Improved oil-gas mixing press punch used for lead installation

A technology of oil and gas mixing and pressing, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of uneven pressure, affecting the quality of lead punching, etc., and achieve a uniform level, stable pressure, and waste-free use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable examiners to further understand the purpose of the present invention, a preferred embodiment is now attached for detailed description as follows. This embodiment is only used to illustrate the technical solution of the present invention, not to limit the present invention.

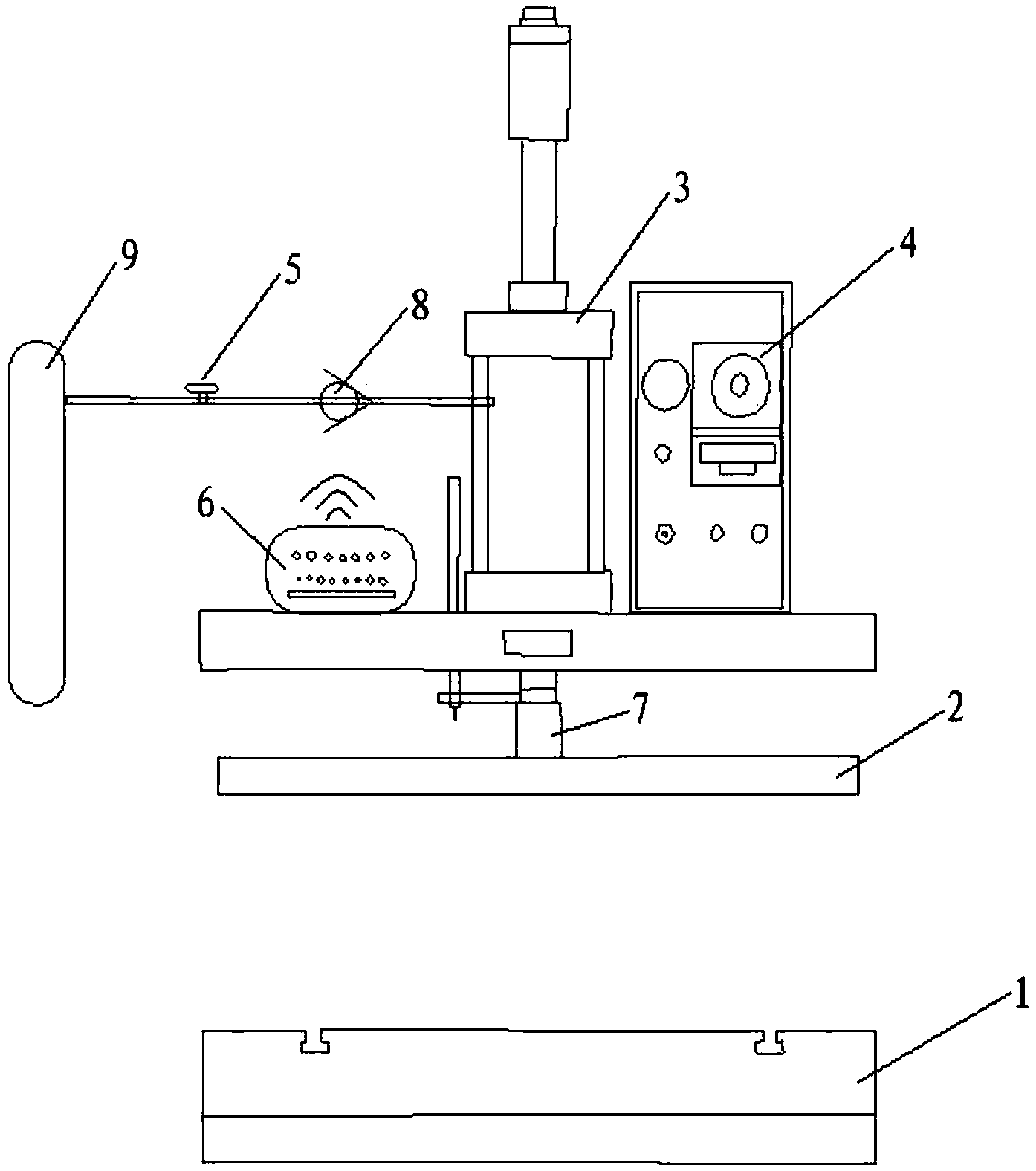

[0018] refer to figure 1 , the oil-air mixed press press used for the installation of heat sink lead wires in this example is improved on the basis of the existing oil-air mixed press press. Therefore, in the existing oil-air mixed press press, except for the limit block, all Introduced in this example. The punch press of the oil-air mixed press in this example includes the main body of the oil-air mixed press, a pressure switch 5 and a relay 6. The main body of the oil-air mixed press includes a base 1, a crimping die 2, and a cylinder 3, which control the cylinder switch of the cylinder and display the air intake. The intake pressure gauge 4 and the pressure switch 5 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com