Ignition oil gun head with blockage removal device

The technology of ignition oil gun and oil passage hole is applied in the field of ignition oil gun head, which can solve the problems of low blocking efficiency, long cleaning cycle, complicated operation, etc., and achieve the effects of reducing manpower and material resources, short cleaning cycle and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

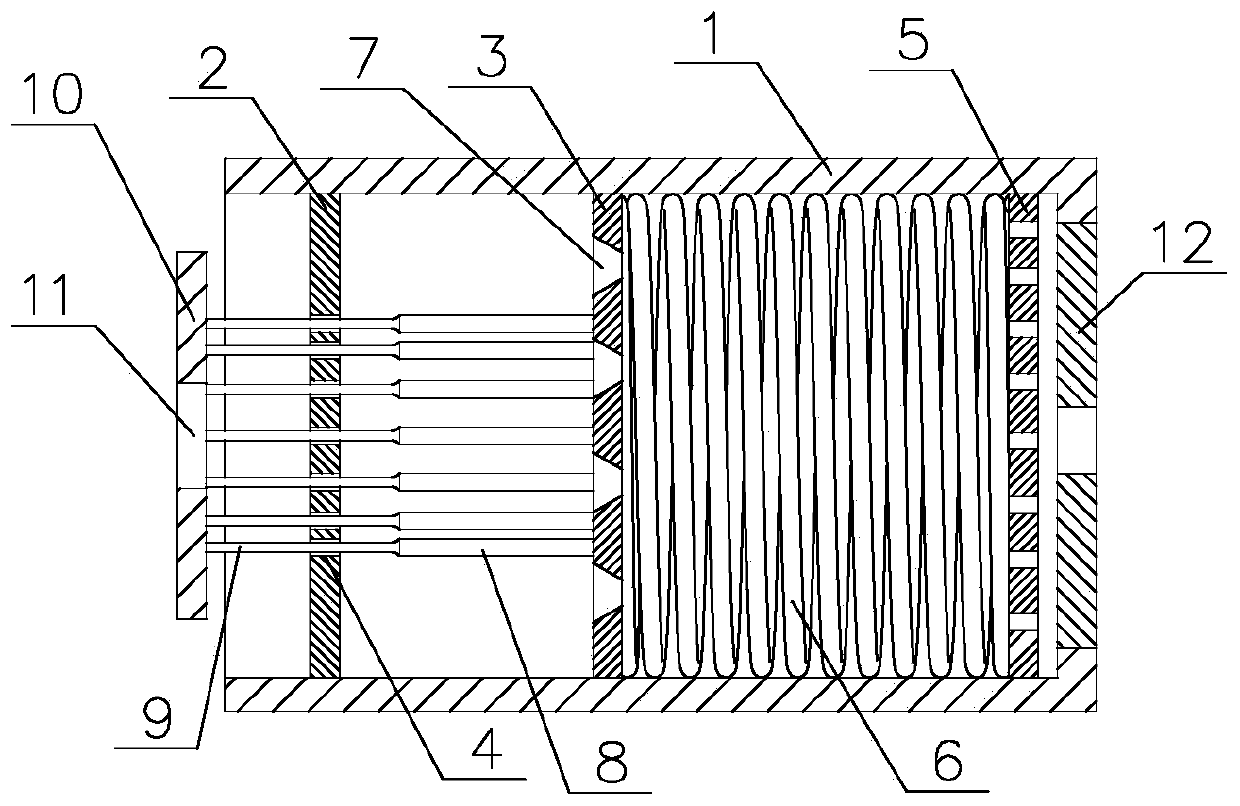

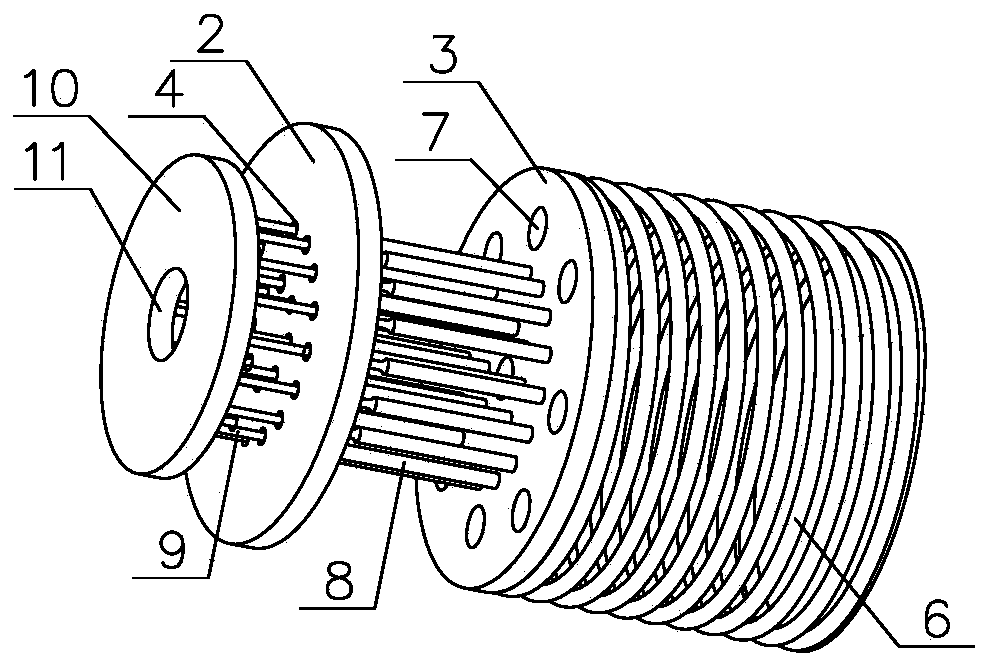

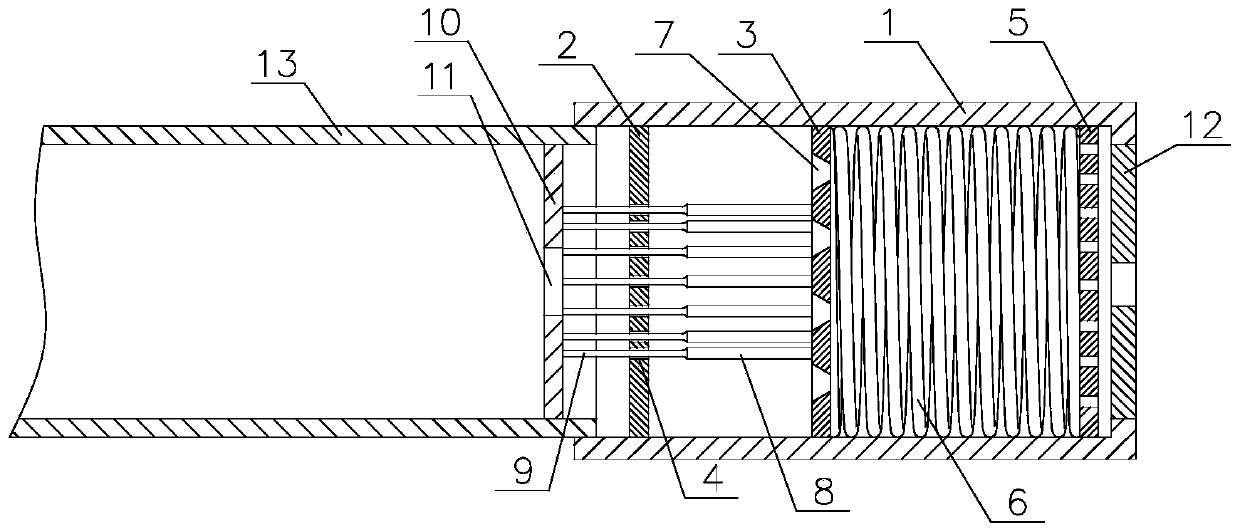

[0011] Such as Figure 1 to Figure 3 As shown, a kind of ignition oil gun head with the plugging device, it comprises gun head main body 1, is fixed with swirl plate 12 on the oil outlet end of gun head main body 1, is fixed in the inner chamber of gun head main body 1 There is a splitter 5 attached to the swirl sheet 12, which also includes a slag cutting disc 2 and a first push plate 3 arranged in the gun head main body 1; The direction from the oil inlet to the diverter plate 5 is provided with a slag cutting plate 2, a first push plate 3 and a spring 6 in sequence; The inner wall of the first push plate 3 is slidingly placed in the inner cavity of the gun head body 1, and the edge of the first push plate 3 is in sliding contact with the inner wall of the gun head body 1; the spring 6 is placed on the first push plate 3 and the shunt 5 Between; on the first push plate 3, there are evenly distributed oil through holes 7, the oil through holes 7 are tapered holes, the open e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com