Method for cleaning anode mud on zinc electrodeposition anode plate

A cleaning method and anode plate technology, applied in the metallurgical field, can solve the problems of increased power consumption, high labor intensity of workers, and damage to the anodic oxide film layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

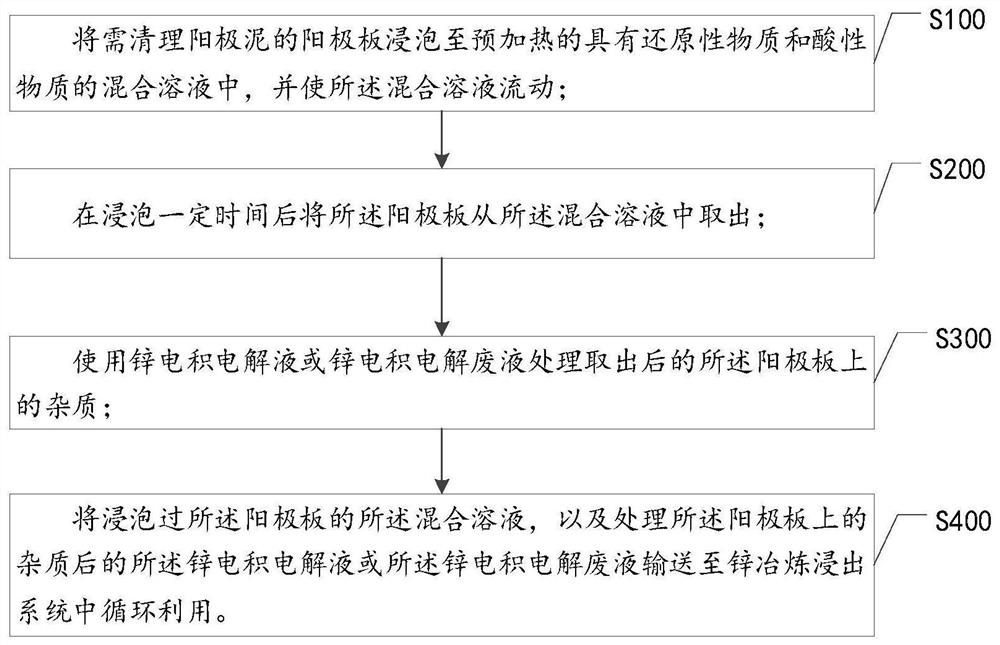

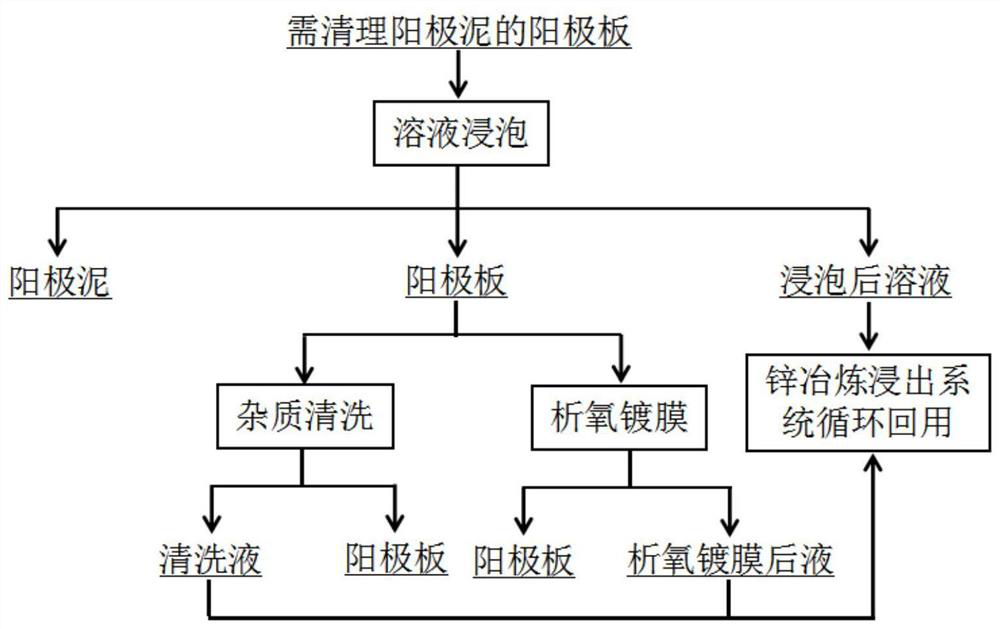

Method used

Image

Examples

Embodiment 1

[0049] Get 18 pieces of the same type of anode plates that need to be cleaned of hanging plate anode slime, divide them into three groups by 6 pieces / group, adopt manual cleaning, mechanical cleaning and soaking cleaning of the present invention to clean up the three groups of anode plates respectively, after cleaning is completed The anode plate is directly used for zinc electrowinning until it is cleaned again, and the cleaning cycle of the anode slime is 20 days / time until the anode is scrapped. Wherein the heating mixed solution that has reducing substance and acidic substance among the present invention is cobaltous sulfate 150g / L, sulfurous acid 30g / L, sulfuric acid 150g / L, and mixed solution is placed in the tank, and solution temperature is 50 ℃, and 6 The anode plate that needs to be cleaned is placed in the tank, and the circulation pump is used to make the mixed solution flow in 20m 3 / h circulation speed flow. The anode plate to be cleaned of anode slime is soaked...

Embodiment 2

[0054] Get 18 pieces of the same type of anode plates that need to be cleaned of hanging plate anode slime, divide them into three groups by 6 pieces / group, adopt manual cleaning, mechanical cleaning and soaking cleaning of the present invention to clean up the three groups of anode plates respectively, after cleaning is completed The anode plate is directly used for zinc electrowinning until it is cleaned again, and the cleaning cycle of the anode slime is 20 days / time until the anode is scrapped. Wherein the heating mixed solution with reducing substances and acidic substances in the present invention is zinc sulfite 150g / L, nitric acid 60g / L, sulfuric acid 120g / L, the solution temperature is 60°C, the mixed solution is placed in the tank, and 60 tablets The anode plate to be cleaned is placed in the tank, and a circulation pump is used to make the mixed solution flow at 30m 3 / h circulation speed flow. Soak the anode plate that needs to be cleaned of anode slime in a mixed...

Embodiment 3

[0059] Get 18 pieces of the same type of anode plates that need to be cleaned of hanging plate anode slime, divide them into three groups by 6 pieces / group, adopt manual cleaning, mechanical cleaning and soaking cleaning of the present invention to clean up the three groups of anode plates respectively, after cleaning is completed The anode plate is directly used for zinc electrowinning until it is cleaned again, and the cleaning cycle of the anode slime is 20 days / time until the anode is scrapped. Wherein the heating mixed solution with reducing substance and acidic substance in the present invention is cobaltous sulfate 150g / L, zinc sulfite 30g / L, sulfuric acid 170g / L, mixed solution is placed in the groove, and solution temperature is 55 ℃, will 60 anode plates to be cleaned are placed in the tank, and a circulation pump is used to make the mixed solution flow in 25m 3 / h circulation speed flow. Soak the anode plate that needs to be cleaned of anode slime in the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com