Side wall welding mould for passenger bus

A technology for passenger cars and molds, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low versatility and difficulty in manufacturing passenger car side wall welding molds, so as to improve versatility and reduce Labor intensity and difficulty, the effect of reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

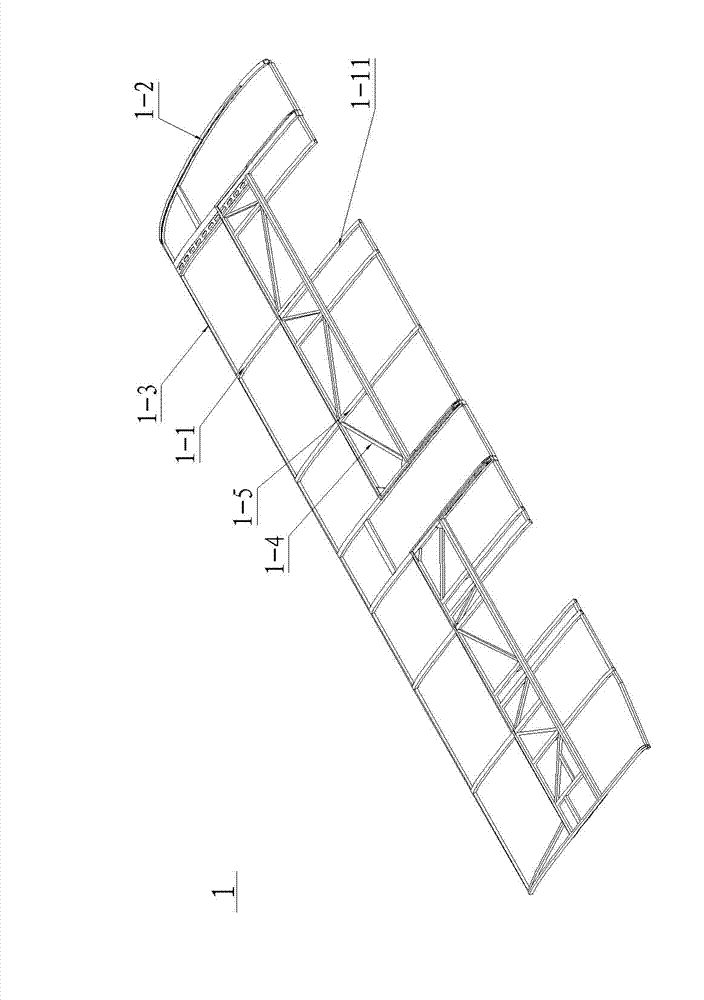

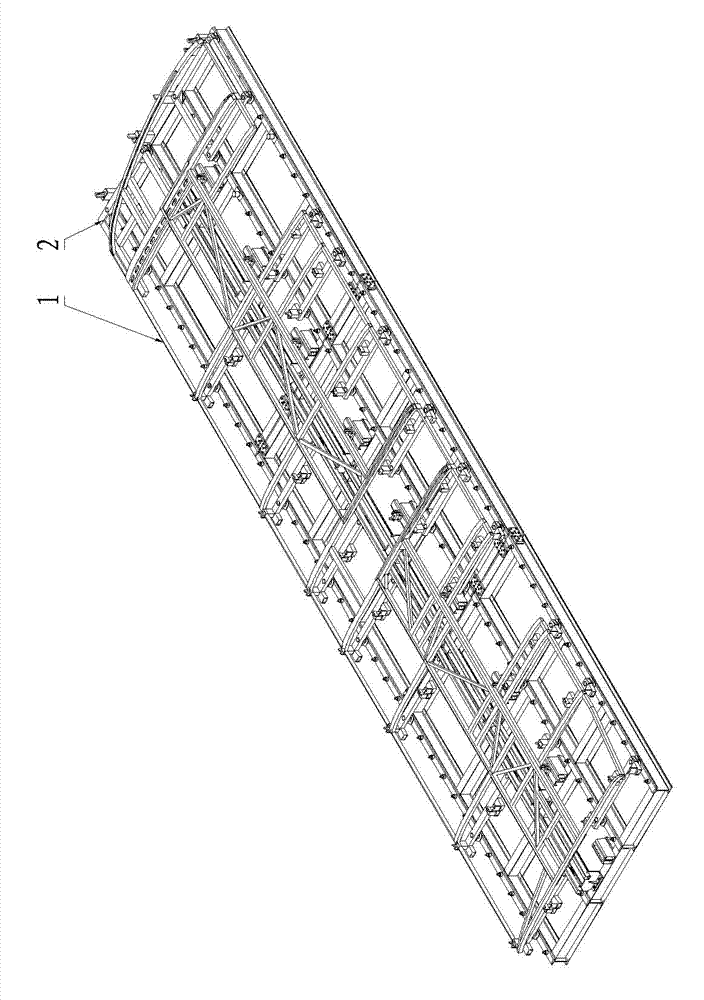

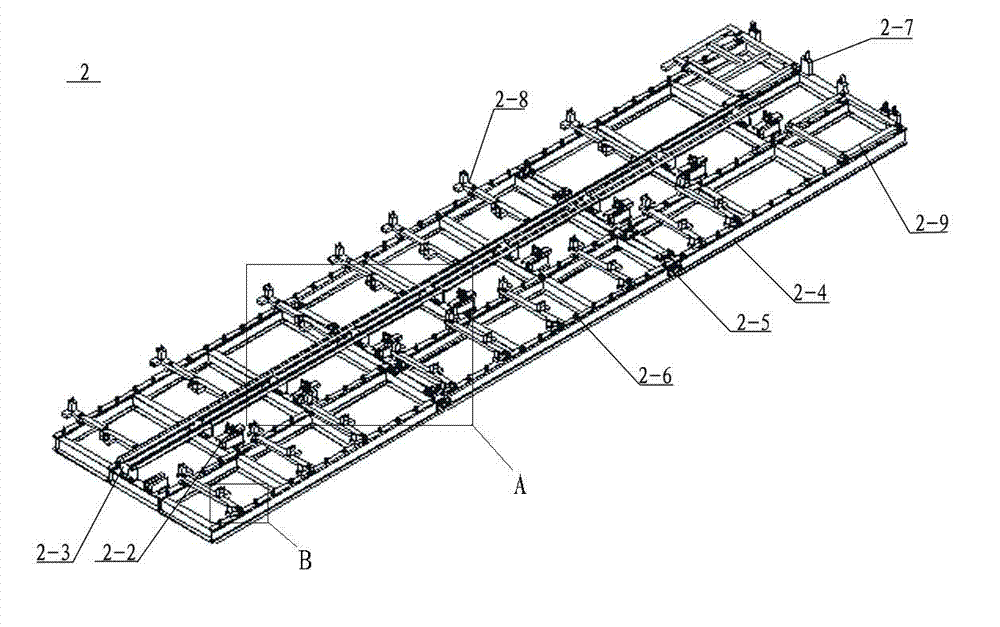

[0019] The embodiment of the passenger car side wall welding mold of the present invention: as Figure 1 to Figure 5 As shown, the mold 2 includes a chassis 2-1, a detachable and fixed column positioning frame on the chassis 2-1, a longitudinal beam positioning frame 2-2 and a bracket 2-3. The base frame 2-1 is formed by splicing three splicing frames 2-4, and two adjacent splicing frames 2-4 are detachably and fixedly connected by a bridging structure 2-5 arranged between them, and each splicing frame 2-4 Each has four longitudinal beams distributed in parallel and at intervals and a cross beam bridged between two adjacent longitudinal beams, and each longitudinal beam is protruded with longitudinally extending positioning pins 2-6, which are on the same splicing frame 2-4 The positioning pins 2-6 on the adjacent longitudinal beams on the same longitudinal beam and different splicing frames 2-4 form a row of positioning pins 2-6, and are divided into two rows of positioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com