A home sewer motor actiyator

A motor speed regulation, sewing machine technology, applied in the direction of sewing machine control devices, sewing equipment, sewing machine components, etc., can solve the problem of small output torque and achieve the effect of smooth needle movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

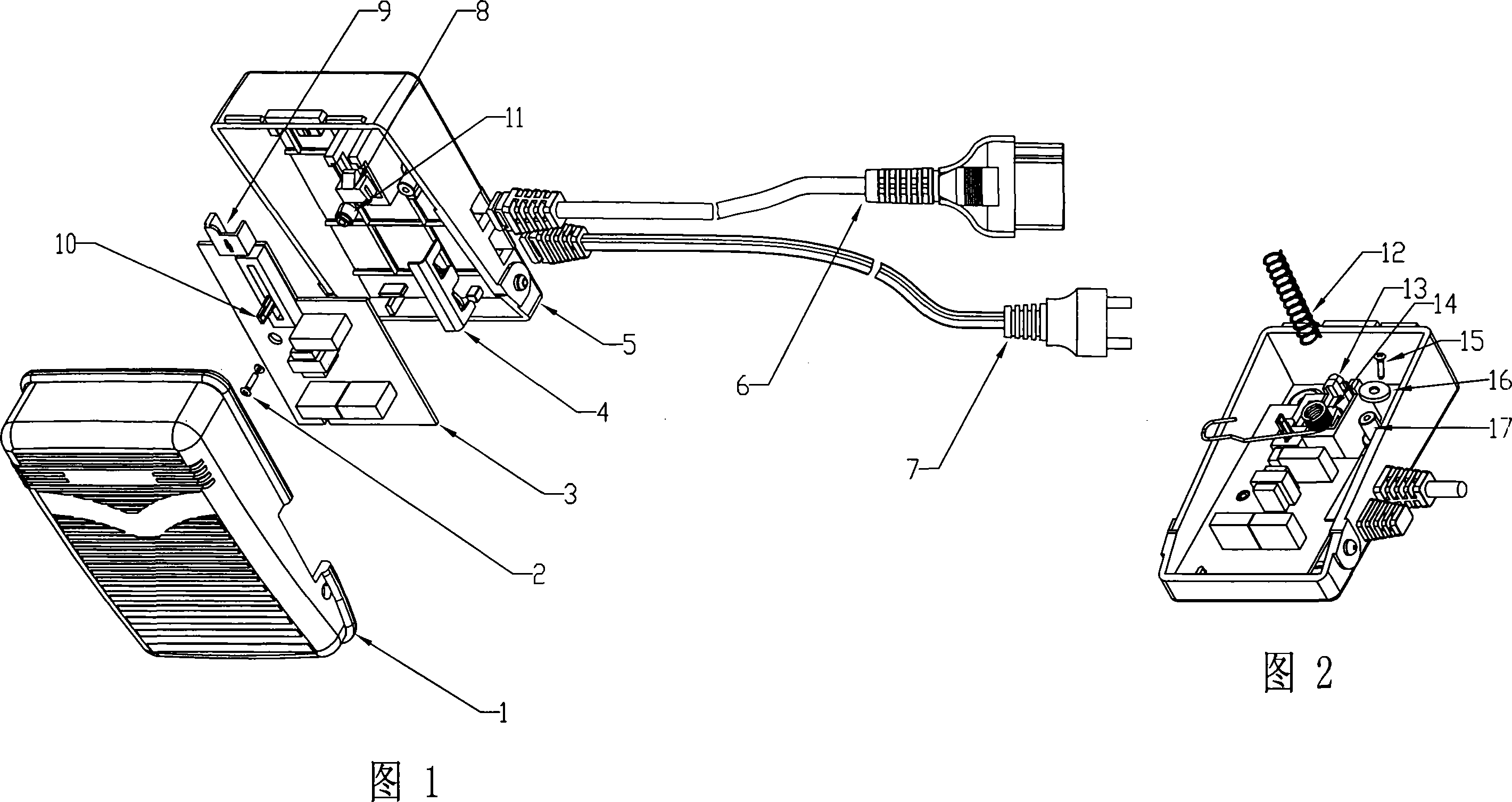

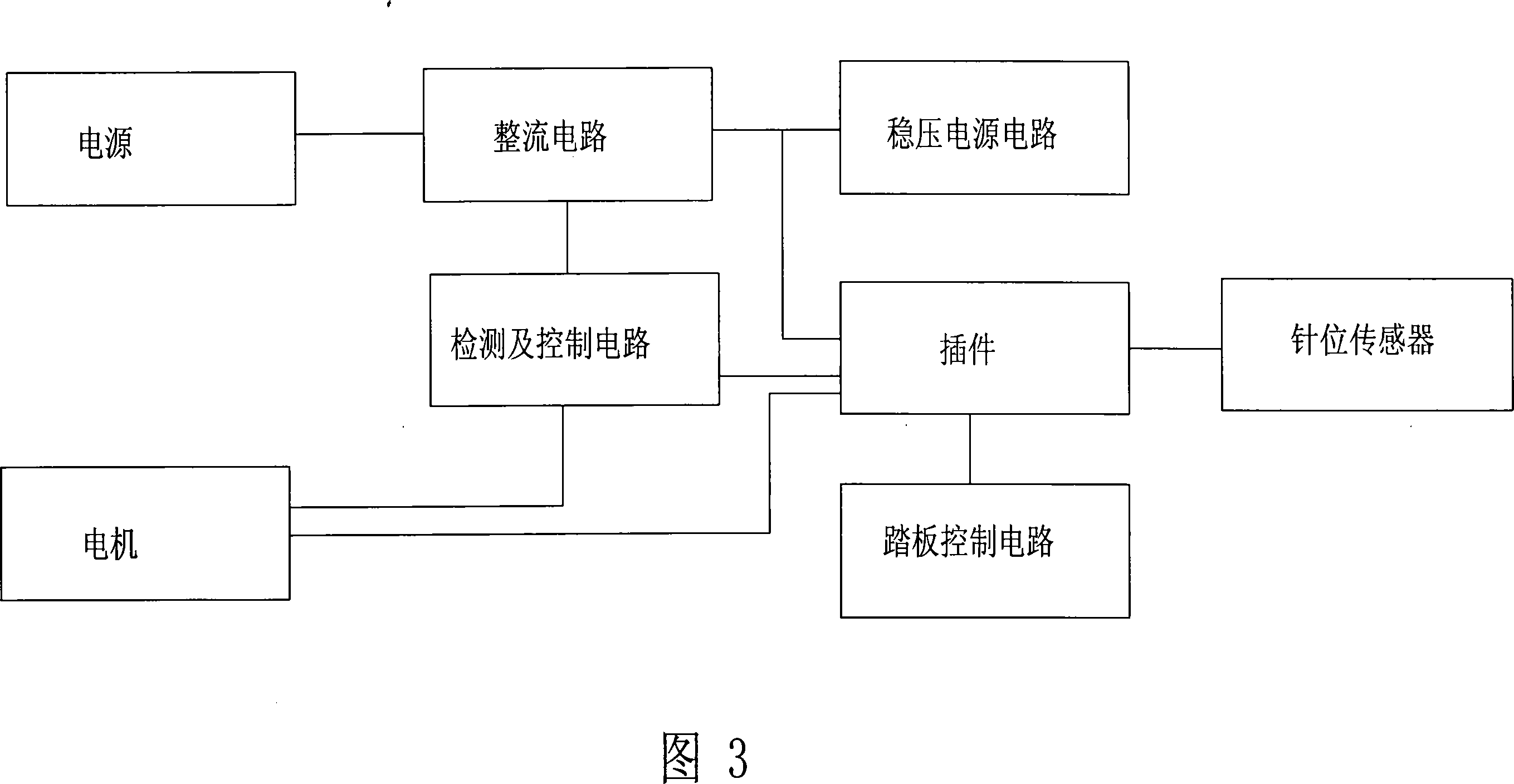

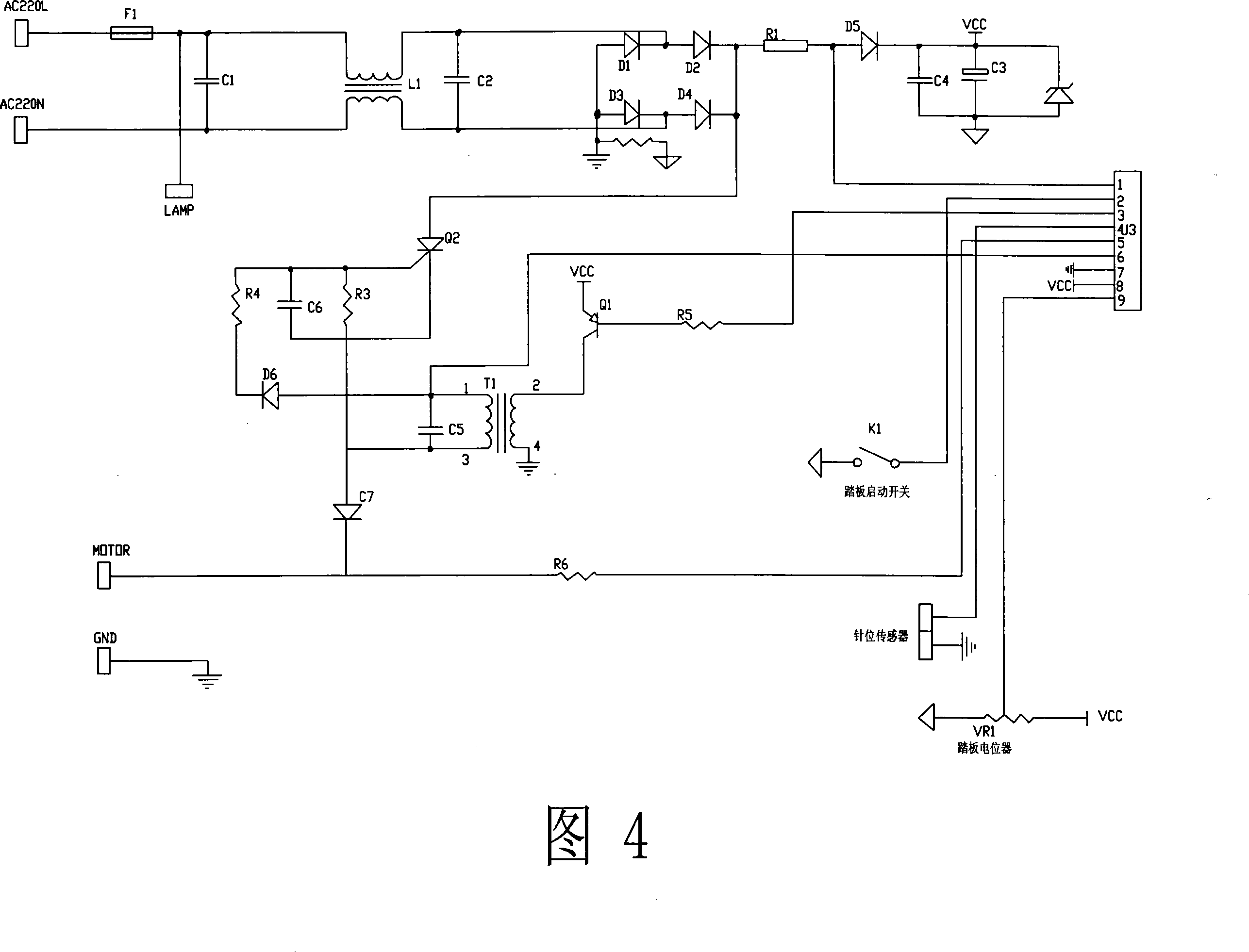

[0017] As shown in Figures 1 and 2, the pedal control panel of the household sewing machine is formed by interlocking the front cover 1 and the rear cover 5. One end of the two is connected by rotation, and the other end is pushed against by a built-in spring. When the machine stops, the The lower edge of the end upper cover 1 is engaged with the upper edge of the lower cover 5 . One side of the back cover 5 offers two grooves, and the ends of the control line plug 6 and the power line plug 7 are respectively inserted into the two grooves and then buckled into the lock plate 4 to fix. A protrusion 11 is provided on the inner side of the rear cover 5, and the M3X8 self-tapping screw 2 is screwed into the protrusion 11 to fix the circuit board 3 between the front cover 1 and the rear cover 5. The circuit board 3 is provided with a chute, and the chute is built in Inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com