Surface acoustic wave device and method of manufacturing device

A surface acoustic wave device and surface acoustic wave technology, which is applied in the manufacture of electric solid devices, semiconductor devices, semiconductor/solid state devices, etc., can solve problems such as damage to output, failure to provide sealing characteristics, damage to cut off or separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

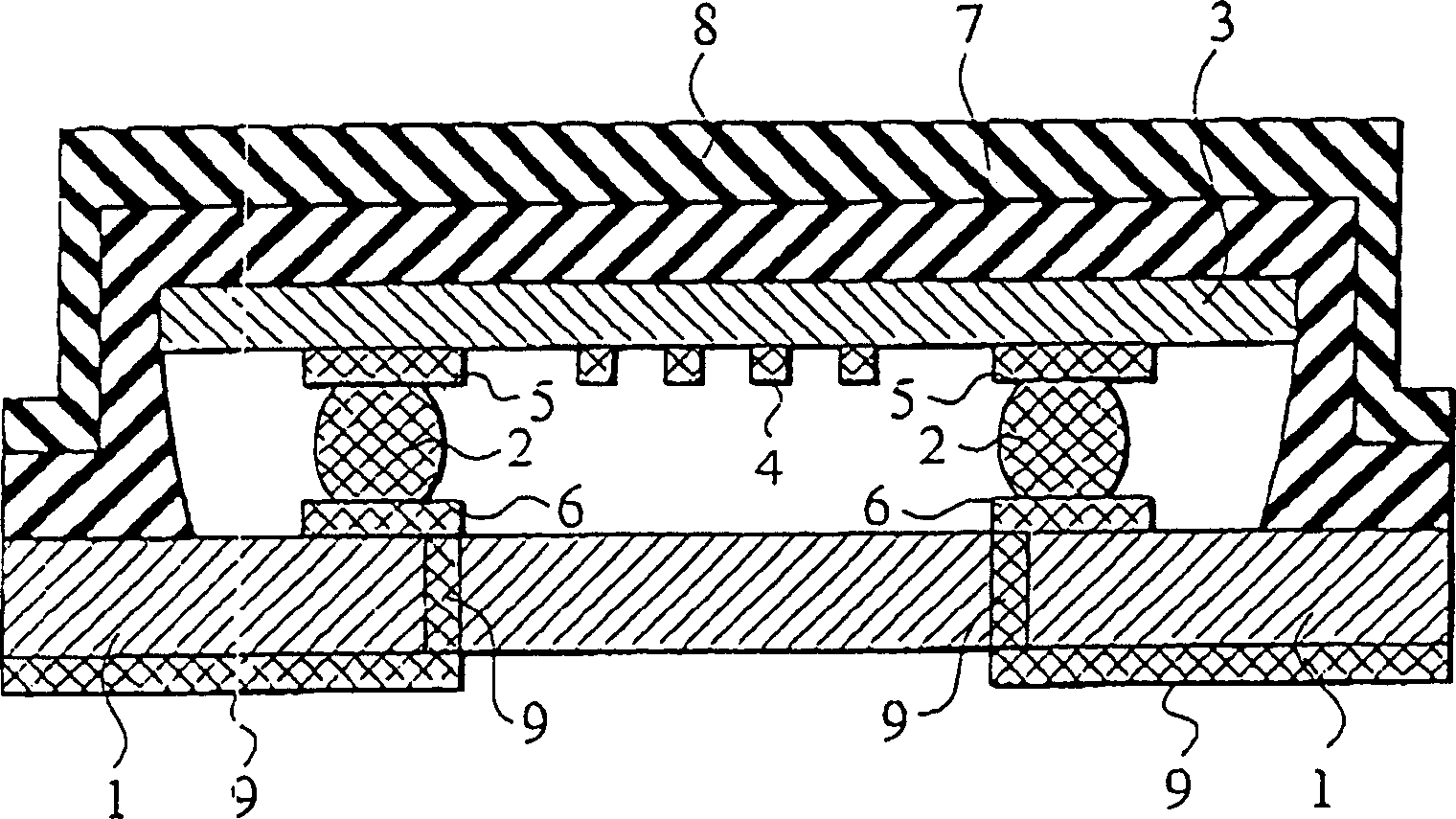

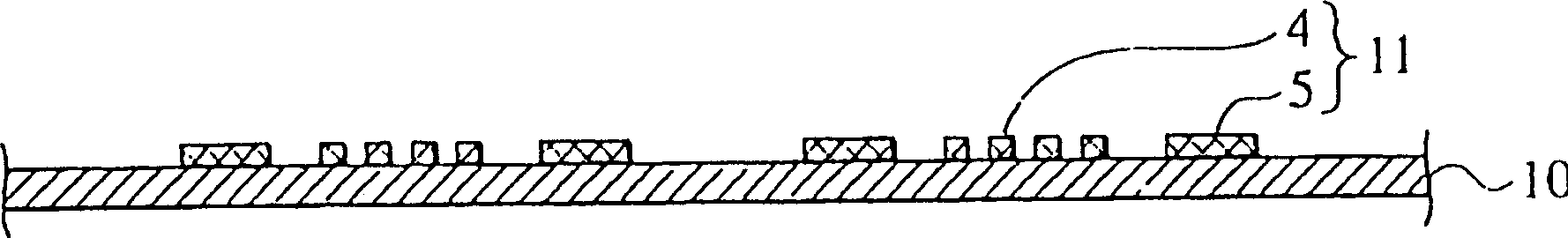

[0026] figure 1 is a sectional view showing a surface acoustic wave device according to Embodiment 1 of the present invention. The surface acoustic wave device according to Embodiment 1 has a base plate 1 with a predetermined line and electrode pads 6 formed on its front and rear faces; a striker 2 connected to the electrode pads 6 on the base plate 1; a surface acoustic wave element with Electrode sheet 5 and transducer 4 formed on the surface of piezoelectric substrate 3; and sealing materials 7 and 8, which are mechanically connected to chassis 1 and cover and seal the surface acoustic wave element.

[0027] On the back of the base plate 1, terminals 9 connected to the outside are formed, and a circuit pattern and electrode pads 6 connected to the terminals 9 are formed on the surface thereof. The striker 2 is a connection part that electrically and mechanically connects the electrode sheet 6 to the electrode sheet 5 . The surface acoustic wave element has a piezoelectric...

Embodiment 2

[0057] Figure 7 is a sectional view showing a surface acoustic wave device according to Embodiment 2 of the present invention. The surface acoustic wave device of embodiment 2 also has the base plate 1, the striker 2 and the surface acoustic wave element, and this instrument has the same arrangement as the base plate 1, the striker 2 and the surface acoustic wave element in the apparatus of embodiment 1. The sealing material is mechanically connected to the base plate 1, and together with the base plate covers and seals the surface acoustic wave element. The structure of the sealing material is different from that of Example 1, and it has a three-layer structure.

[0058]According to Embodiment 2, the sealing material is composed of the insulating resin 22 , the first sealing material 7 and the second sealing material 8 . The insulating resin 22 is, for example, polyvinyl alcohol resin. Application of the insulating resin 22 prevents a short circuit between the metal wirin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com