Three-dimensional adjustable dropping hammer experiment workbench system

A workbench and adjustable technology, applied in the direction of using one impact force to test the strength of materials, can solve problems such as material waste, and achieve the effect of shortening the experiment time and saving processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

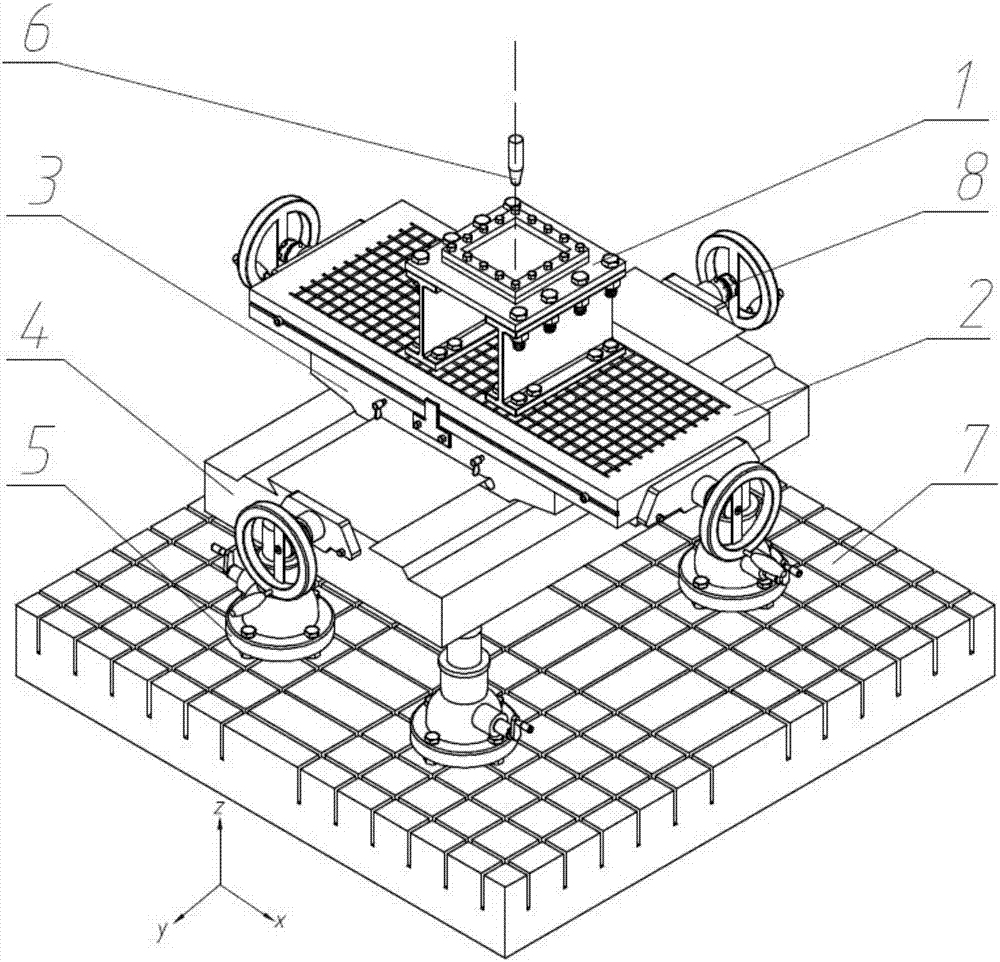

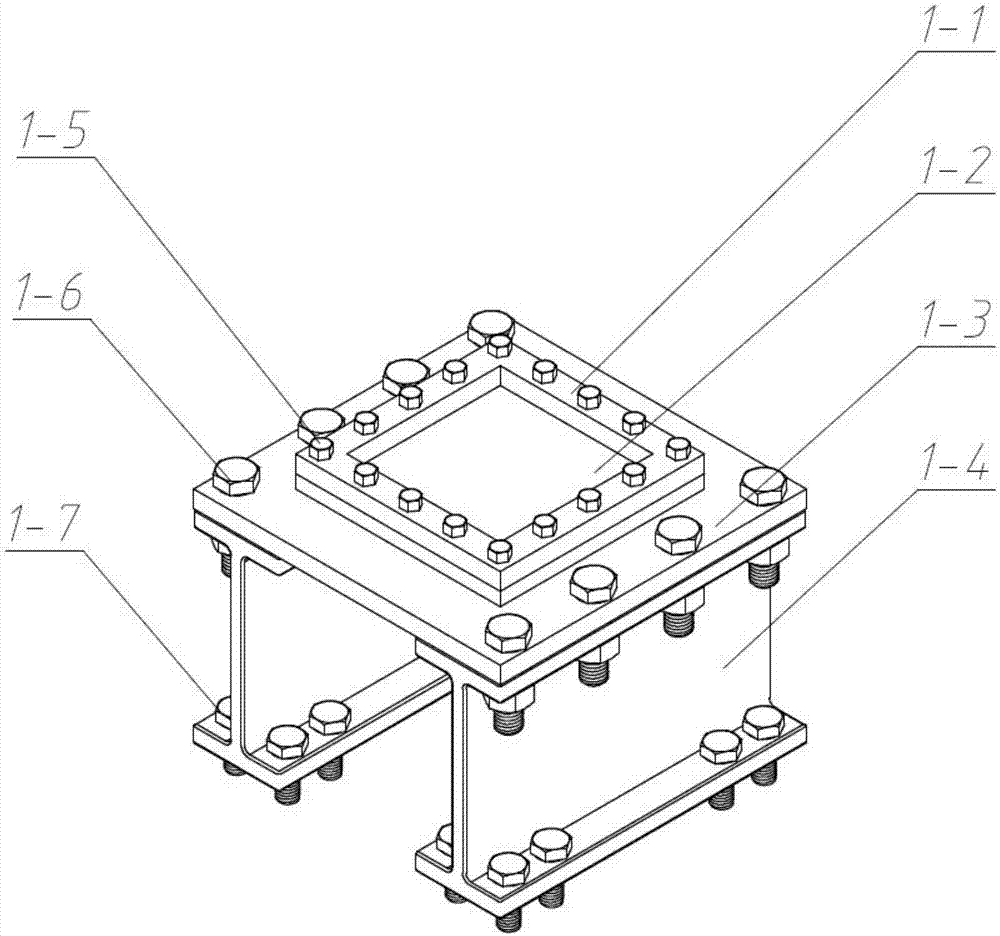

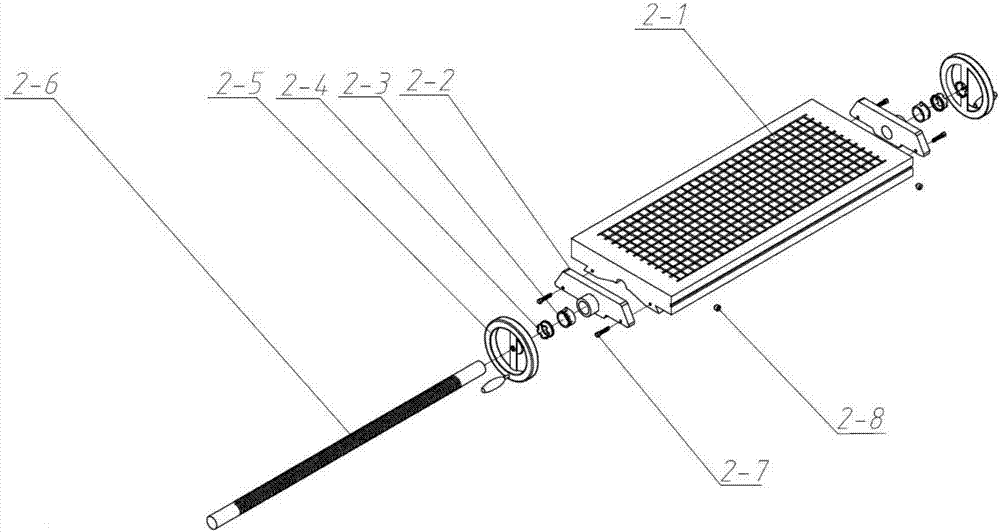

[0043] like figure 1 As shown, the assembly schematic diagram of a three-dimensional adjustable drop hammer test bench system in this embodiment; the drop hammer test bench system realizes the impact test of any point of the test specimen in the three-dimensional coordinate space, and the system includes test fixtures And the test piece 1, the horizontal is the X-direction workbench 2, the saddle 3, the longitudinal is the Y-direction workbench 4, the vertical is the Z-direction lifting column 5, the drop hammer punch 6, the anvil 7, and the feed scale ring 8; The experimental fixture and specimen 1 are fixed on the horizontal X-direction workbench 2 by bolts, the horizontal X-direction workbench 2 is fixed by the dovetail slot and the saddle 3, and the vertical Y-direction workbench 4 is fixed by the dovetail slot and the slide saddl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com