Zipper with different tooth patterns

A sprocket and zipper technology, applied in the field of zippers, can solve the problems of restricting sprocket shape design, affecting the aesthetics of zippers, increasing the volume of sliders and manufacturing costs, etc., to reduce material costs, improve aesthetics, and reduce processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

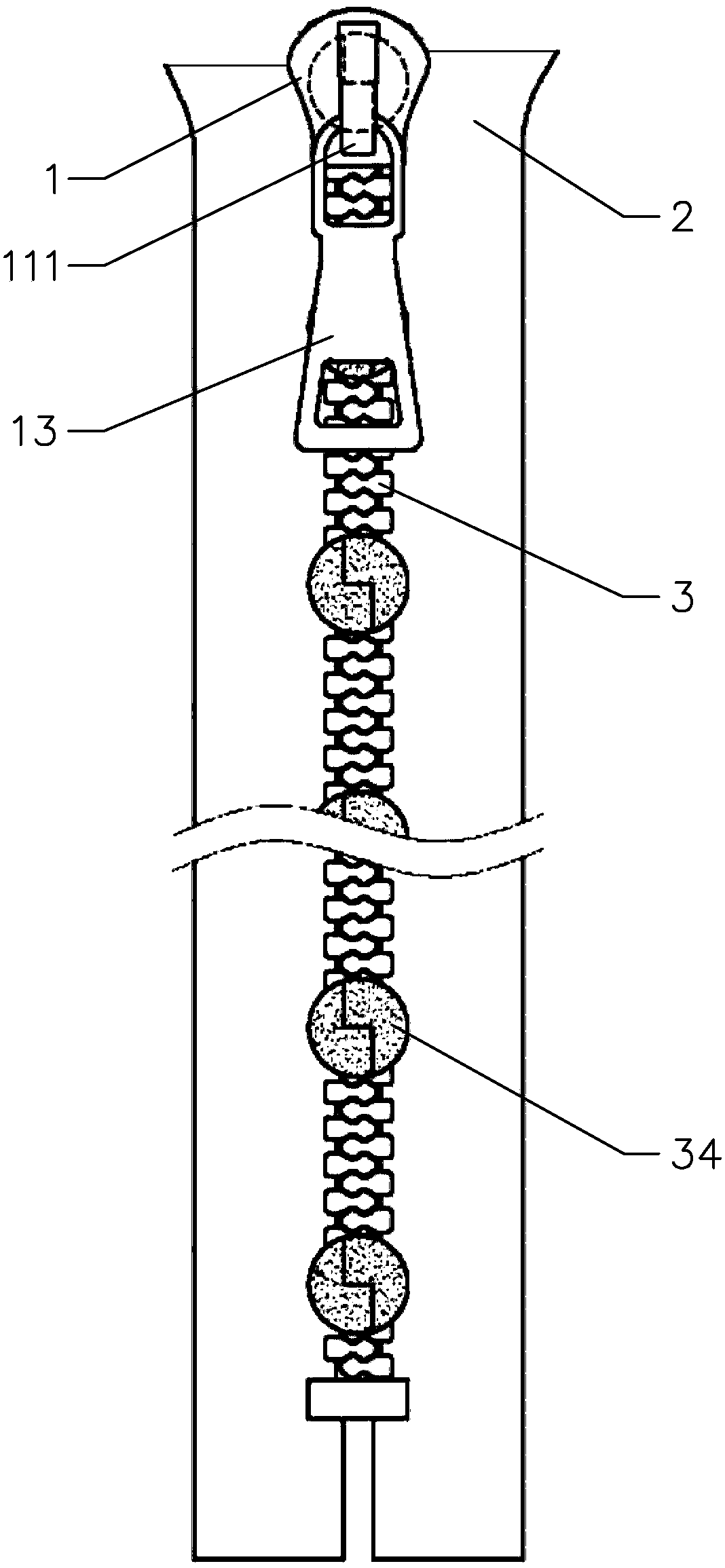

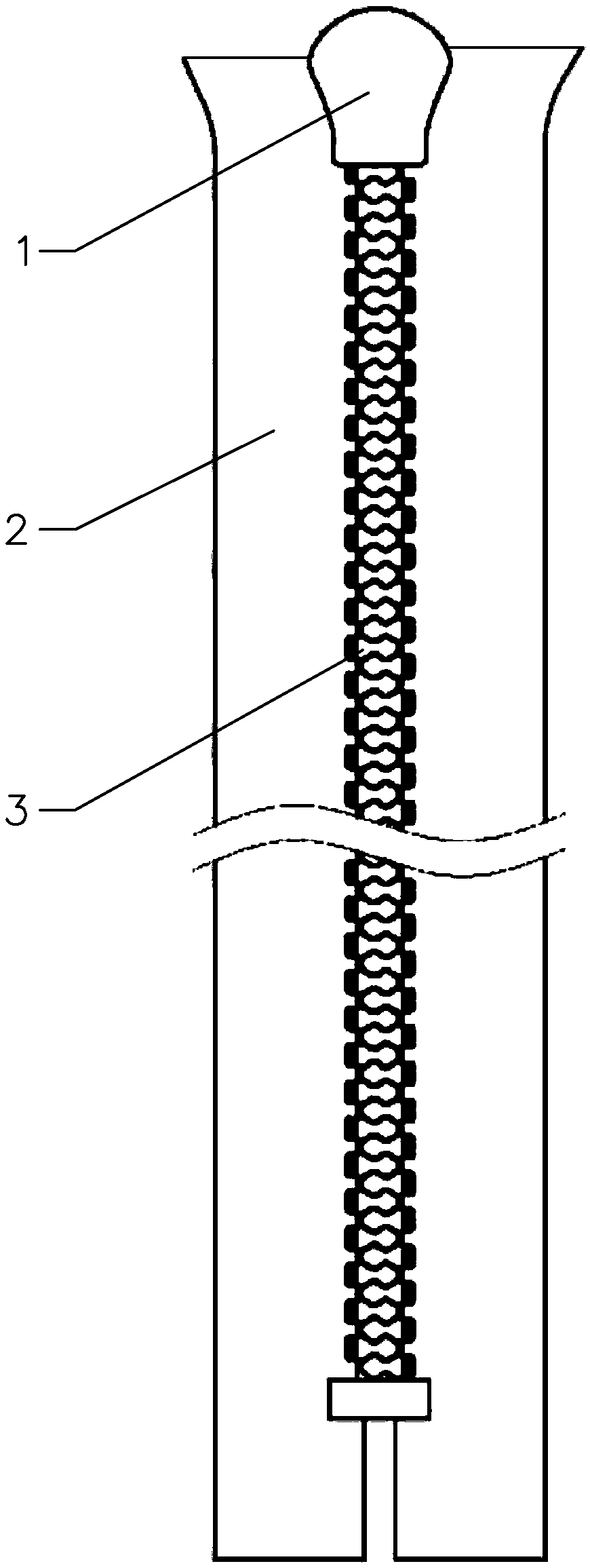

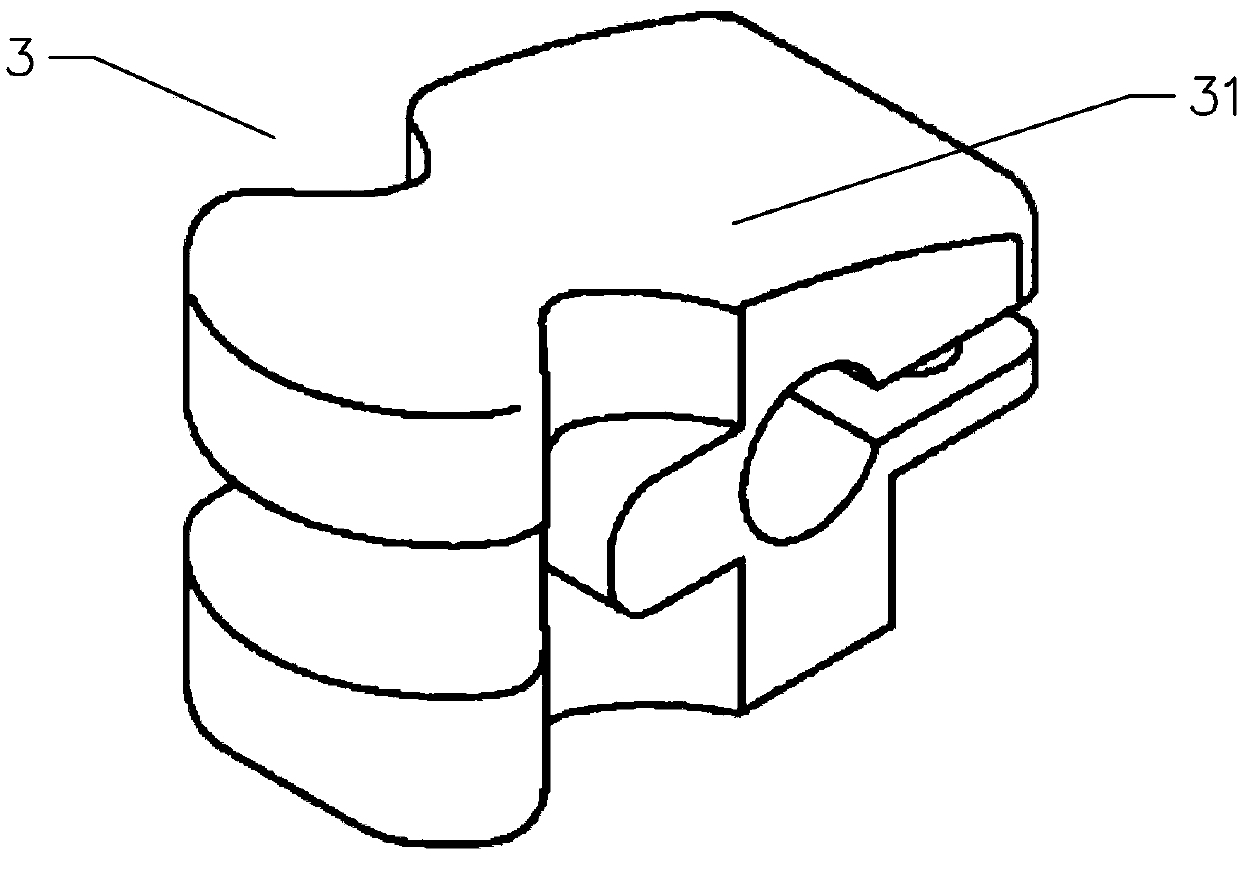

[0035] Such as Figures 1 to 10 As shown, the present invention provides a zipper convenient for the shape of the chain teeth, specifically a rubber tooth zipper, including a slider 1, a pair of chain belts 2 and a plurality of chain teeth 3 arranged on the chain belt 2, and a plurality of chain teeth 3 They are all rubber chain teeth. The slider 1 includes an upper slide seat 11 located on the front of the chain belt 2, a lower slide seat 12 located on the back of the chain belt 2, and a partition plate connecting the upper slide seat and the lower slide seat. Multiple sprockets are injected It is fixed on the inner edge of the chain belt 2, and the slider 1 is arranged between the two chain belts 2, and the slider 1 is pulled to engage or separate the chain teeth, so as to realize the opening and closing of the zipper.

[0036] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com