Chemical cleaning method for scales on tube of evaporator for producing ammonium sulfate

A chemical cleaning and evaporator technology, which is applied in the coating process of metal materials, etc., can solve the problems of being easily corroded by harmful ions, high labor intensity, and long operation cycle, so as to achieve good promotion and application value, solve cleaning problems, and clean cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

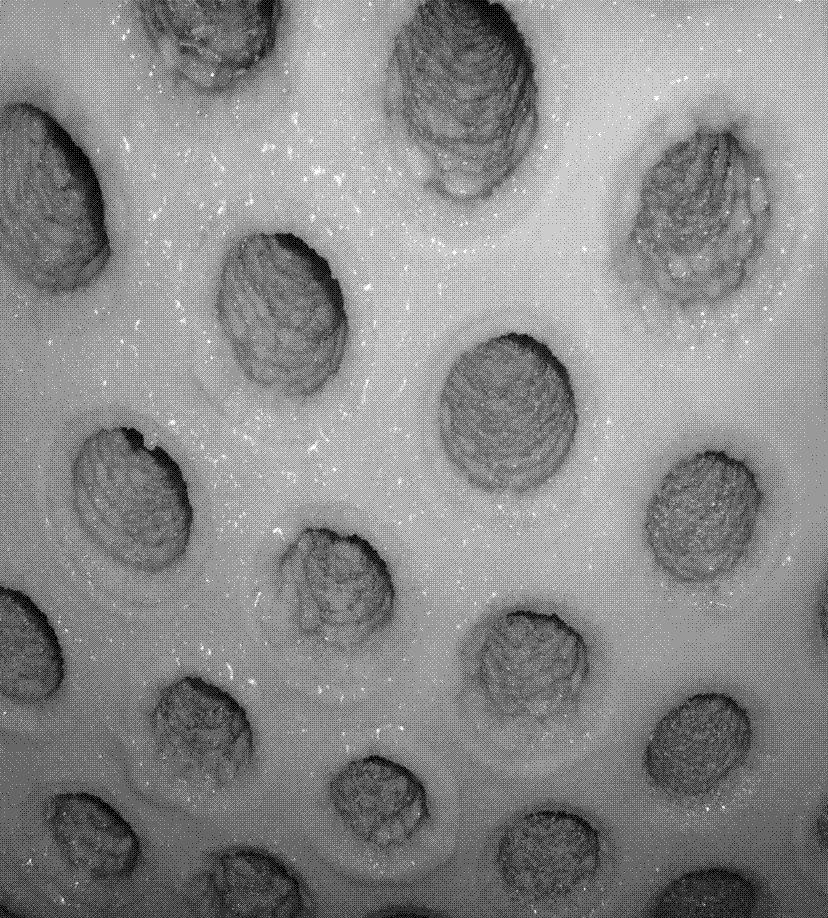

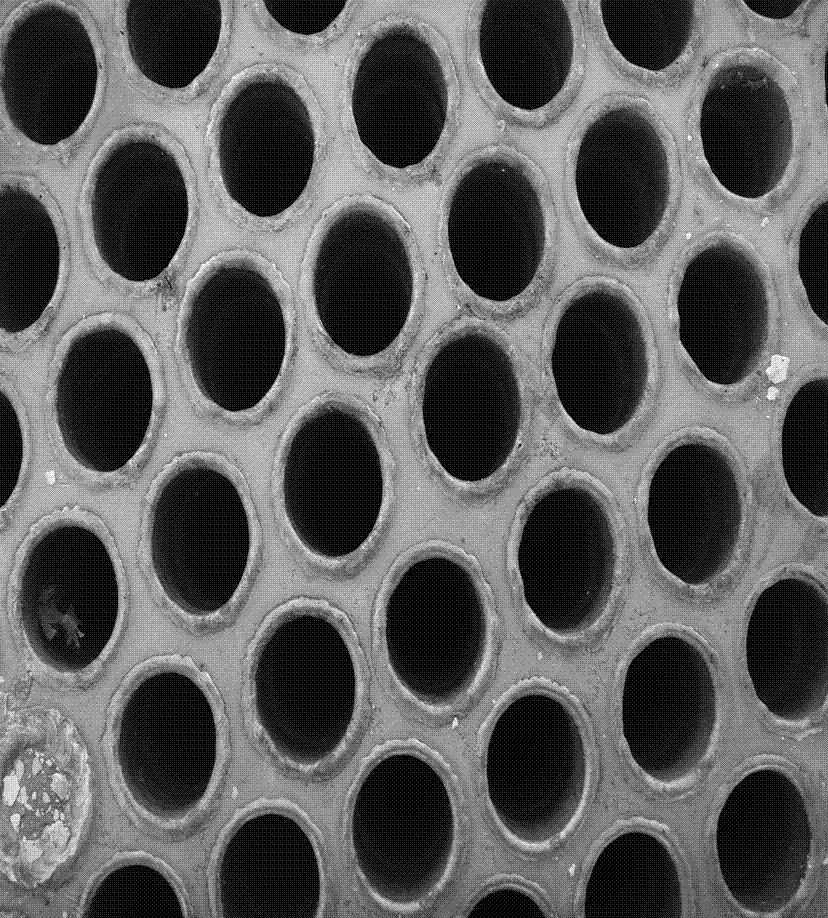

[0020] Evaporator tube heat exchange area 725m 2 , the tube length is 9m, and the tube diameter is 35mm. Scaling components: calcium 25.4wt%, magnesium 0.225wt%, of which sulfate accounted for 65wt%, silicate 20wt%, phosphate 10wt%, and others accounted for 5wt%.

[0021] The evaporator tube fouling chemical cleaning method of the present invention is as follows (the following percentages are all percentages by weight of water):

[0022] (1) Dredging and washing: Use a high-pressure dredging pump to dredge the blocked evaporator tubes, use a dredging gun head, and maintain the water pressure of the dredging pump at 700 to 1200Mpa for mechanical dredging; after dredging, add 3m 3 The acid-resistant stainless steel pump is used to circulate the tap water to clean the dredged materials and the materials in the water-soluble tubes, and empty the water after cleaning.

[0023] (2) Alkali washing: Add 3m to the evaporator 3 The tap water is circulated with an acid-resistant stain...

Embodiment 2

[0028] Evaporator tube heat exchange area 826m 2 , the length of the tubes is 9m, the diameter of the tubes is 35mm, about 30% of the tubes are completely blocked, and the scaling of the rest of the tubes is thin on the top and thick on the bottom, with 5mm of scaling on the upper part and 10mm on the lower part. Scaling components: calcium 23.5wt%, magnesium 0.462wt%, of which sulfate accounted for 70wt%, silicate 18wt%, phosphate 7wt%, and others accounted for 5wt%.

[0029] The evaporator tube fouling chemical cleaning method of the present invention is as follows (the following percentages are all percentages by weight of water):

[0030] (1) Dredging and washing: Use a high-pressure dredging pump to dredge the blocked evaporator tubes, use a dredging gun head, and maintain the water pressure of the dredging pump at 700 to 1200Mpa for mechanical dredging; after dredging, add 3m 3 The acid-resistant stainless steel pump is used to circulate the tap water to clean the dredg...

Embodiment 3

[0035] Evaporator tube heat exchange area 666m 2 , the length of the tubes is 9m, the diameter of the tubes is 35mm, 52 tubes are blocked, and the rest of the scales are thin on the top and thick on the bottom, with 1mm on the upper part and 3mm on the lower part. Scaling components: calcium 24.4wt%, magnesium 0.323wt%, of which sulfate accounted for 68wt%, silicate 15wt%, phosphate 12wt%, and others accounted for 5wt%.

[0036] The evaporator tube fouling chemical cleaning method of the present invention is as follows (the following percentages are all percentages by weight of water):

[0037] (1) Dredging and washing: Use a high-pressure dredging pump to dredge the blocked evaporator tubes, use a dredging gun head, and maintain the water pressure of the dredging pump at 700 to 1200Mpa for mechanical dredging; after dredging, add 3m 3 The acid-resistant stainless steel pump is used to circulate the tap water to clean the dredged materials and the materials in the water-solub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com