Method for repairing long-life thermal barrier coating of turbine blade of F-class ground heavy-duty gas turbine

A technology of turbine blades and thermal barrier coatings, applied in coatings, metal material coating processes, furnace types, etc., can solve the problems that the long-life thermal barrier coatings of turbine blades cannot be repaired, and achieve easy solution Embrittlement, reduced boundary layer separation, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

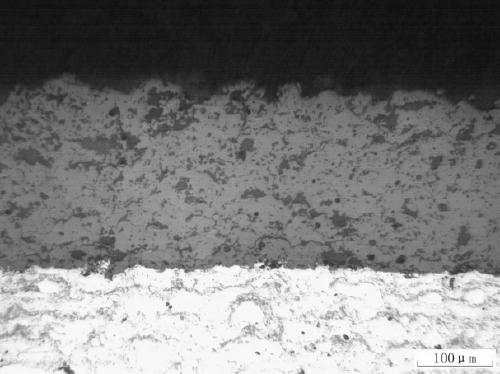

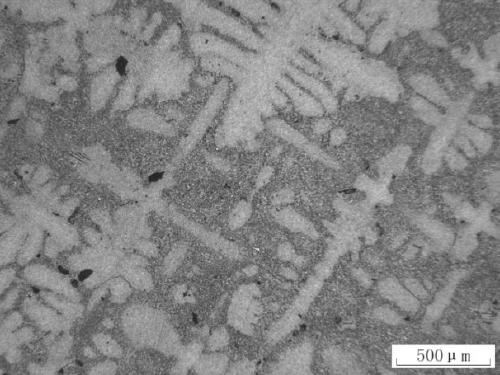

[0043] 1.1 Repair of thermal barrier coating:

[0044] After 48,000 equivalent operating hours (EOH) of the turbine blades of a F-class heavy-duty gas turbine, the back of the blade, the edge plate, and the inlet edge of the blade appeared coating pieces, coating cracks, and coating burns. The thermal barrier coating of the transparent vane is repaired, and the specific steps are as follows:

[0045] (1) Peel off the surface layer of the old thermal barrier coating on the turbine blade: use the sand blowing method to peel off the surface layer of the old thermal barrier coating, the white corundum particles are 60 mesh, the sand blowing pressure is 0.4MPa, and the distance is 150mm;

[0046] (2) Remove the old thermal barrier coating bonding layer on the turbine blade:

[0047] Use hydrochloric acid solution to remove the old thermal barrier coating adhesive layer, immerse the turbine blade with the surface layer of the old thermal barrier coating peeled off in a hydrochloric...

Embodiment 2

[0072] 2.1 Repair of thermal barrier coating:

[0073] After 48,000 equivalent operating hours (EOH) of the turbine blades of a F-class heavy-duty gas turbine, the back of the blade, the edge plate, and the inlet edge of the blade appeared coating pieces, coating cracks, and coating burns. The thermal barrier coating of the transparent vane is repaired, and the specific steps are as follows:

[0074] (1) Peel off the surface layer of the old thermal barrier coating on the turbine blades: use the sand blowing method to peel off the surface layer of the old thermal barrier coating, the white corundum particles are 60 mesh, the sand blowing pressure is 0.3MPa, and the distance is 140mm;

[0075] (2) Remove the old thermal barrier coating bonding layer on the turbine blade:

[0076] Use hydrochloric acid solution to remove the old thermal barrier coating adhesive layer, immerse the turbine blade with the surface layer of the old thermal barrier coating peeled off in a hydrochlori...

Embodiment 3

[0099] 3.1 Repair of thermal barrier coating:

[0100] After 48,000 equivalent operating hours (EOH) of the turbine blades of a F-class heavy-duty gas turbine, the back of the blade, the edge plate, and the inlet edge of the blade appeared coating pieces, coating cracks, and coating burns. The thermal barrier coating of the transparent vane is repaired, and the specific steps are as follows:

[0101] (1) Peel off the surface layer of the old thermal barrier coating on the turbine blade: use the sand blowing method to peel off the surface layer of the old thermal barrier coating, the white corundum particles are 60 mesh, the sand blowing pressure is 0.5MPa, and the distance is 160mm;

[0102] (2) Remove the old thermal barrier coating bonding layer on the turbine blade:

[0103] Use hydrochloric acid solution to remove the old thermal barrier coating adhesive layer, immerse the turbine blade with the surface layer of the old thermal barrier coating peeled off in a hydrochloric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com