Combined friction stir welding mixing head aiming at different thicknesses of sheets

A friction stir welding, combined technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of affecting welding quality, low production efficiency, slow welding speed, etc., saving loading and unloading time, simple and compact structure , The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

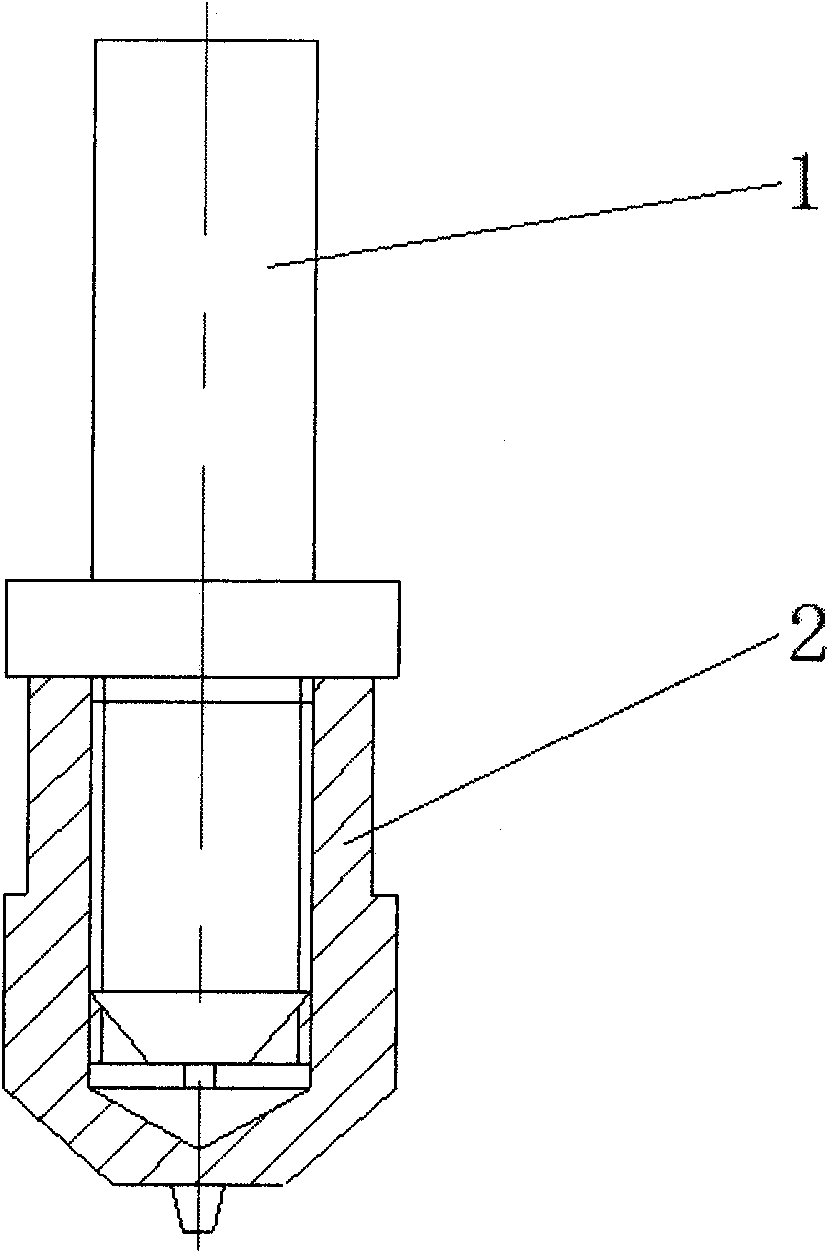

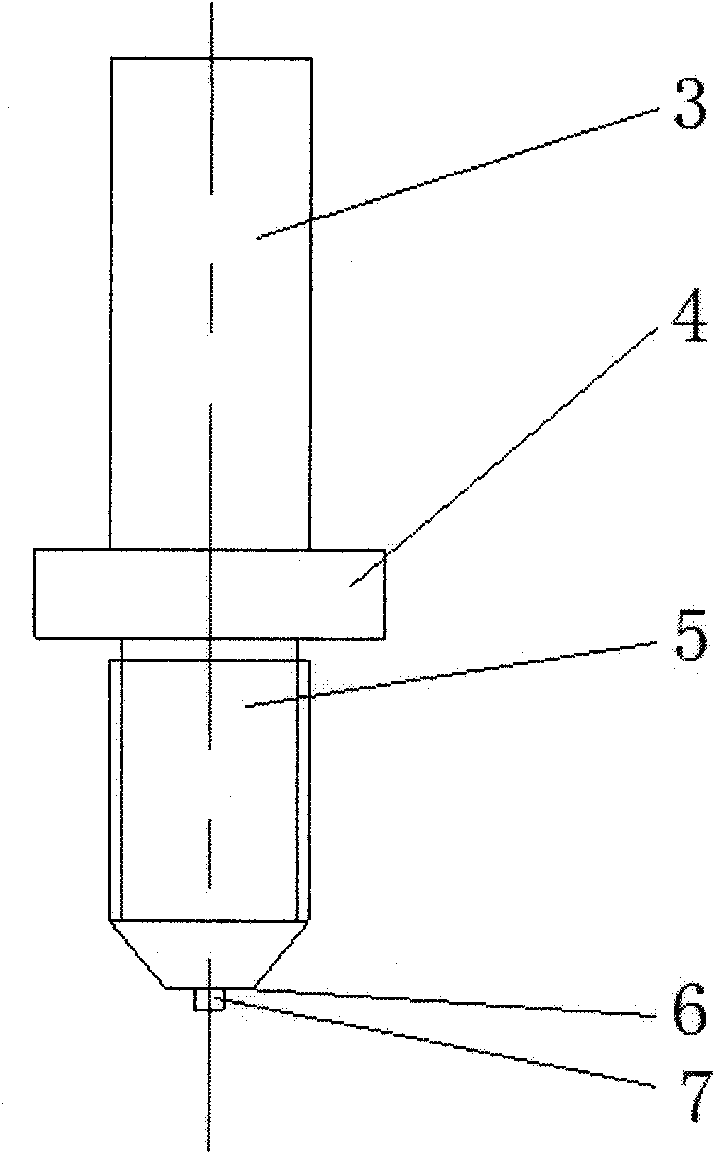

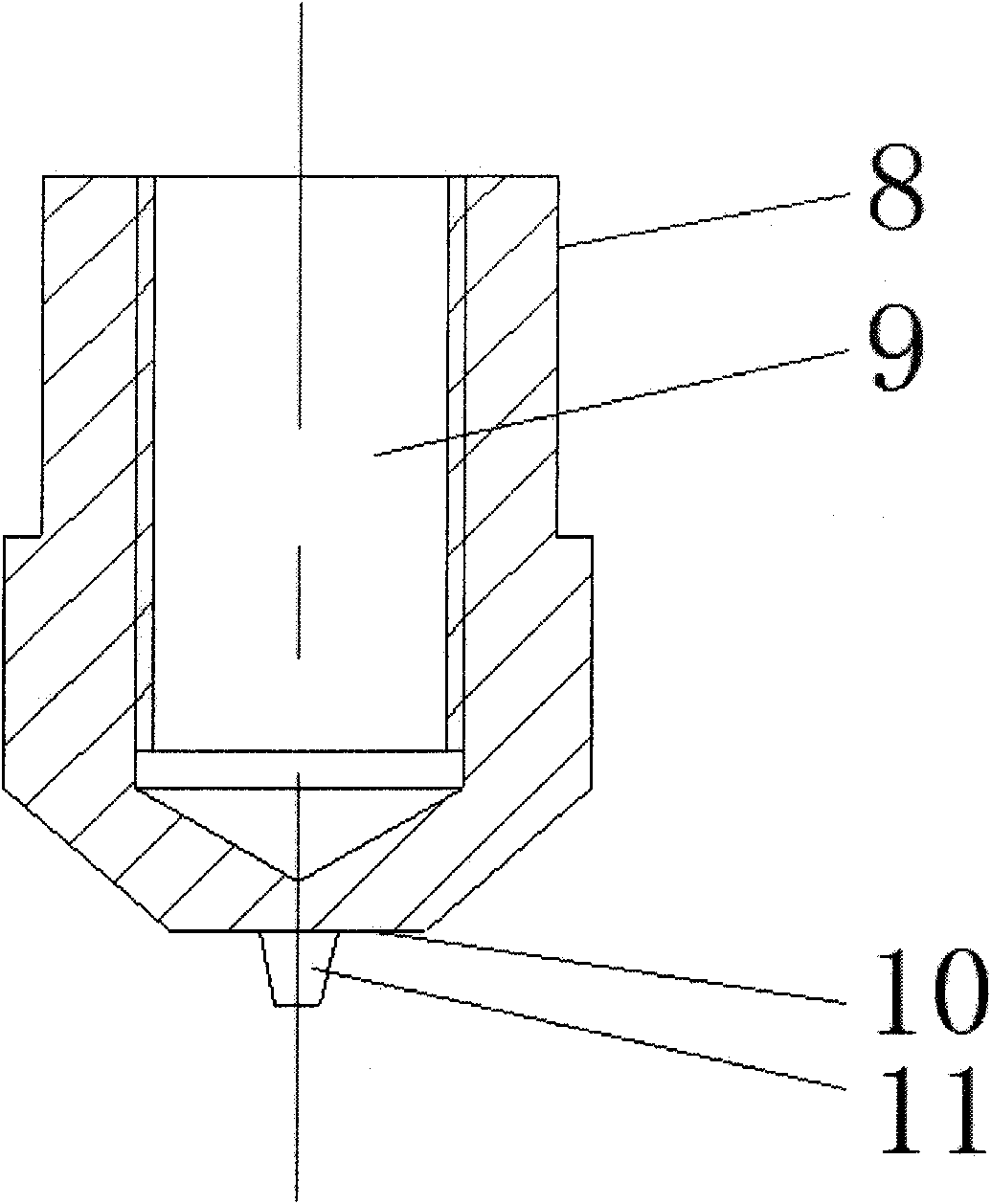

[0022] According to different materials to be welded, the central substrate stirring pin 7 and the sleeve stirring pin 11 can be made of different materials such as low carbon steel, stainless steel, high-speed steel and high-temperature alloy, and the materials of the central substrate 1 and the sleeve 2 can be different. The central matrix stirring needle 7 and the sleeve stirring needle 11 can be in different forms such as cylindrical bald head, cylindrical thread, tapered bald head and tapered thread. In this embodiment, the length of the central substrate stirring needle 7 on the central substrate 1 is h=2.5 mm, the diameter of the central substrate shoulder 6 is D=8 mm, and the length of the sleeve stirring needle 11 on the sleeve 2 varies in the range of h=4 ~10mm, the diameter of sleeve shaft shoulder 10 can be taken as D=8~24mm. On the threaded connecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com