Ultrasonic material distributing machine applied to the die castings

An ultrasonic and die-casting technology, which is applied in the field of ultrasonic splitters, can solve the problems of low efficiency of manual splitting, mechanical damage on the surface of workpieces, and high splitting force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

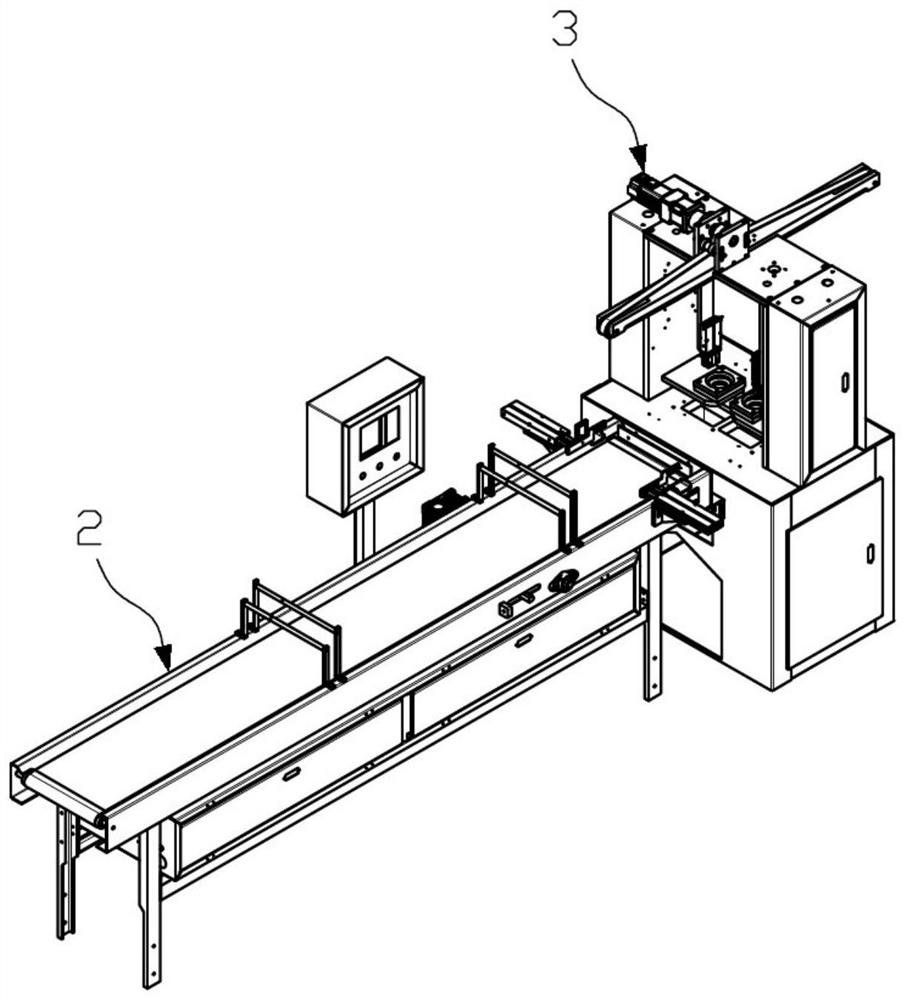

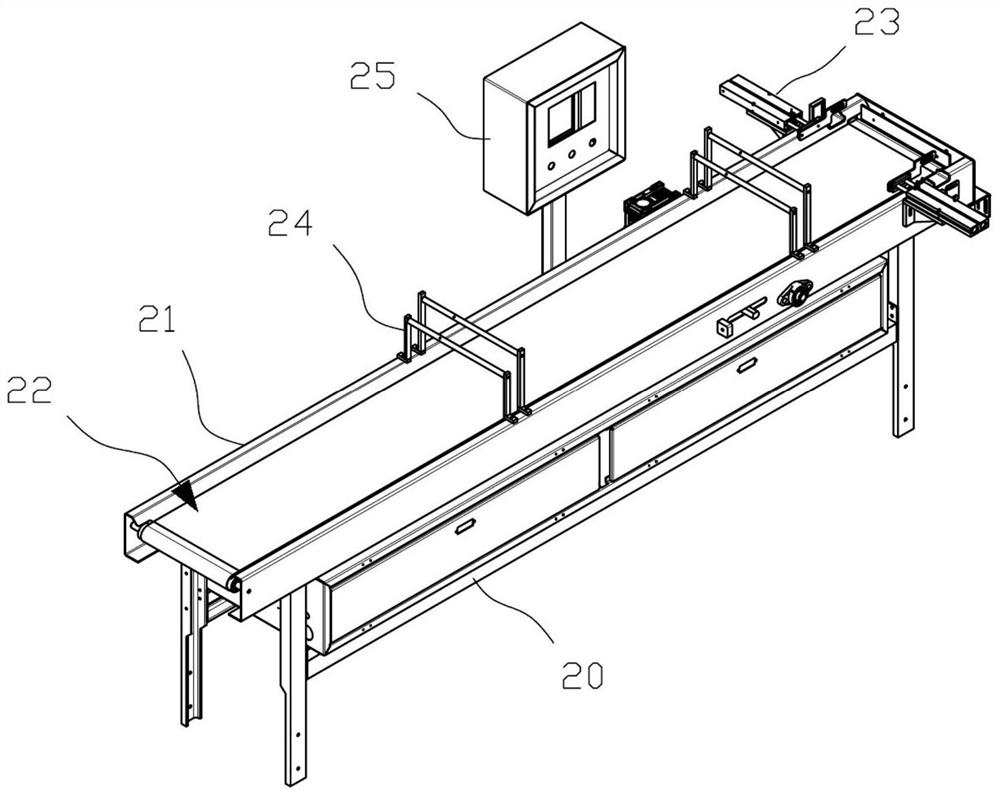

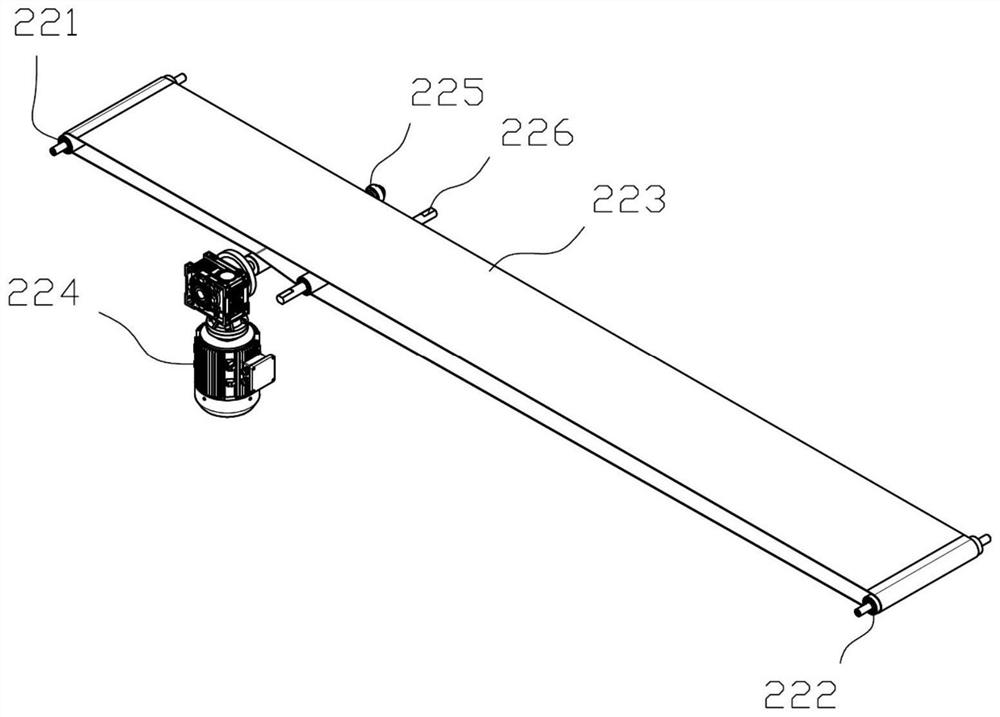

[0034] Such as figure 1 — Figure 8 As shown, the present invention provides an ultrasonic distributing machine applied to die castings, which is applied to an ultrasonic distributing production line of die castings, including: an ultrasonic distributing unit 3 for separating two die castings connected together;

[0035] The ultrasonic distributing unit 3 includes

[0036] Transfer manipulator member 32, it can carry described die casting;

[0037] an ultrasonic transducer member capable of ultrasonically separating said die casting;

[0038] Distributing chassis 30, which is provided with a blanking port 300 for guiding the waste of die castings; and

[0039] Distribution top frame 31, which is fixed on the distribution bottom frame 30;

[0040] Wherein, the material di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com