Temperature-responsive membrane, temperature-responsive membrane module, and membrane filtration system in which the same are used

A temperature-responsive, membrane module technology, applied in the direction of membrane, ultrafiltration, membrane technology, etc., can solve problems such as energy increase, and achieve the effects of increased operating speed, reduced cost, and good washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] (Embodiment of Temperature Responsive Membrane)

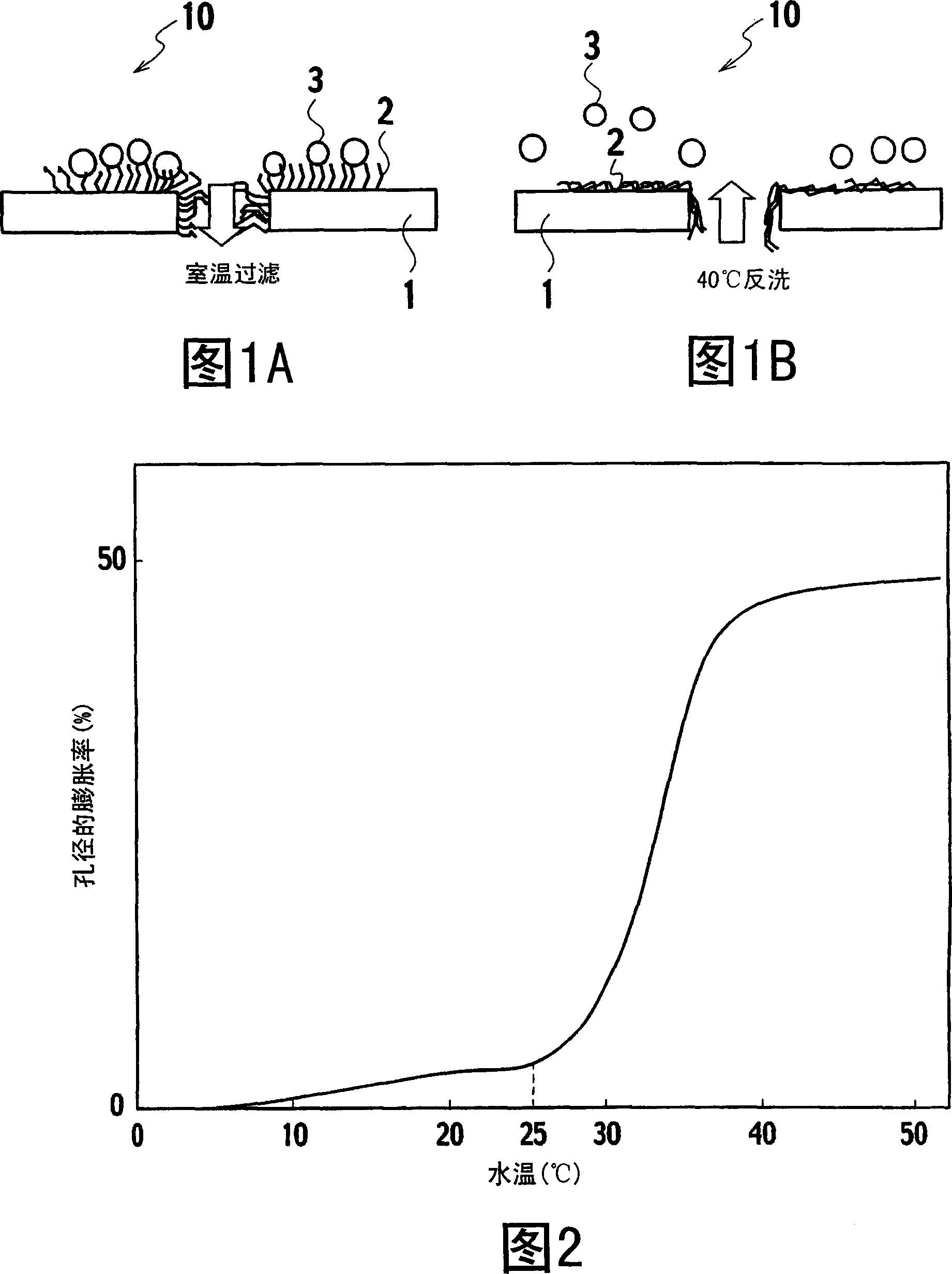

[0040] Figures 1A and 1B show embodiments of temperature responsive membranes of the present invention.

[0041] The temperature-responsive membrane 10 of the present invention is composed of a membrane substrate 1 and a pore size adjusting member 2 . The film substrate 1 is made of a polymer material. The pore size adjusting member 2 is formed by adding a polymer material on the outer surface side of the membrane substrate 1 . The polymer material reversibly expands / contracts at a given temperature. N-isopropylacrylamide is an example of the pore size adjusting member 2 . N-isopropylacrylamide itself does not respond to temperature. However, polymers obtained by polymerizing N-isopropylacrylamide are responsive to temperature.

[0042] As shown in FIG. 1A, raw water (fresh water such as river water, ground water, and lake water; waste water such as stored rainwater, industrial waste water, and sewage; and sea water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com