Laser cleaning method for tire moulds

A laser cleaning and tire mold technology, applied in the field of laser cleaning, can solve the problems of limited cleanliness, high labor intensity, noise pollution by dry ice cleaning, etc., to achieve the effect of not losing mold life, no noise pollution, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

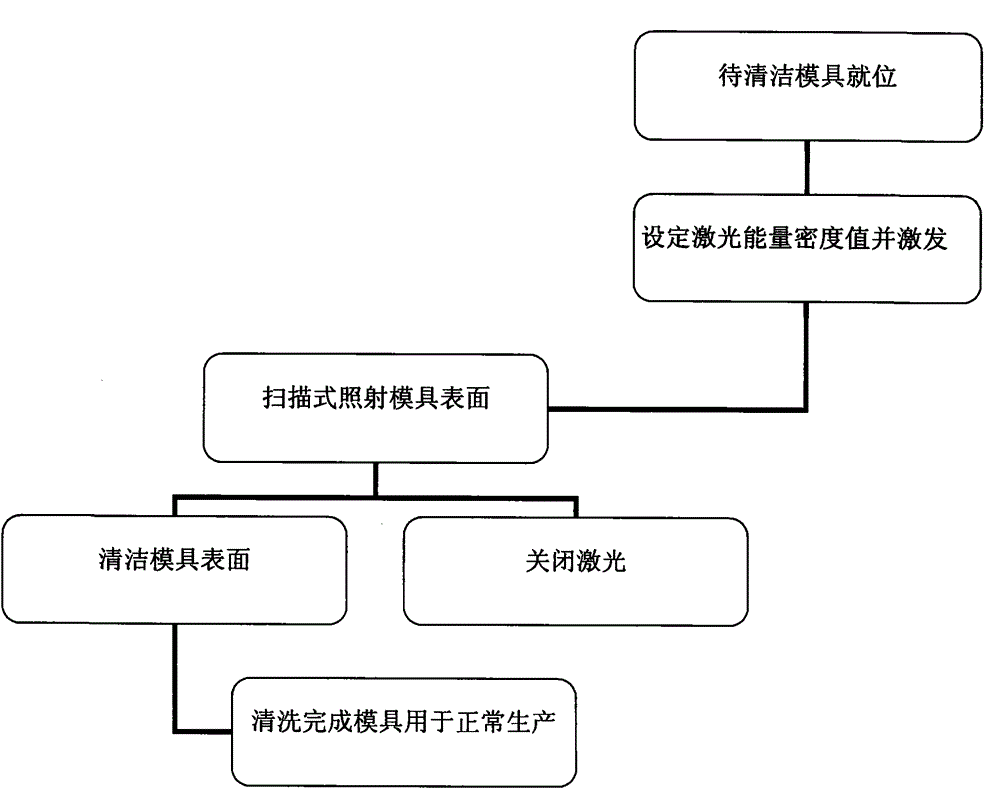

[0020] According to accompanying drawing, tire mold laser cleaning method of the present invention comprises the following steps:

[0021] 1. Mold preparation, determine the mold material to be cleaned, the general tire mold material includes carbon steel, aluminum.

[0022] 2. Set the laser energy density according to the material of the mold. The set value of the energy density should meet the energy density value less than the damage threshold of the mold surface, and slightly greater than the energy density value of the damage threshold of the attachment.

[0023] 3. Using the above-mentioned laser energy density value, excite the laser, and radiate the surface of the mold in a scanning manner. The attachment absorbs the laser energy and instantly expands or evaporates. The resultant force of these effects is greater than the adsorption force of the mold on the attachment, so that the attachment is detached.

[0024] 4. After laser c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com