Variable-diameter bent pipe anti-wrinkle mandrel

A mandrel and pipe bending technology, which is applied in the field of bending pipe anti-wrinkle devices, can solve problems such as limited effect and complex structure of flexible mandrels, and achieve the effects of saving processing materials, good supporting effect, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

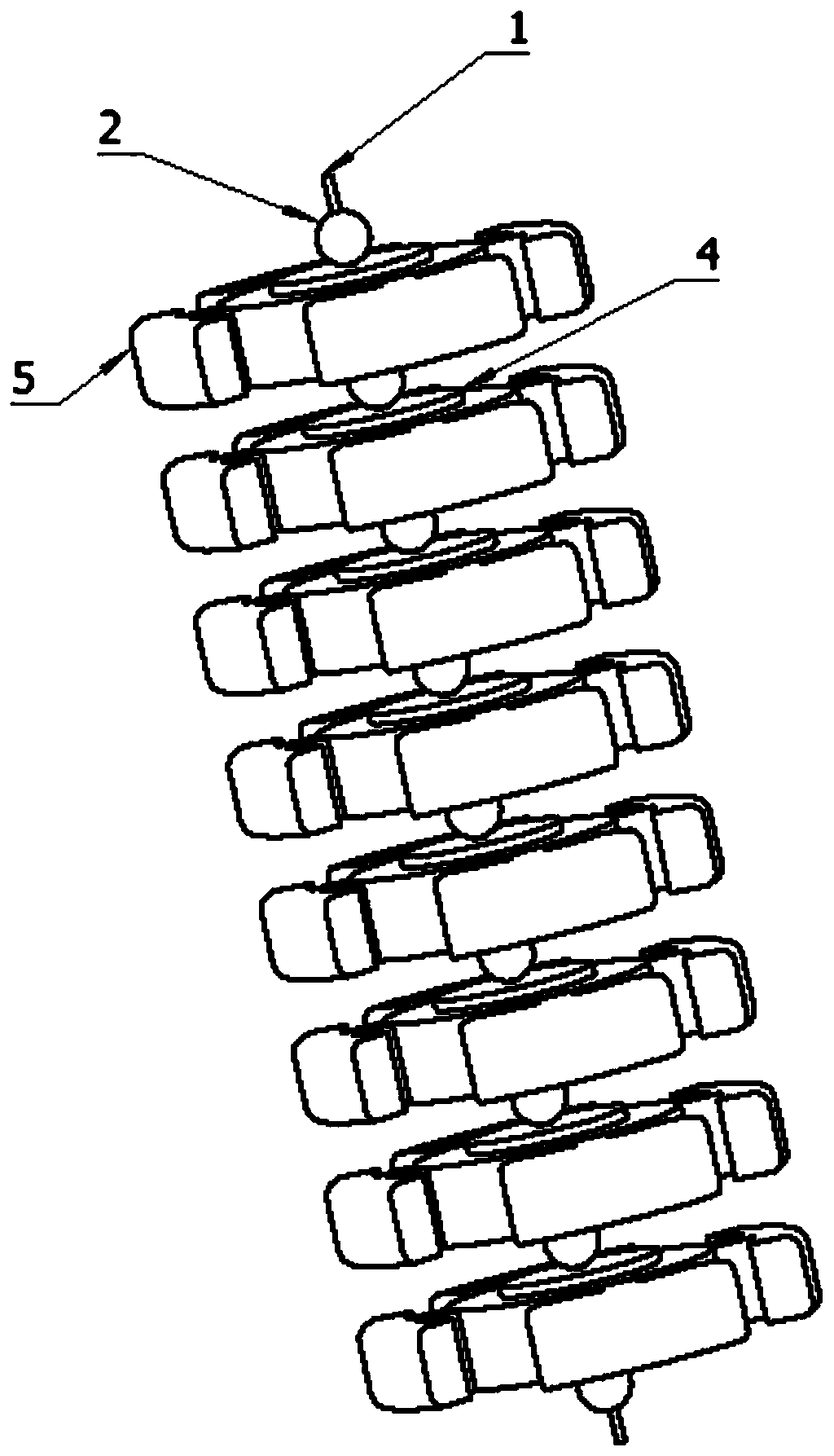

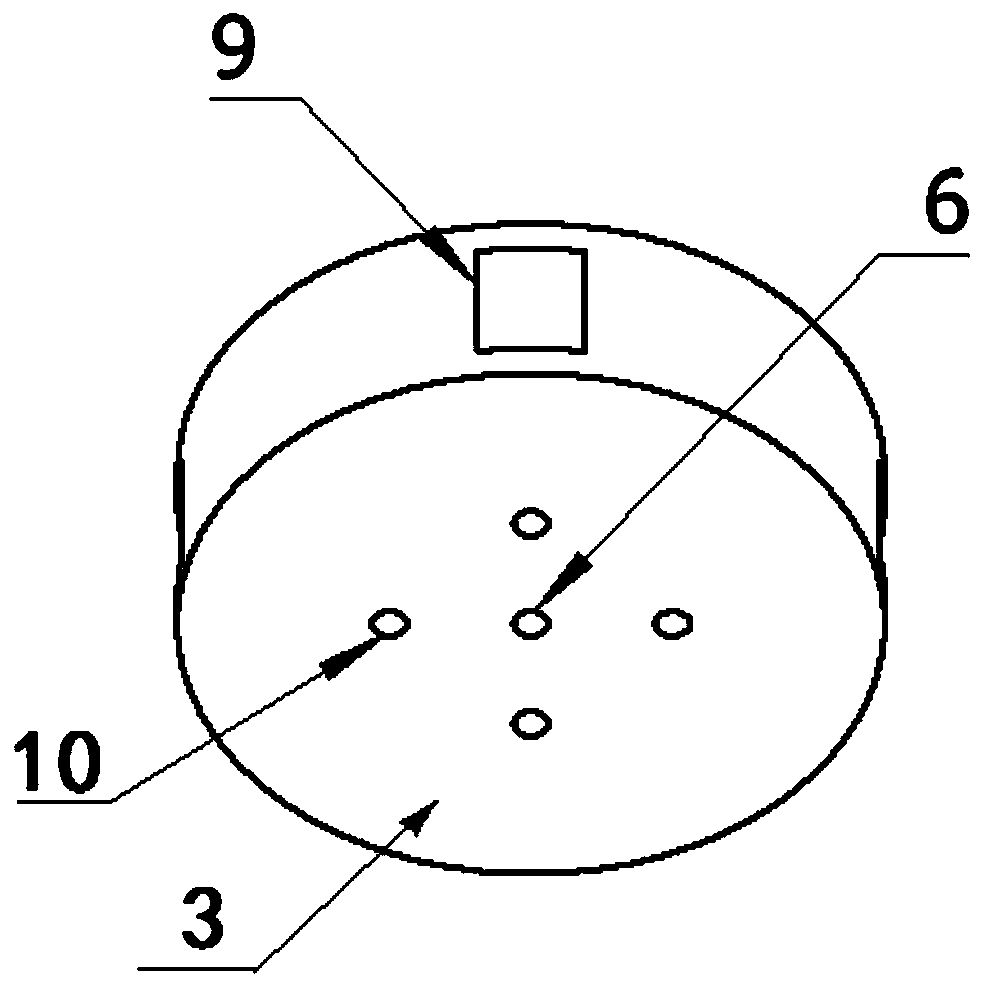

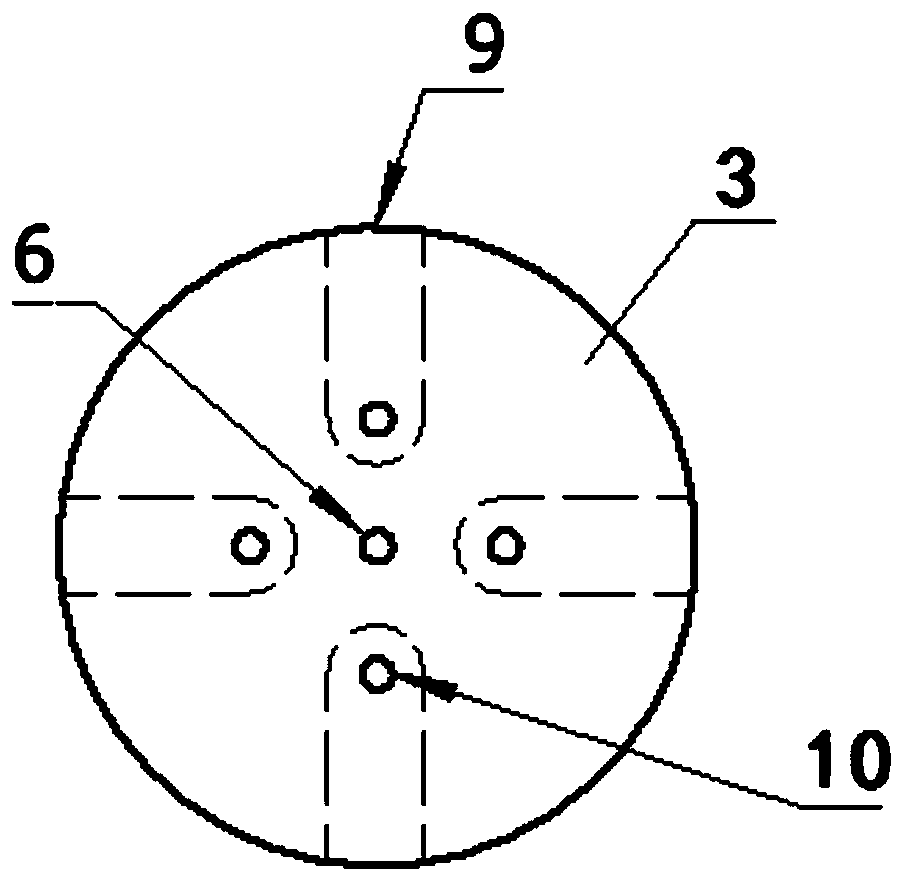

[0029] Such as Figure 1-Figure 7 As shown, a bendable anti-wrinkle mandrel with variable diameter includes a plurality of mandrel elements 3 with the same shape and size, a plurality of small balls 2 with the same diameter, and a core wire 1. The mandrel element 3 is a flat cylinder, Each mandrel element 3 has an axial central through hole 6 respectively, and each small ball 2 has a central through hole respectively, the diameter of the small ball 2 is greater than the diameter of the central through hole 6 of the mandrel element 3, and the core wire 1 passes through Through the central through hole of each mandrel element 3 and small ball 2, to connect each mandrel element 3 and small ball 2 in series, the same number of at least one small ball 2 is clamped between adjacent mandrel elements 3, The circumferential side of each mandrel element 3 is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com