Ultrafiltration membrane washing method, ultrafiltration membrane washing device and water purifier provided with ultrafiltration membrane washing device

A flushing device and ultrafiltration membrane technology, applied in the field of water purifiers, ultrafiltration membrane flushing methods, and devices, can solve the problems of unsatisfactory ultrafiltration membrane flushing effect, the effect is not as good as back flushing, and the pipeline system is complex, etc. The effect of saving water treatment materials, improving flushing effect, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

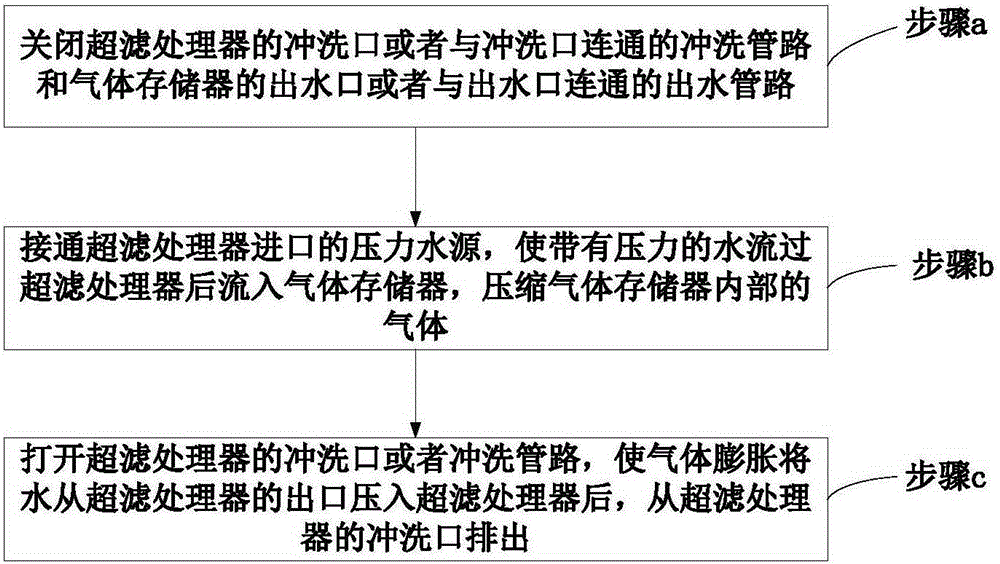

[0062] Such as figure 1 Shown, be the flowchart of a kind of ultrafiltration membrane flushing method provided by the present invention, this method comprises the following steps:

[0063] Step a: closing the flushing port of the ultrafiltration processor or the flushing pipeline connected with the flushing port and the water outlet of the gas storage or the water outlet pipeline connected with the water outlet.

[0064] Step b: connect the pressure water source at the inlet of the ultrafiltration processor, make the water with pressure flow through the ultrafiltration processor and then flow into the gas storage, and compress the gas inside the gas storage.

[0065] Step c: Open the flushing port or the flushing pipeline of the ultrafiltration processor, expand the gas and press water into the ultrafiltration processor from the outlet of the ultrafiltration processor, The flush port of the device is discharged.

Embodiment 2

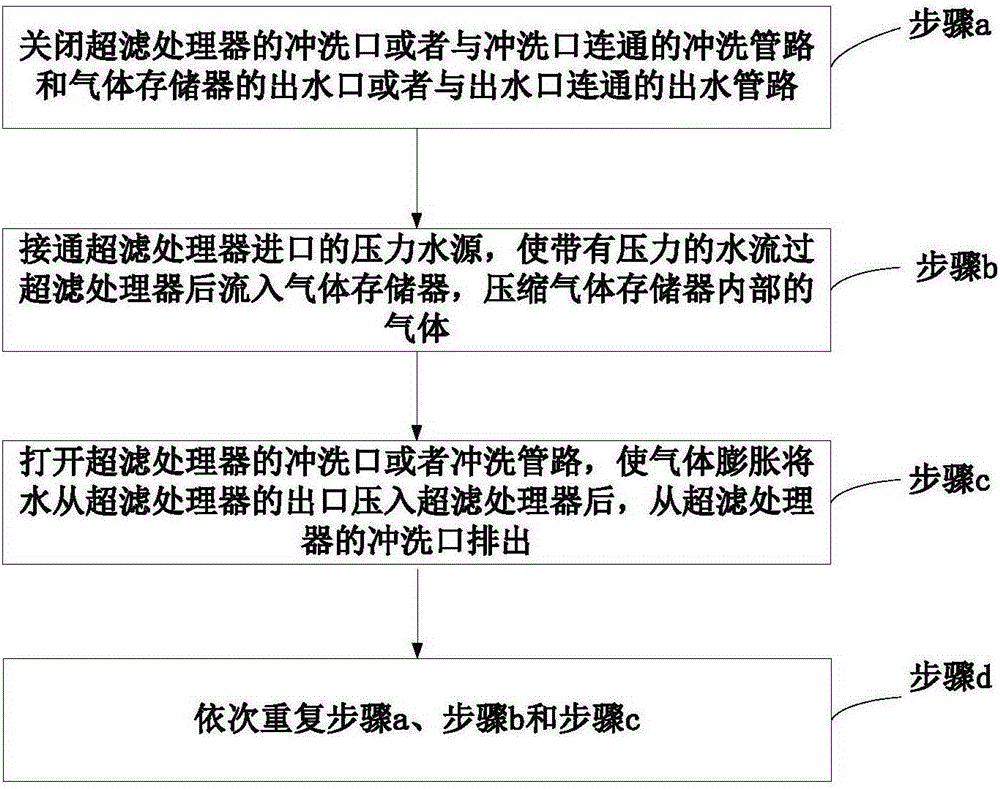

[0067] Such as figure 2 Shown, is the flow chart of another kind of ultrafiltration membrane flushing method provided by the present invention, and this method comprises the following steps:

[0068] Step a: closing the flushing port of the ultrafiltration processor or the flushing pipeline connected with the flushing port and the water outlet of the gas storage or the water outlet pipeline connected with the water outlet.

[0069] Step b: connect the pressure water source at the inlet of the ultrafiltration processor, make the water with pressure flow through the ultrafiltration processor and then flow into the gas storage, and compress the gas inside the gas storage.

[0070] Step c: Open the flushing port or the flushing pipeline of the ultrafiltration processor, expand the gas and press water into the ultrafiltration processor from the outlet of the ultrafiltration processor, The flush port of the device is discharged.

[0071] Step d: Repeat step a, step b and step c i...

Embodiment 3

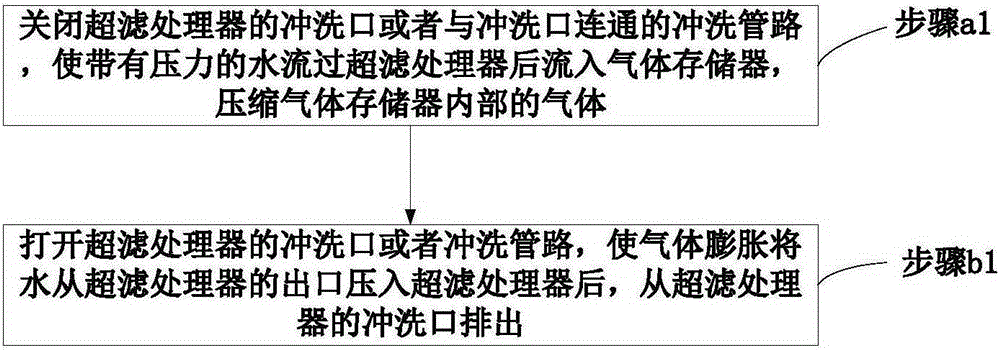

[0073] Such as image 3 As shown, it is a flow chart of another ultrafiltration membrane flushing method provided by the present invention. When the water outlet of the gas storage or its outlet pipeline is kept closed and the pressure water source of the ultrafiltration processor is kept connected, the ultrafiltration The membrane flushing method includes the following steps:

[0074] Step a1: close the flushing port of the ultrafiltration processor or the flushing pipeline connected with the flushing port, so that the water with pressure flows through the ultrafiltration processor and then flows into the gas storage, compressing the gas inside the gas storage gas.

[0075] Step b1: Open the flushing port or the flushing pipeline of the ultrafiltration processor, expand the gas and press water into the ultrafiltration processor from the outlet of the ultrafiltration processor, Rinse port to discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com