Ring piece angle detection tool and detection method and application using same

An angle inspection and ring technology, which is applied in the field of semiconductor parts processing and parts processing, can solve the problems of easy deviation of the bump angle, inability to inspect the annular structure, and difficulty in the inspection process. Industrial value, easy to put in and take out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

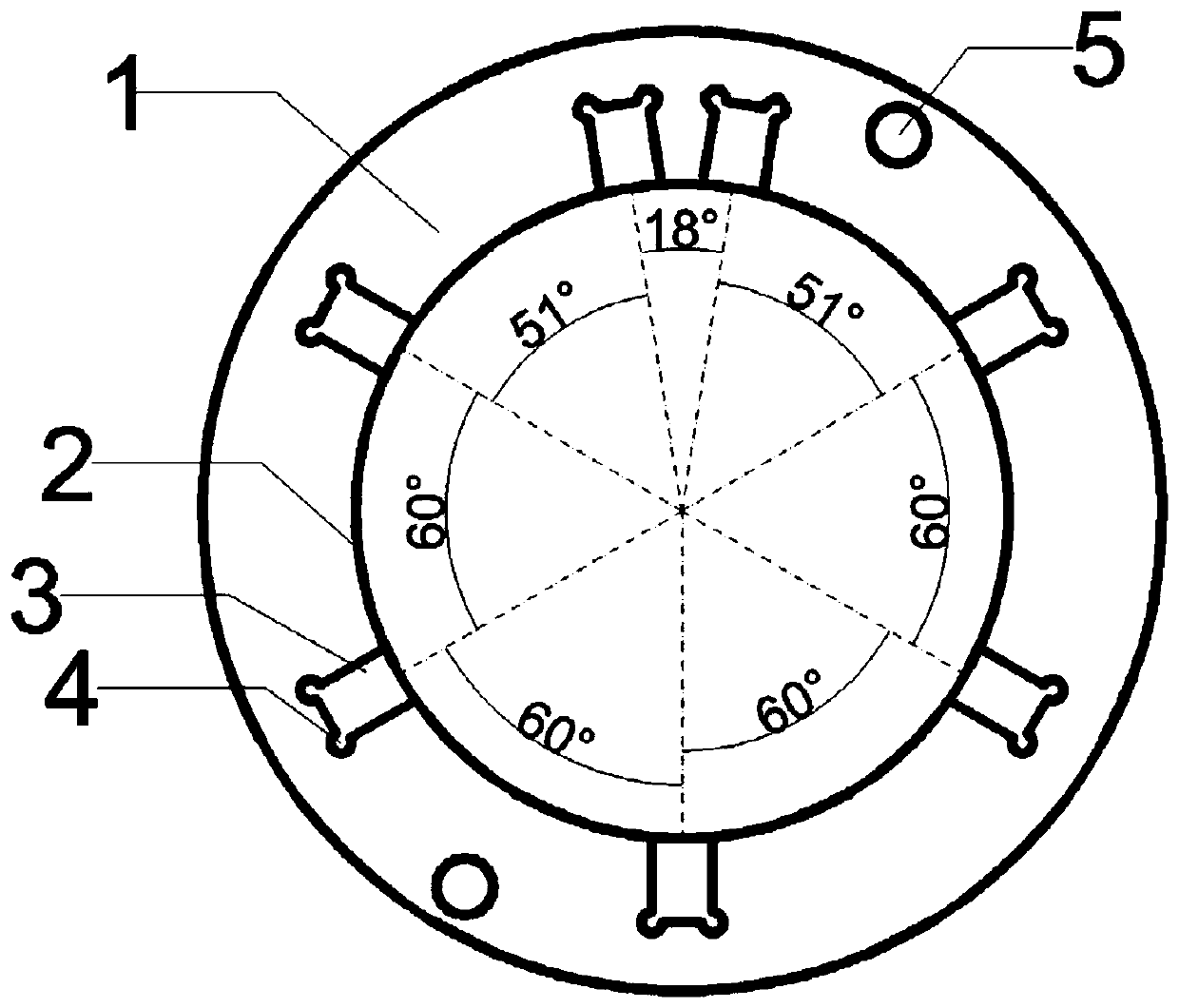

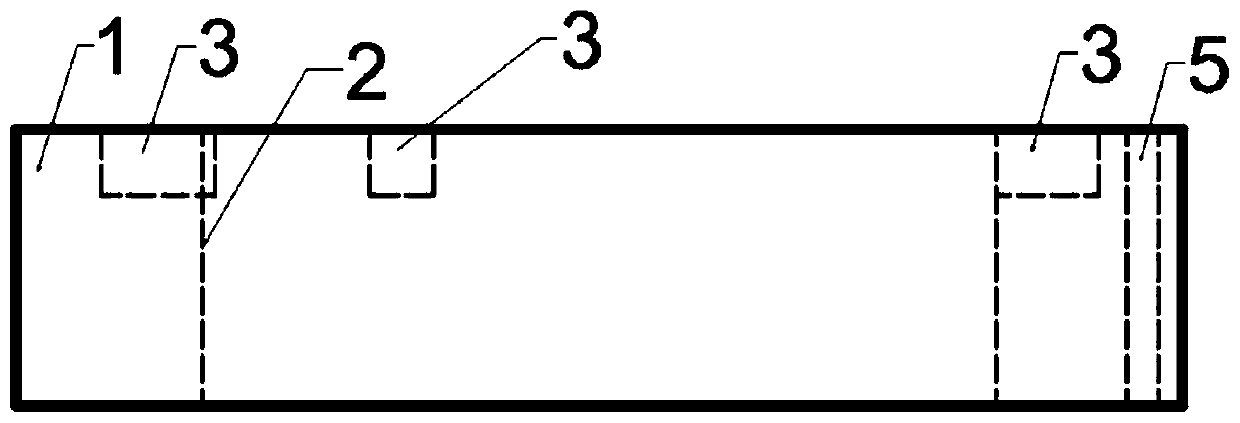

[0078] The present embodiment provides a kind of angle checker of ring piece A to be tested, such as figure 1 and figure 2 As shown, the inspection tool includes a detection sleeve 1 including an inner ring surface 2;

[0079] The detection cover 1 is a circular detection cover 1, the diameter of the inner ring surface 2 is 387.63mm, the height is 38mm, the ring width is 40mm, and a layer of plastic tape is arranged along the inner ring surface 2;

[0080] The inner ring surface 2 is provided with 7 axial grooves 3 in the radial direction, the depth is 20.5mm, the width is 20.5mm, and the length is 23.2mm. The angle between the centerlines of the 7 axial grooves 3 18°, 51°, 60°, 60°, 60° and 60° respectively;

[0081] Two process holes 4 with a diameter of 5 mm and a depth of 20.5 mm are provided on both sides of the groove surface of the axial groove 3 away from the inner ring surface 2 of the detection sleeve 1, and a layer of plastic tape is arranged on the surface of th...

Embodiment 2

[0085] This embodiment provides an angle inspection tool for the ring B to be tested, and the inspection tool includes a detection sleeve including an inner ring surface;

[0086] The detection sleeve is an annular detection sleeve, the diameter of the inner ring surface is 285.2mm, the height is 41mm, and the ring width is 45mm;

[0087] There are 5 axial grooves in the radial direction on the inner ring surface, the depth is 16.1mm, the width is 16.1mm, and the length is 20.1mm. The angles between the centerlines of the 5 axial grooves are respectively 30 °, 75°, 90° and 90°;

[0088] Two process holes with a diameter of 5.2 mm and a depth of 16.1 mm are provided on both sides of the groove surface of the axial groove away from the inner ring surface of the detection sleeve;

[0089] The detection sleeve is made of steel 508.

Embodiment 3

[0091] This embodiment provides an angle inspection tool for the ring B to be tested, and the inspection tool is the same as that in Embodiment 2 except that a layer of 3M electrical tape is arranged along the inner ring surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com