Denitration system and denitration processing method of plasma synergistic catalyst

A plasma and treatment method technology, applied in the field of environmental protection, can solve the problems of deactivation, high discharge energy consumption, catalyst clogging, etc., and achieve the effects of improving life, reducing NO2 generation, and avoiding erosion and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

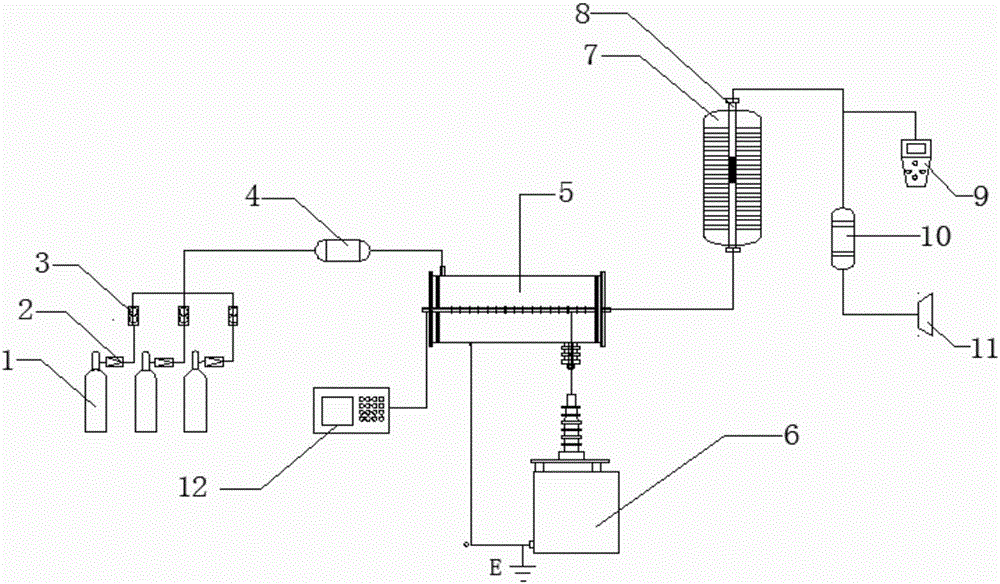

[0058] Such as figure 1 As shown, this embodiment provides a denitrification system with plasma co-catalyst, which includes a gas mixing system, a plasma reaction system, a fixed bed catalytic reactor 8, an absorption device 10 and an air induction device 11 connected in sequence. The plasma reaction system includes a plasma reactor 5 and a discharge power supply 6 ; an oscilloscope 12 is arranged between the plasma reactor 5 and the discharge power supply 6 .

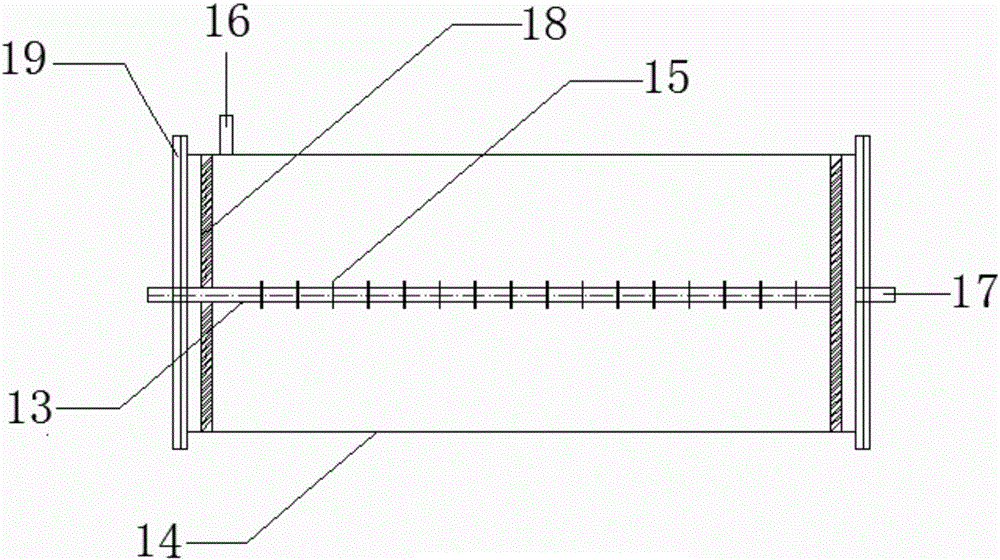

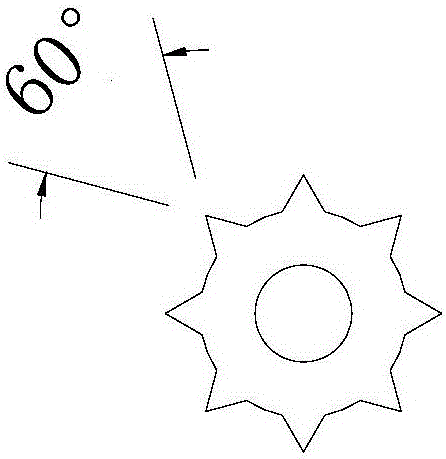

[0059] The plasma reactor 5 is a line-barrel structure, such as figure 2 As shown, it includes a center electrode 13 and a ground electrode 14, and the ground electrode 14 surrounds the center electrode 13 in a cylindrical shape; the center electrode 13 is connected to the positive pole of the discharge power supply 6, and the ground electrode 14 is connected to the ground electrode of the discharge power supply 6, and the center electrode 13 The discharge gap with the grounding electrode 14 is 18.5mm; the center ele...

Embodiment 2

[0069] In this embodiment, except that the oxygen volume content in the flue gas to be treated prepared in step (1) is 5%, the structure and layout of other devices, and the treatment process are all the same as in Example 1, and the nitrogen oxides are detected after the reaction. The removal rate is 94.21%.

Embodiment 3

[0071] In this embodiment, except that the oxygen volume content in the flue gas to be treated prepared in step (1) is 7%, the structure and layout of other devices, and the treatment process are all the same as in Example 1, and the concentration of nitrogen oxides is detected after the reaction. The removal rate is 96.33%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com