Ultrasonic descaling energy converter for plate heat exchanger and descaling method of ultrasonic descaling energy converter

A plate heat exchanger, ultrasonic technology, applied in the direction of cleaning heat transfer devices, lighting and heating equipment, vibration cleaning, etc., can solve the problems of not being suitable for long-term work, mechanical damage of plates, affecting service life, etc., and achieve high descaling Efficiency, reliability, and long mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

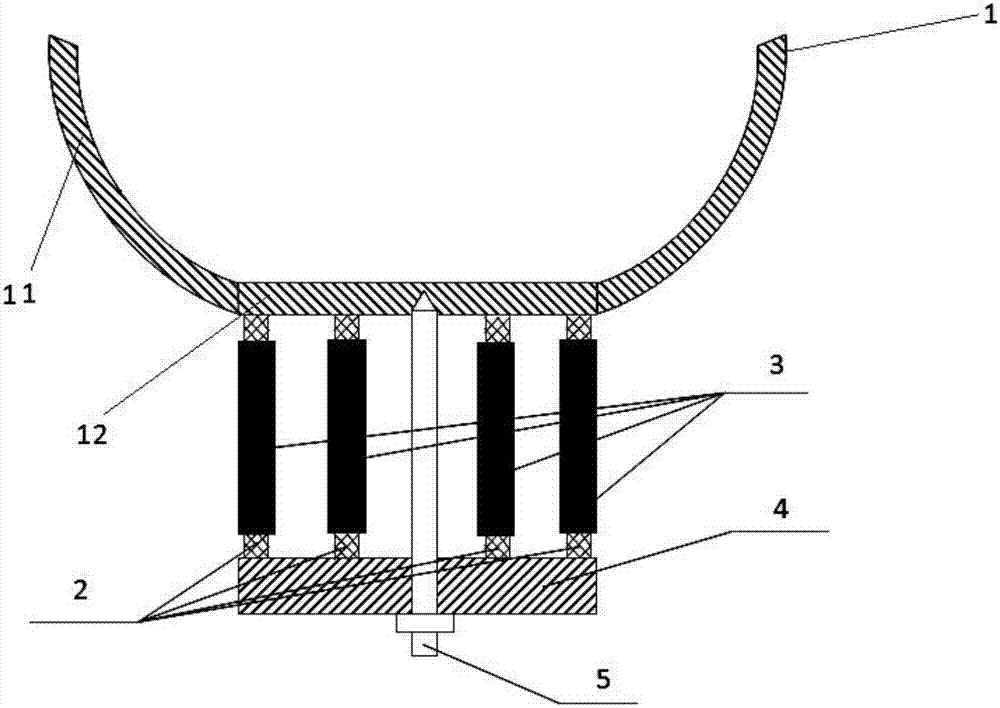

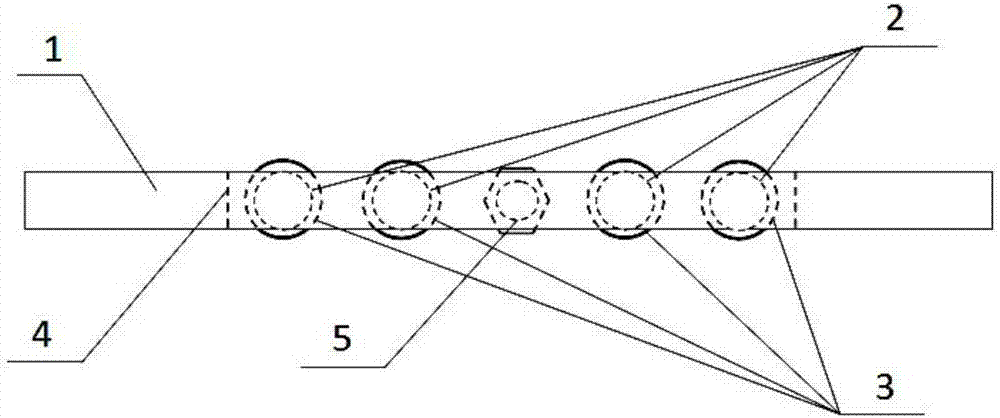

[0024] Such as figure 1 , 2 As shown, the present invention provides an ultrasonic descaling transducer for a plate heat exchanger, comprising: a radiating surface 1, the radiating surface 1 is a flat horn-shaped structure, and the bottom of the radiating surface 1 is equipped with several magnetic The telescopic rod 2, the other end of the magnetostrictive rod 2 is equipped with a rear cover 4, the bottom of the radiation surface 1 and the rear cover 4 clamp the magnetostrictive rod 2 by a fastening device, and the magnetostrictive rod 2 is A coil 3 is wound. The radiating surface 1 includes a flat radiating surface 11 and arc-shaped radiating surfaces 12 symmetrically arranged on both sides of the flat radiating surface 11. The symmetrically arranged arc-shaped radiating surfaces 12 form a trumpet-shaped structure, and the main The function is to gather radiant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com