Low-melting-point metal powder as well as preparation method and application thereof

A low-melting-point metal and powder technology, which is applied in the field of low-melting-point metal powder and its preparation, can solve the problems of seldom involving low-melting-point metals, wires cannot be printed well for a long time, and the hardness of low-melting-point metals is not enough. It is easy to promote industrialization Production, significant industrial value, fine particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

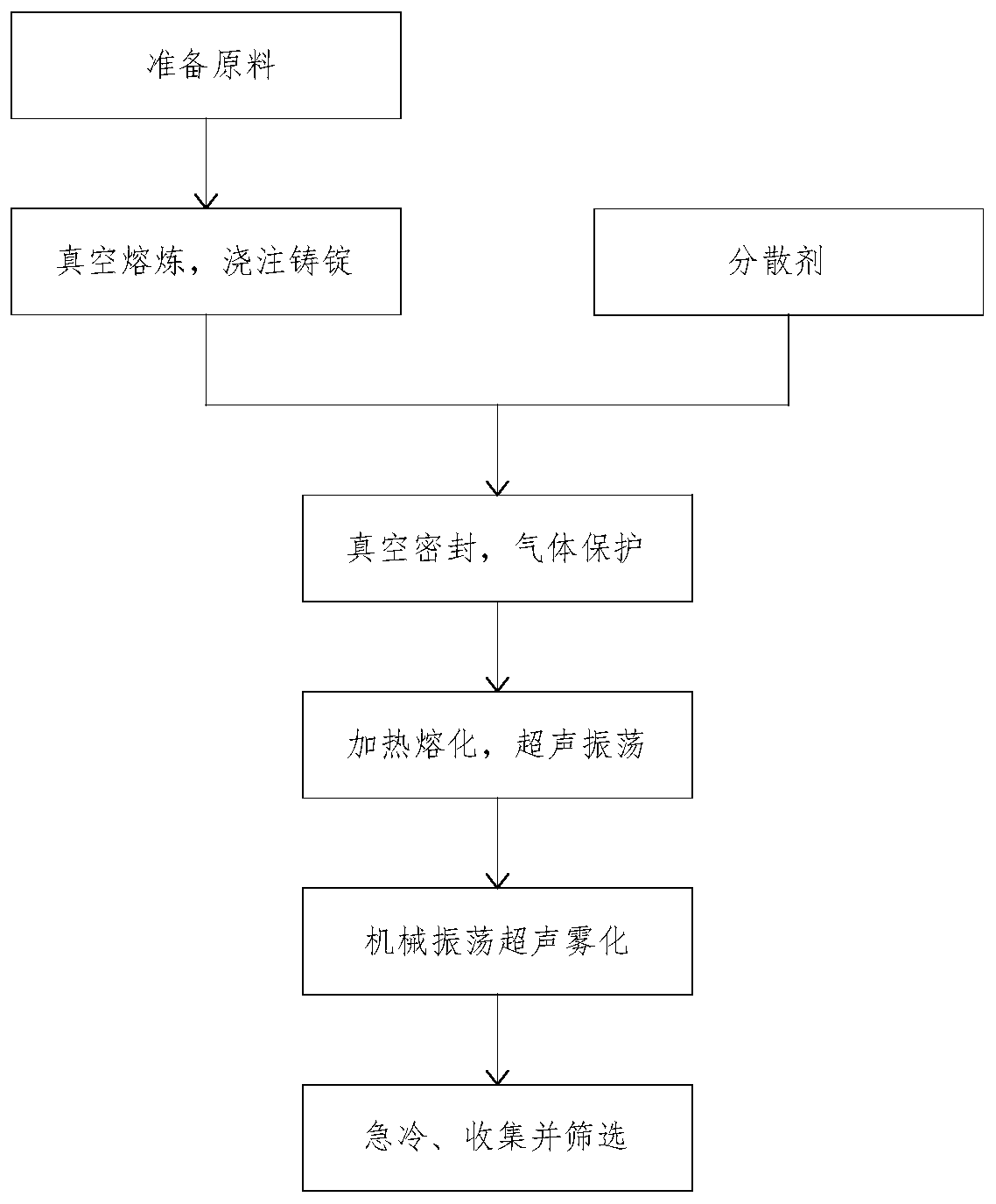

[0045] This embodiment provides a kind of preparation method of low-melting point metal powder, such as figure 1 As shown, it specifically includes the following steps:

[0046](1) Prepare 150 grams of raw materials with pure bismuth, indium, tin and zinc metals at a mass ratio of 35:48.6:15.9:0.4, then place the raw materials in a vacuum melting furnace and heat them to 200°C for smelting, and the solution is smelted from time to time Stir and keep argon flowing during the whole stirring process to avoid oxidation of the melt. After the melting is completed, pour the alloy into an ingot for use. The melting point of this alloy is 58°C;

[0047] (2) Prepare the ingot in step (1) and ethanol (about 19 ml) at a volume ratio of 1:1, put it in a quartz tube, seal the tube, vacuumize and seal it, and fill it with argon for protection, and place the quartz tube in an ultrasonic generator. In the container, and heated to 65 ° C, after the alloy is completely melted, start ultrasonic...

Embodiment 2

[0051] This embodiment provides a method for preparing low melting point metal powder, which specifically includes the following steps:

[0052] (1) Prepare 150 grams of raw materials with pure bismuth, indium, tin and zinc metals at a mass ratio of 35:48.6:15.9:0.4, then place the raw materials in a vacuum melting furnace and heat them to 200°C for smelting, and the solution is smelted from time to time Stir and keep argon flowing during the whole stirring process to avoid oxidation of the melt. After the melting is completed, pour the alloy into an ingot for use. The melting point of this alloy is 58°C;

[0053] (2) Prepare the ingot in step (1) and ethylene glycol (about 19 ml) at a volume ratio of 1:1, put it in a quartz tube, seal the tube, vacuumize and seal it, and fill it with argon for protection. Place the quartz tube in Ultrasonic generator, and heated to 65 ° C, after the alloy is completely melted, start ultrasonic oscillation, and obtain a mixed solution after os...

Embodiment 3

[0057] This embodiment provides a method for preparing low melting point metal powder, which specifically includes the following steps:

[0058] (1) Prepare 150 grams of raw materials with pure bismuth, indium and tin metal in a mass ratio of 35:49:16, then place the raw materials in a vacuum melting furnace and heat them to 200°C for smelting, and stir the solution from time to time. Keep argon flowing during the stirring process to avoid oxidation of the melt. After the melting is completed, pour the alloy into an ingot for use. The melting point of this alloy is 60°C;

[0059] (2) Prepare the ingot in step (1) and ethylene glycol (about 19 ml) at a volume ratio of 1:1, put it in a quartz tube, seal the tube, vacuumize and seal it, and fill it with argon for protection. Place the quartz tube in Ultrasonic generator, and heated to 65 ° C, after the alloy is completely melted, start ultrasonic oscillation, and obtain a mixed solution after oscillation for about 30 minutes;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com