A kind of copper indium gallium selenide thin film solar cell metal electrode exposure method

A technology of solar cells and metal electrodes, which is applied in the field of solar cells to meet the requirements of ensuring the focus position, reducing flatness, and solving the effect of film residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be specifically described below based on the drawings showing the embodiments of the present invention.

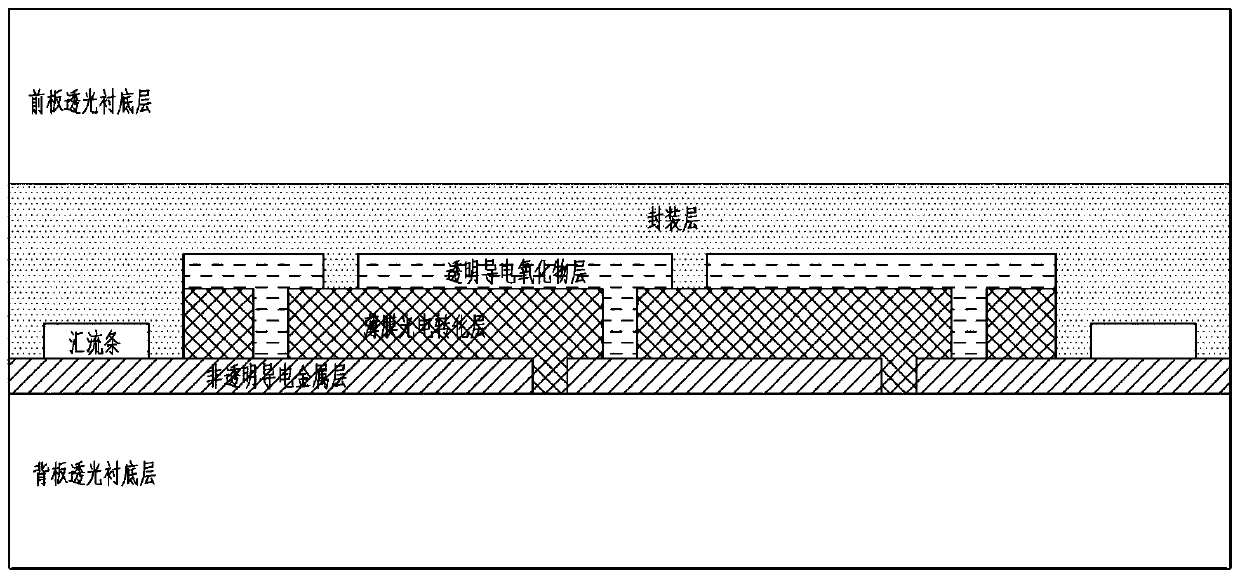

[0025] figure 1 It is a cross-sectional view of a CIGS thin film solar cell module. From bottom to top, they are the backplane transparent substrate layer, non-transparent conductive metal layer, thin film photoelectric conversion layer, transparent conductive oxide layer, encapsulation layer and front panel transparent substrate layer. The metal electrodes involved in the present invention need to be exposed The position is the area of the non-transparent conductive metal layer under the bus bar in the figure. The battery will generate current when it is exposed to light, and the current is drawn out through the bus bar shown in the figure. If the electrode exposure process is not performed, the bus bar will only be compatible with figure 1 The transparent conductive oxide layer shown in , but the resistivity of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com