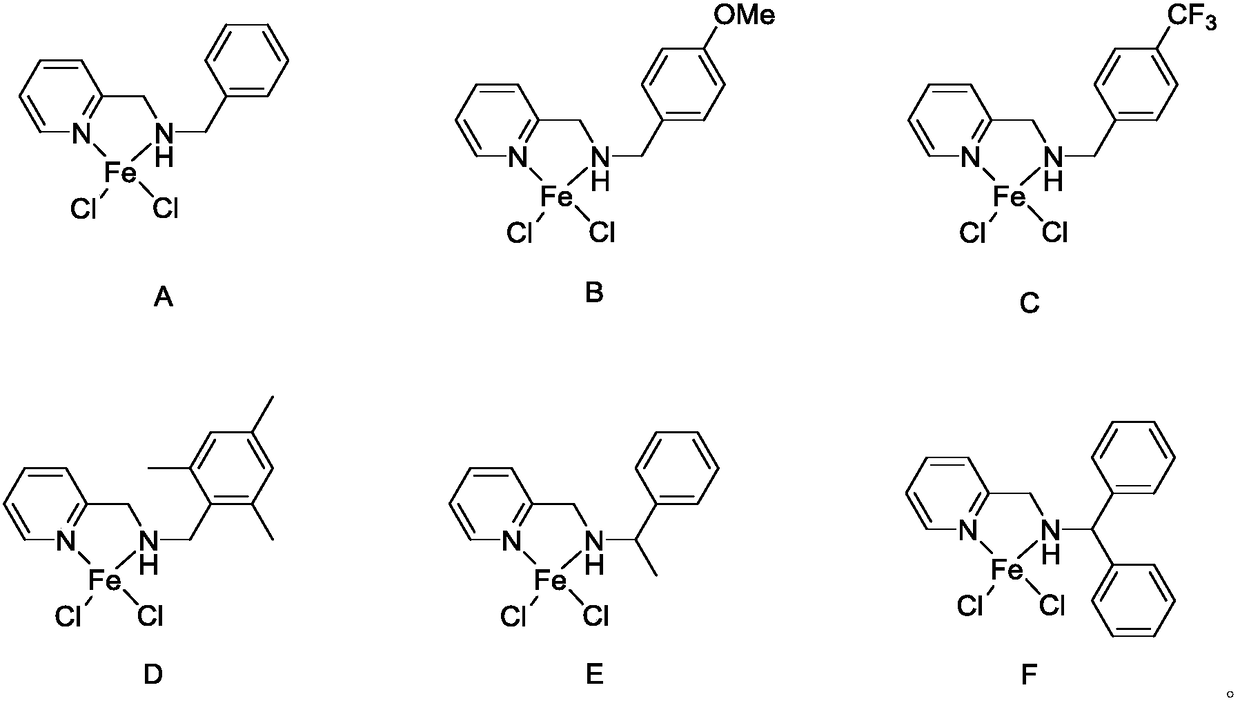

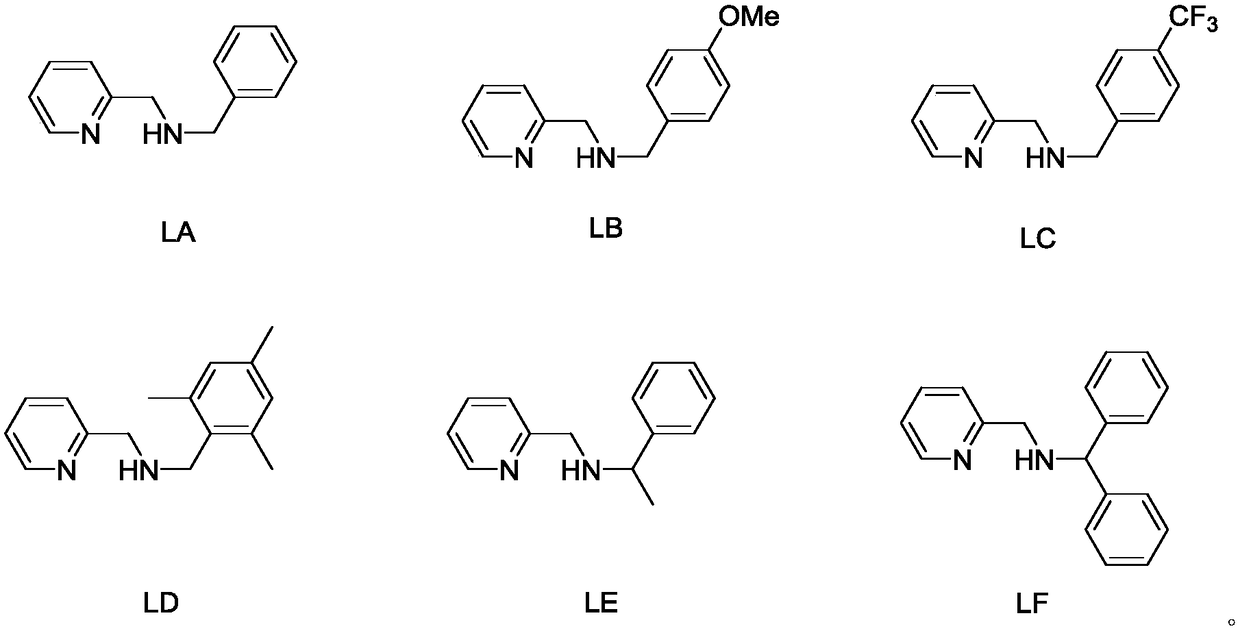

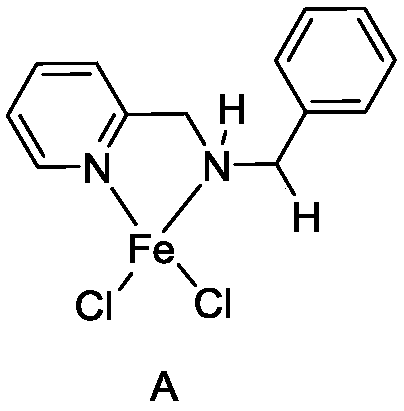

[0033] This embodiment prepares pyridine amine iron complex A:

[0034] The 25mL Schlenk reaction tube was pumped and baked three times, and 15mL redistilled dichloromethane, equimolar ratio of anhydrous FeCl 2 And benzyl-substituted pyridinium amine ligand (1.5mmol) (structural formula LA), stirred at room temperature for 48h. After the reaction, filter under an argon atmosphere, collect the filter residue, vacuum-dry dichloromethane, add 10 mL of distilled n-hexane to wash twice (the filtrate is colorless and clear), and vacuum-dry to constant weight to obtain a white solid, structural formula:

[0035]

[0036] Mass Spectrometry: C 13 h 14 Cl 2 FeN 2 :[M-Cl] + : Theoretical value: 289.0189; measured value: 289.0191.

[0037] Elemental Analysis: C 13 h 14 Cl 2 FeN 2 : Theoretical value: C, 48.04; H, 4.34; N, 8.62; Measured value: C, 48.10%; H, 4.30%; N, 8.58%.

Embodiment 2

[0039] This embodiment prepares pyridine amine iron complex B:

[0040] The 25mL Schlenk reaction tube was pumped and baked three times, and 15mL redistilled dichloromethane, equimolar ratio of anhydrous FeCl 2and methoxy-substituted benzylpyridinium ligand (1.5mmol) (structural formula LB), stirred at room temperature for 48h. After the reaction was completed, filter under an argon atmosphere, collect the filter residue, vacuum-dry dichloromethane, add 10 mL of distilled n-hexane to wash twice (the filtrate is colorless and clear), and vacuum-dry to constant weight to obtain a light yellow solid, structural formula :

[0041]

[0042] Mass Spectrometry: C 14 h 16 Cl 2 FeN 2 o : [M-Cl] + : Theoretical value: 319.0295; measured value: 319.0290.

[0043] Elemental Analysis: C 13 h 14 Cl 2 FeN 2 : Theoretical value: C, 47.36; H, 4.54; N, 7.89; Measured value: C, 47.41%; H, 4.55%; N, 7.93%.

Embodiment 3

[0045] This embodiment prepares pyridine amine iron complex C:

[0046] The 25mL Schlenk reaction tube was pumped and baked three times, and 15mL redistilled dichloromethane, equimolar ratio of anhydrous FeCl 2 And trifluoromethyl-substituted benzylpyridinium ligand (1.5mmol) (structural formula LC), stirred at room temperature for 48h. After the reaction was completed, filter under an argon atmosphere, collect the filter residue, vacuum-dry dichloromethane, add 10 mL of distilled n-hexane to wash twice (the filtrate is colorless and clear), and vacuum-dry to constant weight to obtain a light yellow solid, structural formula :

[0047]

[0048] Mass Spectrometry: C 14 h 13 Cl 2 f 3 FeN 2 :[M-Cl] + : Theoretical value: 357.0063; measured value: 357.0065.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com