Fixed priority reliability perception energy consumption optimization method suitable for numerical control system

A technology of numerical control system and optimization method, applied in general control system, control/regulation system, adaptive control and other directions, can solve the problems of high energy consumption, inability to apply fixed priority system, etc., to improve system reliability and save energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

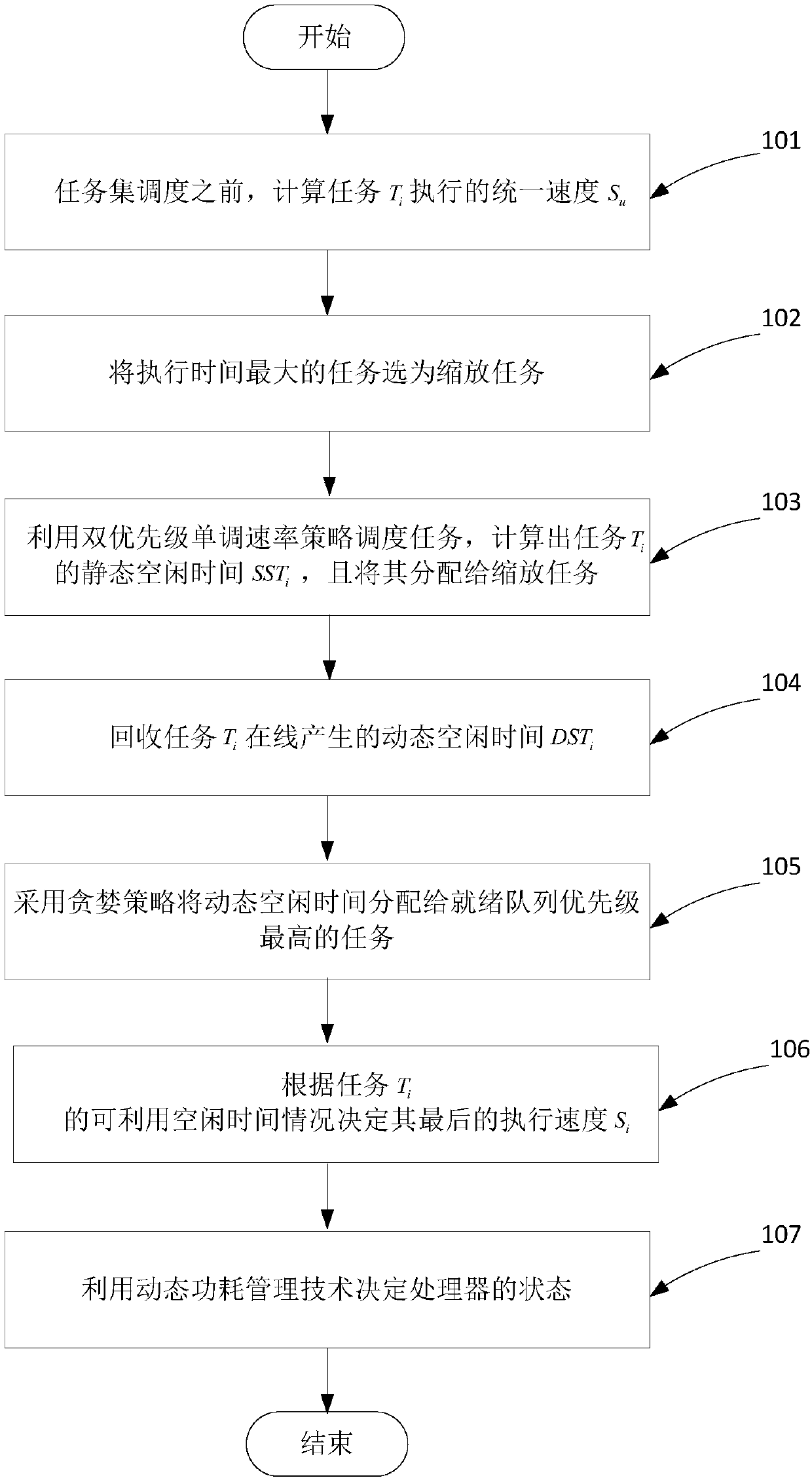

[0059] see figure 1 As shown, the present invention provides a fixed-priority reliability-aware energy consumption optimization method suitable for numerical control systems, including the following steps:

[0060] Step 101: Before task set scheduling, calculate task T i The uniform speed of execution S U .

[0061] Before the task set is scheduled, the calculation task T i The uniform speed of execution S U , the processing steps are as follows:

[0062] S U =min{S T ,S H}

[0063] where S T is the minimum speed at which resource-constrained periodic task set scheduling is feasible, S H is the feasible speed of the resource-constrained periodic task set scheduled by the monotonic rate strategy; S T Calculated by the following formula:

[0064] S T =LS RT +S NRT

[0065] Among them, LS RT is the minimum speed of a task set with resource requirements, and its value is calculated by the following formula:

[0066]

[0067] Among them, r i is task T i The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com