Modular well intervention assembly

a module and well technology, applied in the field of modules, can solve the problems of impractical or undesirable to kill a well, inconvenient transportation, and inability to use drilling mud or other drilling fluid, and achieve the effects of convenient and convenient removal, stable, secure and safe work environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

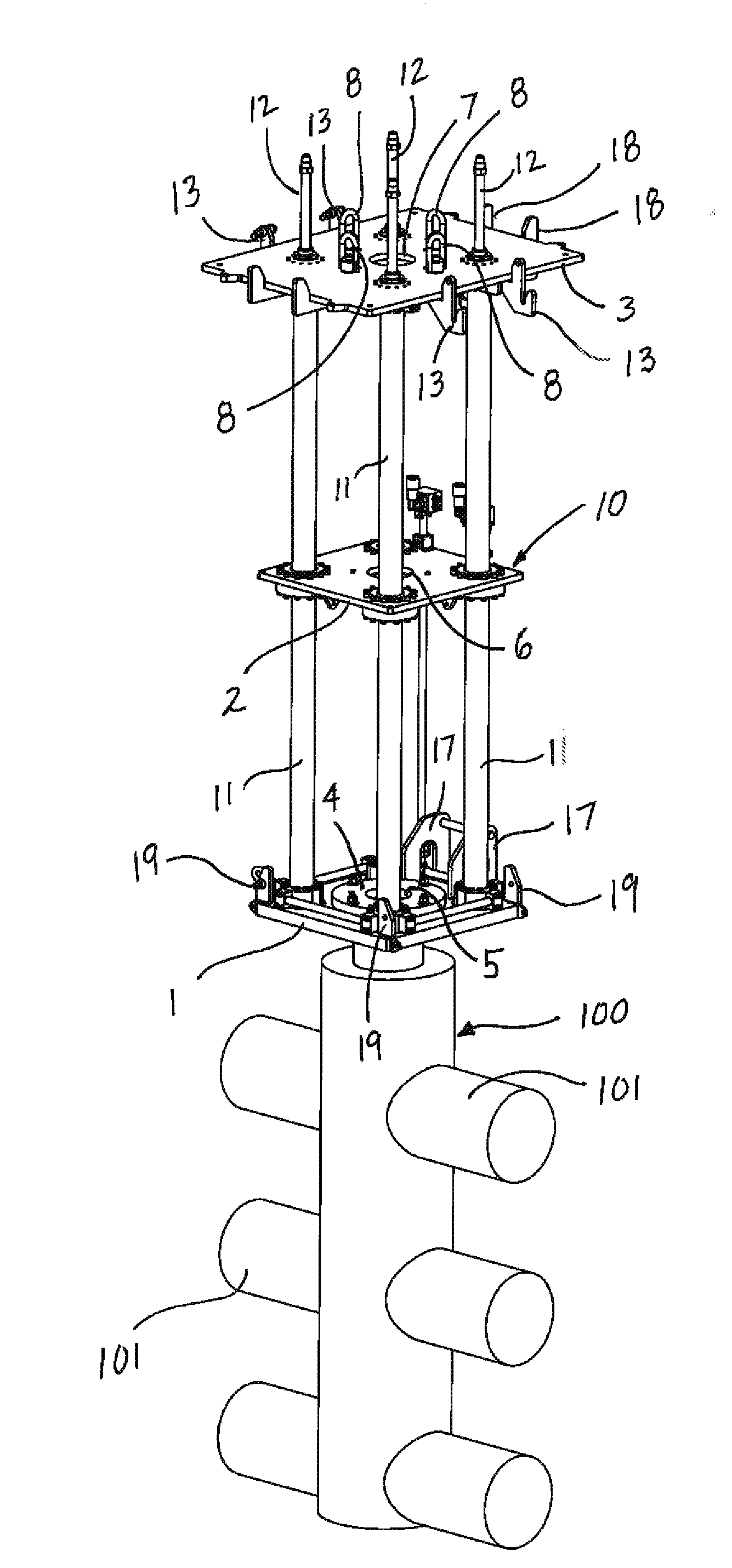

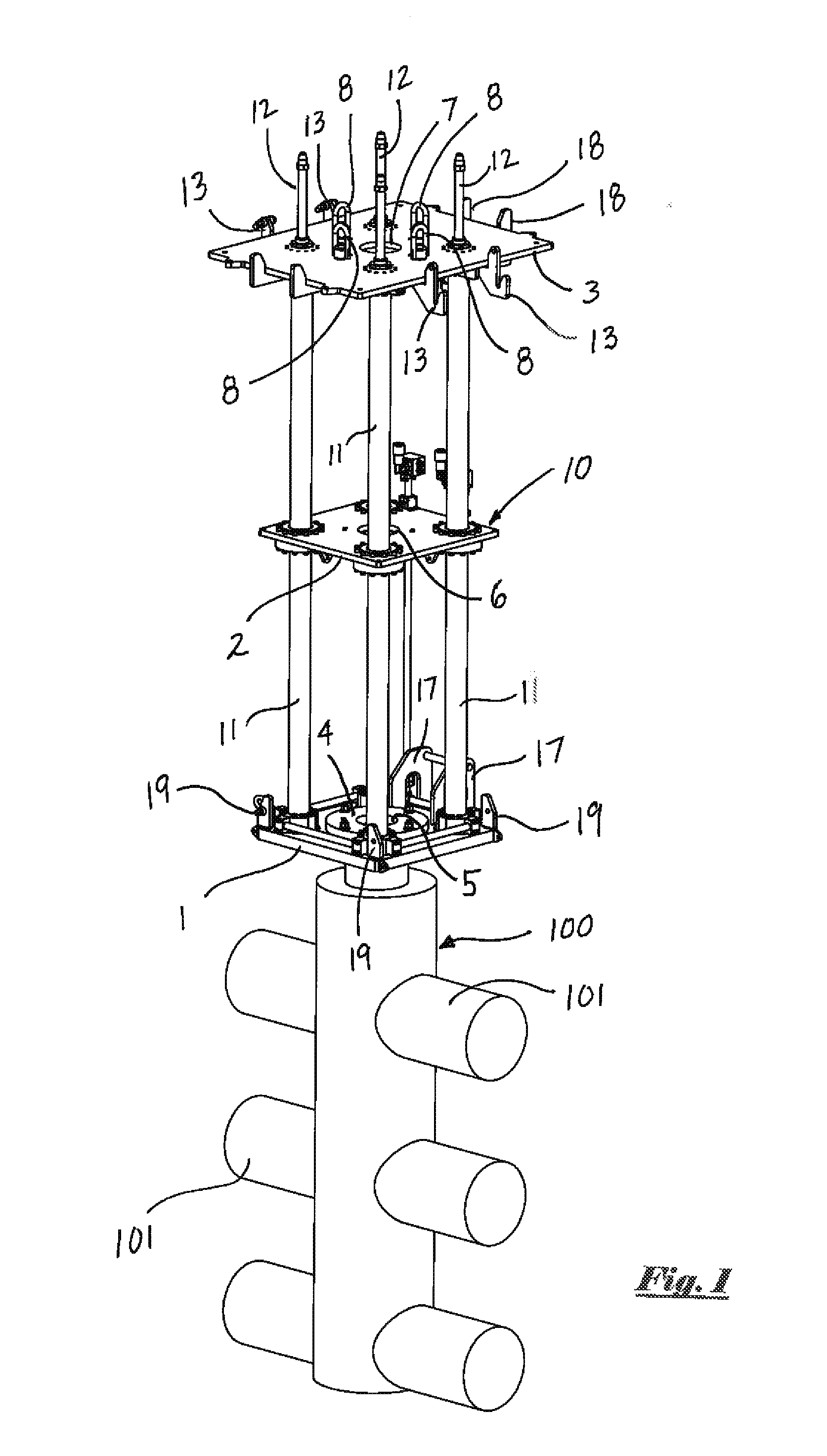

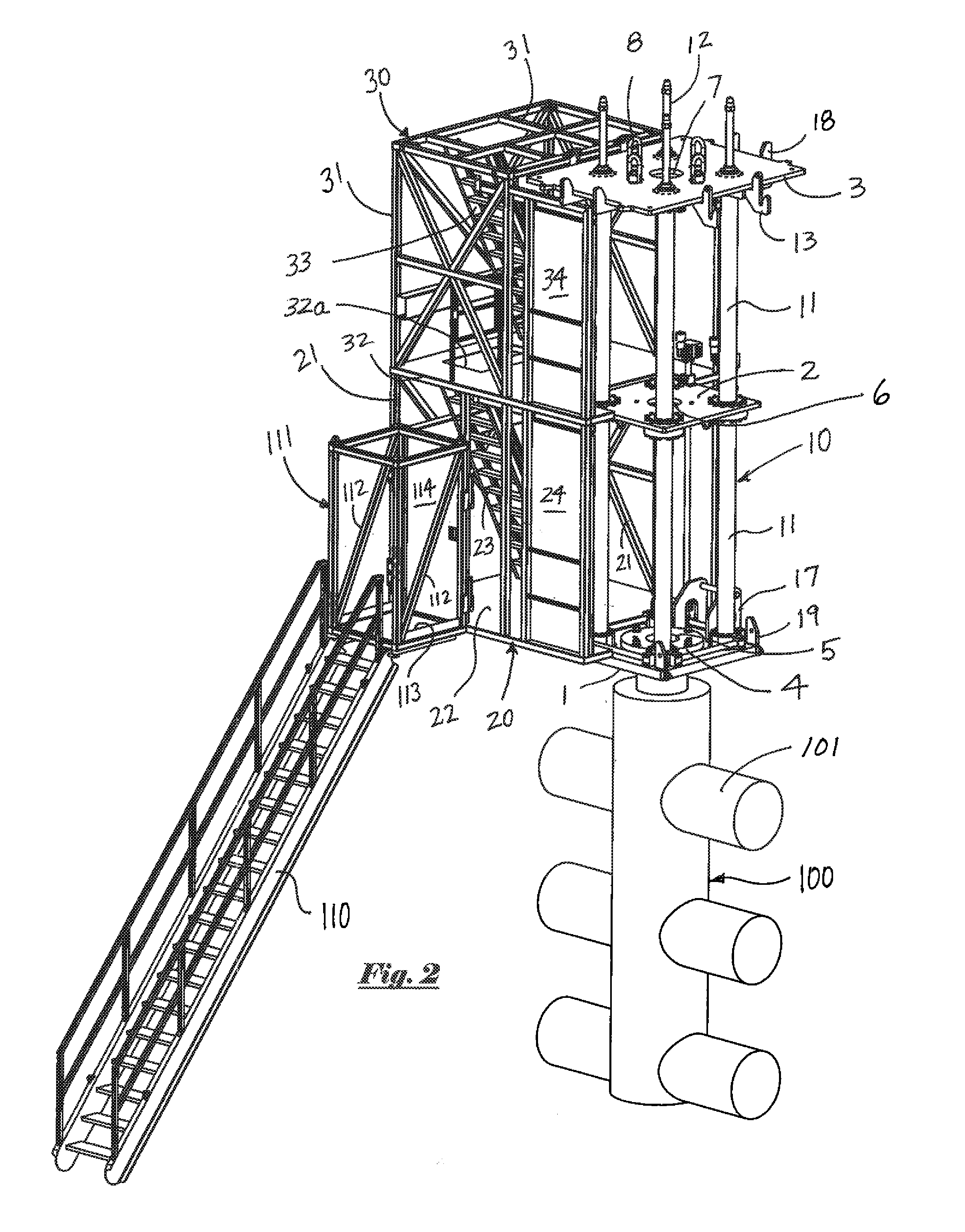

[0032]FIG. 1 depicts a perspective view of a jack assembly 10 of the modular well intervention assembly of the present invention installed on an upper end of a conventional BOP assembly 100, which is itself disposed on the upper opening of a well that extends into the earth's crust. It is to be observed that modular well intervention assembly of the present invention, in general, and jack assembly 10, in particular, can be installed on any number of different well configurations. As such, the depiction of modular well intervention assembly of the present invention installed on BOP assembly 100 is illustrative only, and is not intended to be, and should not be construed as, limiting in any way. As depicted in FIG. 1, BOP assembly 100 comprises a plurality of ram assemblies 101, as well as a top flange (not depicted in FIG. 1) disposed at the upper extent of said BOP assembly 100.

[0033]Still referring to FIG. 1, jack assembly 10 of the present invention comprises substantially planar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com