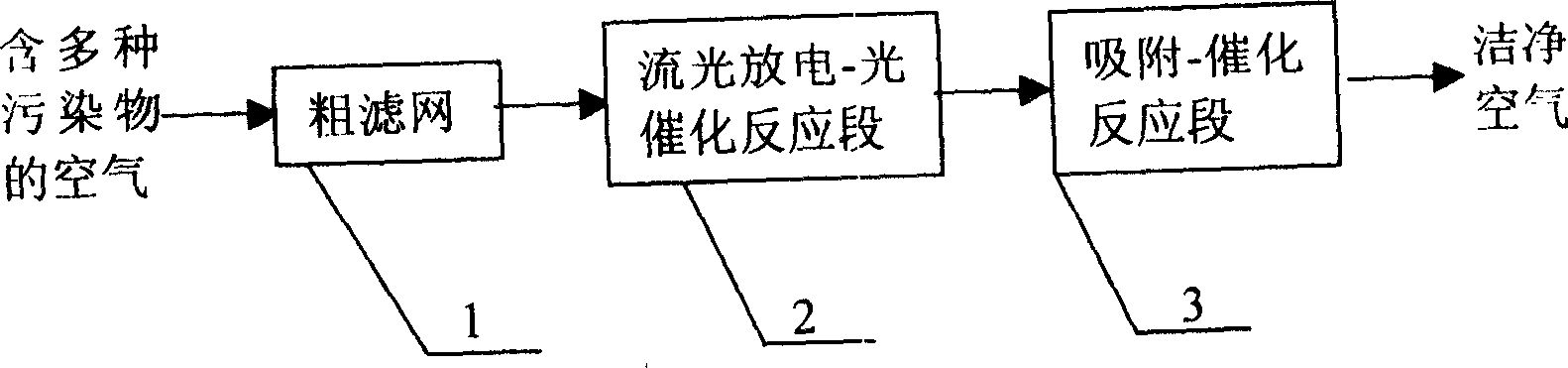

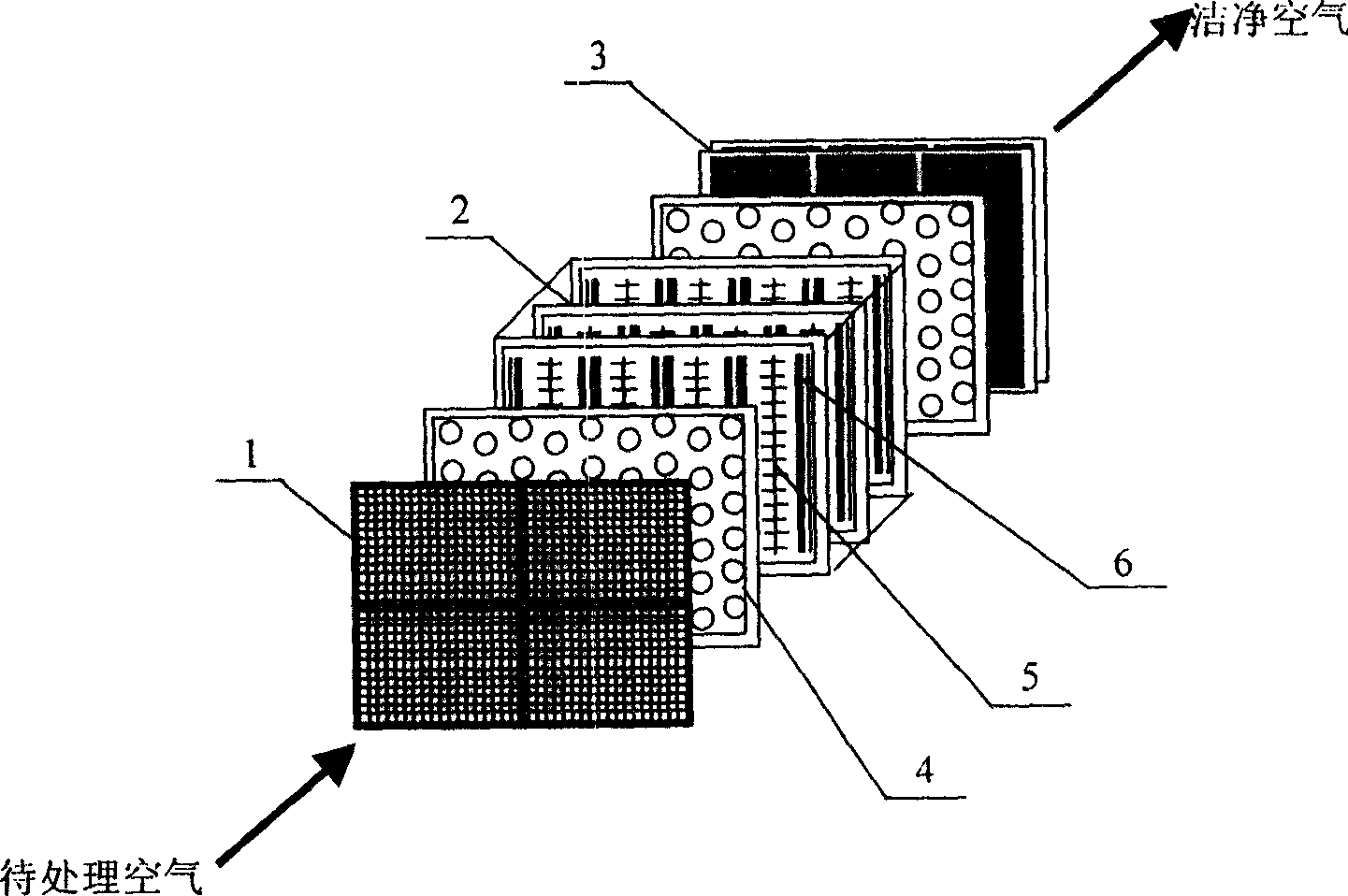

Method of cleaning air pollutant using synergistic action of streamer discharge and photo catalysis

A streamer discharge, air purification technology, applied in chemical instruments and methods, separation methods, applications, etc., can solve the problems of inability to purify a variety of air pollutants, secondary pollution, etc., and achieve the purpose of strengthening catalytic decomposition and improving purification efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A single-phase power frequency DC high voltage is applied between the two electrodes of the streamer discharge-photocatalytic reaction section, the voltage is 20kV, and the ground electrode is coated with titanium dioxide. Granular activated carbon impregnated with manganese oxide is used as the adsorption / catalysis material. The air containing 10.5ppm formaldehyde and 15.1ppm toluene was passed into the purification system, and after 240 hours of continuous operation, the concentrations of toluene and ozone at the outlet of the streamer discharge-photocatalytic reaction section were measured to be 3.6ppm and 4.4ppm respectively, and formaldehyde was not detected; None of the three were detected at the outlet of the adsorption / catalytic reaction section.

Embodiment 2

[0036] The reactor only includes the streamer discharge-photocatalytic reaction section, in which a positive corona discharge electrode and a ground electrode are set. Apply single-phase power frequency DC superimposed high frequency AC high voltage, the power frequency DC voltage is 70kV, the high frequency AC peak-to-peak voltage is 20kV, and the ground electrode is coated with platinum-doped titanium dioxide. Let air containing 18.5ppm formaldehyde and 15.2ppm styrene pass through the reactor, the residence time of the gas in the reactor is 1 second, and the concentrations of formaldehyde, styrene and ozone at the outlet are detected to be 1.5ppm, 2.2ppm and 3.8ppm respectively.

Embodiment 3

[0038] A simple purifier made based on this method is placed in a volume of 3m 3 in the test chamber. Streamer discharge—photocatalytic reaction section is applied with three-phase high-frequency DC voltage with a voltage value of 10kV. The carbon fiber impregnated with potassium permanganate is used as the adsorption / catalysis material. The initial concentrations of benzene and xylene in the test chamber were 15.5ppm and 18.7ppm respectively. One hour after the purification system was turned on, the concentrations of benzene and xylene in the test chamber were 2.8ppm and 3.2ppm respectively, and no ozone was detected. After opening the purification system for 3 hours, the concentrations of benzene, xylene and ozone in the test chamber were not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com