Heat exchanger online cleaning device

A technology for cleaning devices and heat exchangers, which is applied to cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc. It can solve the problems of low efficiency of cooling tubes of heat exchangers, inability to achieve circular cleaning, long cleaning time period, etc. Problems, to achieve the effect of low energy consumption for cleaning operation, short cleaning time period, and strong damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

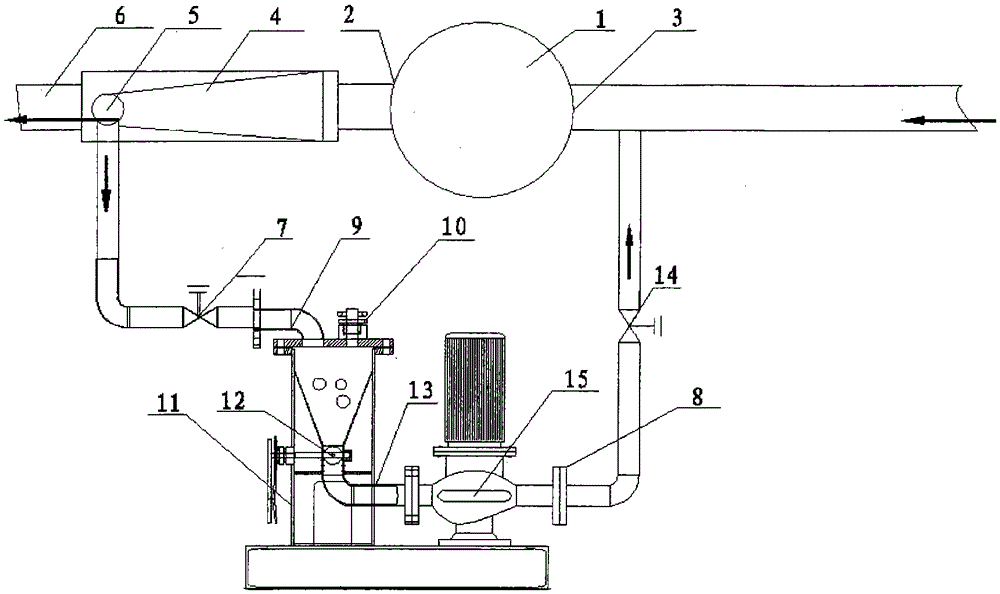

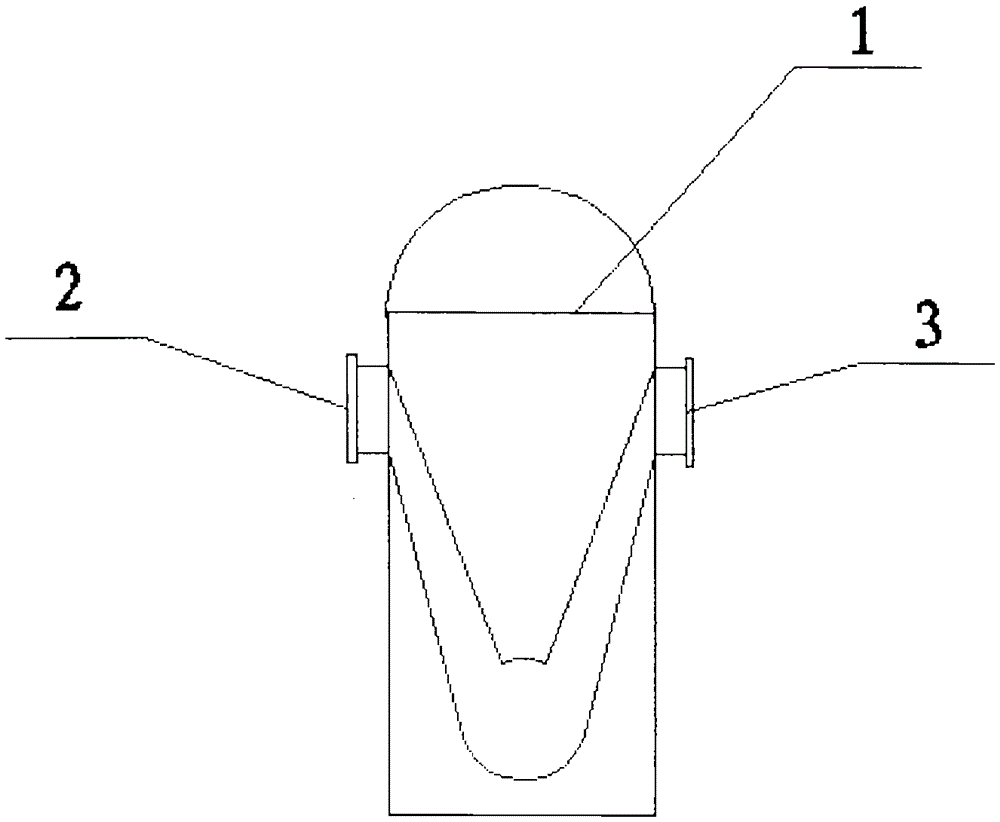

[0019] like figure 1 , 2 As shown, the heat exchanger online cleaning device includes a heat exchanger 1, a ball feeder 11, and a rubber ball delivery pump 15. It is characterized in that: the internal pipeline of the heat exchanger 1 is in a U-shaped structure, that is, the right side of the heat exchanger 1 is There is a water inlet port 3 and a water outlet port 2 on the left side. The water outlet port 2 is connected to the front end of the funnel-type ball collector 4 through a pipeline, and the rear end is a cooling water outlet 6. The funnel-type ball collector 4 is provided with an inverted cone The end of the inverted cone-shaped ball receiving net is a variable-diameter ball loser 5, and the variable-diameter ball loser 5 is connected with the outlet pipe mouth, and the ball outlet pipe mouth of the funnel type ball collector and the fast ball thrower The goal nozzle 9 is connected by a flange 8, and the pipeline of the funnel type ball collector is provided with a ...

Embodiment 1

[0021] Concrete implementation 1, in the above-mentioned workflow, the hole diameter of the punching plate of the inverted conical ball net is 20 mm, the thickness is 66 mm, and the taper of the inverted tapered ball net is 45°.

Embodiment 2

[0022] Concrete implementation 2, the hole diameter of the punching plate of the inverted conical ball receiving net in the above-mentioned workflow is 1 mm, the thickness is 2 mm, and the taper of the inverted tapered ball receiving net is 35°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com