Automatic material arranging method and equipment based on vision robots

A robot and vision technology, applied in the field of automatic material sorting methods and equipment, can solve problems such as unsatisfactory, unable to identify the front and back of finished products, and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

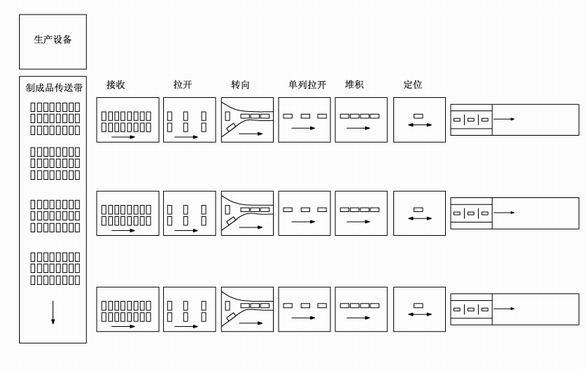

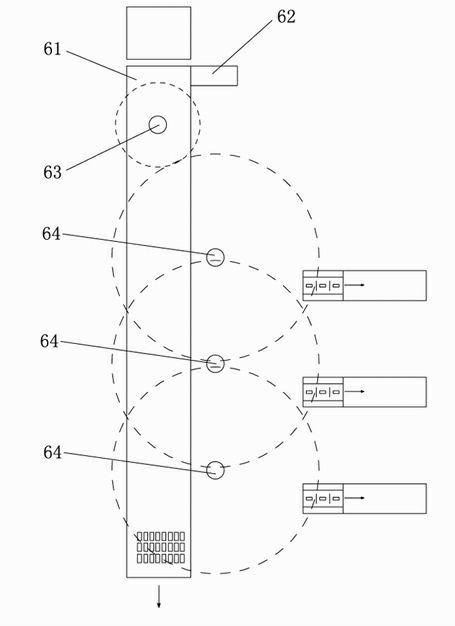

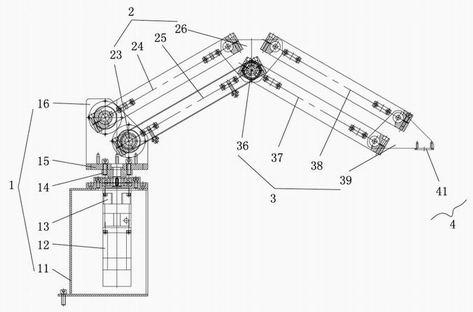

[0077] Such as figure 1 - Figure 6 As shown, the automatic material sorting method and equipment based on the visual robot include: a finished product conveyor belt, a synchronization device, a visual camera, and a robot. The number of configurations of vision cameras and robots can be determined according to the specific conditions of the production equipment, that is, the number of configurations is variable. Production equipment and packaging machines are not included in this system. Among them: finished product conveyor belt 61; synchronization device 62: the synchronization device is installed on the finished product conveyor belt through mechanical connection, and can detect the movement distance of the finished product conveyor belt in real time; visual camera 63: the visual camera is installed on the finished product conveyor belt Above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com