Sheet resistance tester and test method for nondestructive measurement of thin-layer materials

A technology of sheet resistance and thin-layer materials, applied in the direction of measuring resistance/reactance/impedance, measuring electricity, measuring electrical variables, etc., can solve problems such as electrical breakdown, electrical damage of thin-layer materials, excessive voltage, etc., and achieve safety High, less mechanical damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

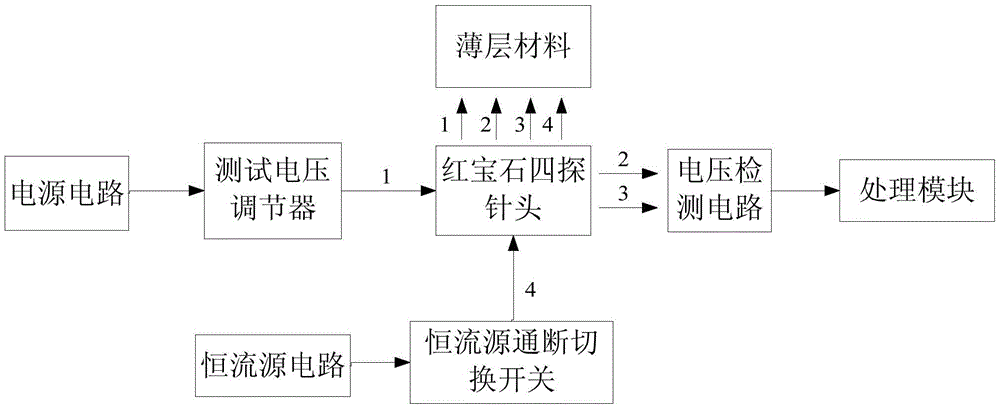

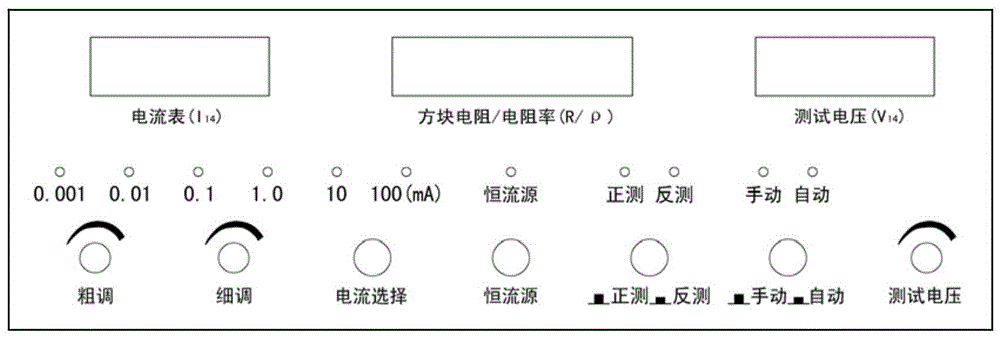

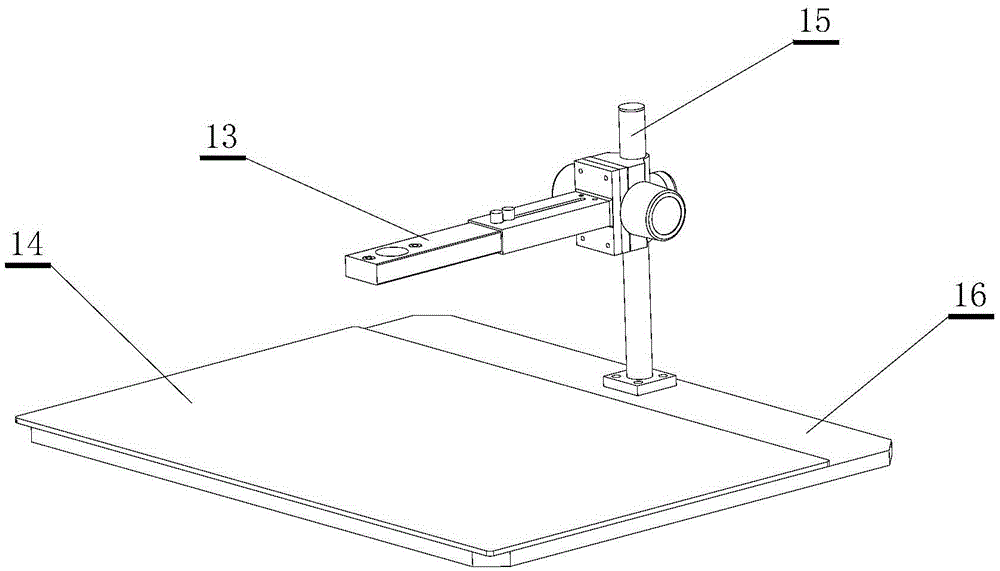

[0032] Such as figure 1 As shown, the sheet resistance tester for non-destructive measurement of thin-layer materials in this embodiment includes a host, a ruby four-probe head, a test frame, and a measurement control system. The host includes a box and a test circuit, and the power supply in the test circuit The circuit and the constant current source circuit are arranged in the box body. The ruby four-probe head includes four probes 1, 2, 3, and 4, of which probes 1 and 4 are outer probes, and probes 2 and 3 are inner probes. Such as Figure 6 As shown, the test voltage regulator includes a potentiometer. In this embodiment, one end of the potentiometer is connected to the power circuit, and the other end is connected to one of the external probes (1 probe). The on-off switching switch of the constant current source is arranged between the constant current source circuit and the four-probe head. The measurement control system includes a voltage detection circuit and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com