Desulfurization and denitrification method for streamer discharge plasma free radical injected flue gas

A technology of plasma and streamer discharge, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as secondary pollution, high operating costs, and large consumption of reducing agents, and achieve low system resistance and low energy consumption. Low, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

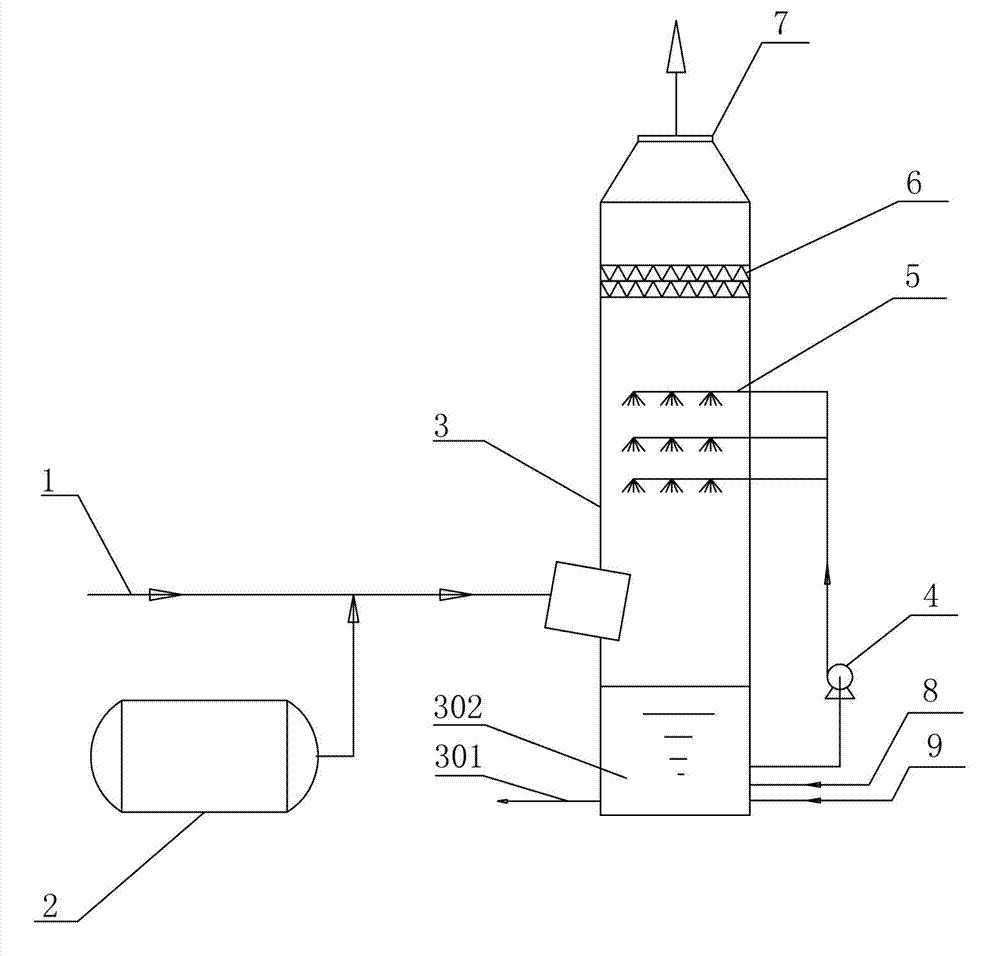

[0023] As shown in Figure 1, a method for desulfurization and denitrification by injecting streamer discharge plasma radicals into flue gas comprises the following steps: the dust-removed boiler flue gas 1 passes through the flue; in the streamer discharge plasma reactor 2, the cathode 201 and The anode 202 constitutes an electric field space, and a high-voltage power supply of 10-50kV is connected to apply a voltage between the two electrodes, and the air injected into the reactor is discharged to generate plasma radicals, and the gas containing plasma radicals is injected into the flue, Plasma free radicals oxidize part or all of sulfur oxides and nitrogen oxides into higher valence oxides (NO 2 , N 2 o 3 , N 2 o 5 , SO 3 Wait). The flue gas that has undergone the action of plasma free radicals enters the desulfurization tower 3, and the flue gas flows from bottom to top in the tower, and the NH-containing gas ejected from the spray layer 5 3 ·H 2 The circulating spra...

Embodiment 2

[0028] As shown in Figure 1, a method for desulfurization and denitrification by injecting streamer discharge plasma radicals into flue gas comprises the following steps: the dust-removed boiler flue gas 1 passes through the flue; in the streamer discharge plasma reactor 2, the cathode 201 and The anode 202 constitutes the electric field space, and the high-voltage power supply of 50-100kV is connected to discharge the oxygen injected into the reactor to generate plasma radicals, and the gas containing plasma radicals is injected into the flue, and the plasma radicals oxidize sulfur substances, nitrogen oxides are partially or fully oxidized to higher valence oxides (NO 2 , N 2 o 3 , N 2 o 5 , SO 3 Wait). The flue gas that has undergone the action of plasma free radicals enters the desulfurization tower 3, and the flue gas flows from bottom to top in the tower, and the NH-containing gas ejected from the spray layer 5 3 ·H 2 The circulating spray absorbent of O is in cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com