Array-type narrow-gap coaxial streamer discharge reactor for gaseous pollutant pretreatment

A technology of streamer discharge and reactor, which is applied in the field of array type narrow-gap coaxial streamer discharge reactor structure, can solve the problems of large reactor volume, high technical requirements for power supply, and less generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

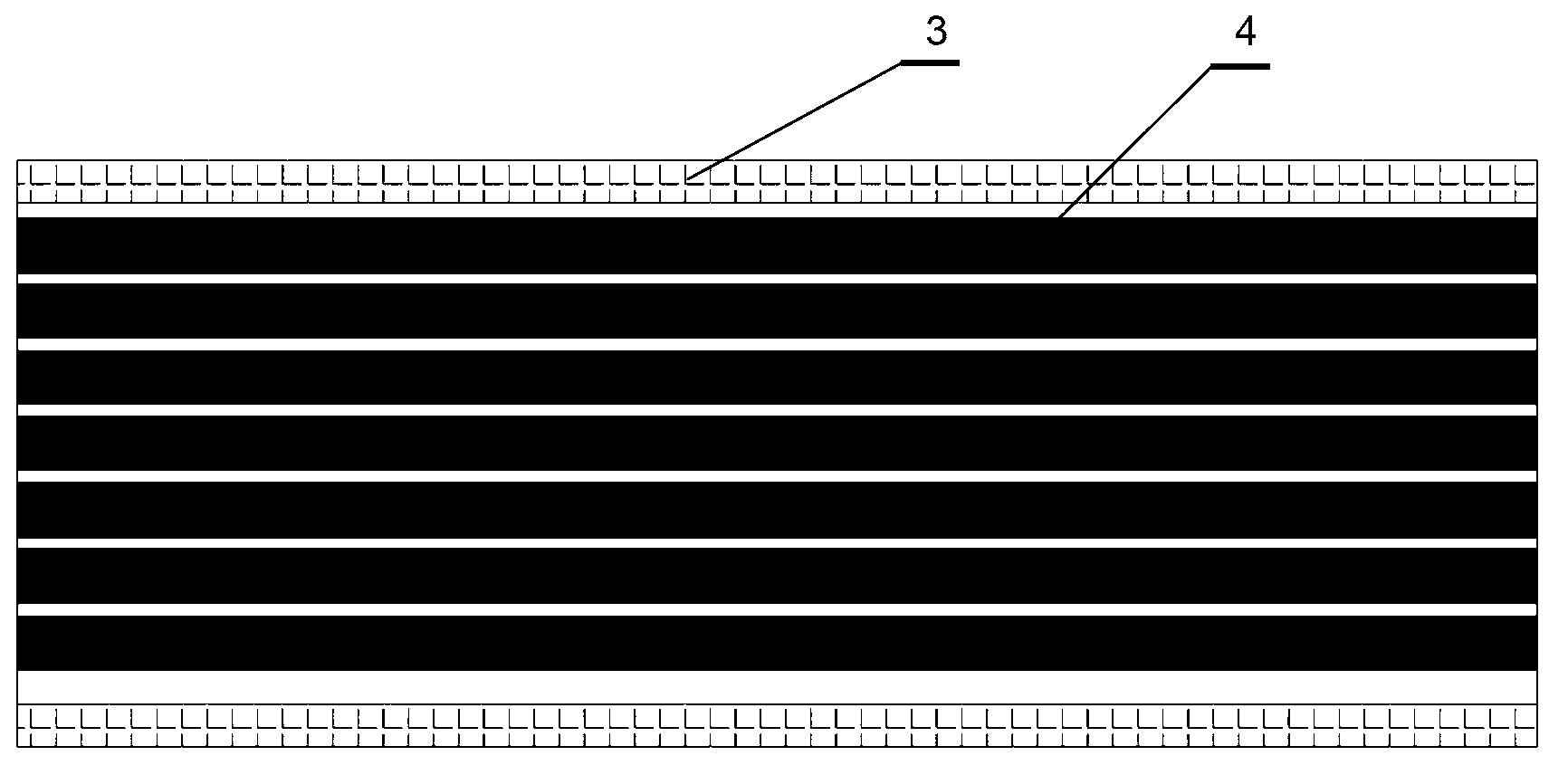

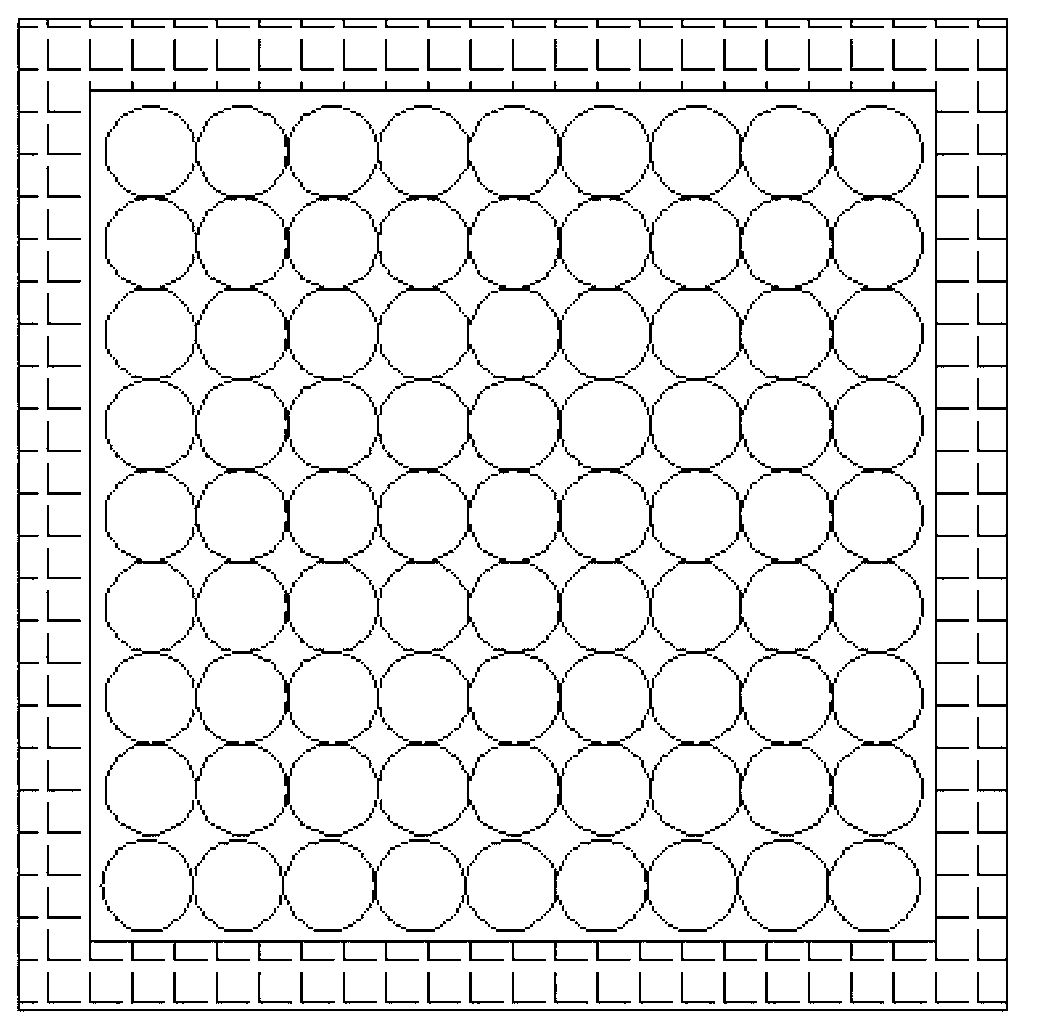

[0022] Such as figure 1 Shown is a schematic diagram of the axial cross-section of an arrayed narrow-gap coaxial streamer discharge reactor 3, as figure 2 Shown is a schematic diagram of an axial cross-section of an array narrow-gap coaxial streamer discharge reactor 3 . The sub-reactors 4 are installed inside the arrayed narrow-gap coaxial streamer discharge reactor 3 in the form of an array. The array type narrow-gap coaxial streamer discharge reactor 3 uses a stainless steel plate with a thickness of 3mm to make a box with a length, width, and height of 600mm*270mm*270mm, and 9 sub-reactors 4 are evenly arranged in the array type narrow-gap coaxial streamer discharge reactor 3 Inside, make 9 holes with a diameter of 56mm on the front and rear two stainless steel plates with a square size of 270mm*270mm, install the metal tube of the low-voltage electrode 2 of the sub-reactor 4, and seal the metal tube of the low-voltage electrode 2 with the stainless steel plate during in...

Embodiment 2

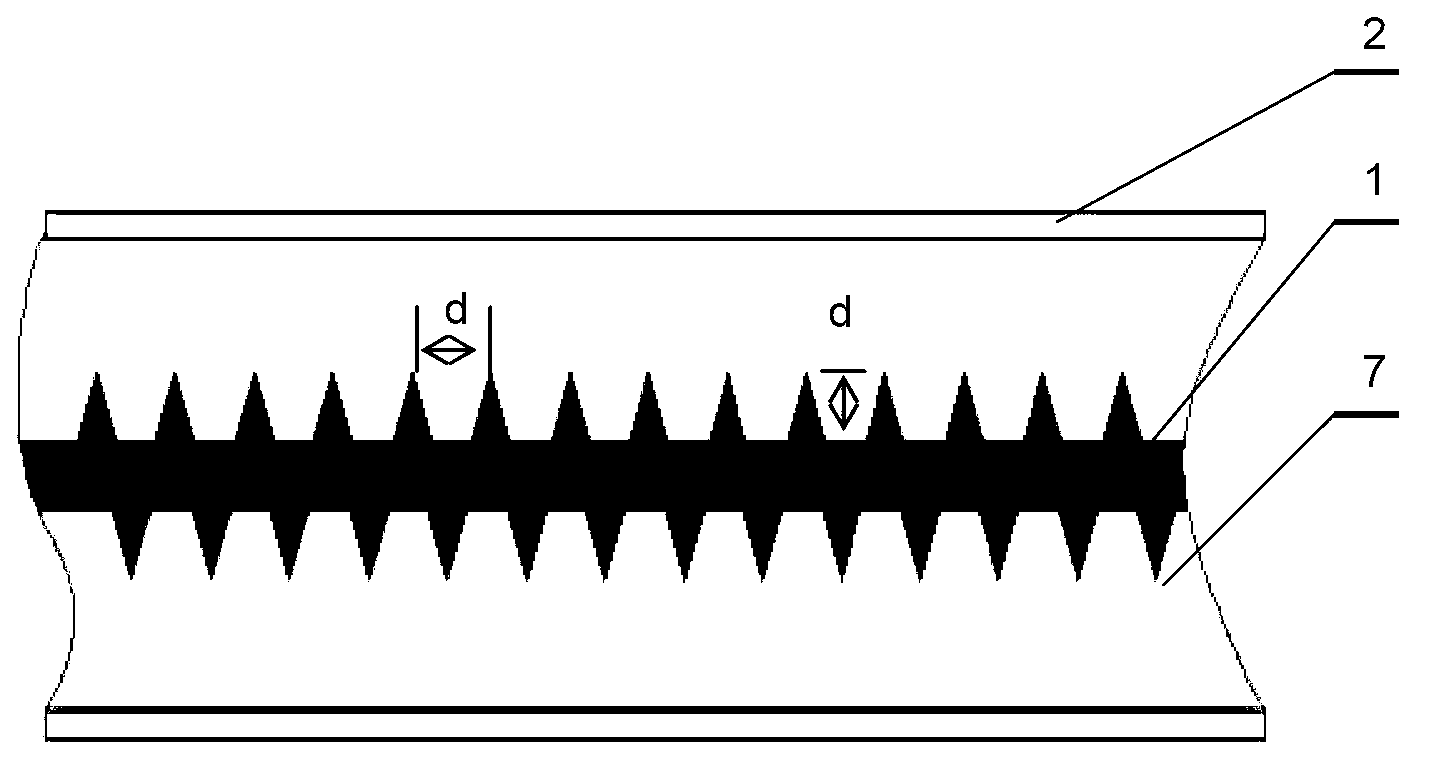

[0024] Such as figure 1 Shown is a schematic diagram of the axial cross-section of an arrayed narrow-gap coaxial streamer discharge reactor 3, as figure 2 Shown is a schematic diagram of the axial cross-section of the arrayed narrow-gap coaxial streamer discharge reactor 3. The sub-reactors 4 are installed inside the arrayed narrow-gap coaxial streamer discharge reactor 3 in the form of an array, and the arrayed narrow-gap coaxial streamer discharge reactor The size and installation method of the low-voltage electrode and the equalizer plate of the device 3 and the sub-reactor 4 are the same as those of the example 1. Such as Figure 4 Shown is a schematic cross-sectional view of the electrode structure of the gear-shaped narrow-gap streamer discharge electron reactor 4. The high-voltage discharge electrode 1 is a metal rod with a total length of 650 mm, and the effective length of the gear installation is 450 mm. For connection with the insulator, the number of gears insta...

Embodiment 3

[0026] Such as figure 1 Shown is a schematic diagram of the axial cross-section of an arrayed narrow-gap coaxial streamer discharge reactor 3, as figure 2 Shown is a schematic diagram of the axial cross-section of the arrayed narrow-gap coaxial streamer discharge reactor 3. The sub-reactors 4 are installed inside the arrayed narrow-gap coaxial streamer discharge reactor 3 in the form of an array, and the arrayed narrow-gap coaxial streamer discharge reactor The size and installation method of the low-voltage electrode and the equalizer plate of the device 3 and the sub-reactor 4 are the same as those of the example 1. Such as Figure 5 Shown is a cross-sectional schematic diagram of the thorn-shaped narrow-gap streamer discharge electron reactor 4 electrode structure, the high-voltage discharge electrode 1 is a metal rod with a length of 650 mm, and the diameter of the metal rod is 16 mm. The effective length of the metal rod used to install the thorn electrode is 450mm; bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com