Streamer corona plasma flue gas denitrification method

A streamer discharge and plasma technology, applied in the field of plasma flue gas denitrification, can solve the problems of secondary pollution, high operating cost, ammonia leakage, etc., and achieve the effects of mild reaction conditions, high denitration efficiency and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

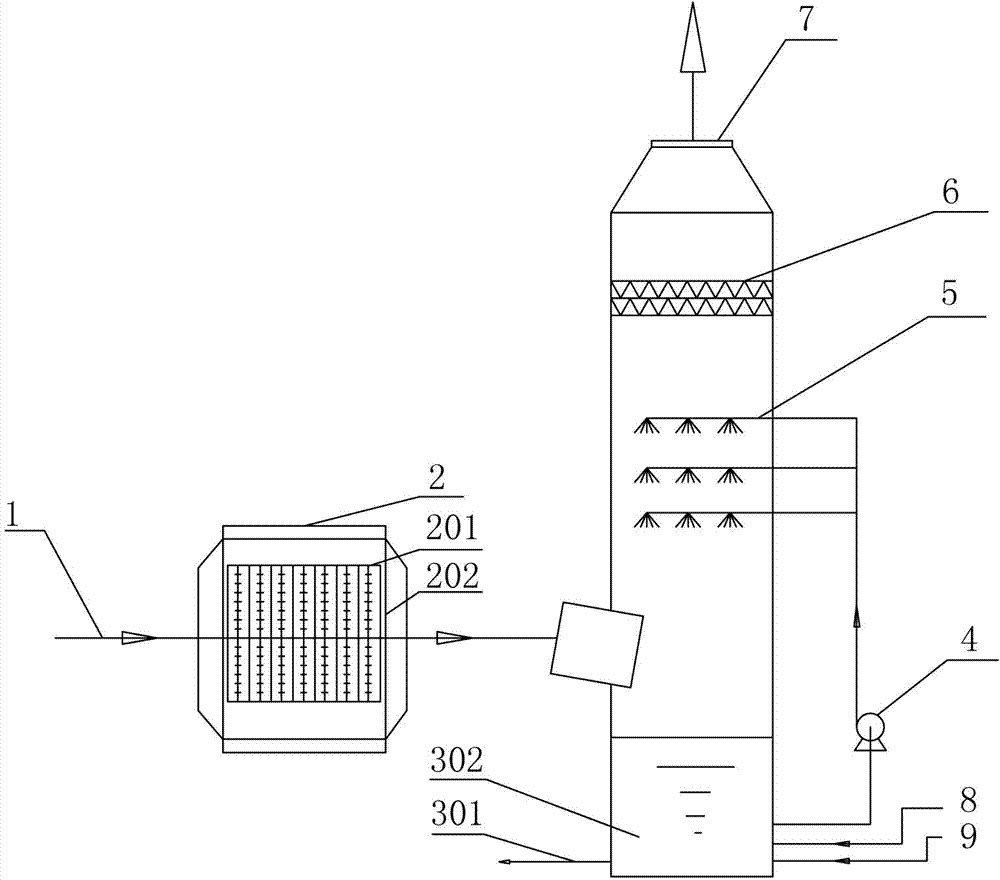

[0022] Such as figure 1 As shown in the streamer discharge plasma flue gas denitrification method, the dust-removed flue gas 1 first enters the streamer discharge oxidation reactor 2, and in the oxidation reactor, the electric field space is formed by the cathode 201 and the anode 202, and the 50-100kV The high-voltage power supply discharges, the ionized gas generates active free radicals, and the active free radicals react with NO in the flue gas to oxidize NO into higher valence nitrogen oxides such as NO 2 , N 2 o 3 , N 2 o 5 . Then, the flue gas enters the absorption tower again, from bottom to top, and the NH-containing gas ejected from the spray layer 5 3 ·H 2 The circulating spray absorption liquid of O is in countercurrent contact, the nitrogen oxides in the flue gas are absorbed into the liquid phase, and NH 3 ·H 2 O reacts to form NH 4 NO 2 , NH 4 NO 3 The ammonium salt mixed solution obtained enters the liquid storage tank 302, and then is sent to the s...

Embodiment 2

[0027] Such as figure 1 As shown in the streamer discharge plasma flue gas denitrification method, the dust-removed flue gas 1 first enters the streamer discharge oxidation reactor 2, and in the oxidation reactor, the electric field space is formed by the cathode 201 and the anode 202, and the 10-50kV The high-voltage power supply discharges, ionizes the flue gas to generate active free radicals, and the active free radicals react with NO in the flue gas to oxidize NO into higher valence nitrogen oxides such as NO 2 , N 2 o 3 , N 2 o 5 . Then, the flue gas enters the absorption tower again, and the flue gas is from bottom to top, and the NH-containing 3 ·H 2 The circulating spray absorption liquid of O is in countercurrent contact, the nitrogen oxides in the flue gas are absorbed into the liquid phase, and NH 3 ·H 2 O reacts to form NH 4 NO 2 , NH 4 NO 3 The ammonium salt mixed solution obtained enters the liquid storage tank 302, and then is sent to the spray laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com