Lathe with automatic control function

A technology of lathes and control devices, applied in automatic lathes/semi-automatic lathes, manufacturing tools, metal processing equipment, etc., can solve problems such as unfavorable product quality, equipment cost increase, parts and equipment mechanical damage, etc. Less and more efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

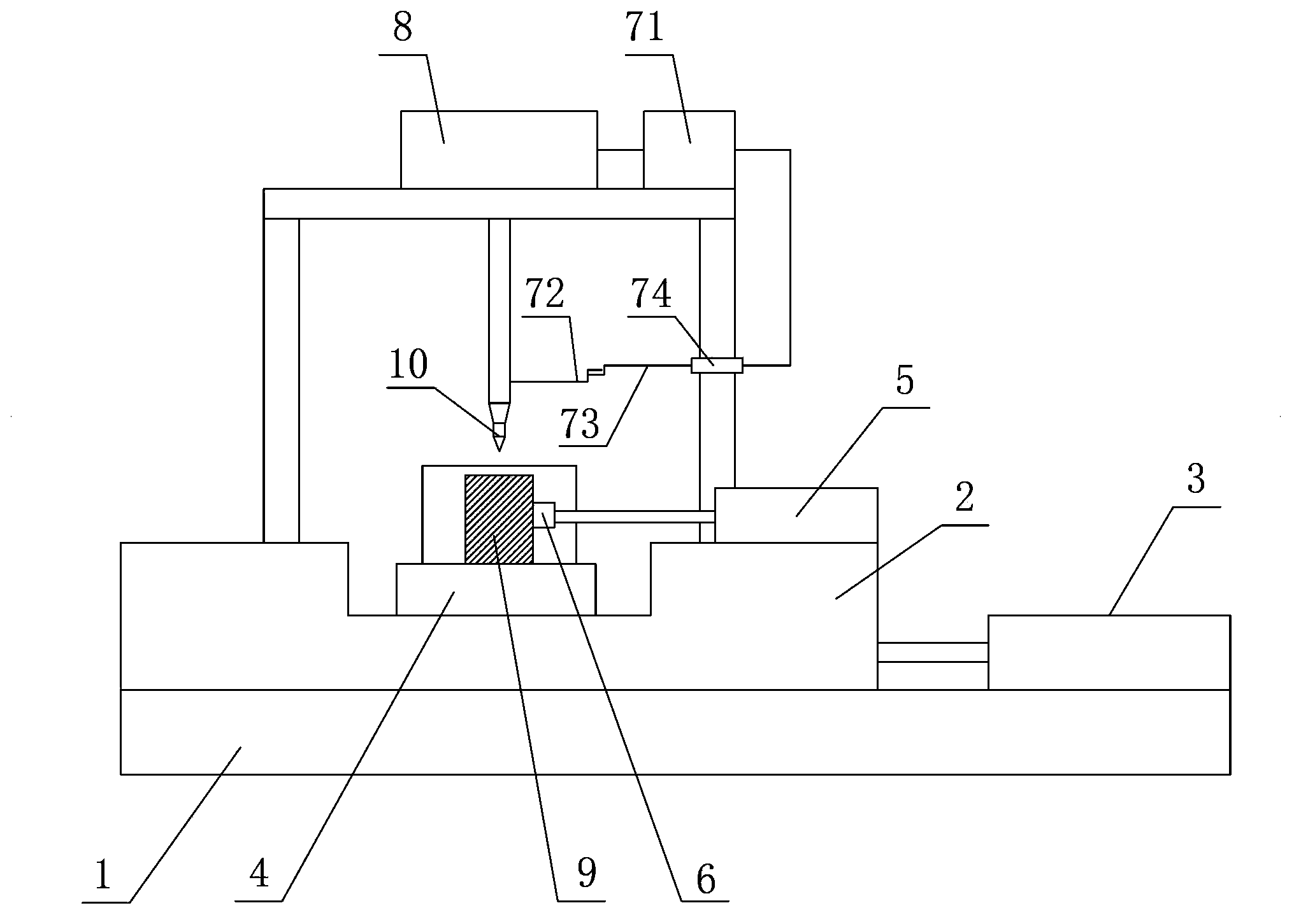

[0015] A processing lathe with automatic control is proposed, including a base 1; a workbench 2, which is movably connected to the base 1; a first power device 8, which is fixed to the base 1, and can drive the tool 10 up / down, and the tool 10 is fixedly connected to the first Contact 72; the second power unit 3, fixed base 1, can drive the workbench 2, so that the limit block 4 fixed on the workbench 2 is close to / away from the bottom of the tool 10; the third power unit 5, fixed workbench 2. It can drive the plug 6 close to / away from the side of the limit block 4; the pressure sensing transmission device 74 includes the sensing part 73, and the first contact 72 is linked with the sensing part 73; the control device 71 controls the opening of the first power device 8 / Close; when the control device 71 receives the pressure information from the pressure-sensing transmission device 74 , the control device 71 controls the first power device 8 to be closed. An accommodating groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com