Method and device for regenerating activated carbon by virtue of pulse discharge plasma

A plasma and pulse discharge technology, which is applied in the field of plasma regeneration of activated carbon, can solve the problems of long regeneration time, slow regeneration speed, and reduced AC adsorption performance, and achieve the effects of no secondary pollution, easy operation, and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

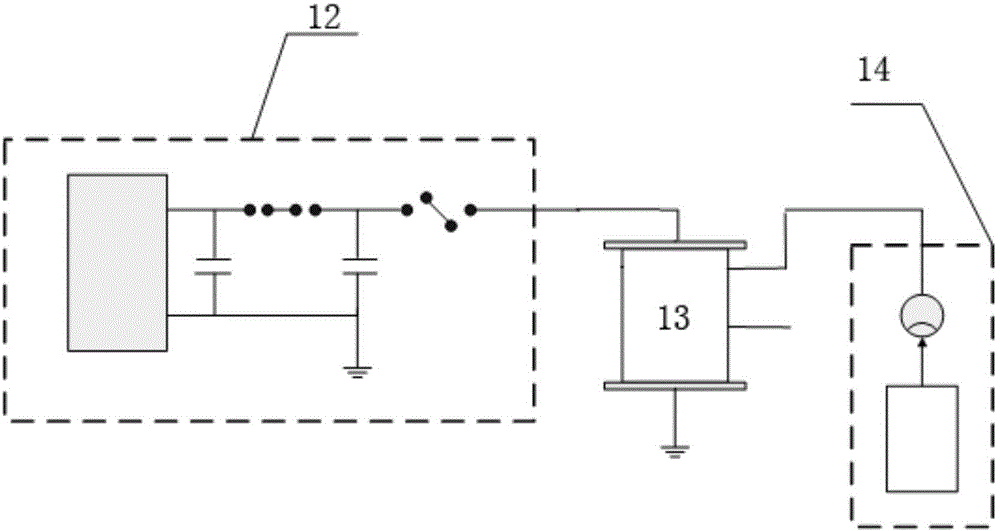

[0026] A pulse discharge plasma activated carbon regeneration device, including a pulse power supply 12, a reactor 13 and a carrier gas system 14, the pulse power supply 12 is a positive polarity narrow pulse rotating spark gap high voltage power supply, the peak voltage is 0-60kV and continuously adjustable, the pulse Frequency 0-150Hz and continuously adjustable.

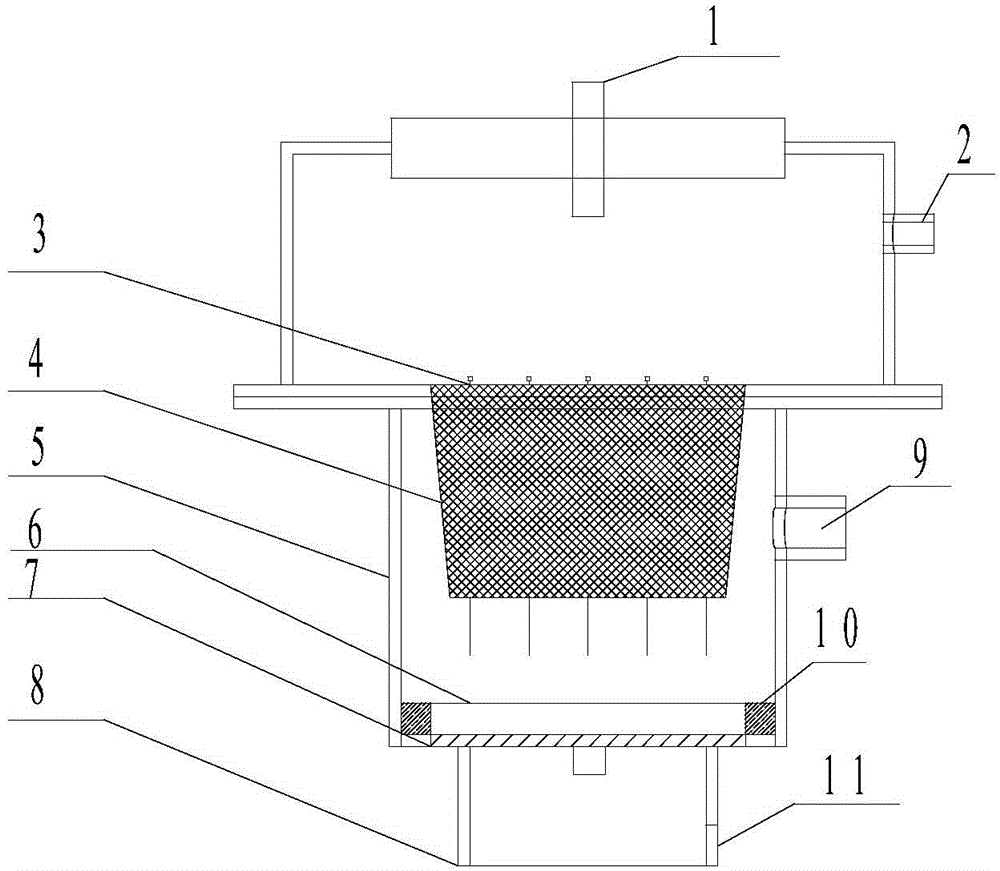

[0027] Described reactor 13 comprises the loam cake that has air inlet 2, outer cylinder body 5 and base 8, and described outer cylinder body 5 is the plexiglass cylinder of internal diameter 96mm, is positioned between loam cake and base 8, and each other connection; the interior is sequentially provided with a high-voltage needle electrode 3, an activated carbon placement layer and a ground electrode 7 from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com