Can cover structure used in fire-fighting vehicle

A technology for fire trucks and tank covers, applied in fire rescue and other directions, can solve the problems of increased processing costs, easy freezing and damage of nozzles, troublesome maintenance, etc., and achieves the effects of saving processing materials, rational distribution, and simplified maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

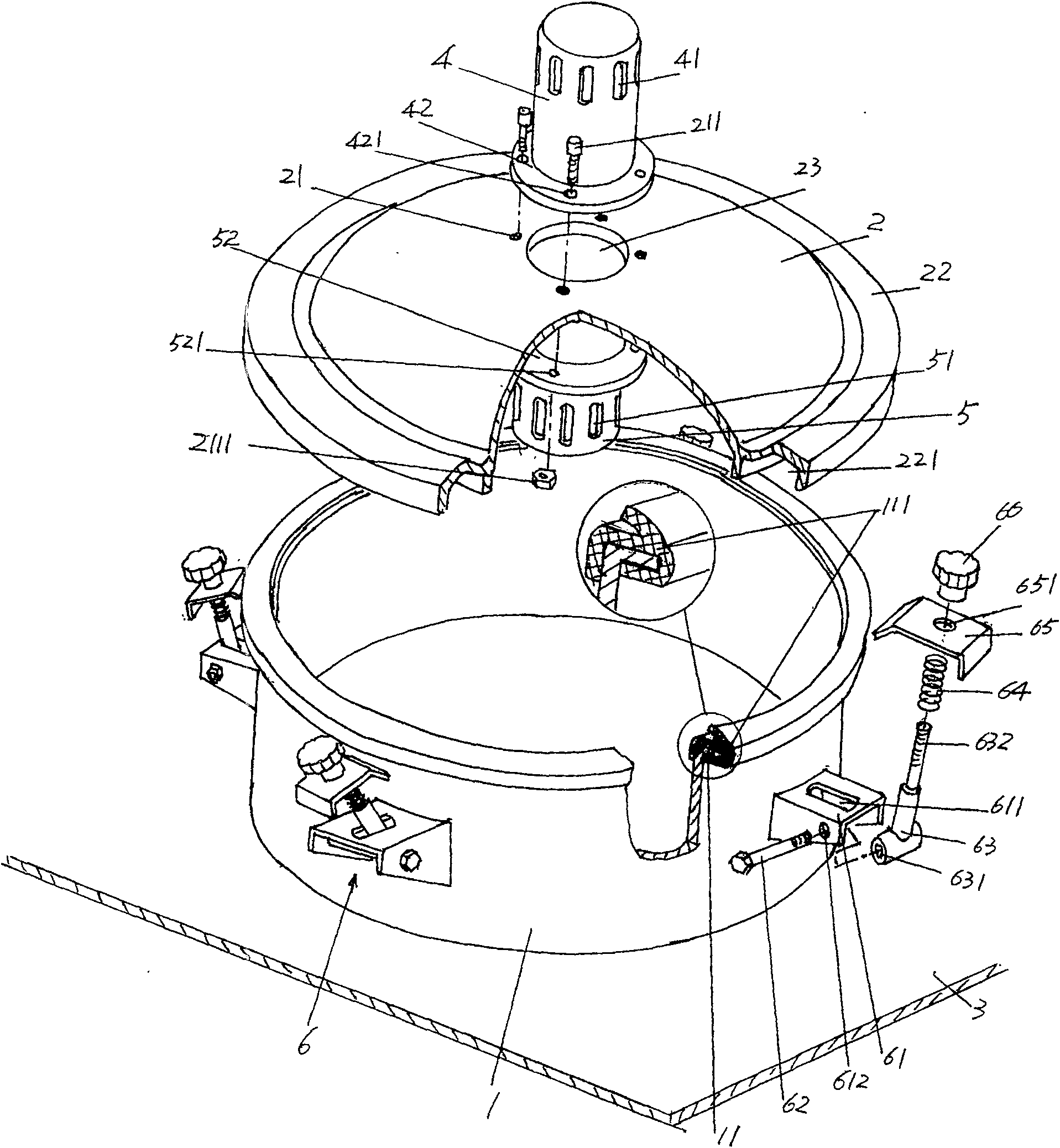

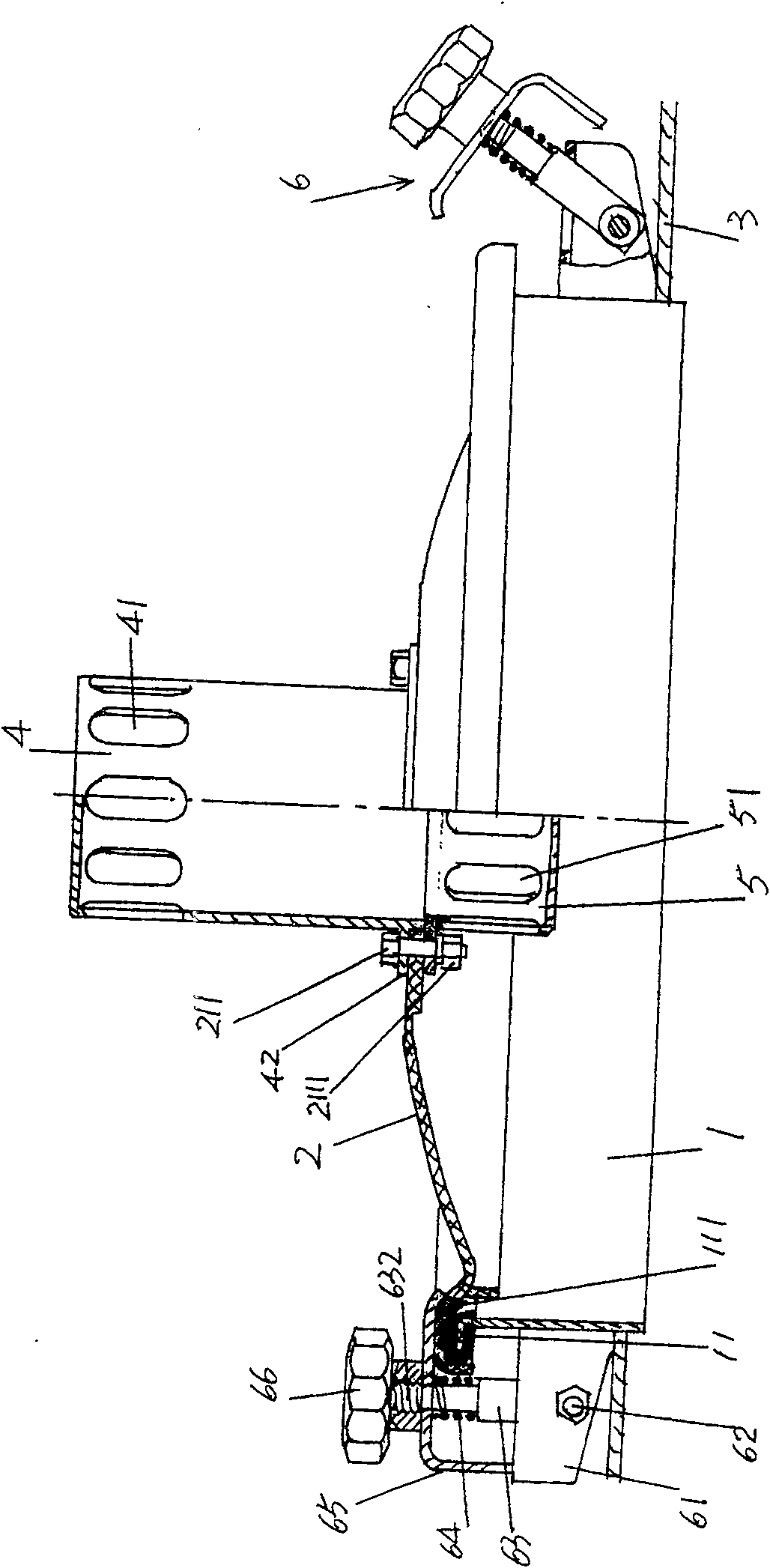

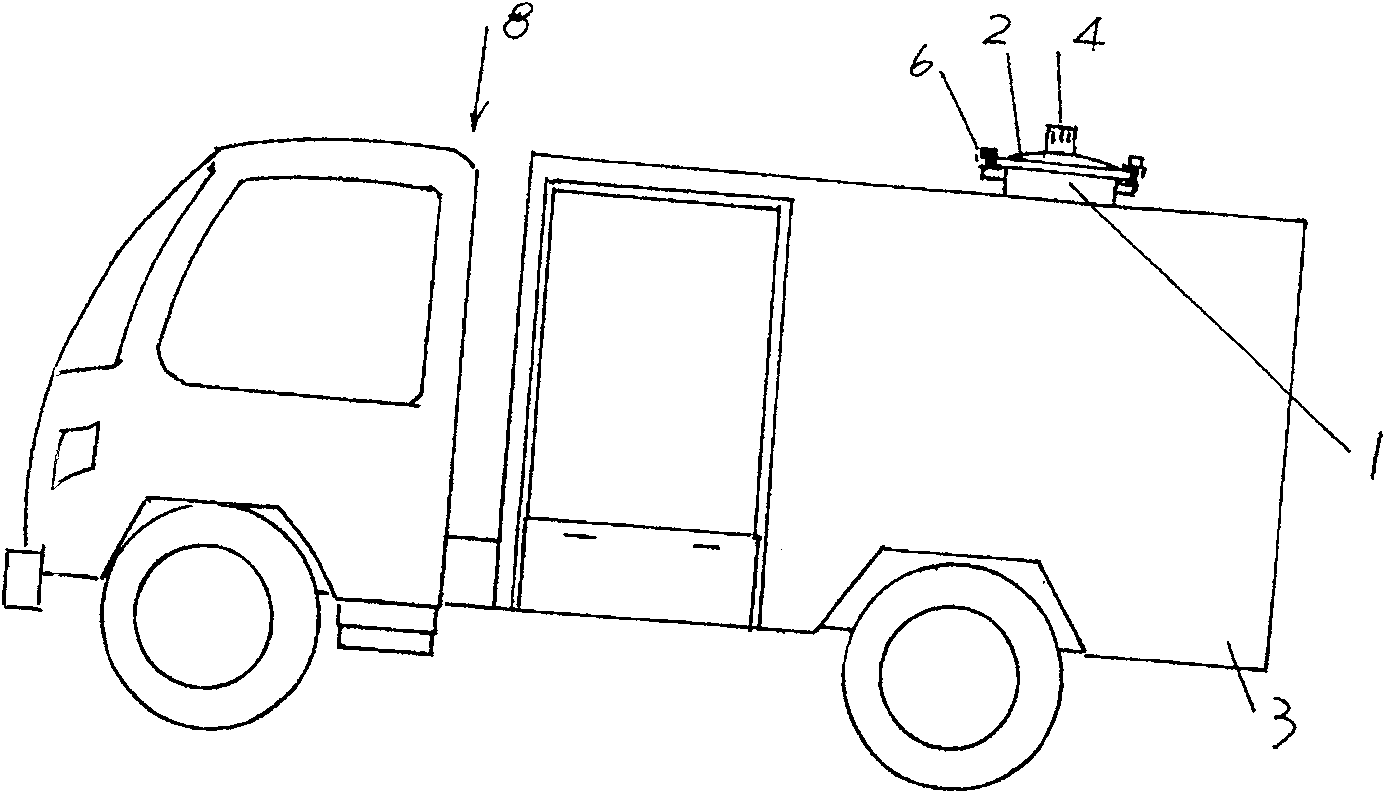

[0020] exist figure 1 , figure 2 Among them, the applicant provides a liquid storage tank 3, and the top of the liquid storage tank 3 is extended with a tank cover seat 1 that is cylindrical in shape and is usually called a manhole cover seat. 3 of the tank chamber for inspection or descaling, then the fire fighters can go in and out from the tank cover seat 1. There are at least three locking devices 6 interspersed on the outer wall of the tank lid seat 1, and as an example, the recommended number of locking devices 6 is five, each spaced at 72°. The bracket 61 of each locking device 6 is fixed to the wall body of the tank cover seat 1 by rivets or other similar methods, and a limiting groove 611 and a connecting shaft hole 612 are respectively opened on the bracket 61, and the pressing shaft 63 is penetrated at the limit. In the slot 611 , the connecting shaft 62 passes through the connecting shaft hole 612 and the shaft hole 631 preset at the base of the pressing shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com