High-heat-conductivity niobium-tin superconducting coil and manufacturing method thereof

A technology of superconducting coil and niobium three tin, applied in superconducting magnet/coil, coil manufacturing, inductor/transformer/magnet manufacturing and other directions, can solve the problems of stainless steel skeleton deformation, poor cooling effect of niobium three tin coil, etc. performance, improve the cooling effect, improve the effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

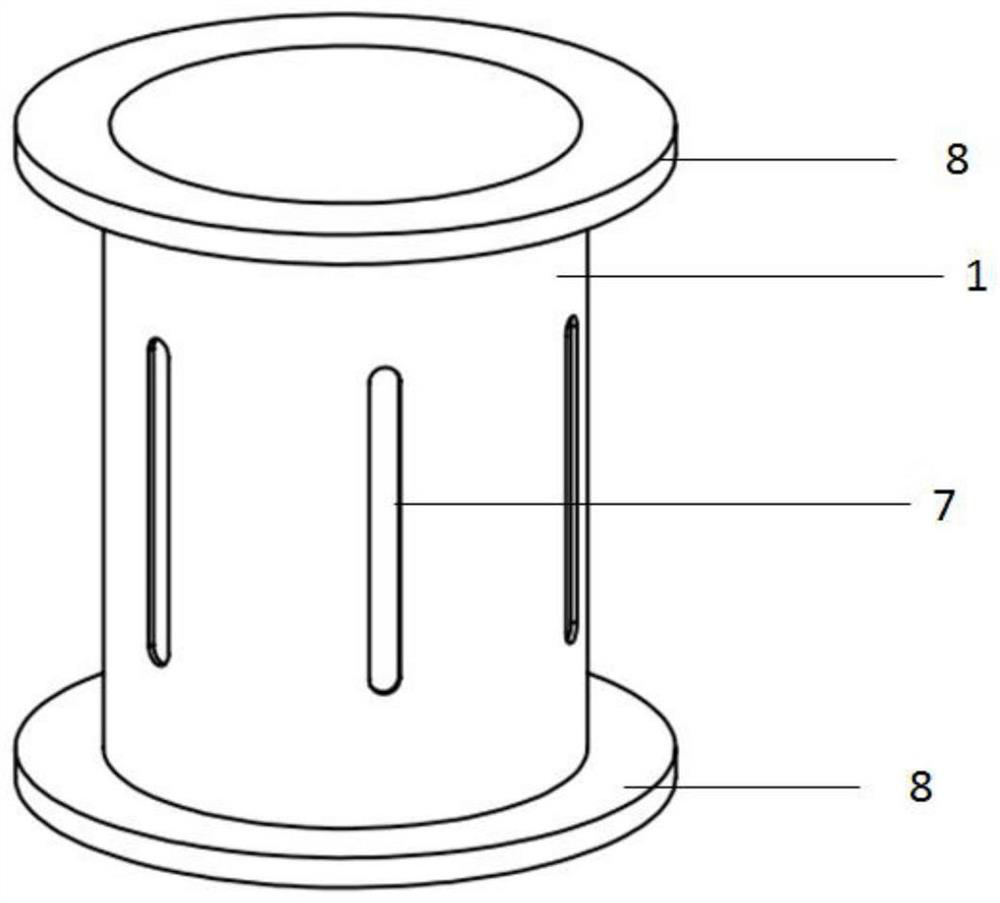

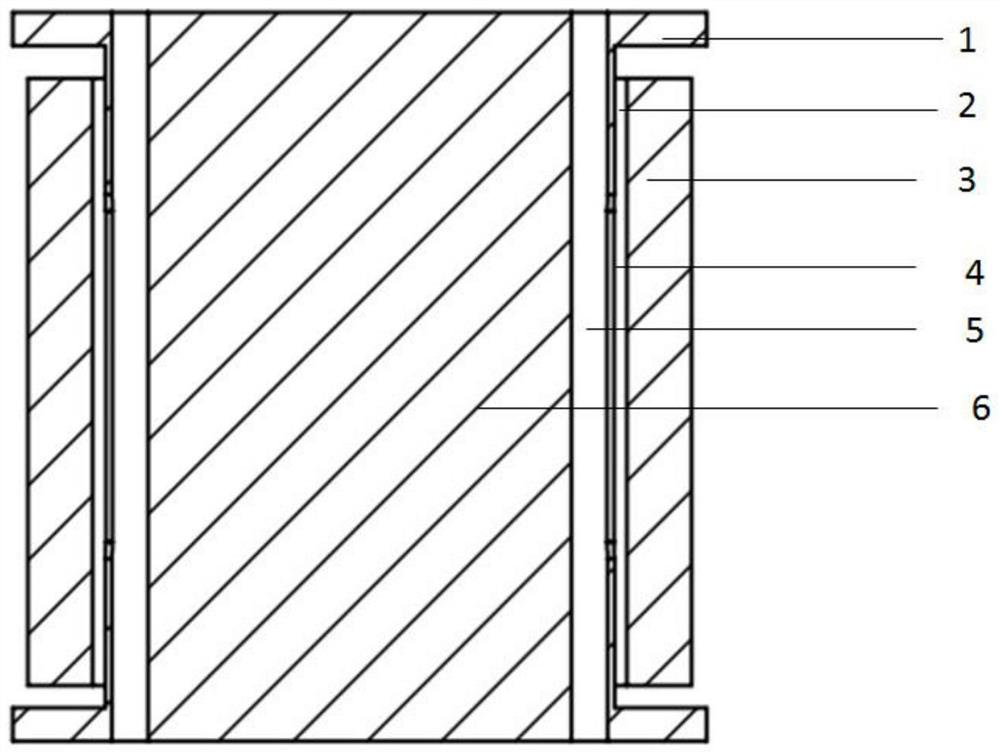

[0041] The stainless steel skeleton 1 is made into a cylindrical structure with end plate flanges 8 at both ends, the middle position of the end plate flanges 8 at both ends is a neutral plane, and grooves 7 are opened on both sides of the neutral plane, The width of the groove 7 is 1 mm, and the edge of the groove 7 is 5 cm away from the end plate flanges 8 at both ends. A solid heat-resistant steel is inserted into the central hole of the stainless steel frame 1 as a central support 6, and the diameter of the central support 6 and the assembly gap between the stainless steel frame 1 are 5mm on one side, so that the solid heat-resistant steel can be easily inserted into the In the center hole of the stainless steel skeleton. Sodium chloride 5 is added into the gap between the stainless steel frame 1 and the central support 6 and compacted from both sides. Add aluminum nitride 4 with high thermal conductivity into the groove 7 opened on the stainless steel skeleton 1, and win...

Embodiment 2

[0043] A groove 7 is opened on both sides of the neutral surface of the stainless steel frame 1, the width of the groove 7 is 10 mm, and the distance between the sides of the groove 7 and the two end plate flanges 8 is 10 cm. A solid heat-resistant steel is inserted into the center hole of the stainless steel skeleton 1 as a central support 6, and the assembly gap between the diameter of the central support 6 and the stainless steel skeleton 1 is 0.5 mm on one side, so that the heat-resistant steel can be easily inserted into the center of the stainless steel skeleton 1 inside the hole. Add sodium chloride 5 into the gap between the stainless steel frame 1 and the central support 6, and compact it from both sides. Add aluminum nitride 4 with high thermal conductivity into the groove 7 opened on the stainless steel frame 1, and wind stainless steel sheets on the stainless steel frame 1, tighten it with a clamp, and compact and fill the stainless steel frame with 100 micron alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com