Patents

Literature

37results about "Vacuum gauge using gaseous frictional resistance variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

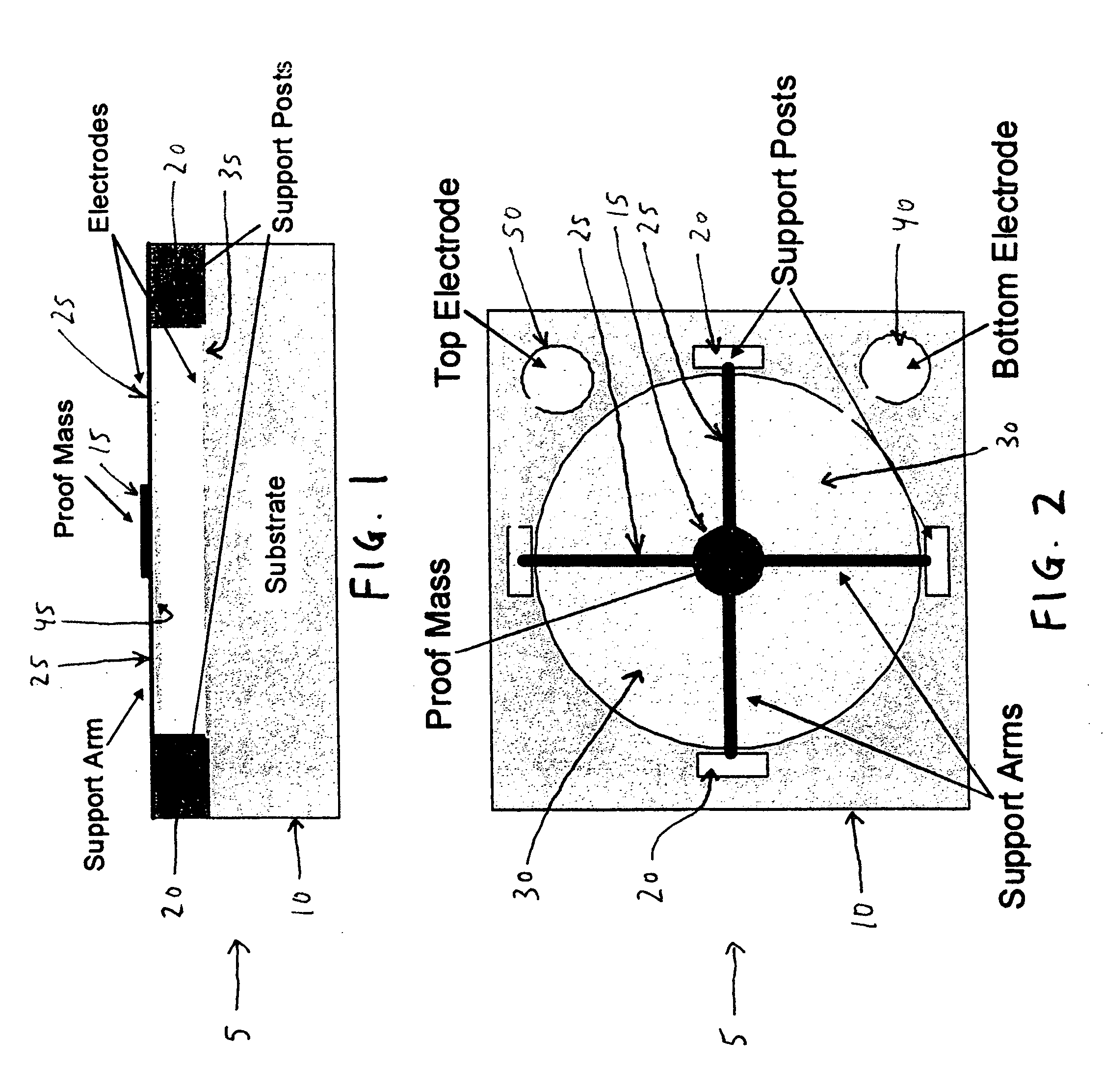

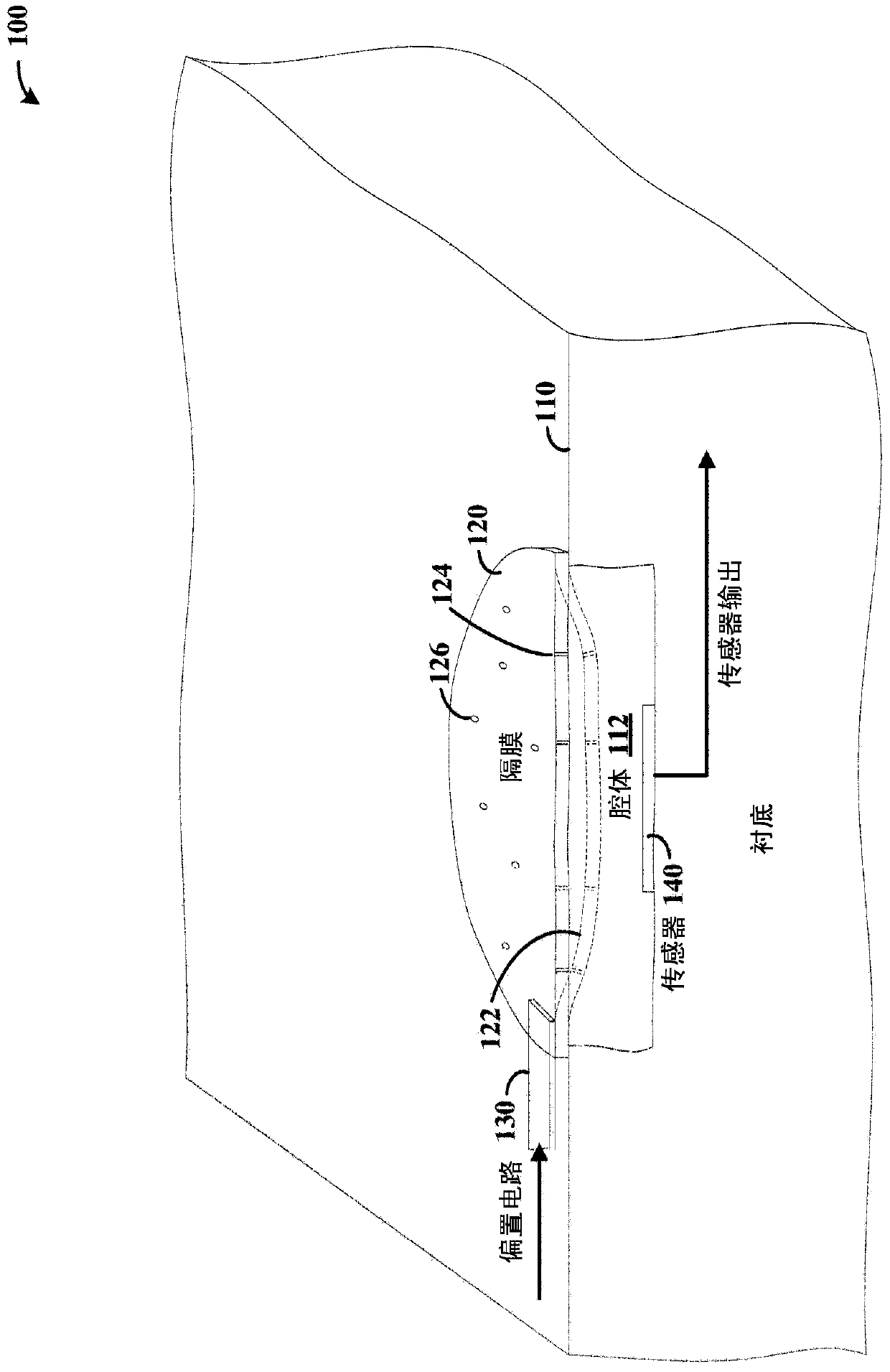

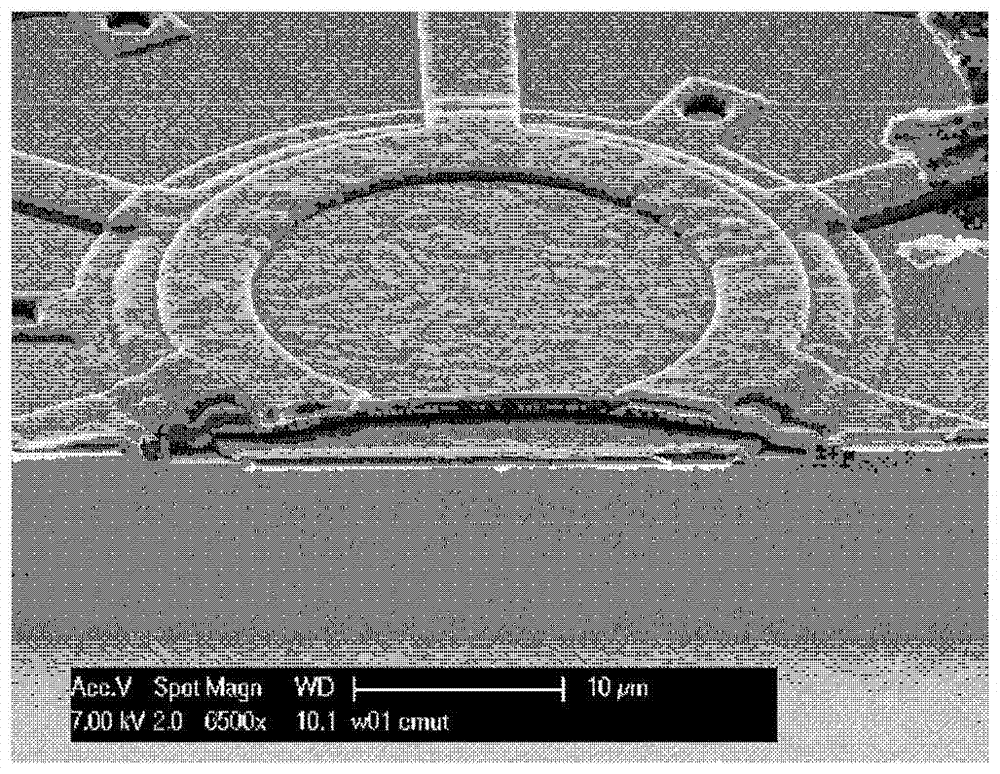

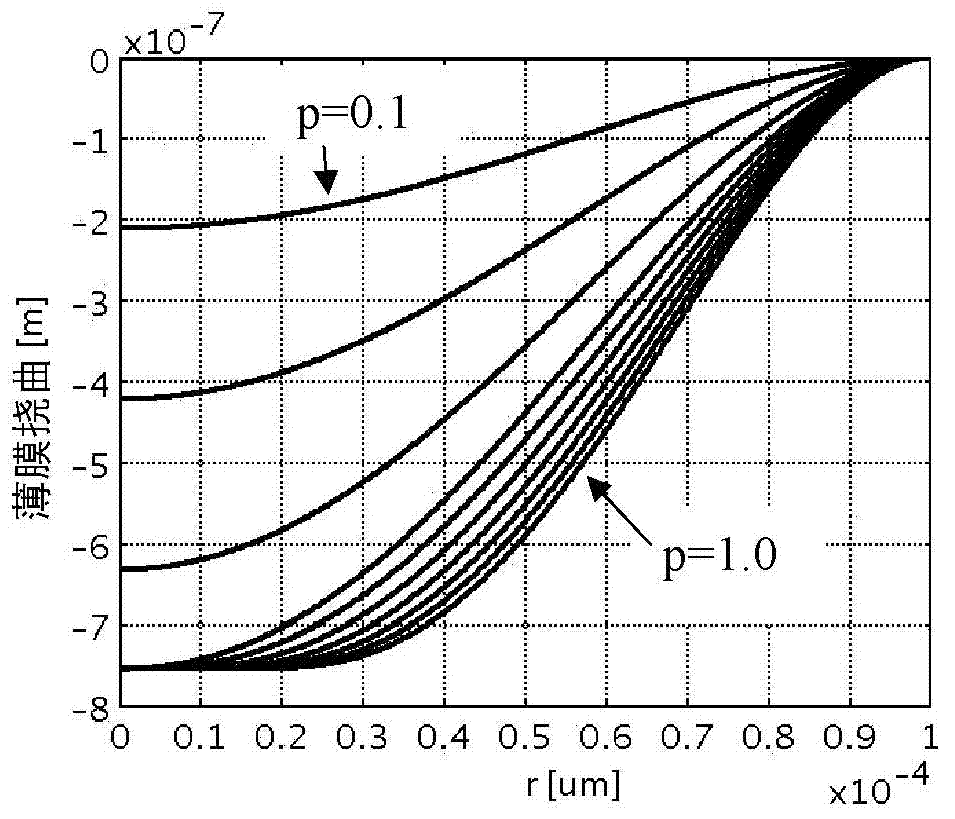

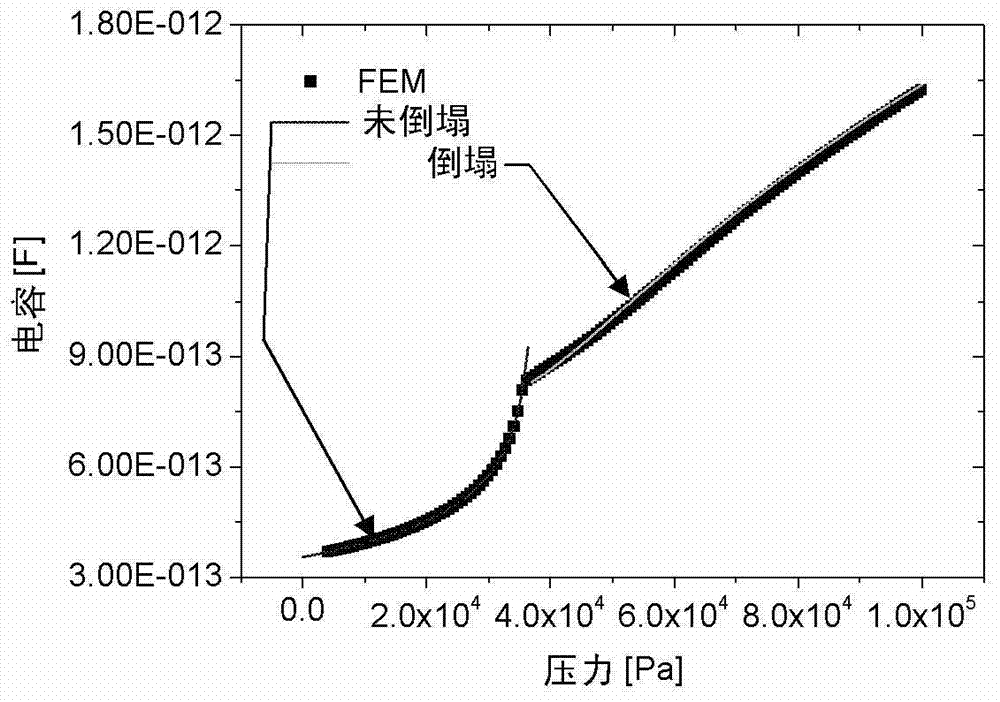

Mems capacitive pressure sensor

ActiveCN103308239AFluid pressure measurement using elastically-deformable gaugesForce measurementInternal pressureCapacitive pressure sensor

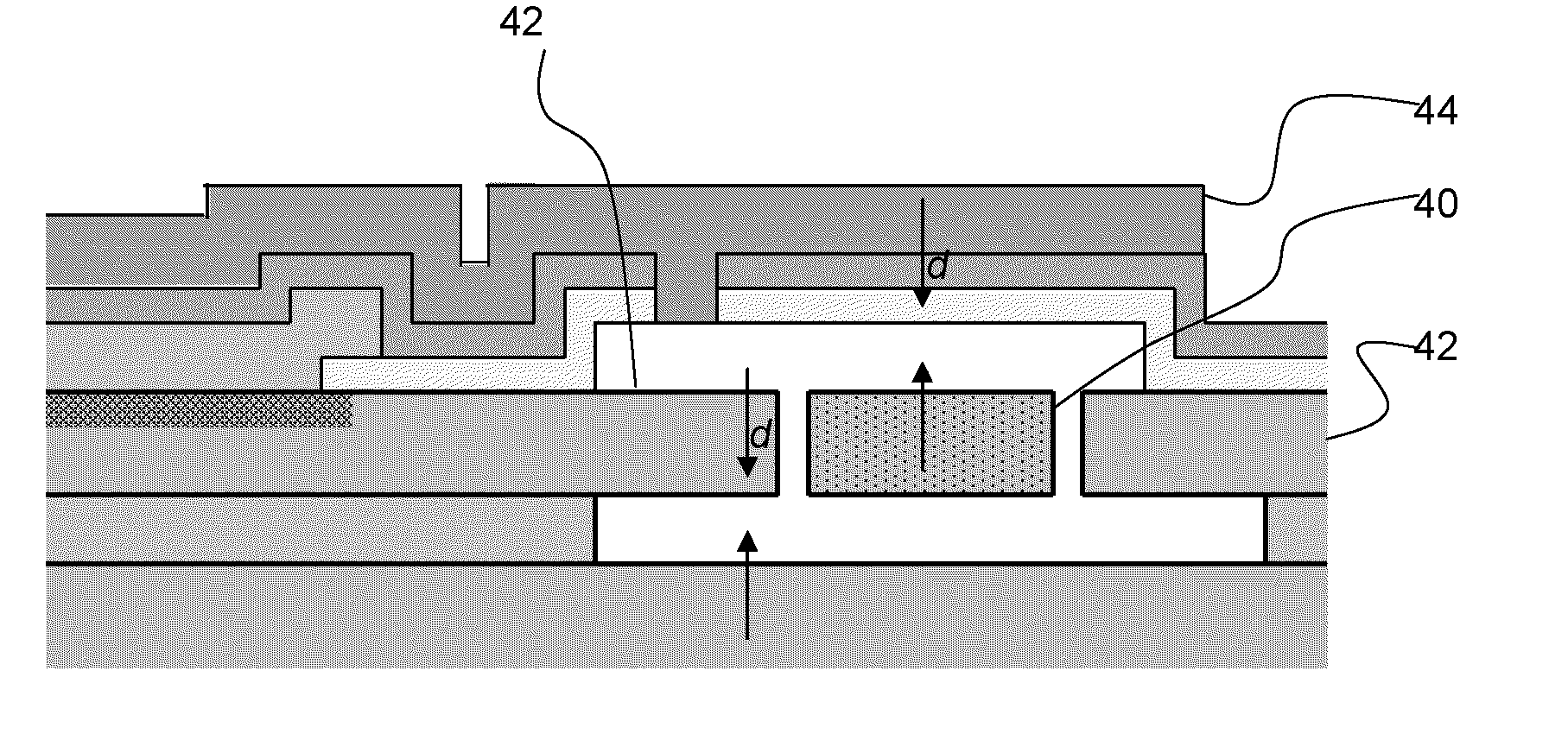

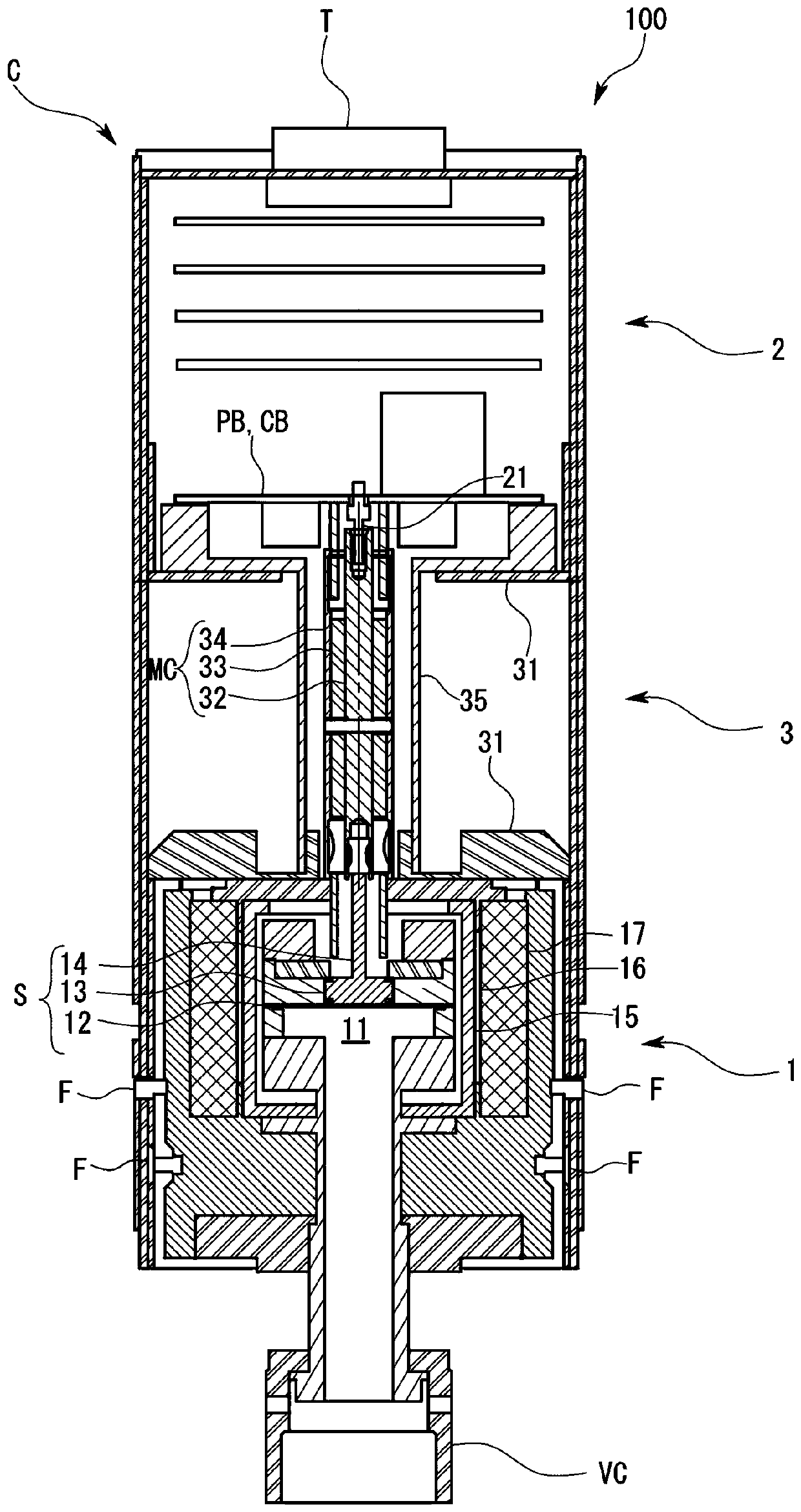

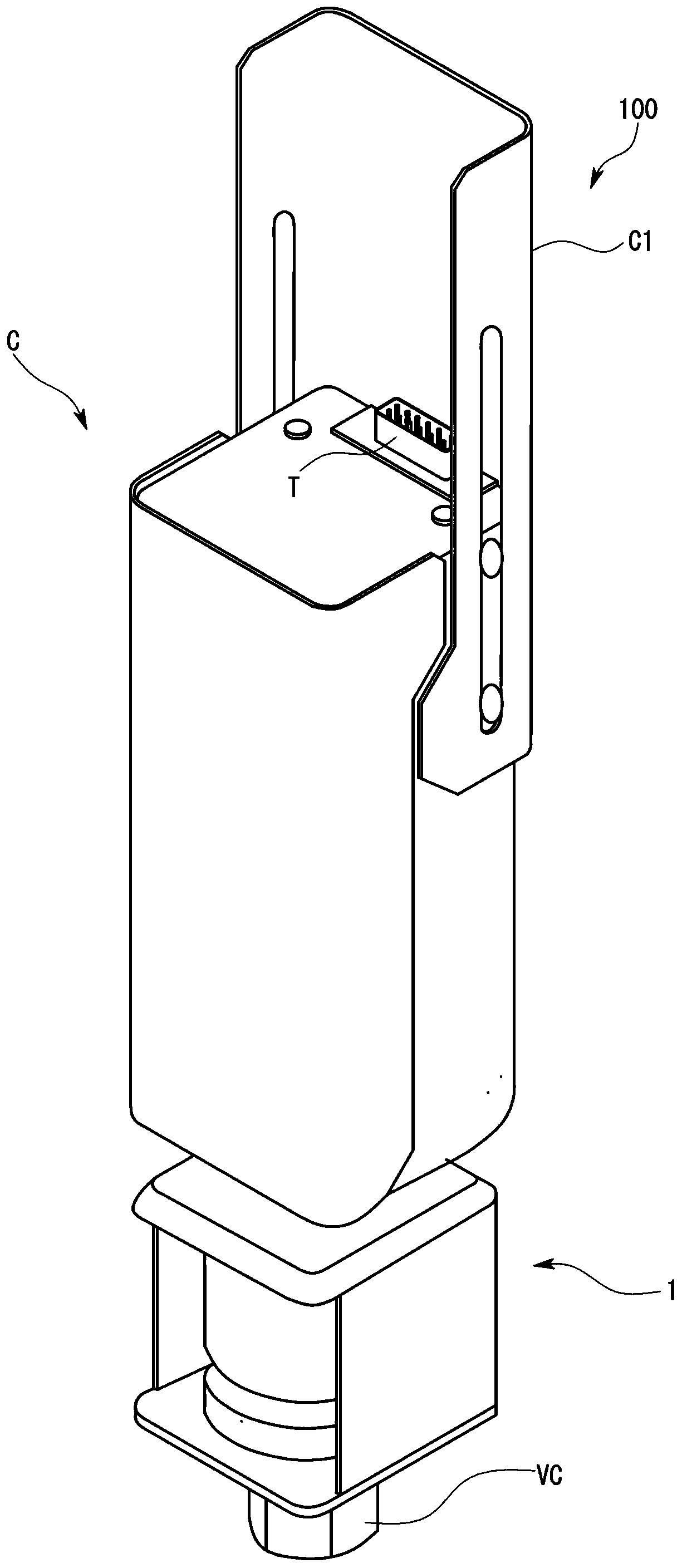

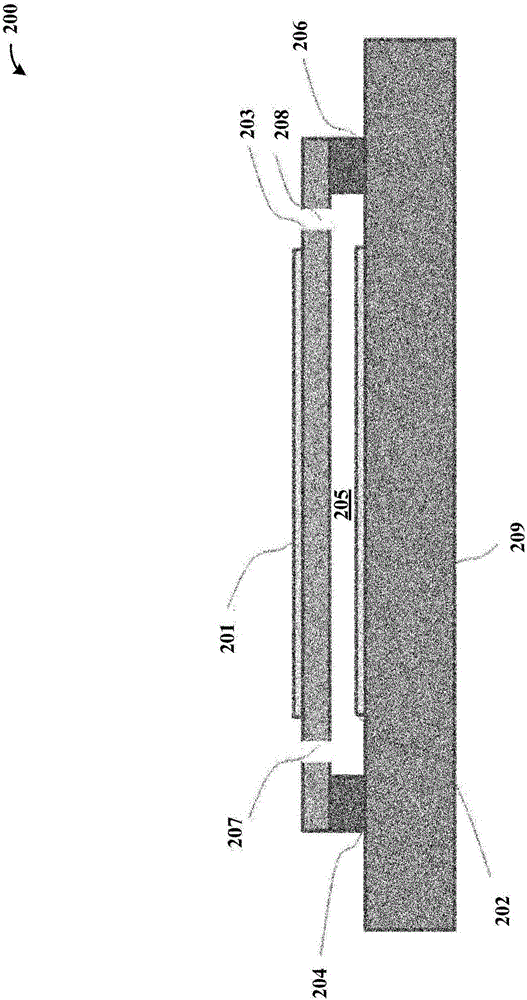

A pressure sensor measures pressure by measuring the deflection of a MEMS membrane using a capacitive read-out method. There are two ways to implement the invention. One involves the use of an integrated Pirani sensor and the other involves the use of an integrated resonator, to function as a reference pressure sensor, for measuring an internal cavity pressure.

Owner:希奥检测有限公司

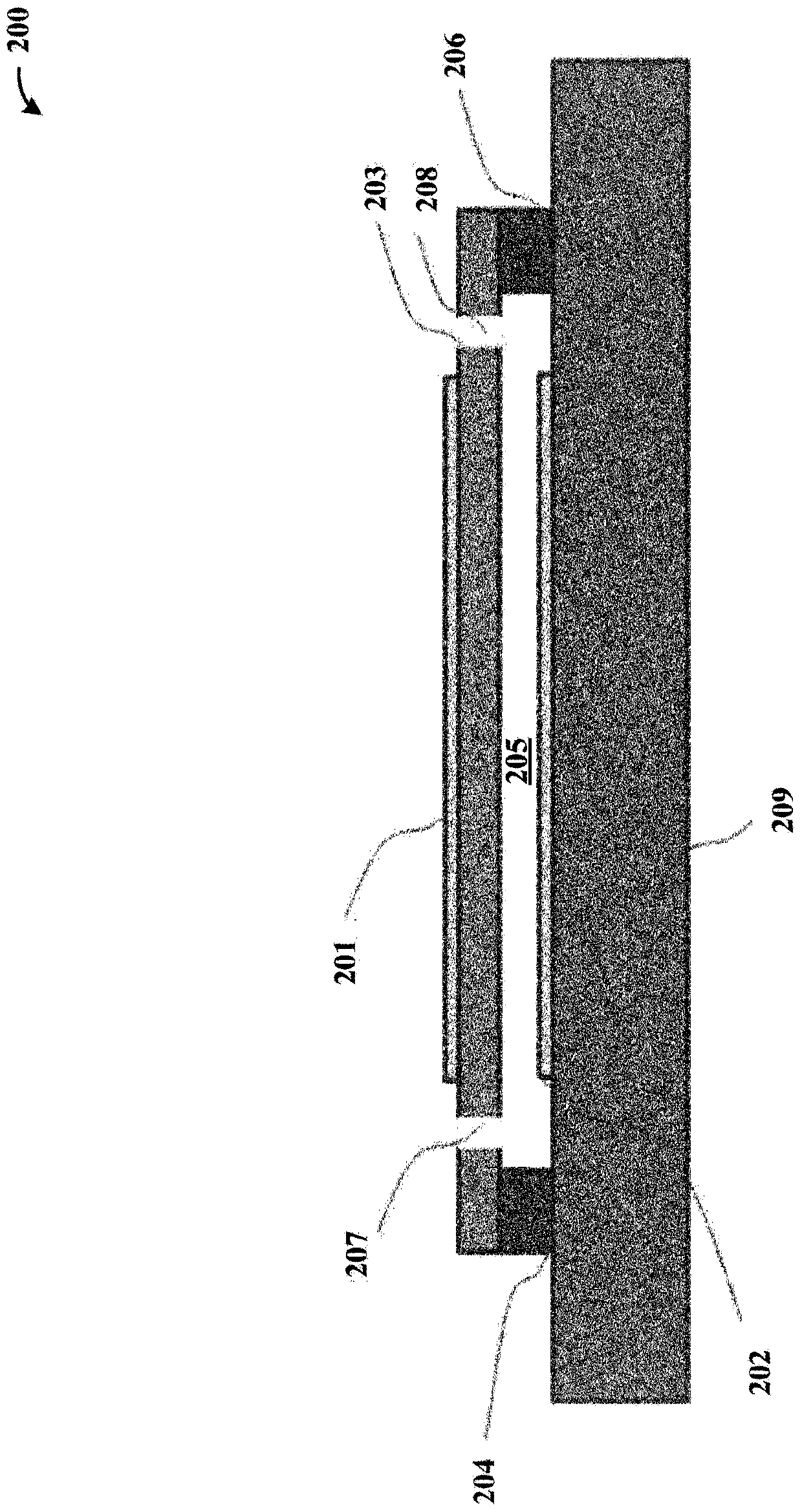

MEMS pressure sensor

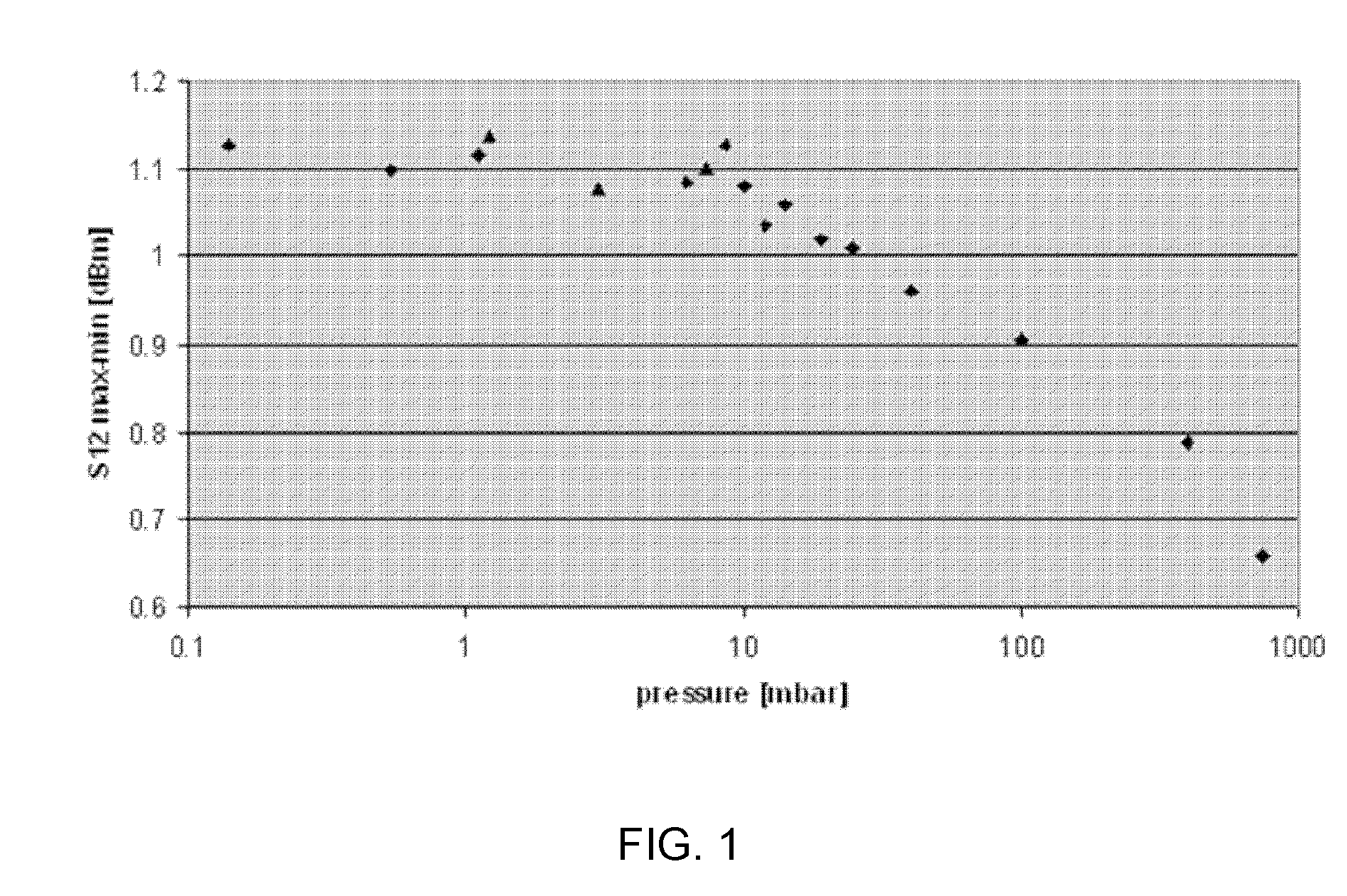

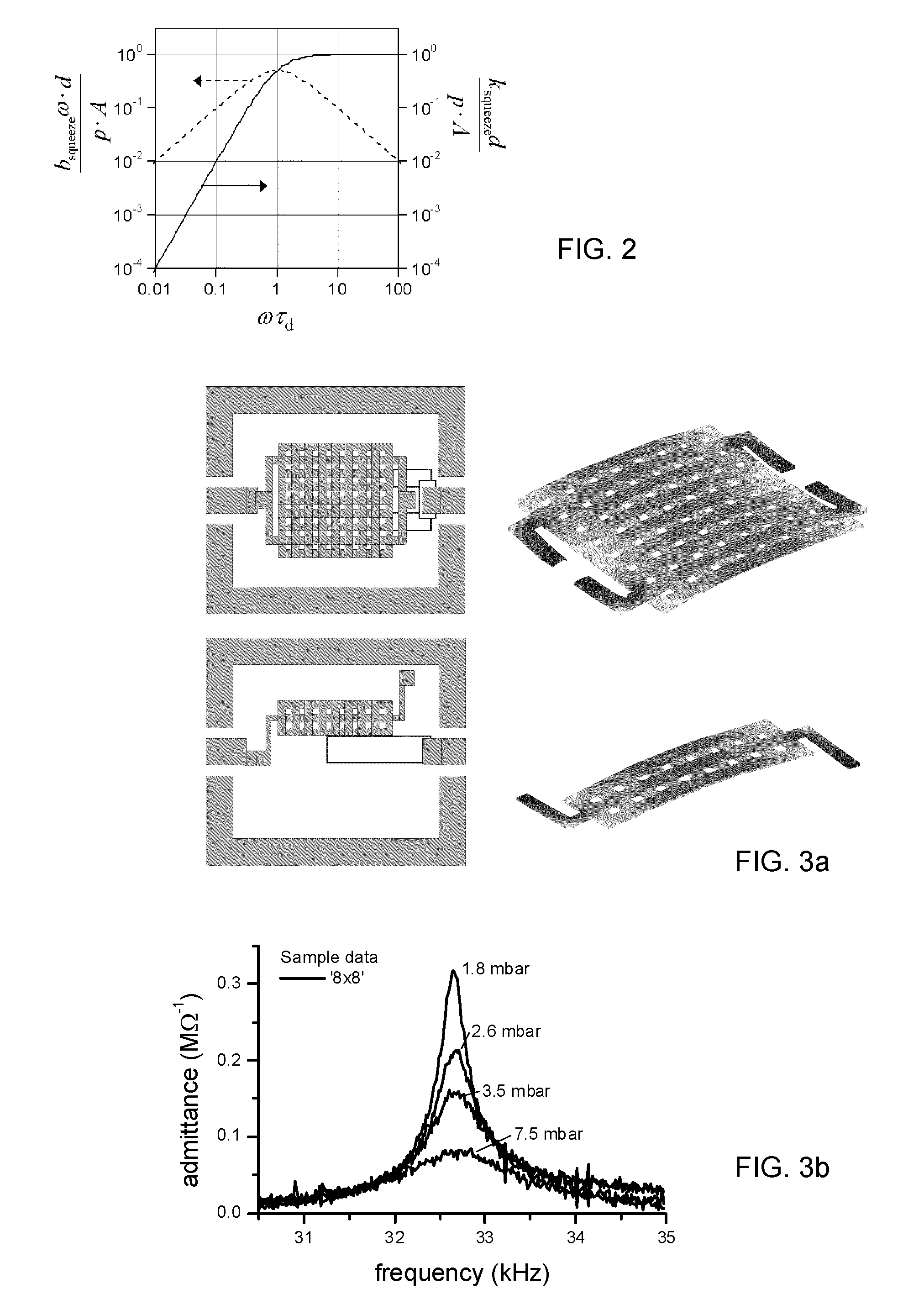

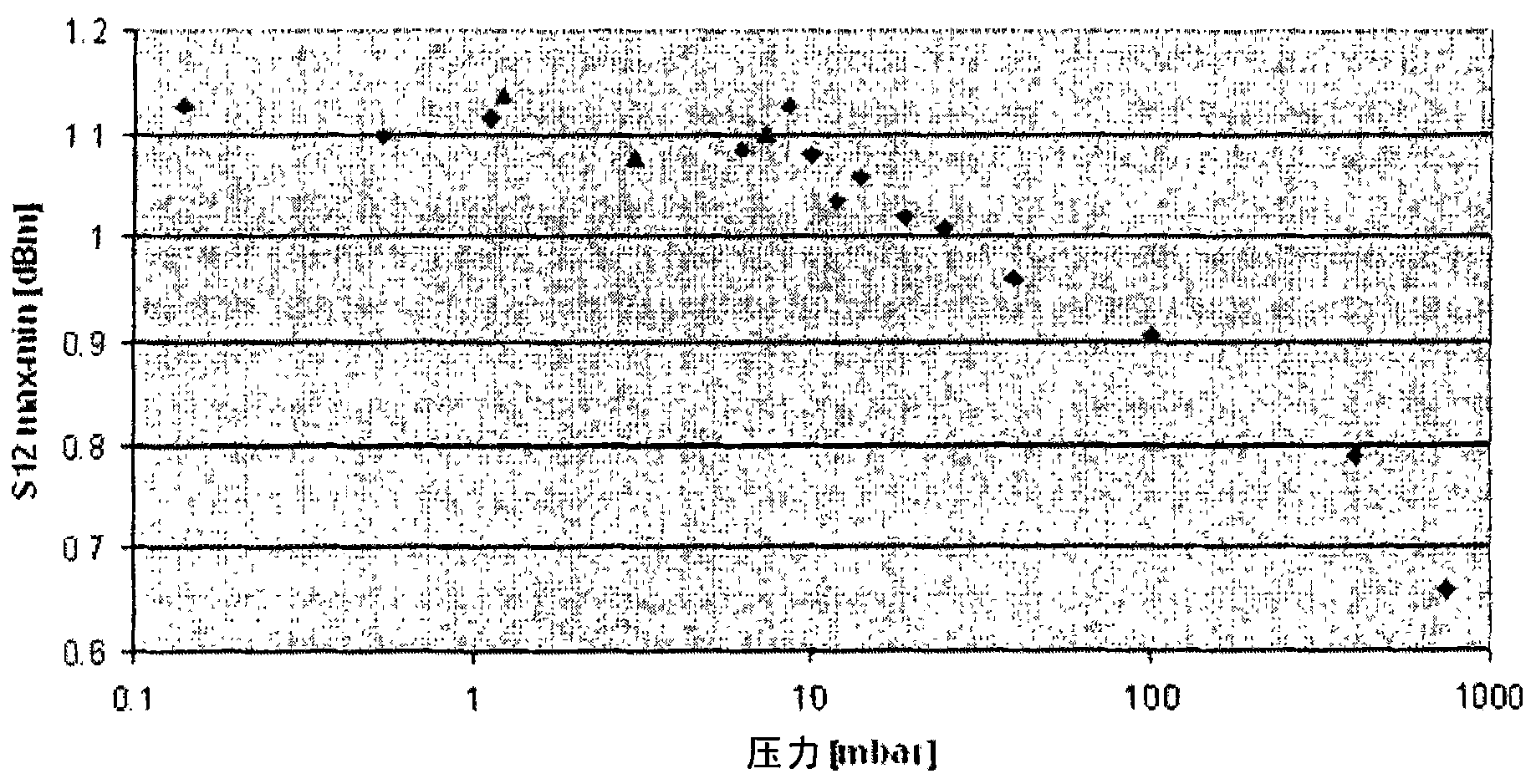

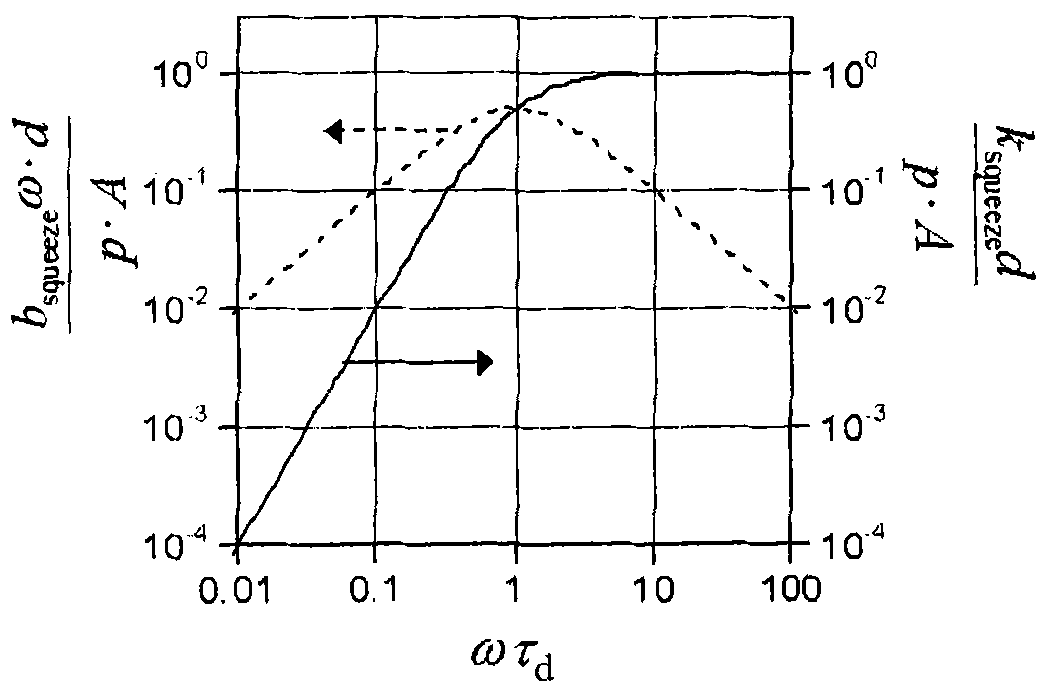

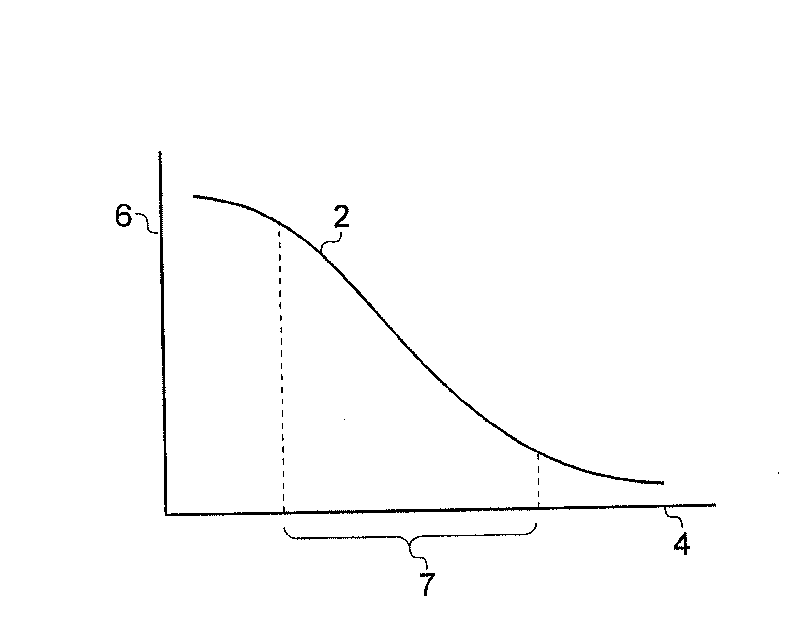

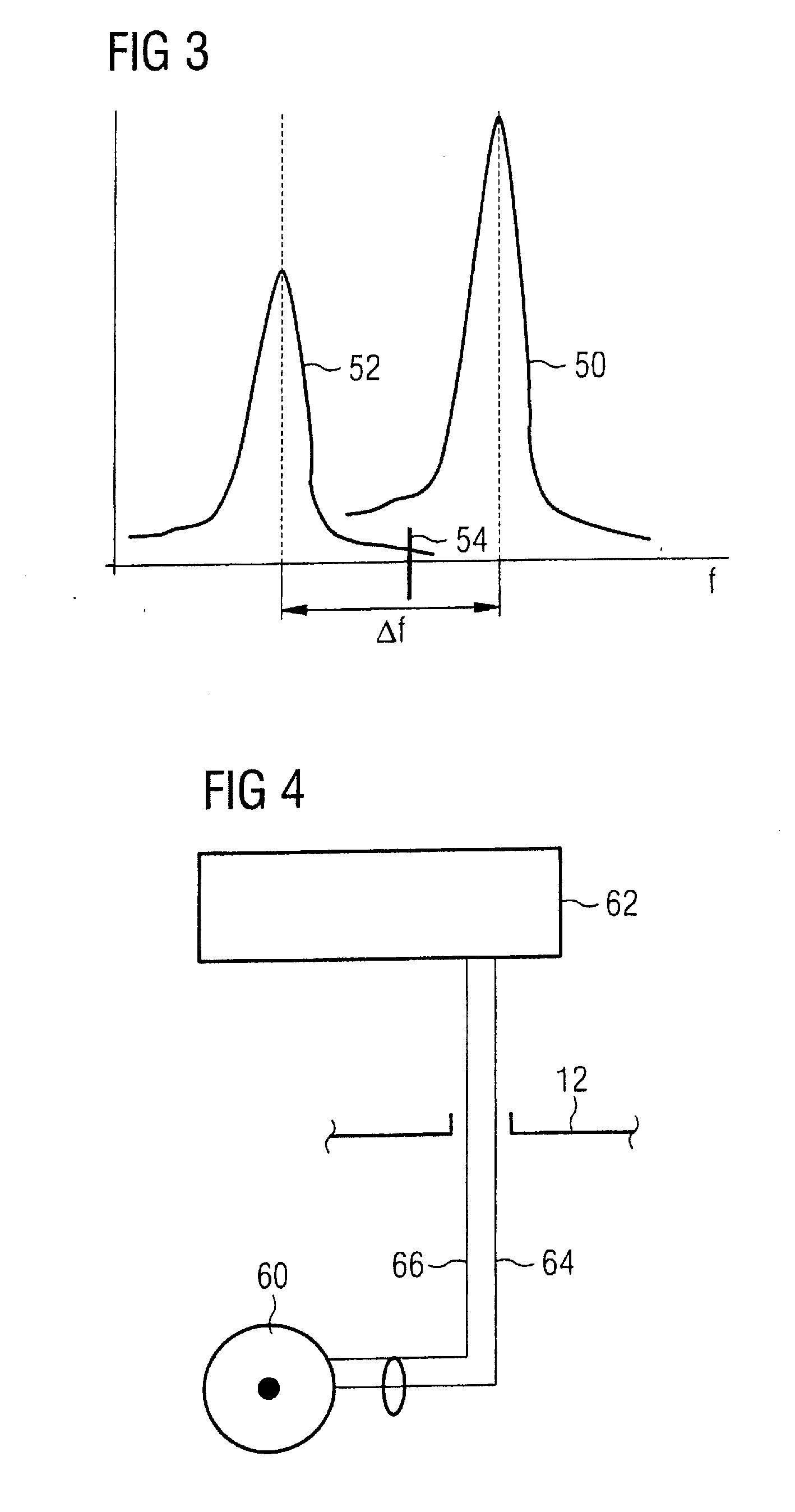

ActiveUS20110107838A1Fluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationMems pressure sensorResonance

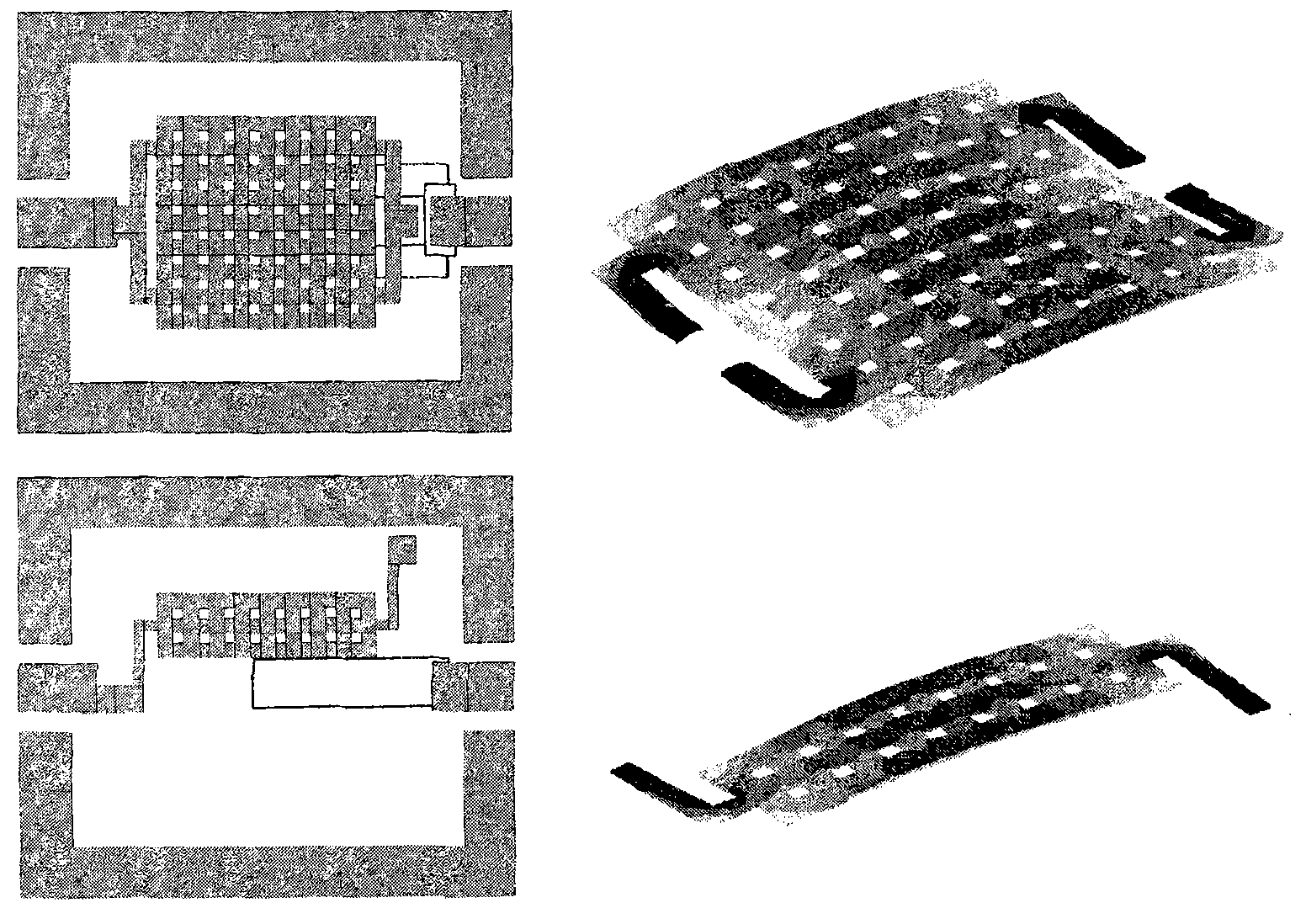

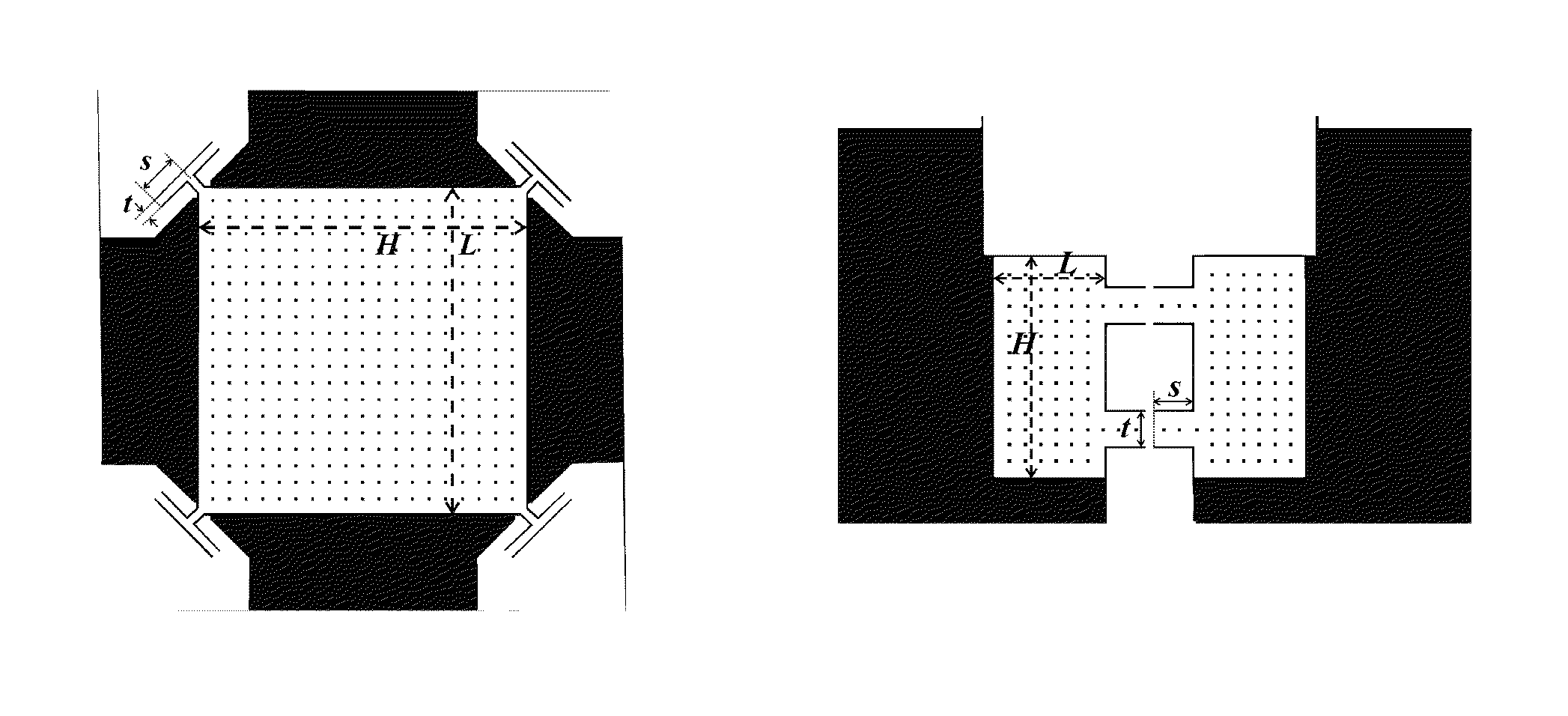

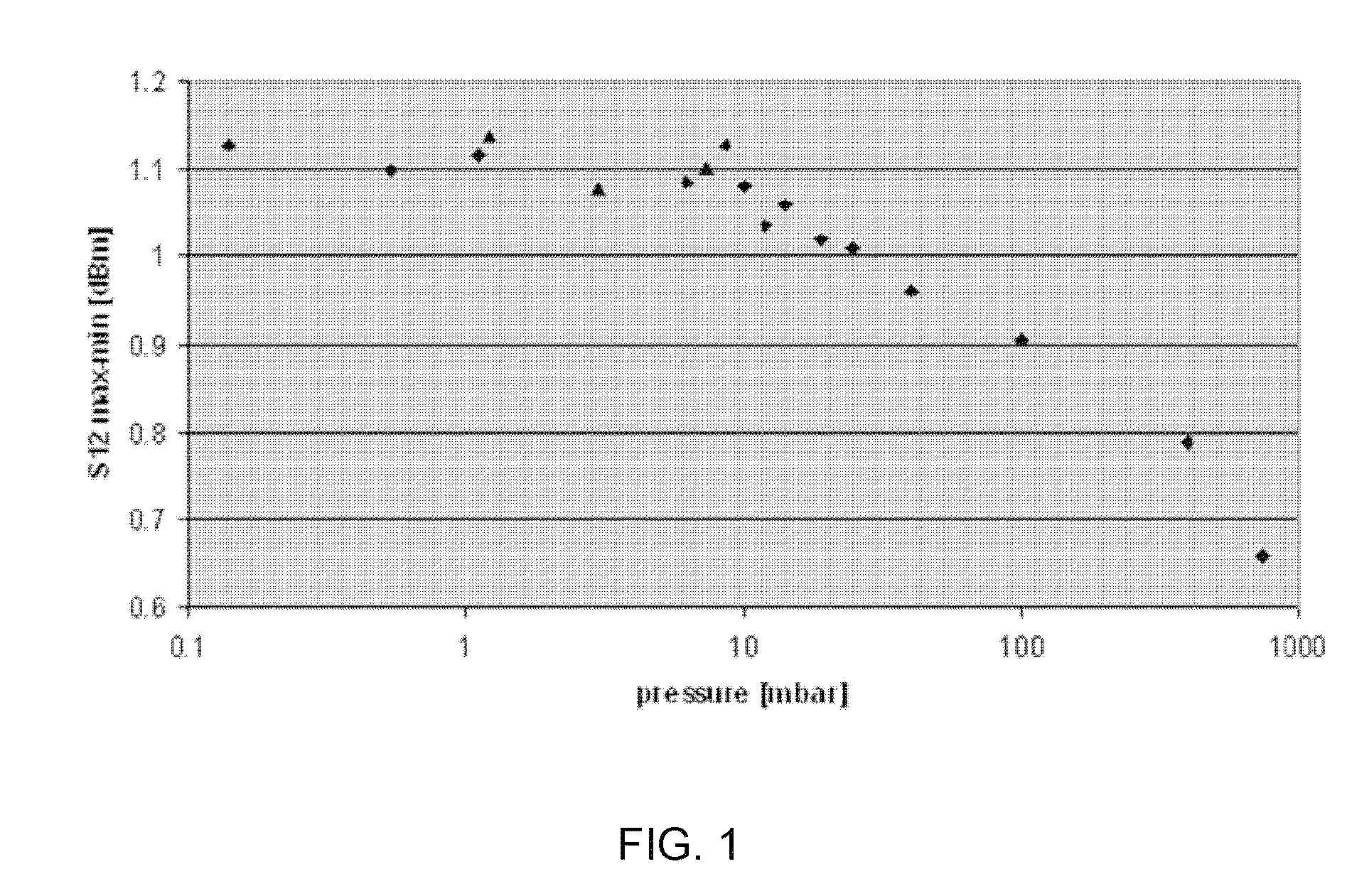

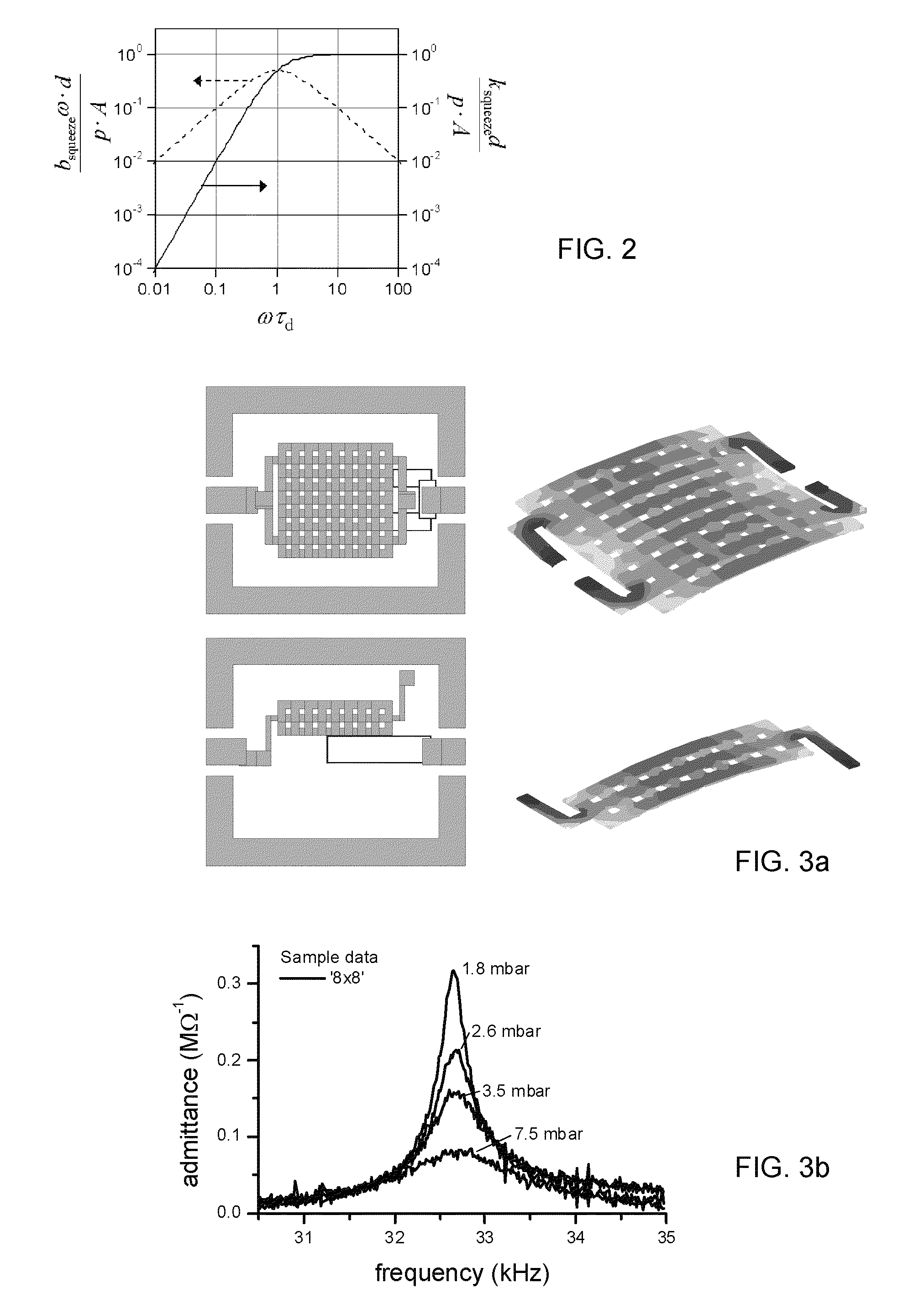

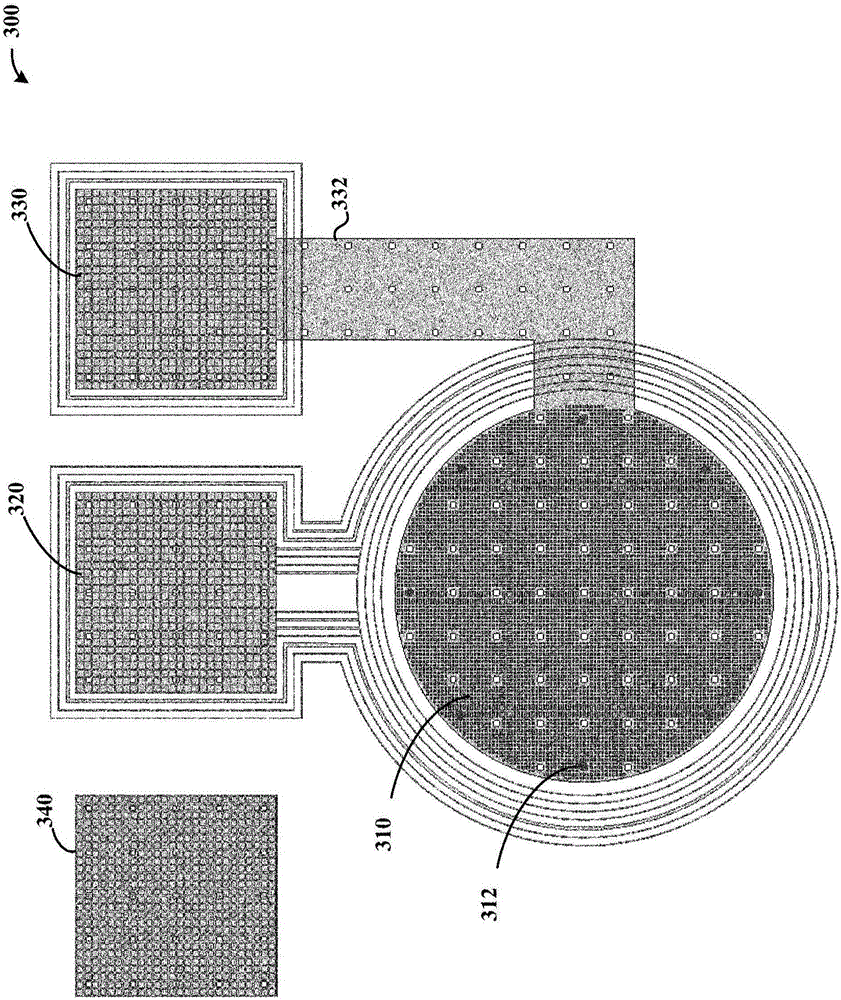

A MEMS pressure sensor for sensing the pressure in a sealed cavity of a MEMS device, comprises a resonant MEMS device having a pressure sensor resonator element which comprises an array of openings. The resonant frequency of the resonant MEMS device is a function of the pressure in the cavity, with resonant frequency increasing with pressure. Over the pressure range 0 to 0.1 kPa, the average change in frequency is at least 10−6 / Pa.The invention is based on the recognition that for fast oscillation, the elastic force causes the resonance frequency to shift. Therefore, it is possible to sense the pressure by a device with resonance frequency that is sensitive to the pressure.

Owner:SCIOSENSE BV

MEMS pressure sensor

ActiveCN102032970AFluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationMems pressure sensorResonance

A MEMS pressure sensor for sensing the pressure in a sealed cavity of a MEMS device, comprises a resonant MEMS device having a pressure sensor resonator element which comprises an array of openings. The resonant frequency of the resonant MEMS device is a function of the pressure in the cavity, with resonant frequency increasing with pressure. Over the pressure range 0 to 0.1 KPa, the average change in frequency is at least 10-6 / Pa. The invention is based on the recognition that for fast oscillation, the elastic force causes the resonance frequency to shift. Therefore, it is possible to sense the pressure by a device with resonance frequency that is sensitive to the pressure.

Owner:XIAO TESTING CO LTD

MEMS pressure sensor

ActiveUS8256298B2Fluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationMems pressure sensorResonance

A MEMS pressure sensor for sensing the pressure in a sealed cavity of a MEMS device, comprises a resonant MEMS device having a pressure sensor resonator element which comprises an array of openings. The resonant frequency of the resonant MEMS device is a function of the pressure in the cavity, with resonant frequency increasing with pressure. Over the pressure range 0 to 0.1 kPa, the average change in frequency is at least 10−6 / Pa. The invention is based on the recognition that for fast oscillation, the elastic force causes the resonance frequency to shift. Therefore, it is possible to sense the pressure by a device with resonance frequency that is sensitive to the pressure.

Owner:SCIOSENSE BV

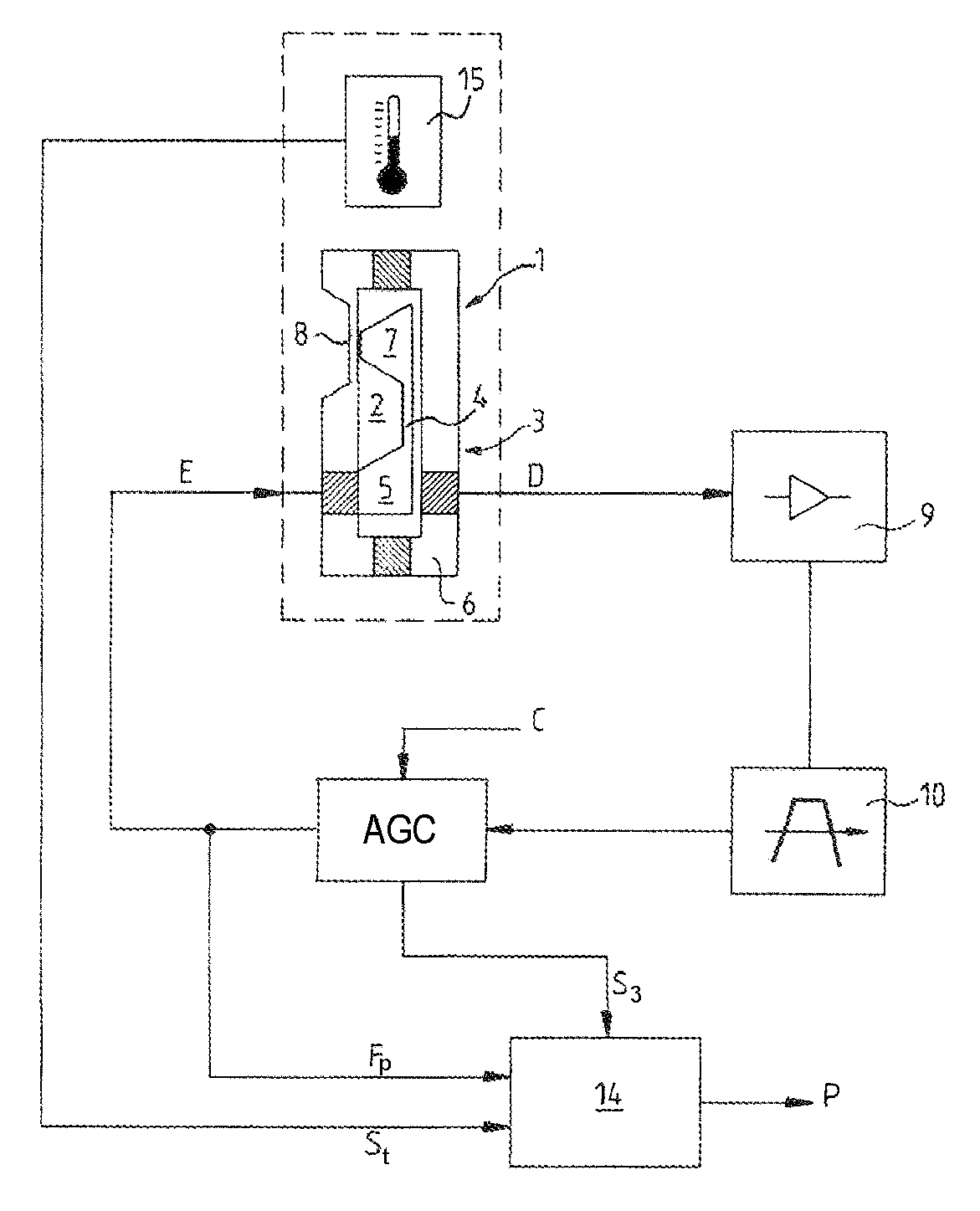

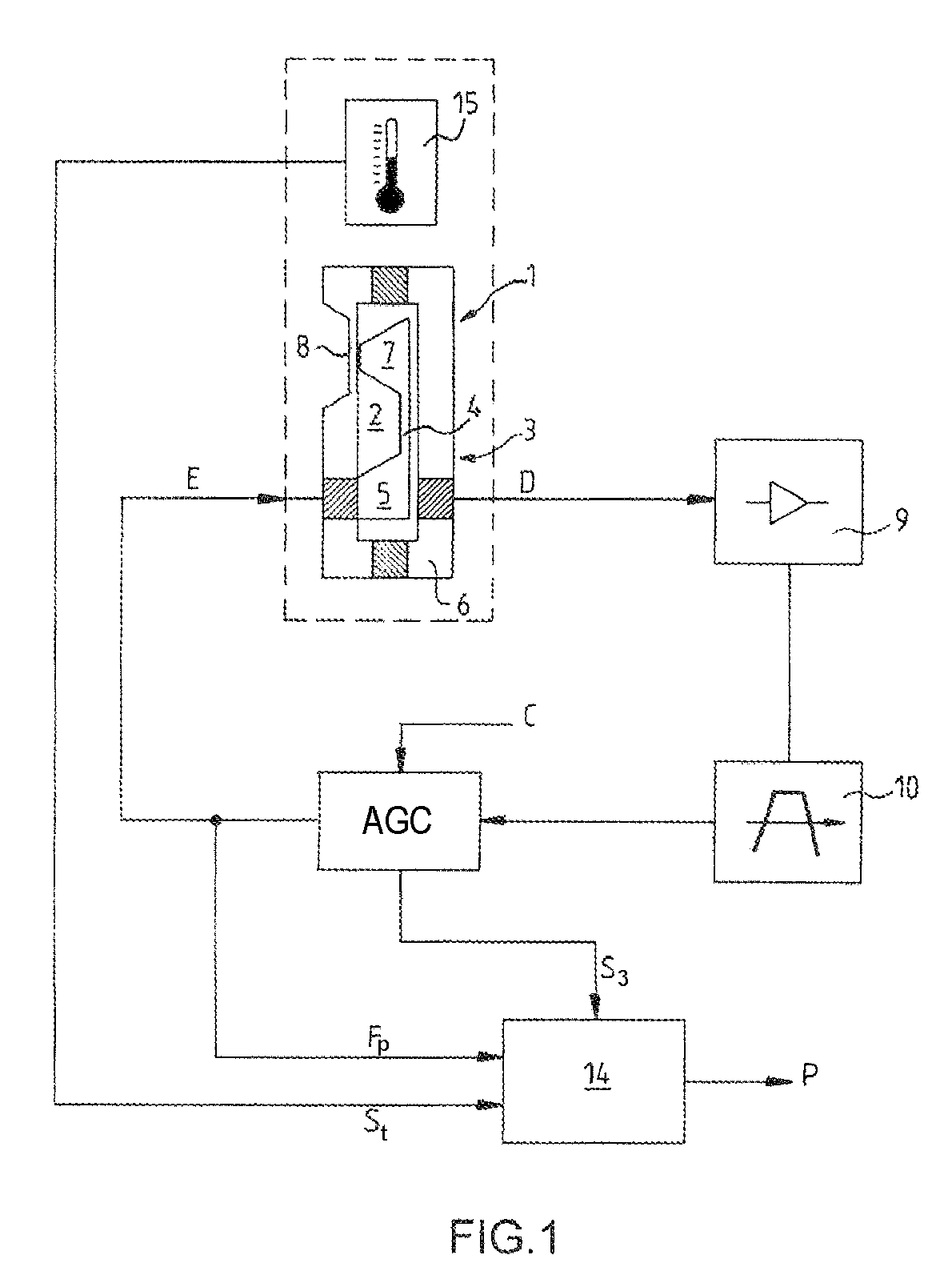

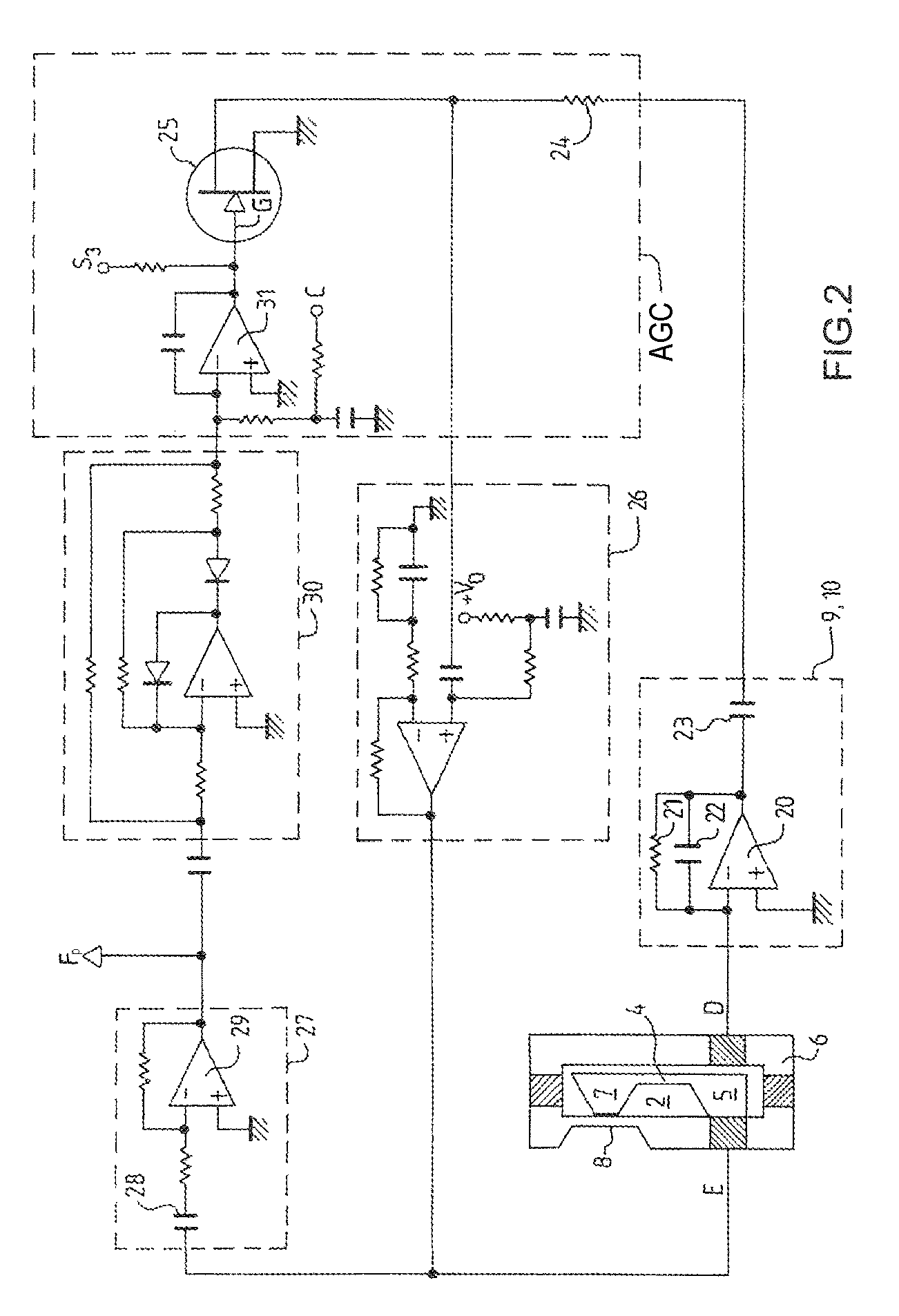

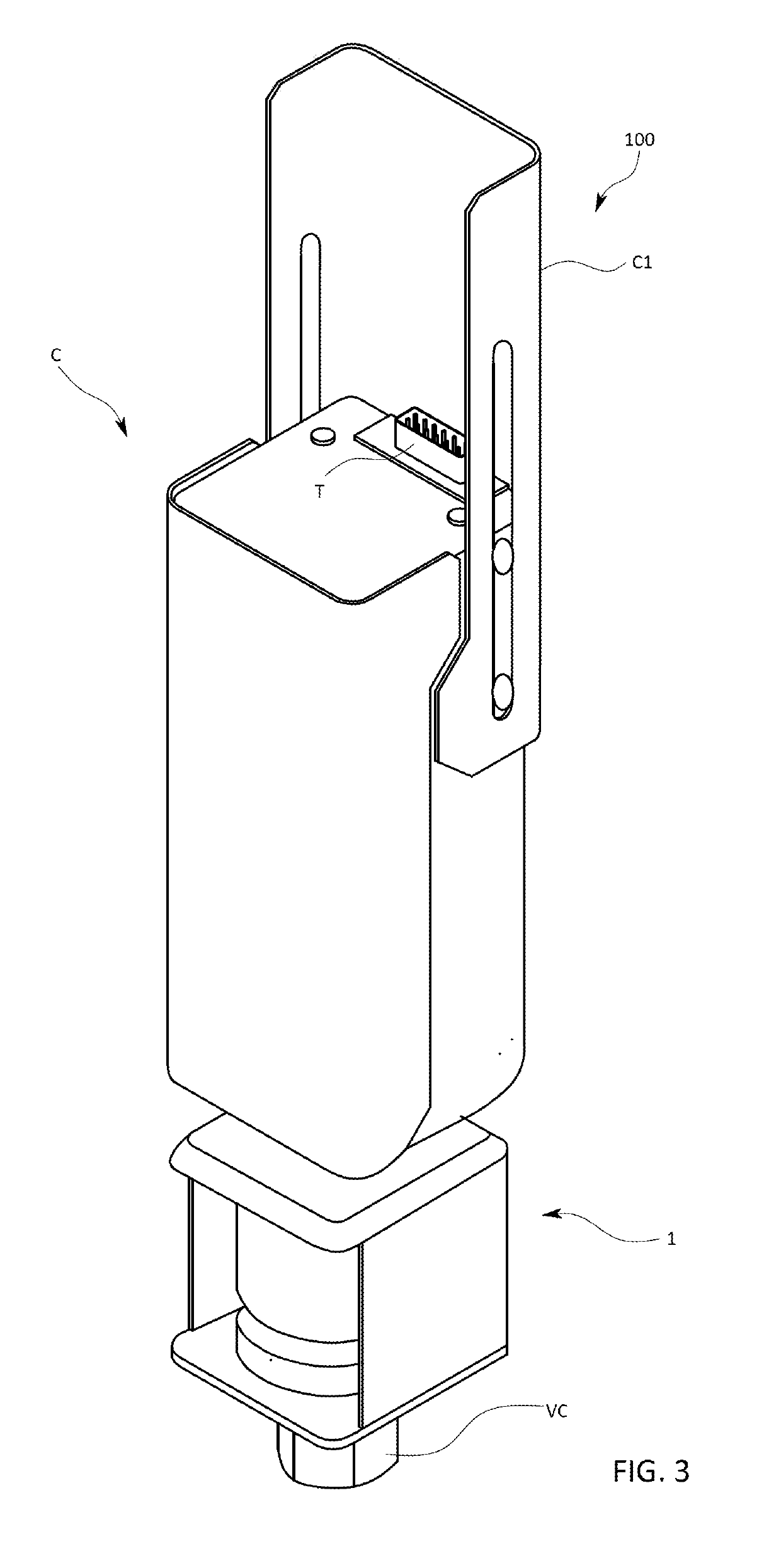

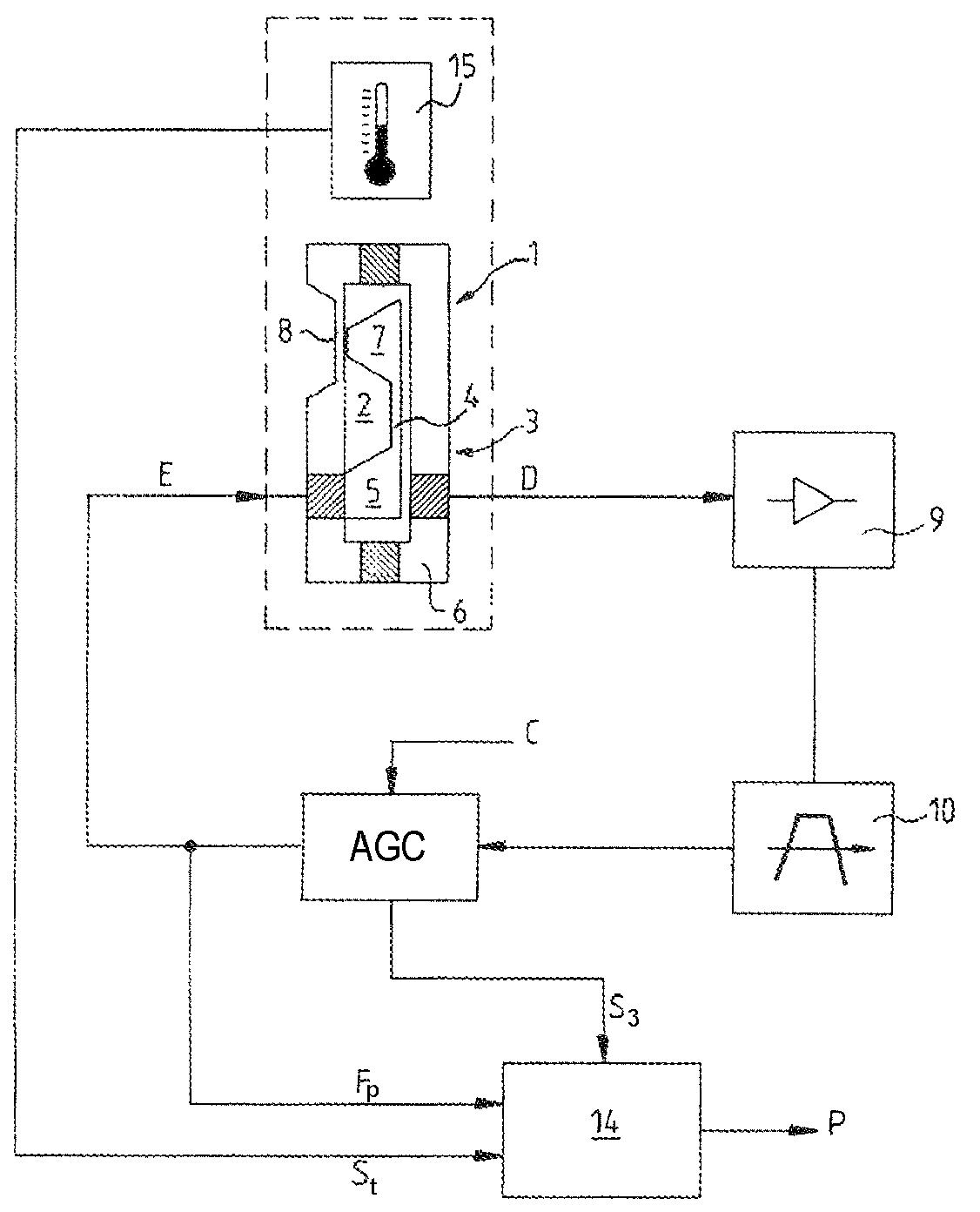

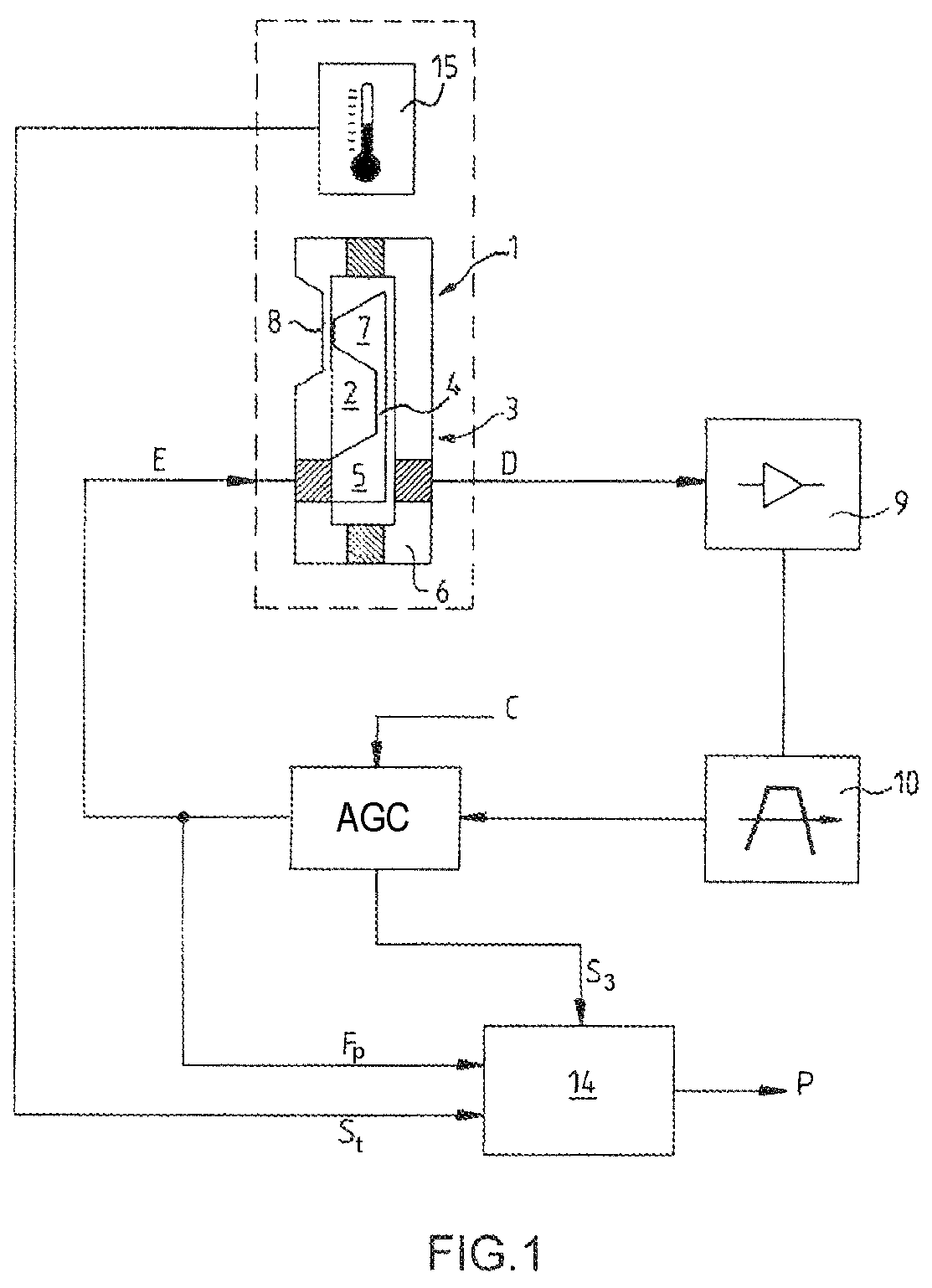

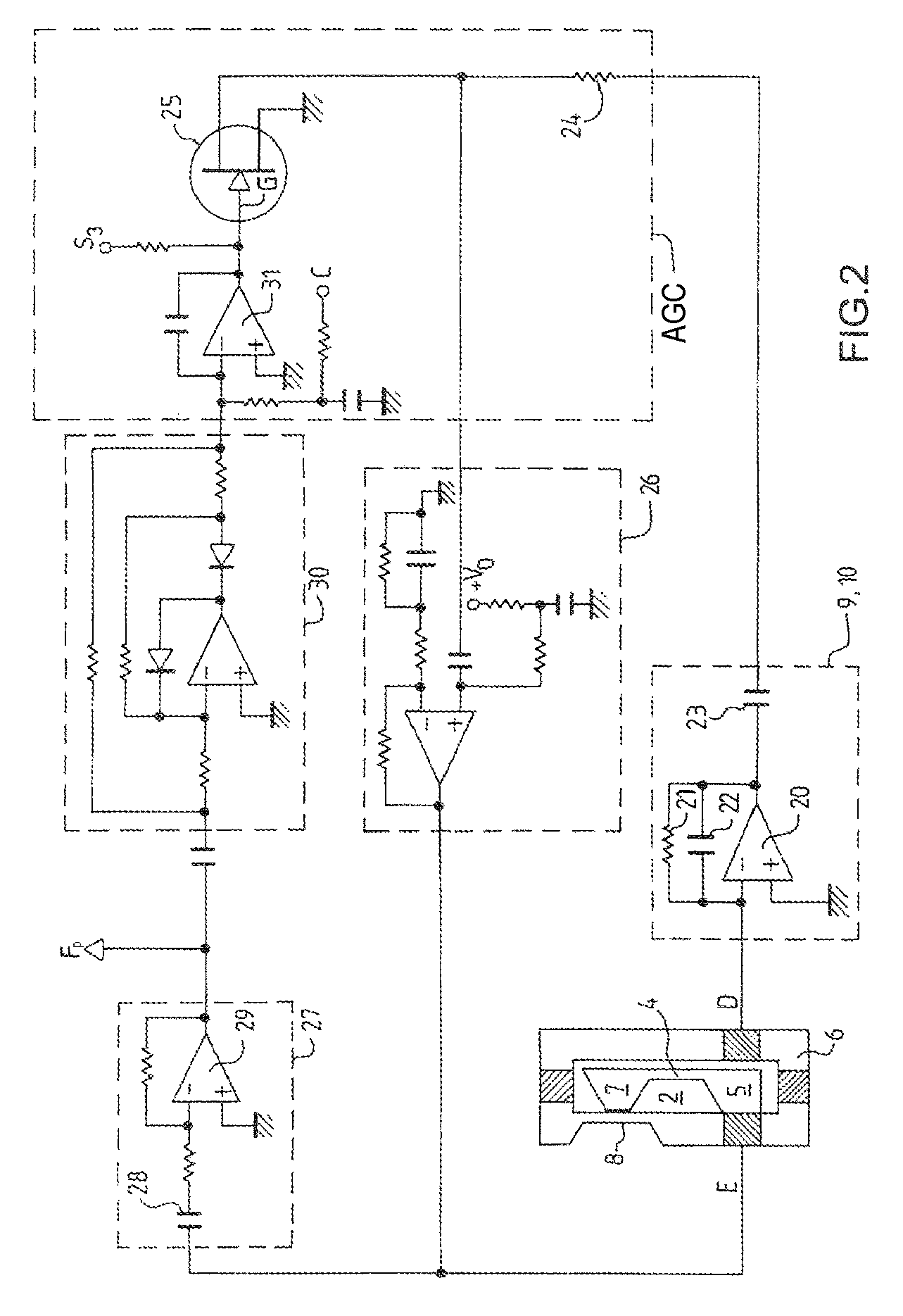

Resonator Measurement Device and Method Employing the Device

ActiveUS20080184804A1Broaden their knowledgeLeveling precisionVibration measurement in solidsAcceleration measurement using interia forcesMeasurement deviceCondensed matter physics

The invention relates to a device and a method for detecting a fault in a measurement device comprising a resonator and means for measuring a resonant frequency of the resonator. According to the invention, the device further includes means delivering information (S3) representative of the quality factor of the resonator (3) at the resonant frequency.

Owner:THALES SA

Micro-electro-mechanical pressure sensor

InactiveUS20070074574A1Remarkable effectVacuum gauge using gaseous frictional resistance variationTransducerPressure sense

A pressure sensor is disclosed for measuring fluid pressure comprising a pressure sensing structure comprising a mass target suspended on a spring mechanism, wherein the mass target and the spring mechanism together exhibit high Q mechanical resonance, wherein the mass target has an area which is presented in a plane perpendicular to the direction of the mechanical oscillation of the structure, and further wherein the mass target and the spring mechanism are in the form of a membrane, and transducer means for measuring the fluid pressure by characterizing the effects that the fluid molecules produce on the motion of the structure.

Owner:AHURA CORP

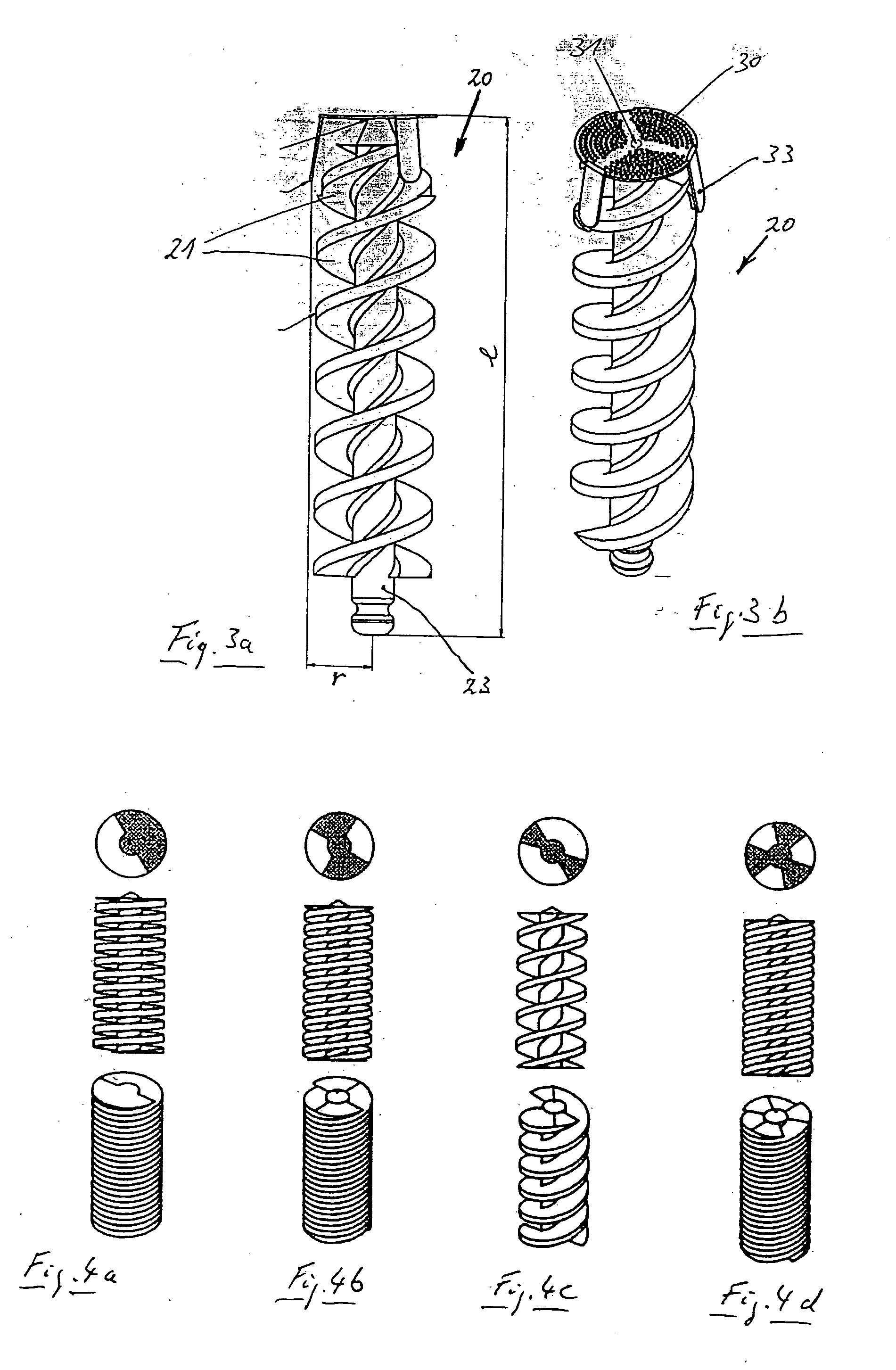

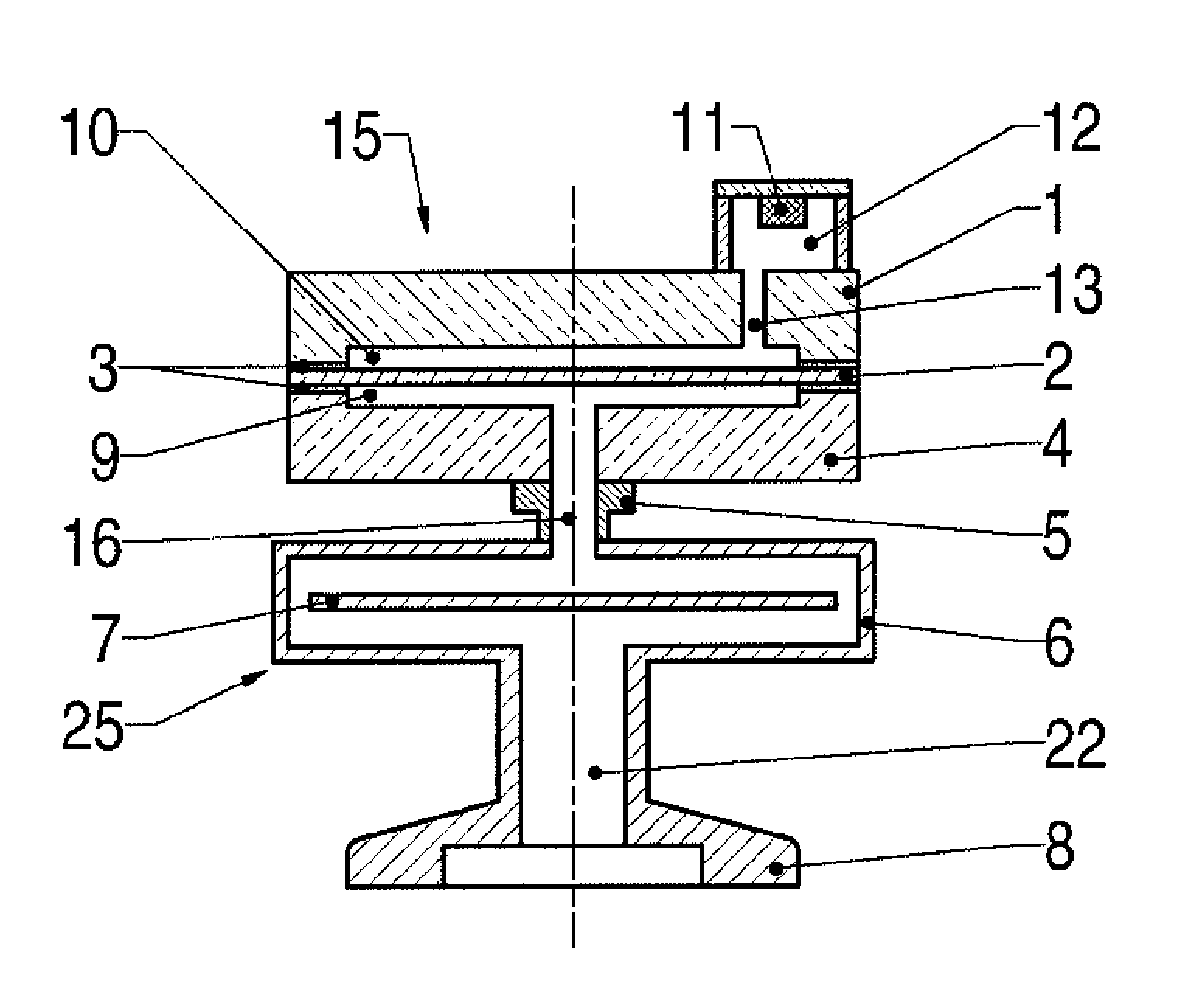

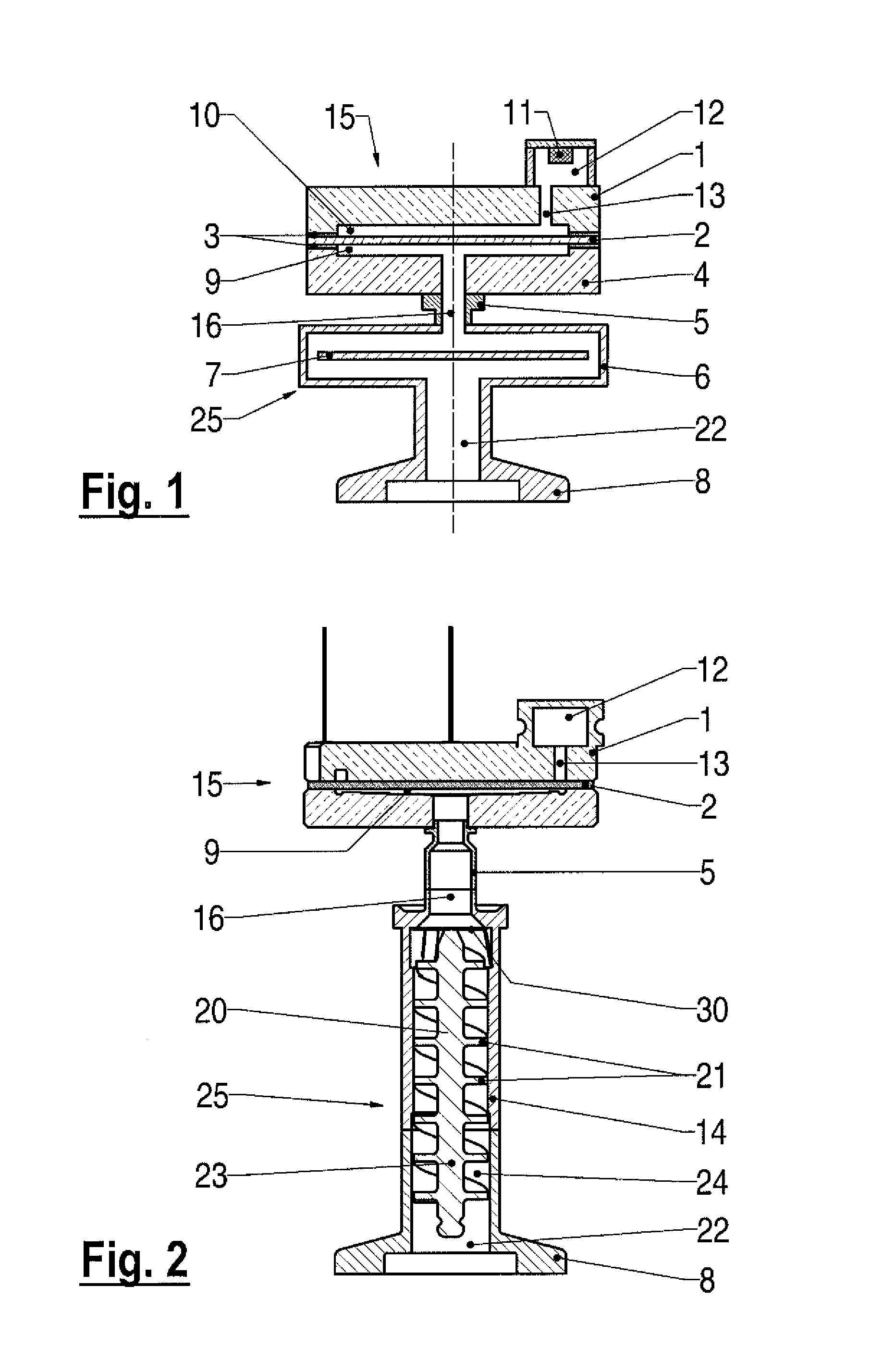

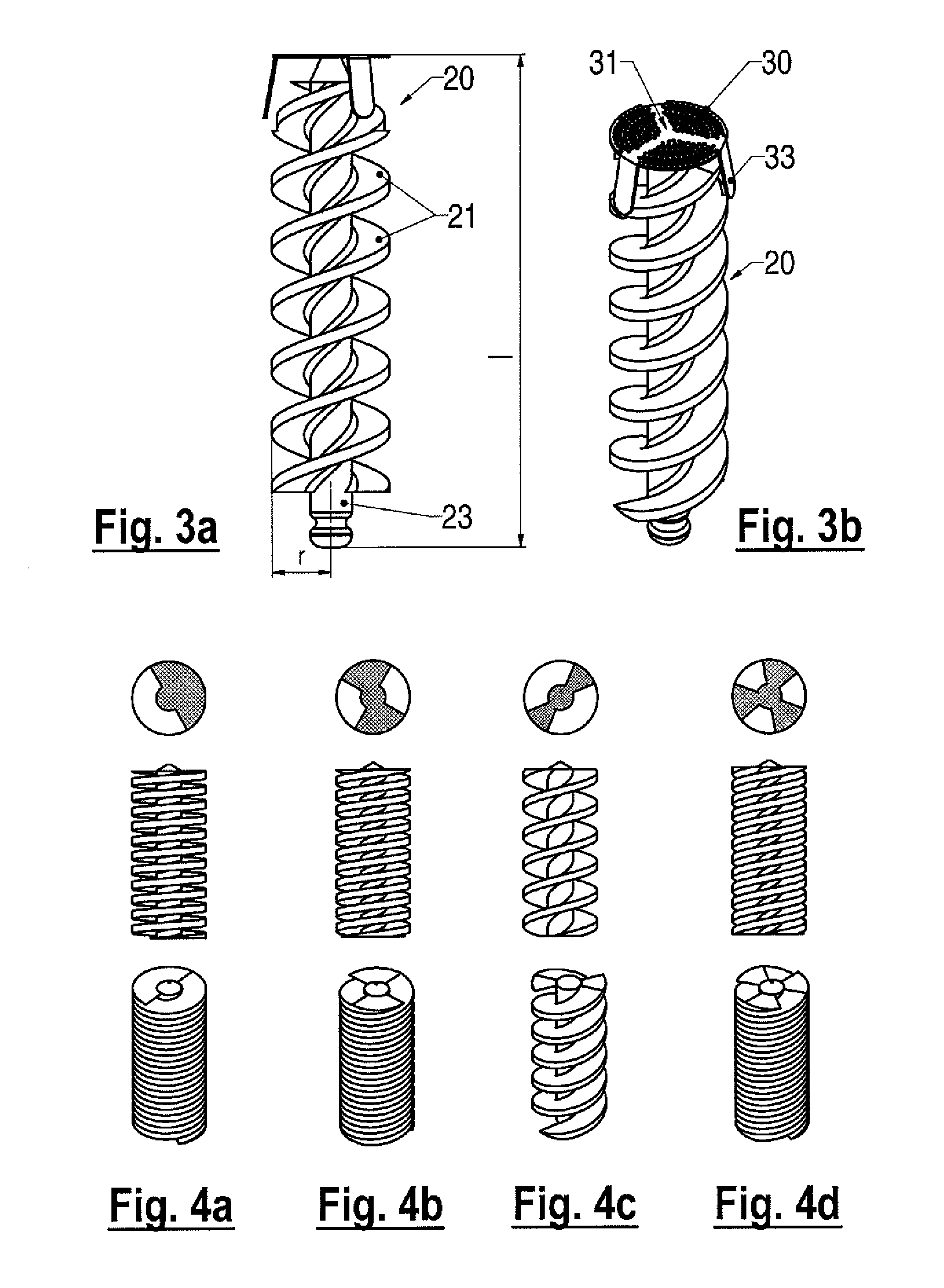

Shield arrangement for a vacuum cell

ActiveUS20070120568A1Eliminate disadvantagesReduce pollutionVacuum gauge using ionisation effectsFluid pressure measurement by electric/magnetic elementsEngineeringScrew thread

A shield arrangement for a vacuum measuring cell has a tubular shield housing encompassing a shield and an exit port for connection to a vacuum measuring cell and a connection opening for the object space to be measured. The shield is between the two openings and is implemented as a screw shield with spiral convolutions, its thread flange in the outer diameter being in contact on the inner wall of the shield housing such that a gas throughflow between the outer diameter of the thread flange and the inner wall is inhibited and is substantially forced into the spiral thread flight, and the exit port is on one side of the tubular section and the connection opening is on the other, opposite side and the screw shield is implemented such that in the axial line of vision the shield arrangement between the two openings is optically tight.

Owner:INFICON HLDG AG

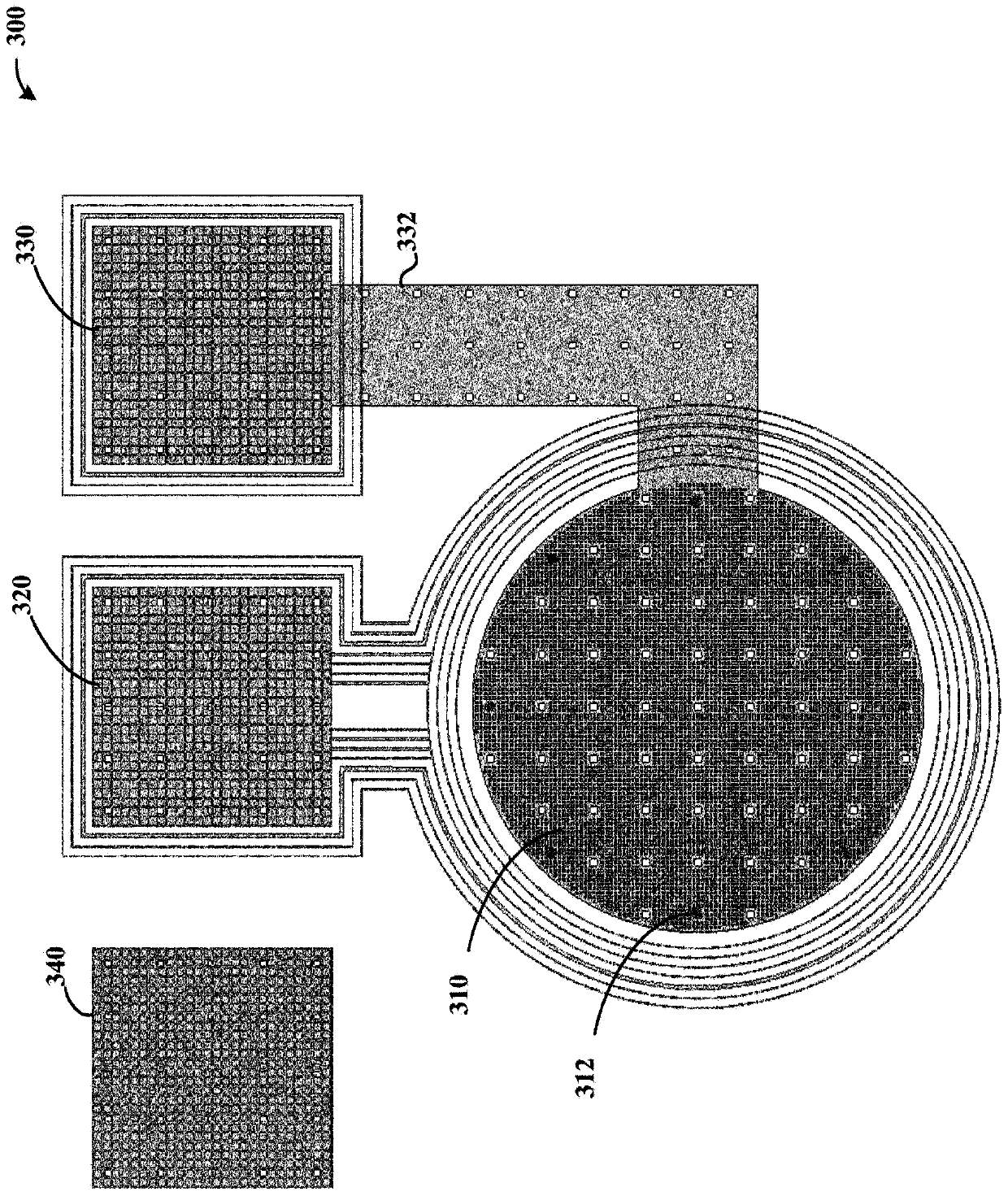

Pressure sensor

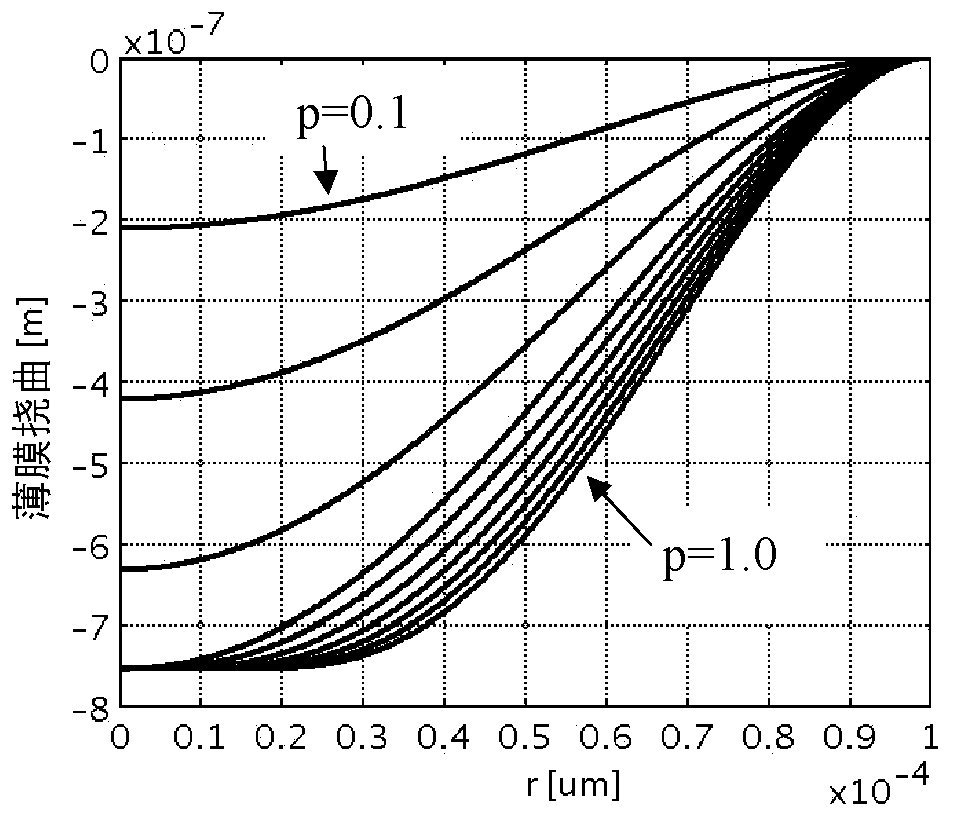

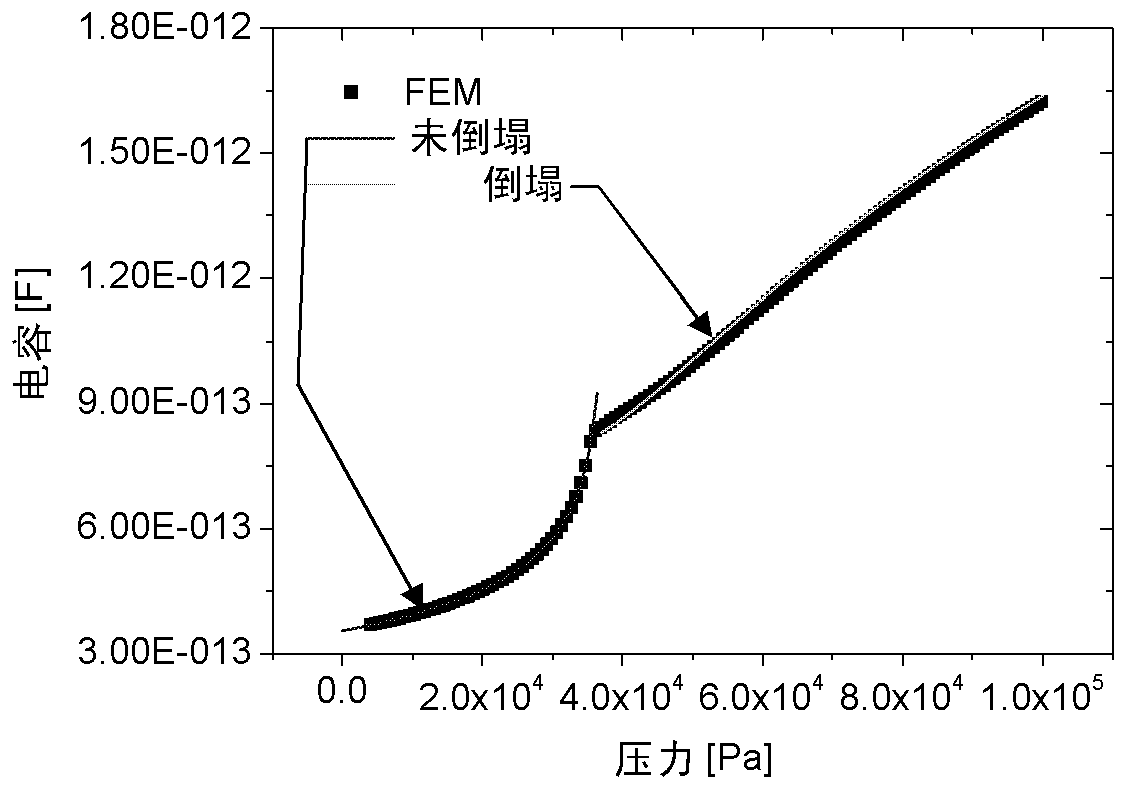

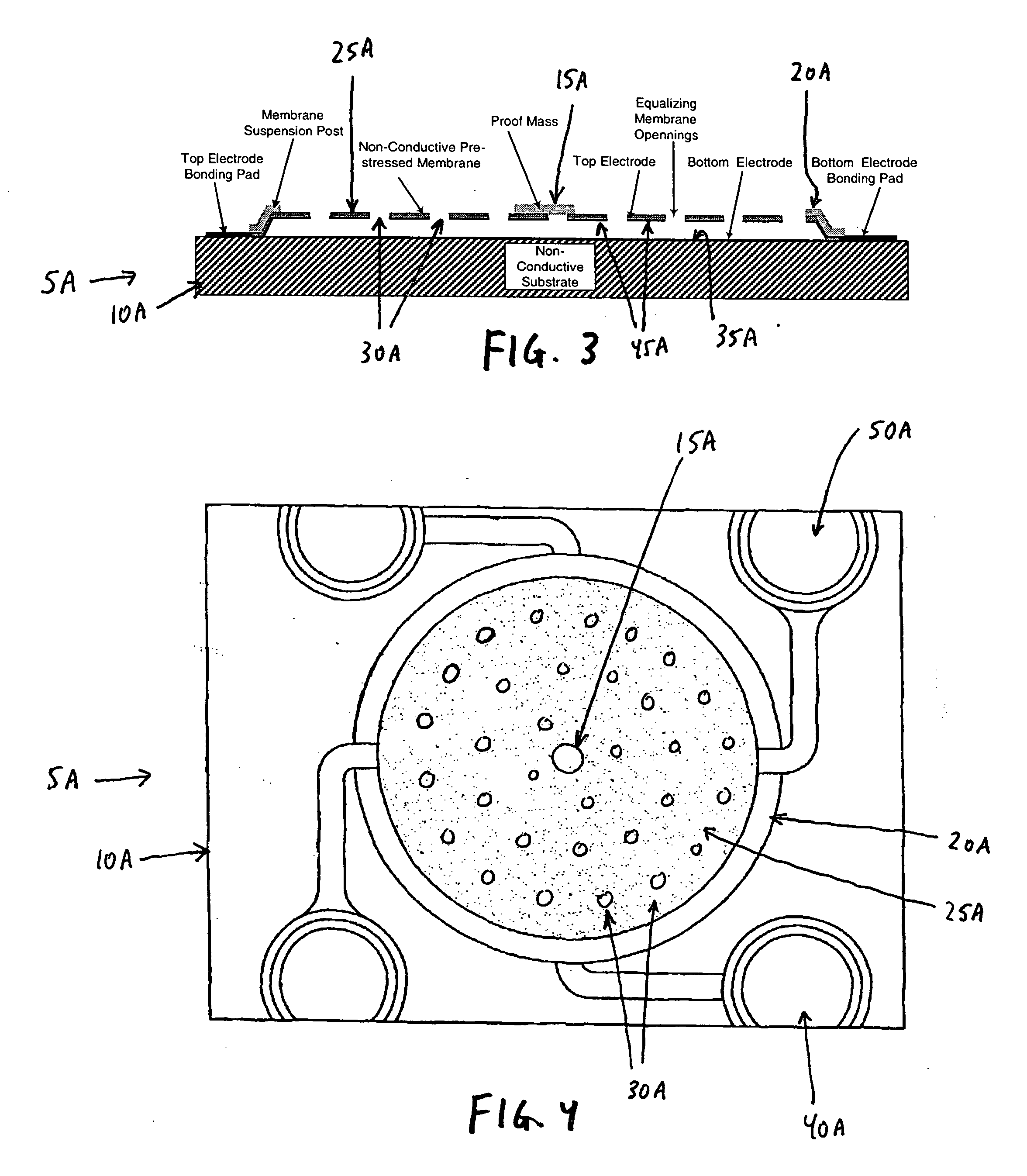

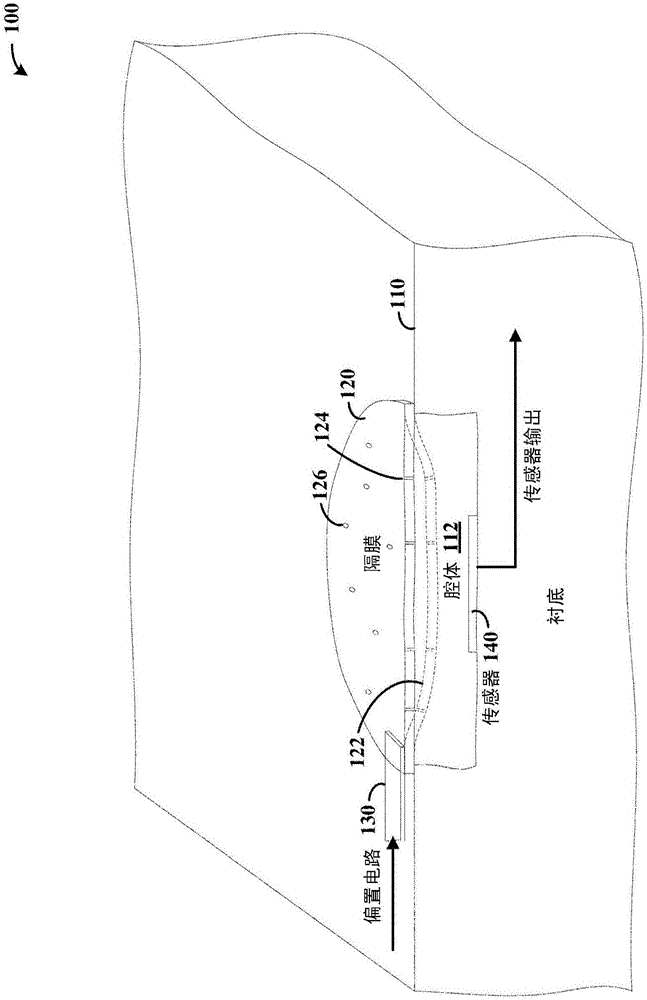

ActiveCN103630286AFluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationBiomedical engineeringMembrane configuration

As may be consistent with one or more embodiments discussed herein, an integrated circuit apparatus includes a membrane suspended over a cavity, with the membrane and cavity defining a chamber. The membrane has a plurality of openings therein that pass gas into and out of the chamber. As the membrane is actuated, the volume of the chamber changes to generate a gas pressure inside the chamber that is different than a pressure outside the chamber. A sensor detects a frequency-based characteristic of the membrane responsive to the change in volume, and therein provides an indication of the gas pressure outside the chamber.

Owner:希奥检测有限公司

Shield arrangement for a vacuum cell

ActiveUS7443169B2Eliminate disadvantagesReduce pollutionVacuum gauge using ionisation effectsFluid pressure measurement by electric/magnetic elementsScrew threadFlange

A shield arrangement for a vacuum measuring cell has a tubular shield housing encompassing a shield and an exit port for connection to a vacuum measuring cell and a connection opening for the object space to be measured. The shield is between the two openings and is implemented as a screw shield with spiral convolutions, its thread flange in the outer diameter being in contact on the inner wall of the shield housing such that a gas throughflow between the outer diameter of the thread flange and the inner wall is inhibited and is substantially forced into the spiral thread flight, and the exit port is on one side of the tubular section and the connection opening is on the other, opposite side and the screw shield is implemented such that in the axial line of vision the shield arrangement between the two openings is optically tight.

Owner:INFICON HLDG AG

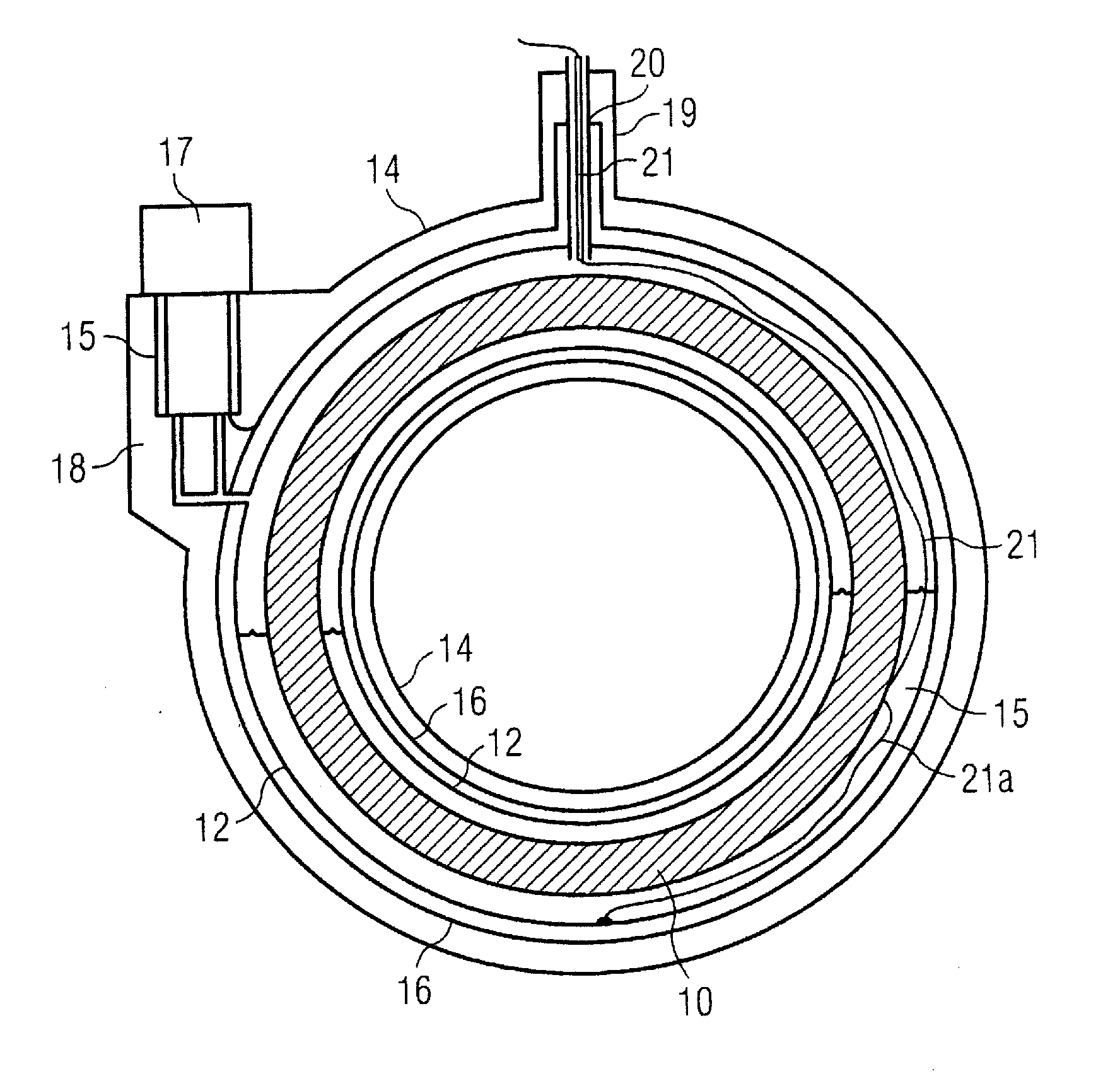

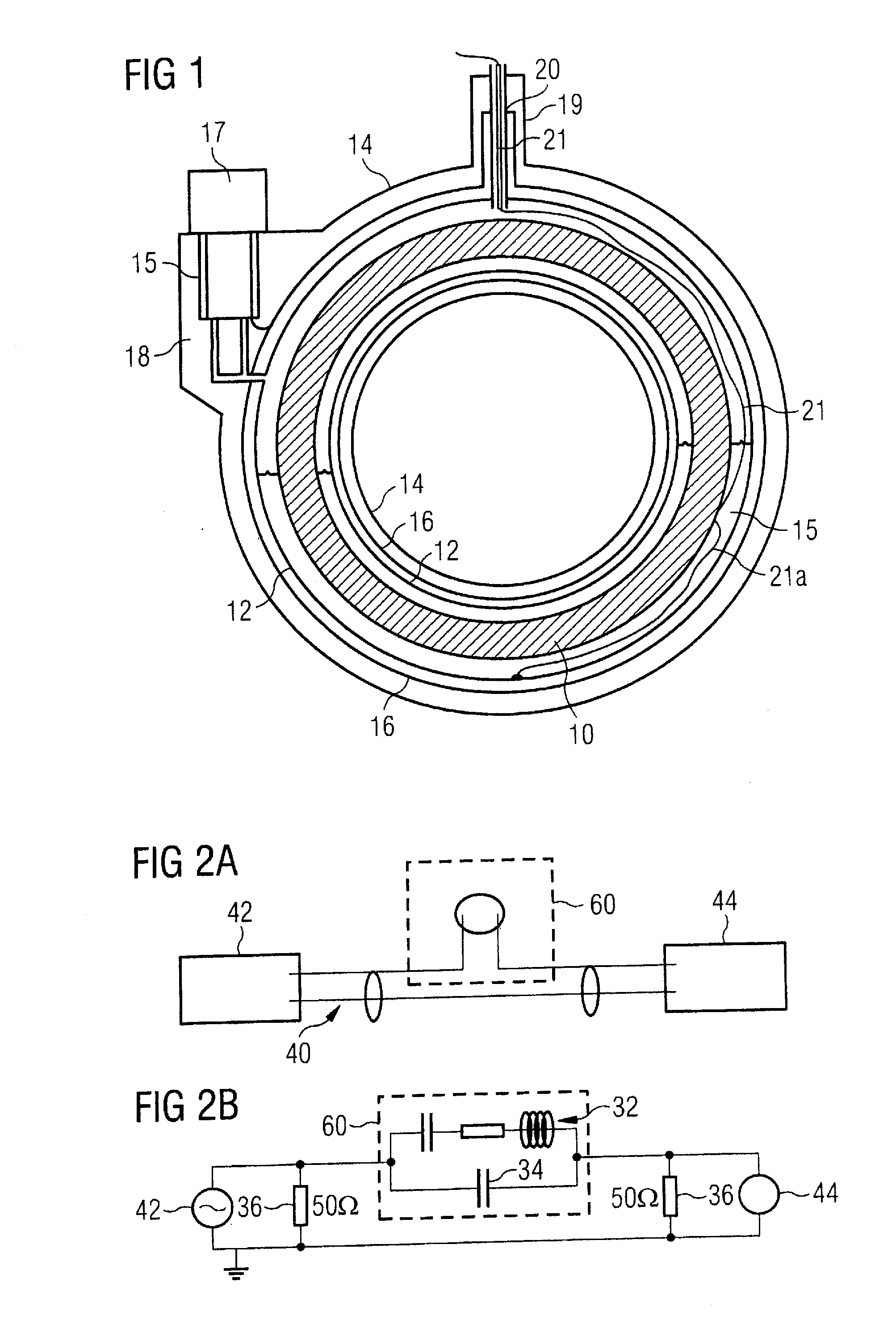

Pressure gauge

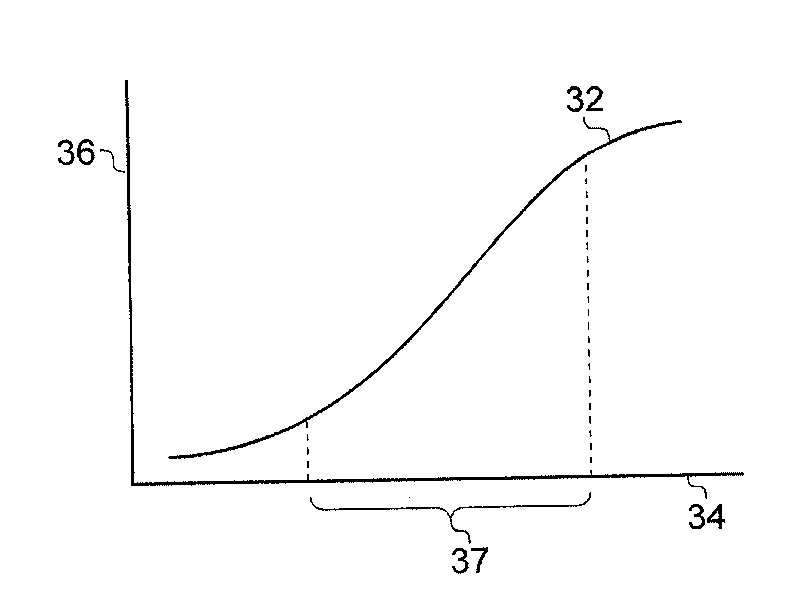

InactiveCN101711348AEfficient preparationLow costImpedence networksFluid pressure measurement by electric/magnetic elementsTime integralCondensed matter physics

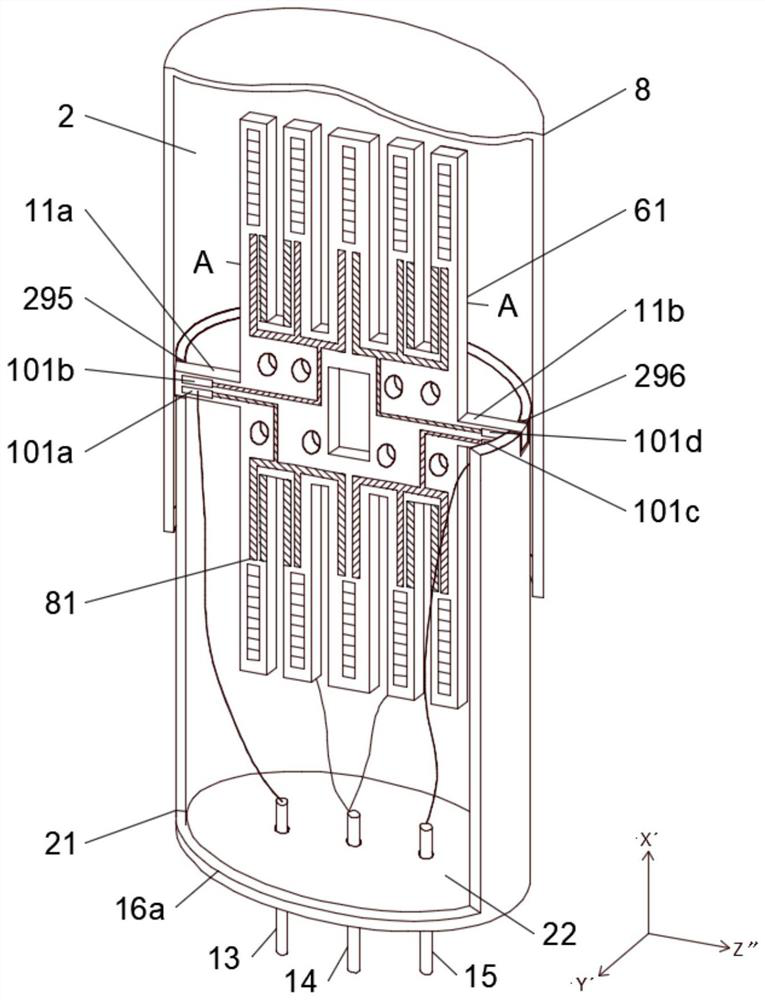

A pressure / vacuum sensor and method, comprising: driving a MEMS piezoresistive resonator (8) into resonant vibration, applying Joule heating to the resonator (8); and sensing a variable parameter that varies in response to the tendency of the resonant frequency (fo) to depend upon the temperature of the resonator (8), the temperature thereof depending upon the pressure. The variable parameter may be the resonant frequency of the resonator (8), or a change therein, or may be derived from a feedback loop, being for example a time integrated feedback signal (82) or a reading (94) of the sense current (22), the loop keeping the resonant frequency constant in opposition to the above mentioned tendency. A reference MEMS capacitive resonator (62) may be located in the vicinity of the resonator (8) for compensating purposes.

Owner:NXP BV

Methods and apparatus for detection of air ingress into cryogen vessels

InactiveUS20100199765A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesFrostResonance

In an apparatus and a method for detecting deposition of solid frost caused by air ingress into a cryogen vessel, a quartz crystal microbalance, that includes a crystal sensor, is placed within the cryogen vessel, and an actuating circuit actuates resonance of the crystal sensor, and detection equipment detects a change in the resonant characteristics of the crystal sensor caused by frost deposition on the crystal sensor, and signaling equipment indicates the detected change.

Owner:SIEMENS PLC

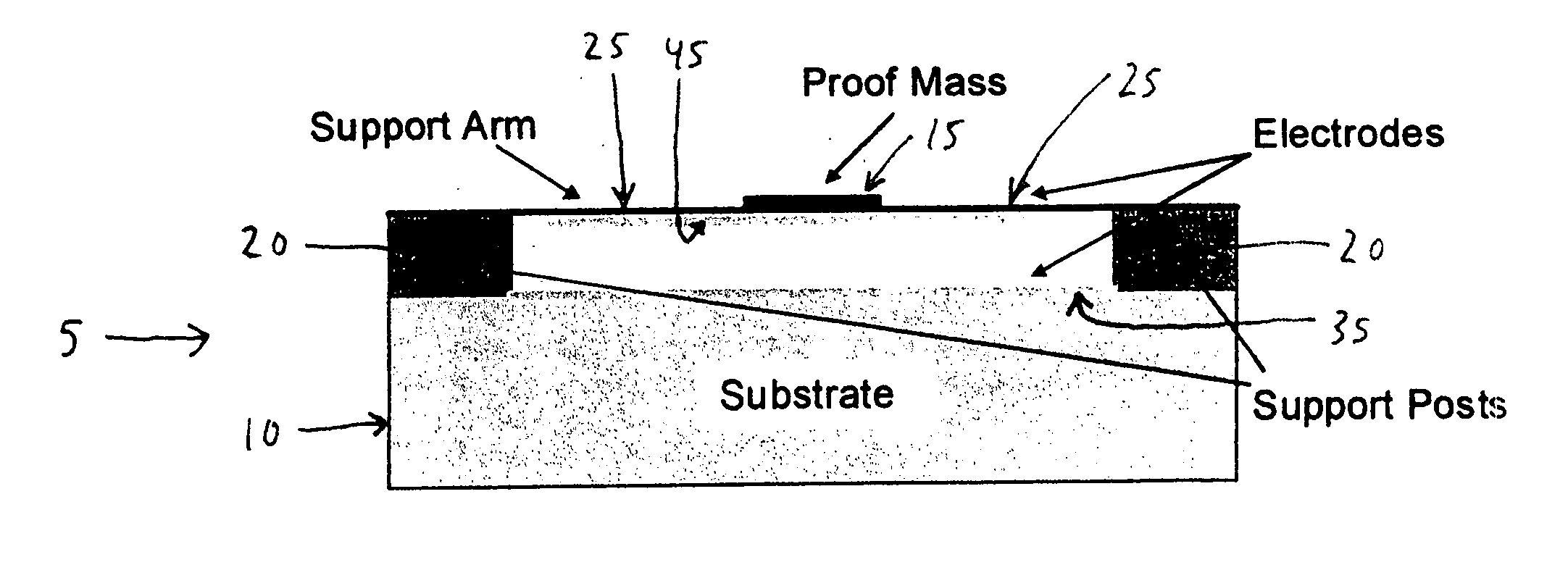

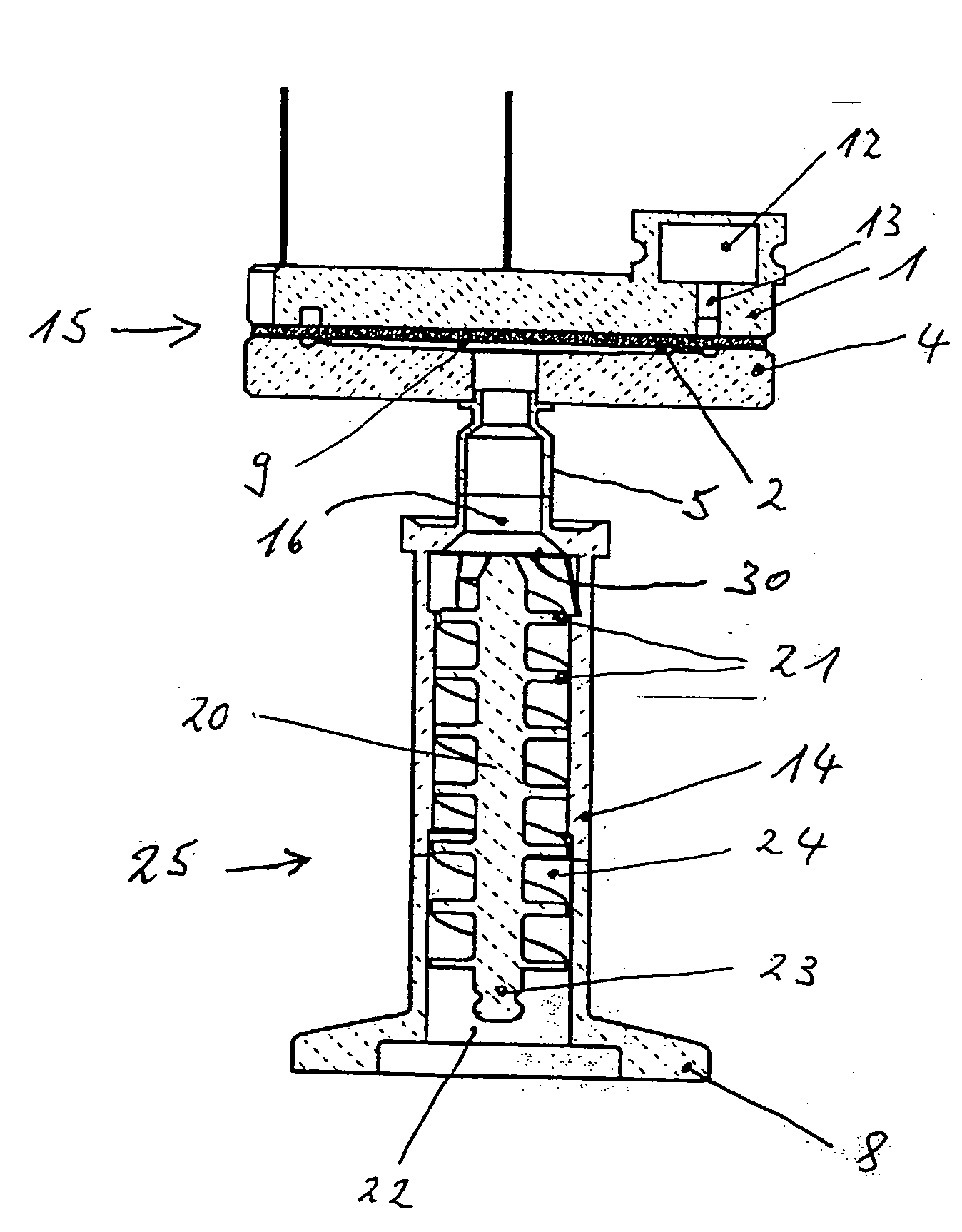

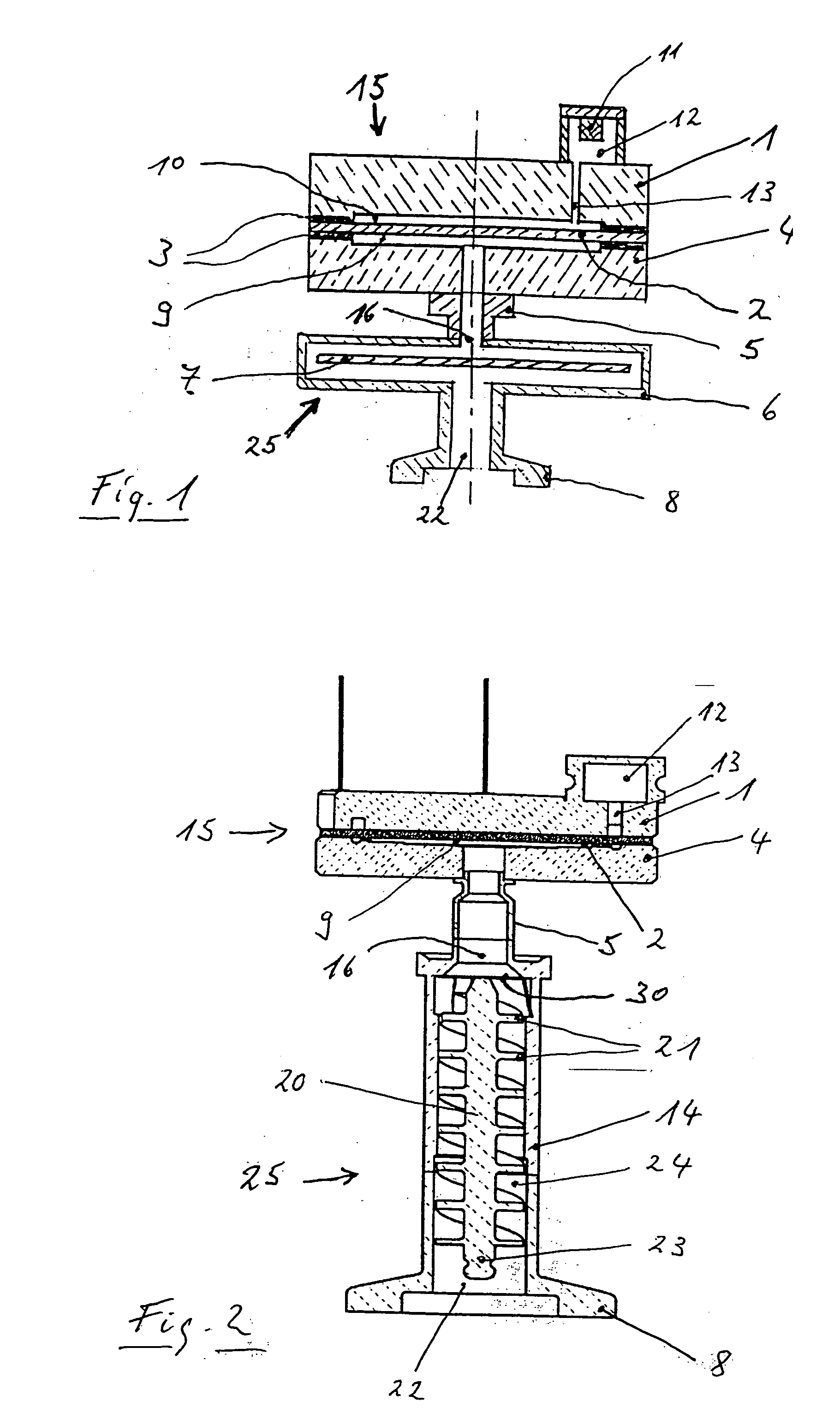

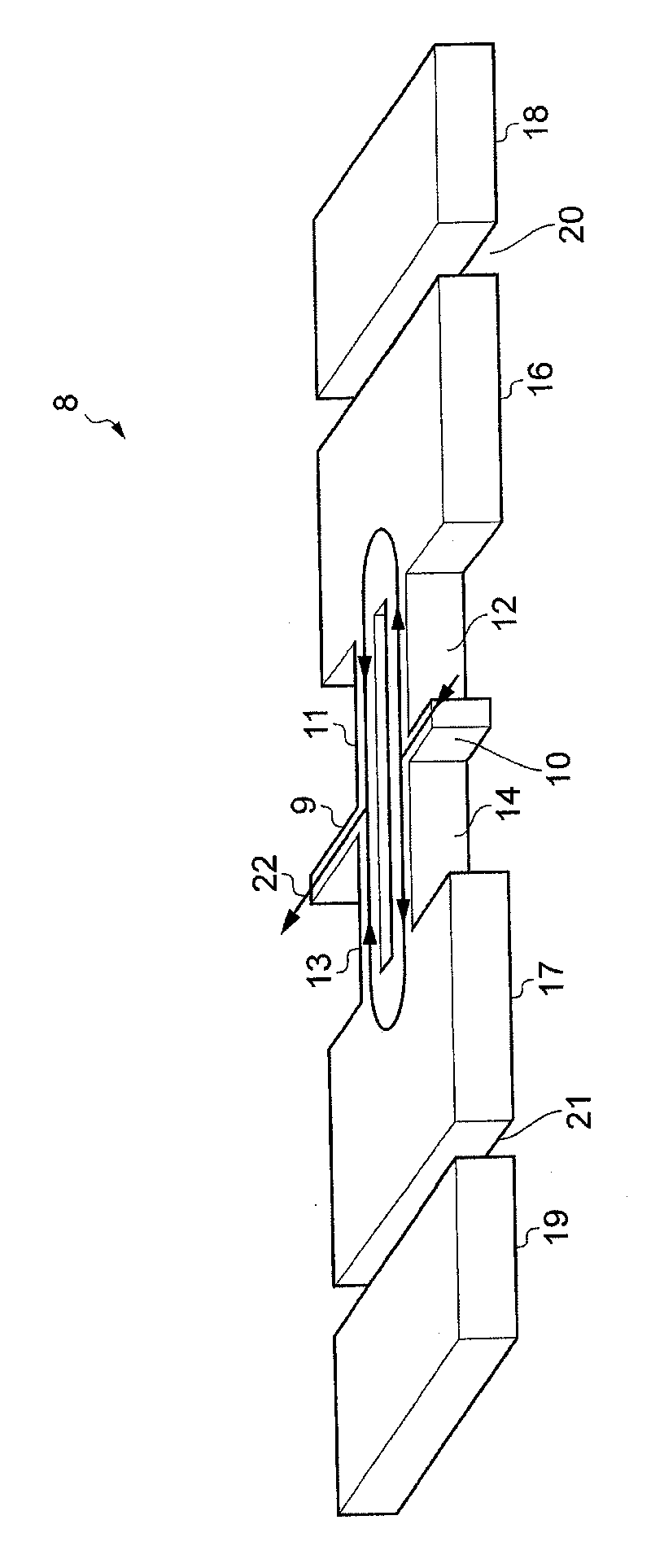

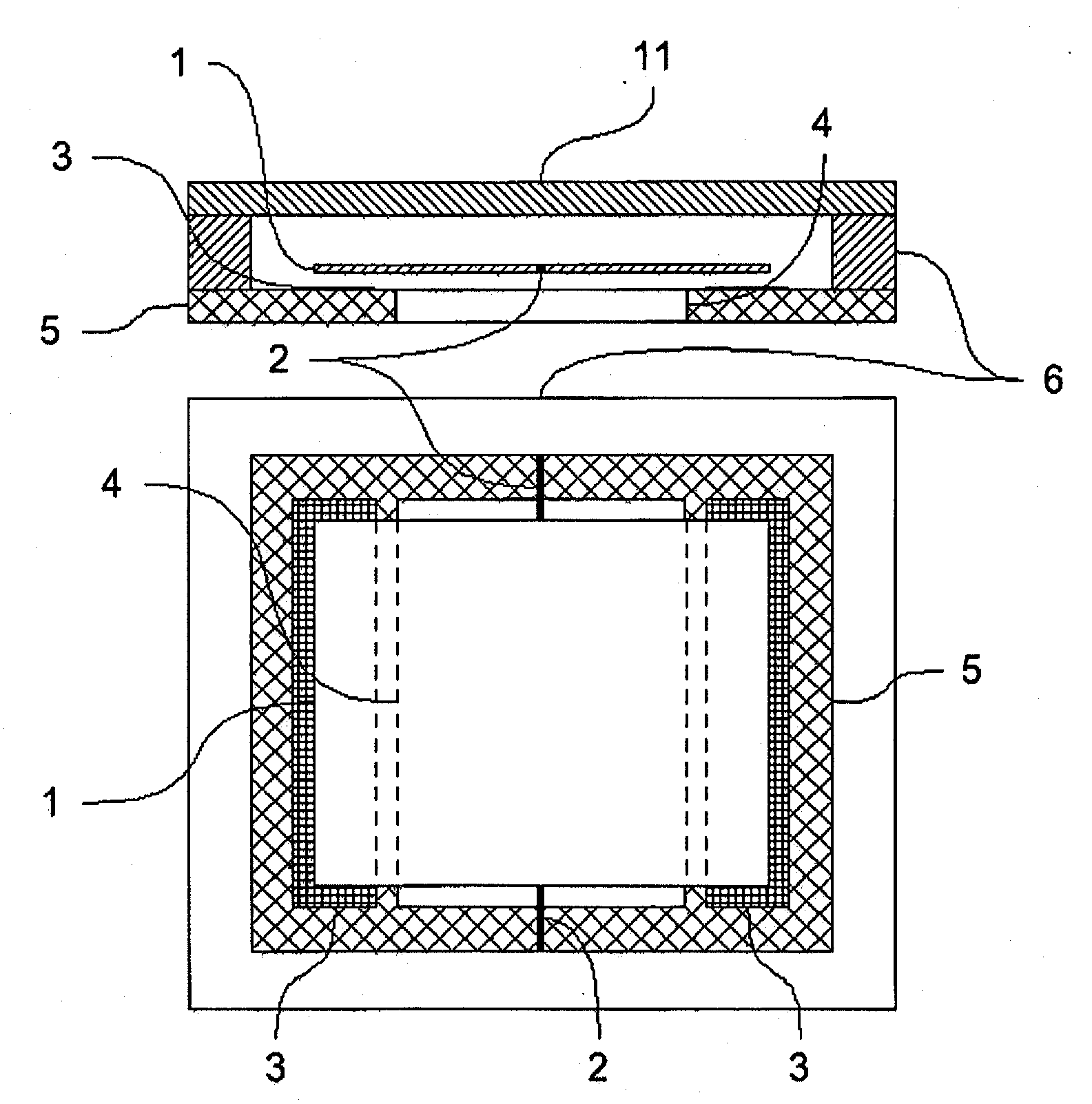

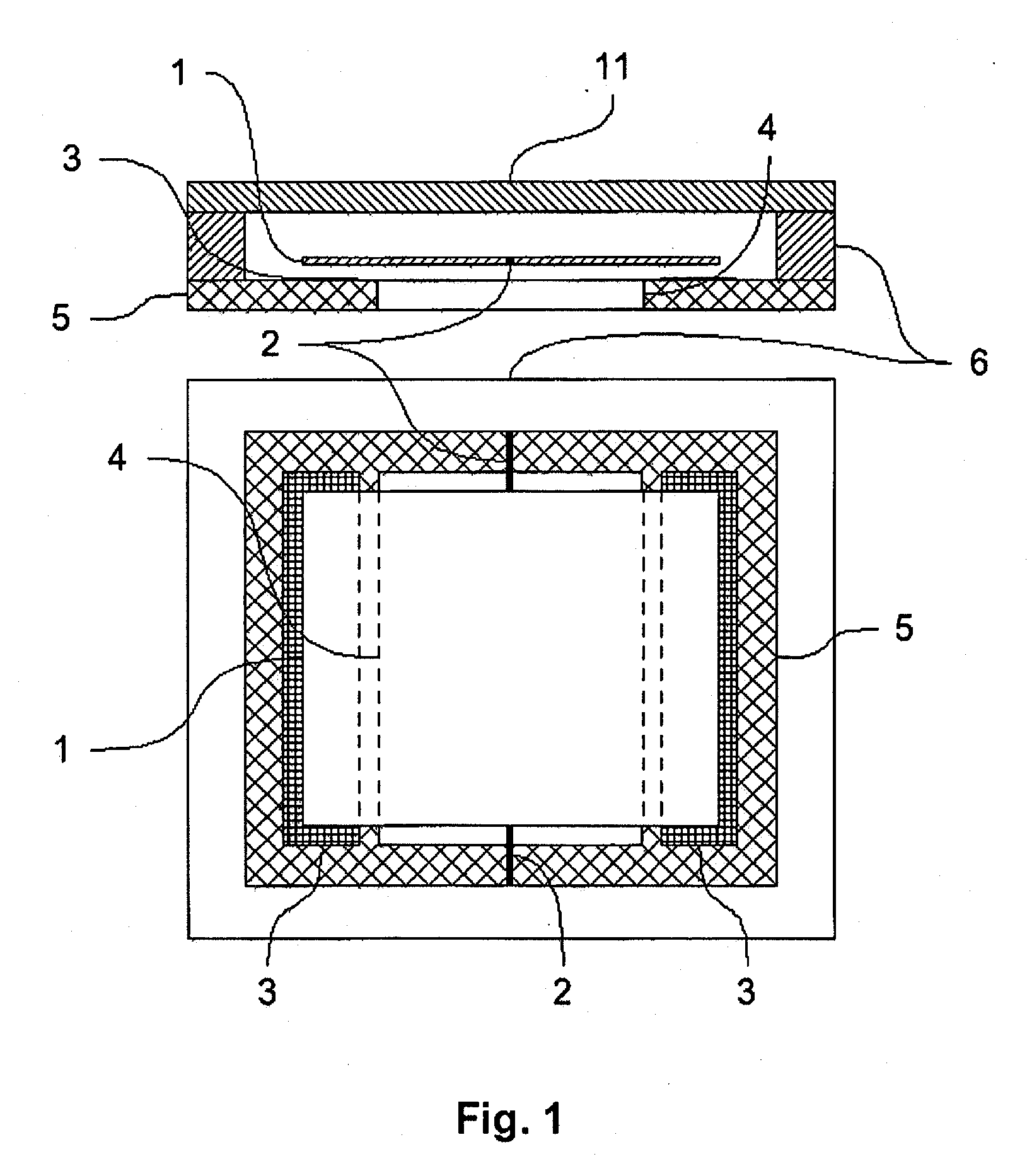

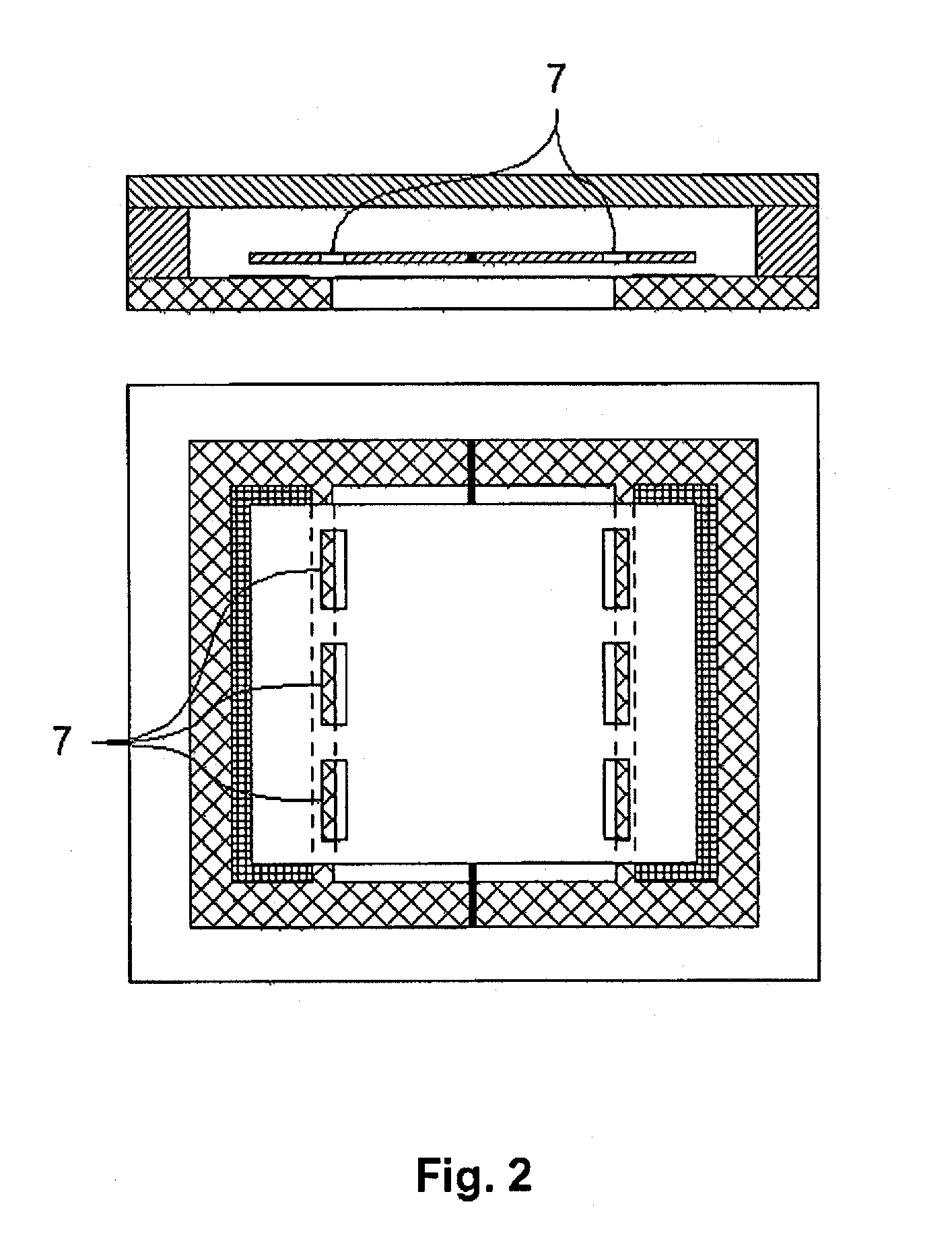

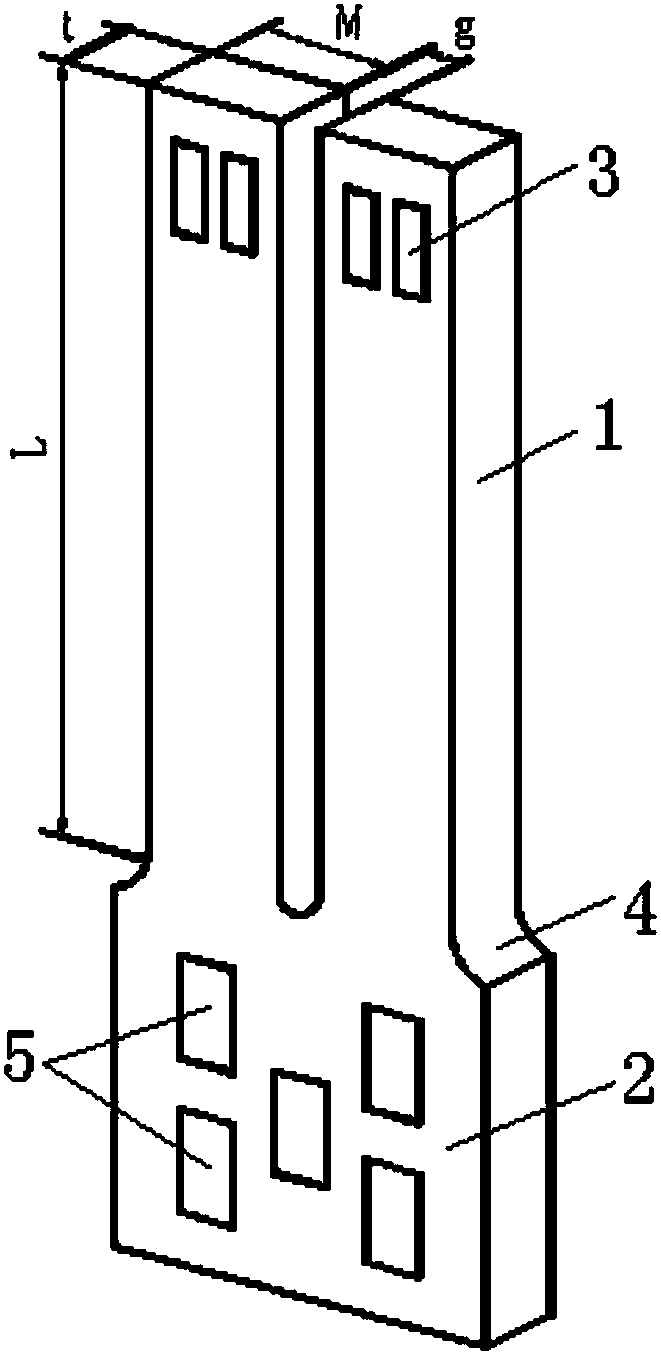

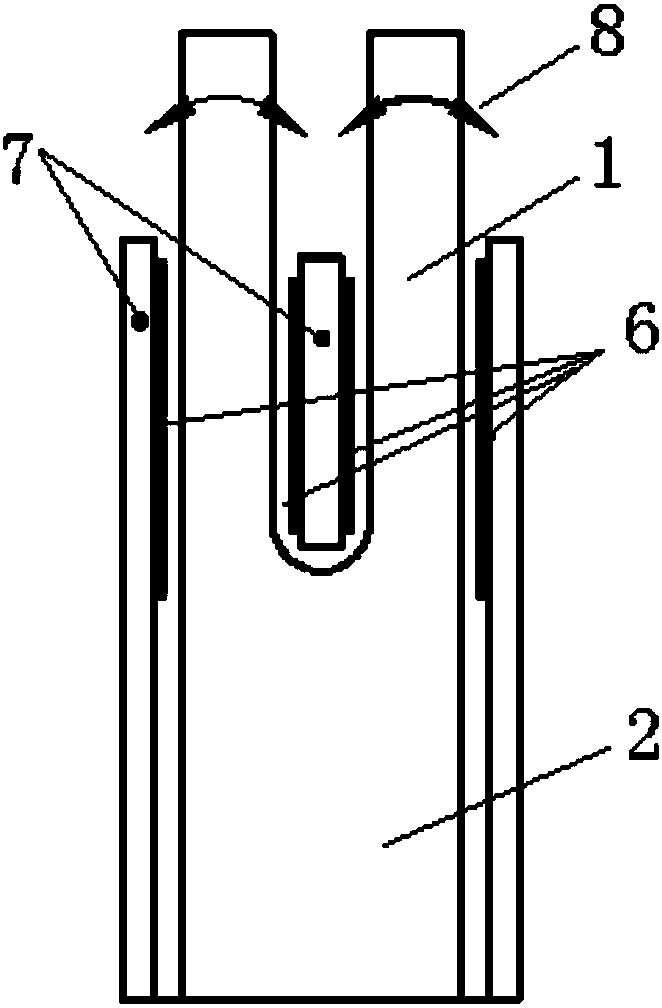

MEMS vacuum sensor based on the friction principle

InactiveUS20100024562A1Reduced dampingVacuum gauge using gaseous frictional resistance variationAtmospheric airEngineering

The invention relates to a sensor element for pressure measurement, having a substrate (5) and at least one mass element (1), which is arranged spaced apart from the substrate (5) and is connected in an oscillating manner to the substrate (5) and / or a support body (6) fixed relative to the substrate (5), so that a gap is formed between the mass element (1) and the substrate (5), the width of which can be varied through oscillations of the mass element (1). At least one recess and / or at least one bushing (4) is located in the surface of the substrate (5) delimiting the gap, which recess is used for reducing the damping of the oscillation of the mass element through the gas or plasma surrounding the mass element (1). The sensor element is used in particular in pressure sensors for measuring pressures in the vacuum range. Through the use of the sensor element according to the invention as a pressure sensor, maximum pressures up to the range of atmospheric air pressure can be recorded. The lowest pressures to be determined are in the range of 10−6 mbar.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

Pressure sensor

InactiveUS7059192B2Fluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsValue setResonance

Owner:AGILENT TECH INC

Vacuum monitor

PendingCN109974929AAvoid accumulationReduce downtimeVacuum gauge using ionisation effectsFluid pressure measurement by electric/magnetic elementsEngineeringAtmosphere

Owner:HORIBA STEC CO LTD

Pressure sensor

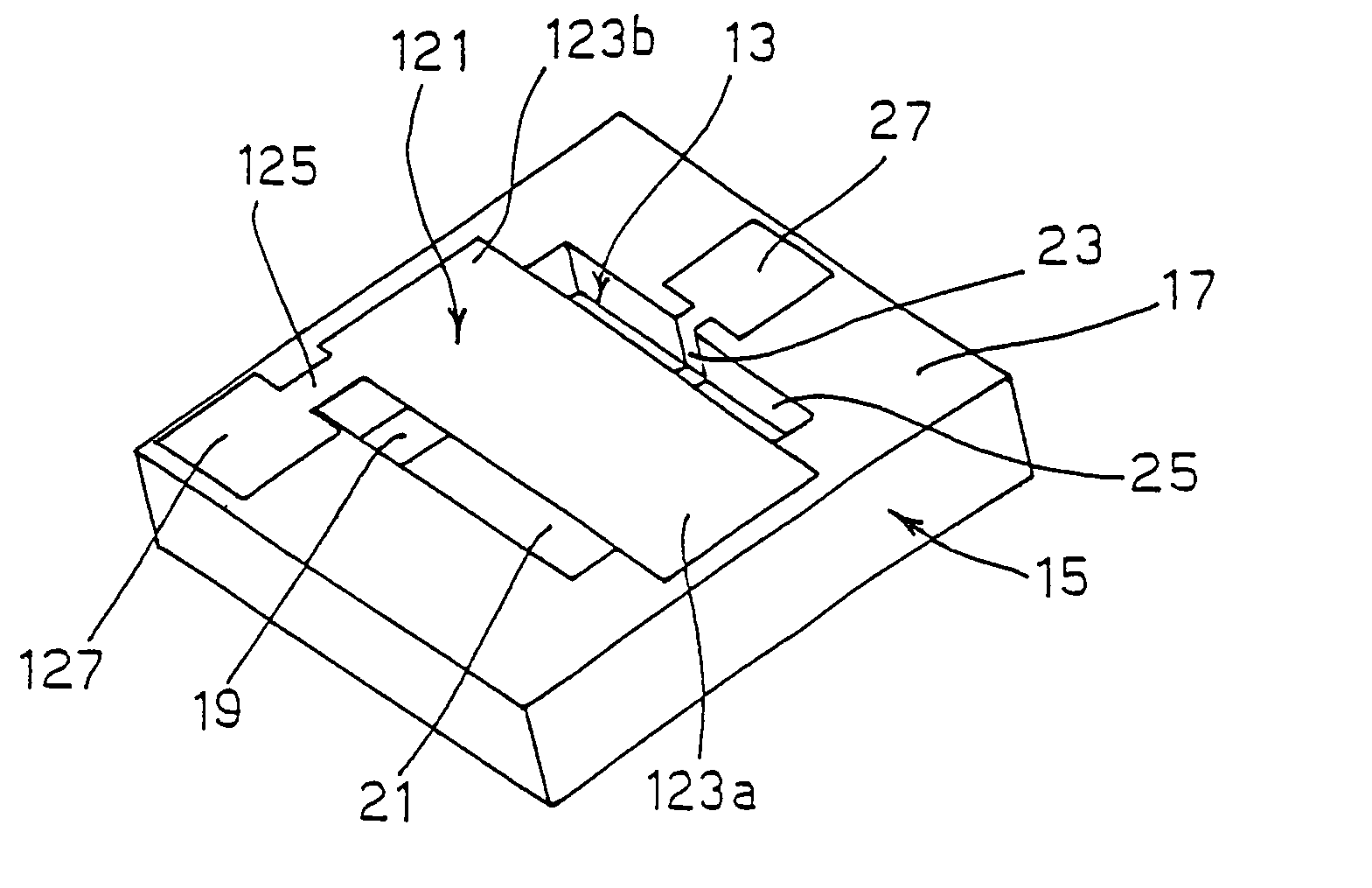

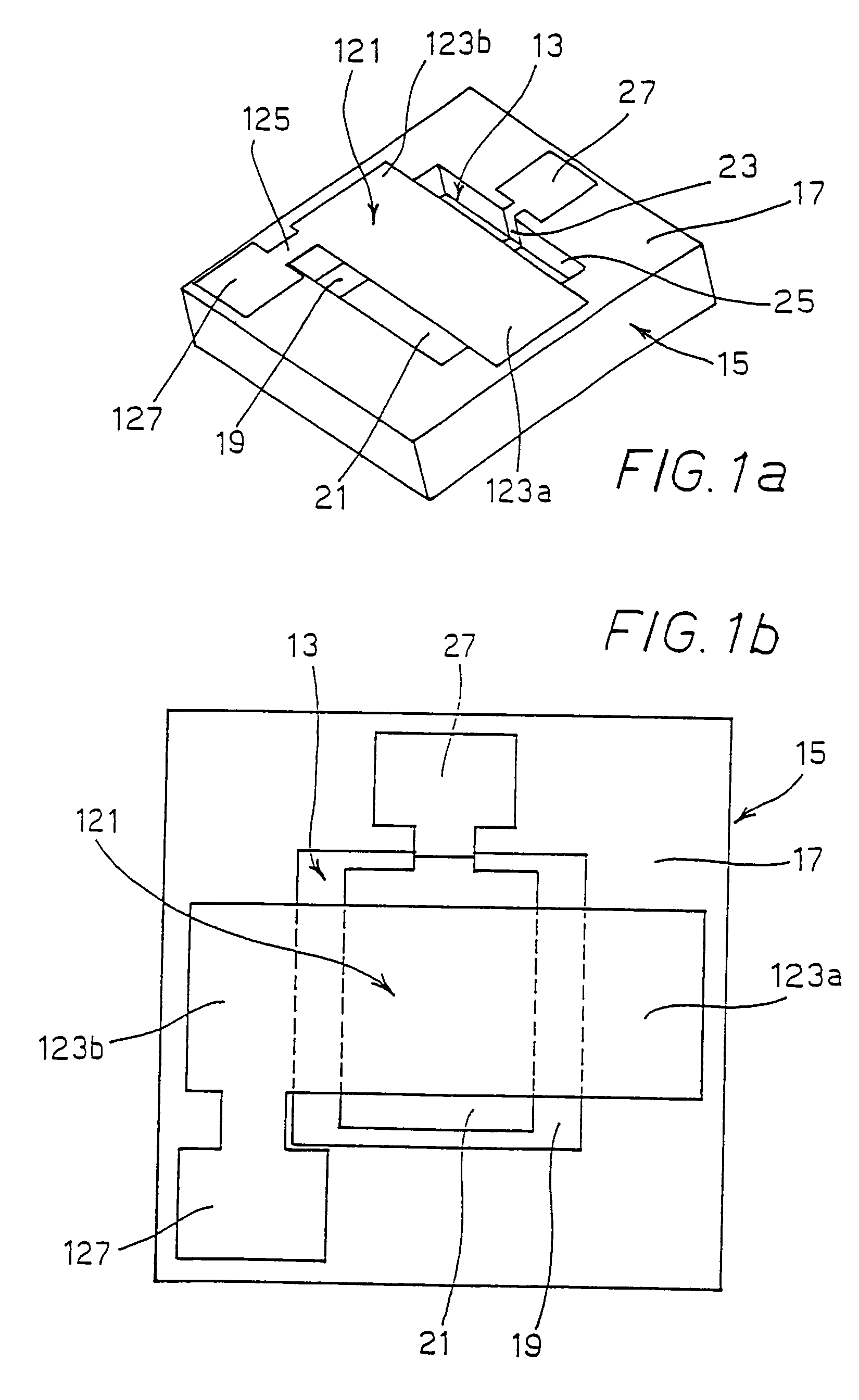

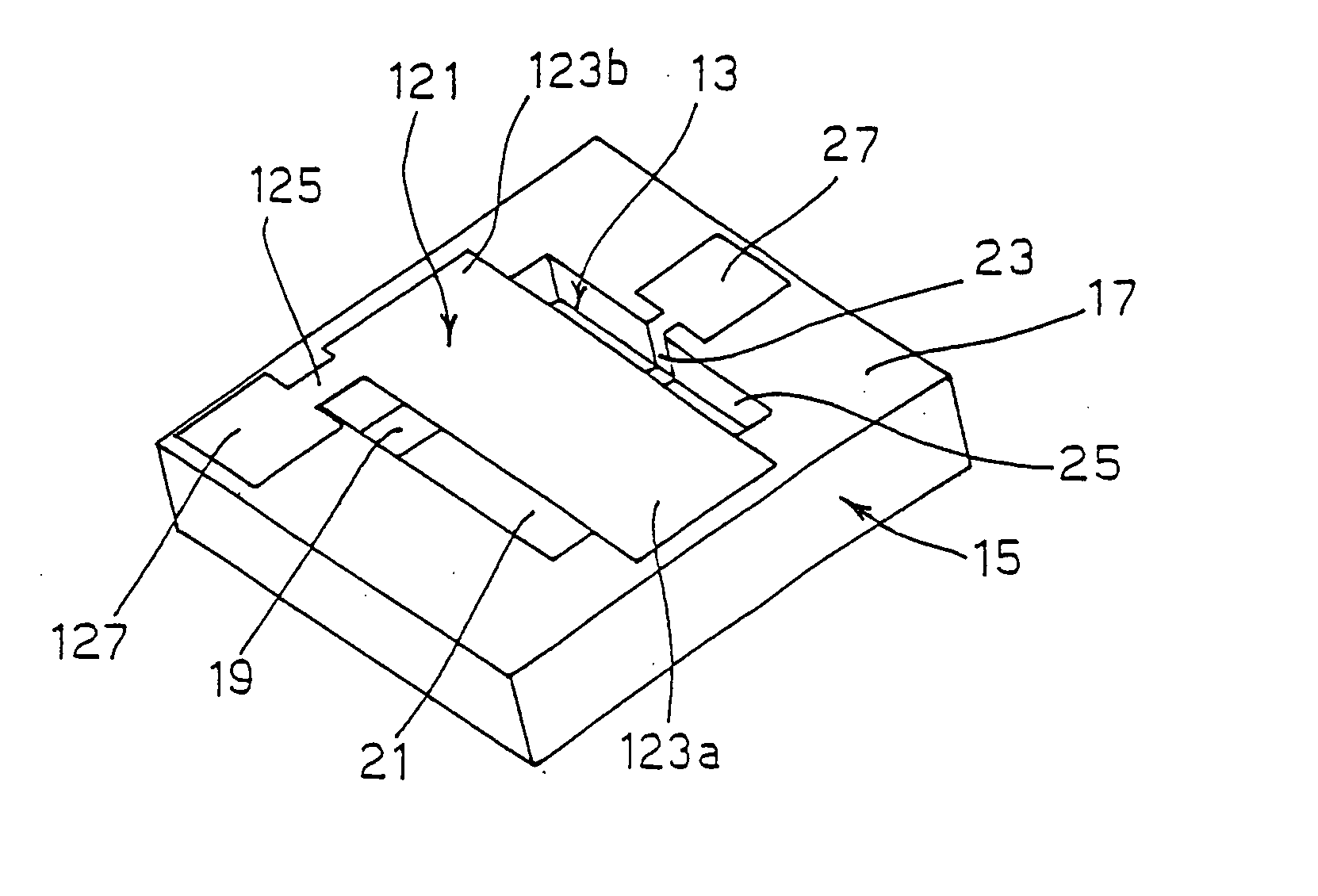

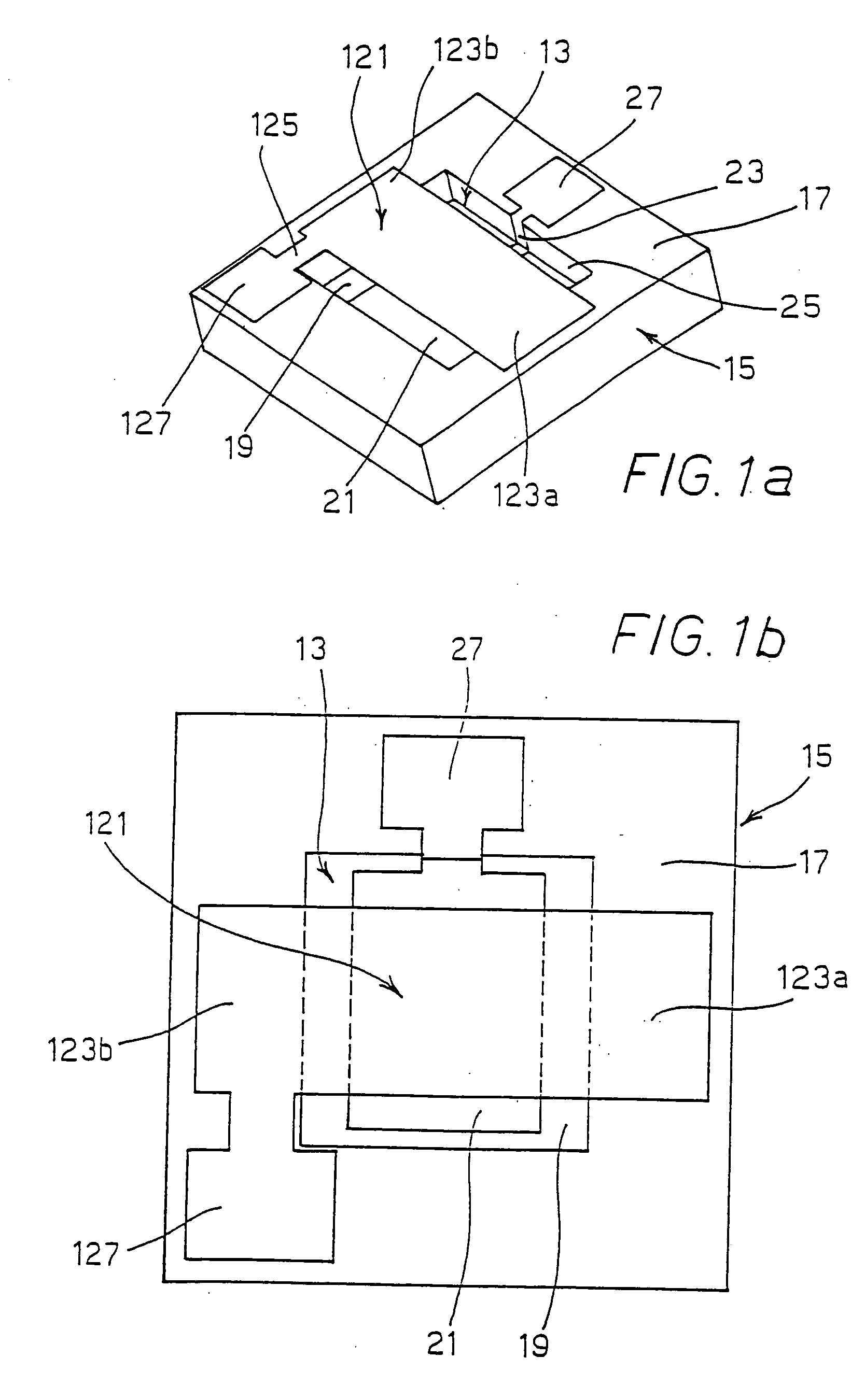

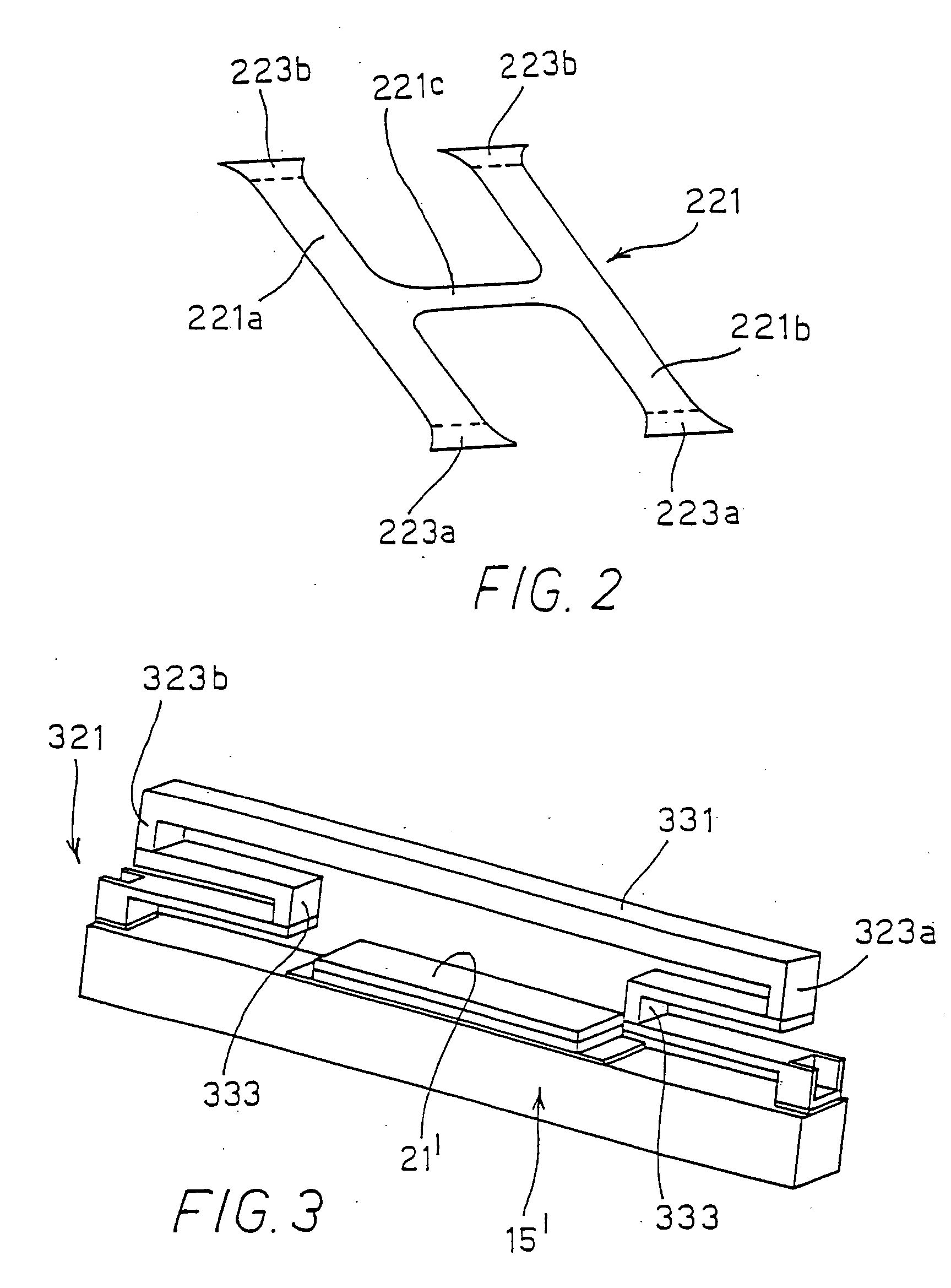

InactiveUS20050126295A1Fluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsValue setResonance

A pressure sensor is a micro-electro-mechanical vibrating device, with a silicon substrate (15; 15′) onto which a single-layer or multilayer vibrating assembly (121; 221; 321) is formed. It comprises an electrode (21; 21′), which makes the assembly to oscillate relative to the substrate at the resonance frequency or at another known frequency, and a detector for detecting the actual frequency and / or amplitude of said oscillation. The actual frequency and / or amplitude are affected by the conditions, in particular the pressure, of the external environment and the variations of the frequency and amplitude with respect to the values set by the electrode is used to measure pressure variations in the surrounding environment.

Owner:AGILENT TECH INC

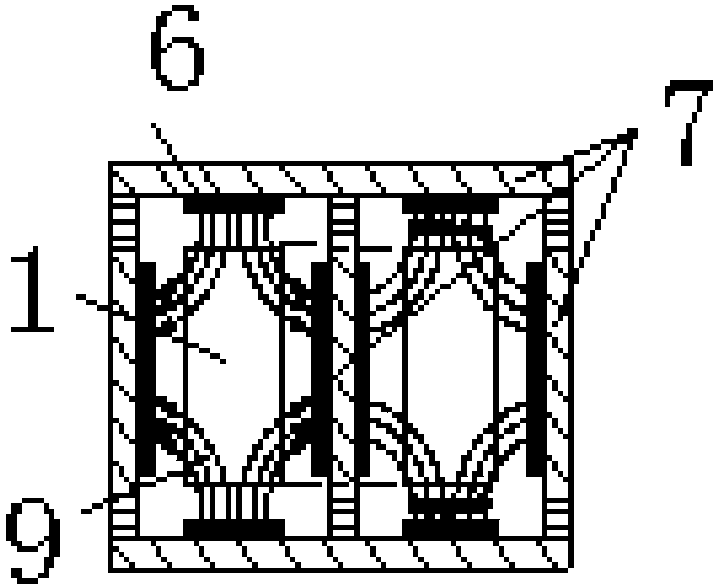

Quartz vacuum sensor with electrodeless tuning fork

InactiveCN107560787AHigh sensitivityBroaden the lower limit of the rangeVacuum gauge using gaseous frictional resistance variationAviationTuning fork

The invention relates to a quartz vacuum sensor with an electrodeless tuning fork and belongs to the quartz vacuum sensor field. The present invention aims to solve the problems of poor stability, poor reliability, poor sensitivity and narrow measuring range of an existing vacuum sensor. A gap is left between two fork arms; arc-shaped grooves are formed at the edge connection positions of each fork arm and a supporting isolation area; two parallel through channels near the top end of each fork arm are formed at the front surface of the corresponding fork arm; 2 to 5 rectangular through groovesare symmetrically formed in the supporting isolation area with the center line of the two fork arms adopted as an axis of symmetry; quartz crystal wafers which are parallel to the two fork arms are arranged at the gap between the two fork arms and around the supporting isolation area and the two fork arms respectively; metal electrodes are bonded onto two side walls of the quartz crystal wafer atthe gap and the inner walls of the quartz crystal wafers around the supporting isolation area and the two fork arms respectively; the metal electrodes and the quartz crystal wafers are of integral structures; and gaps are left between the metal electrodes and the two fork arms. The quartz vacuum sensor is applied to the aviation field and other fields.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

Electromechanical pressure sensor

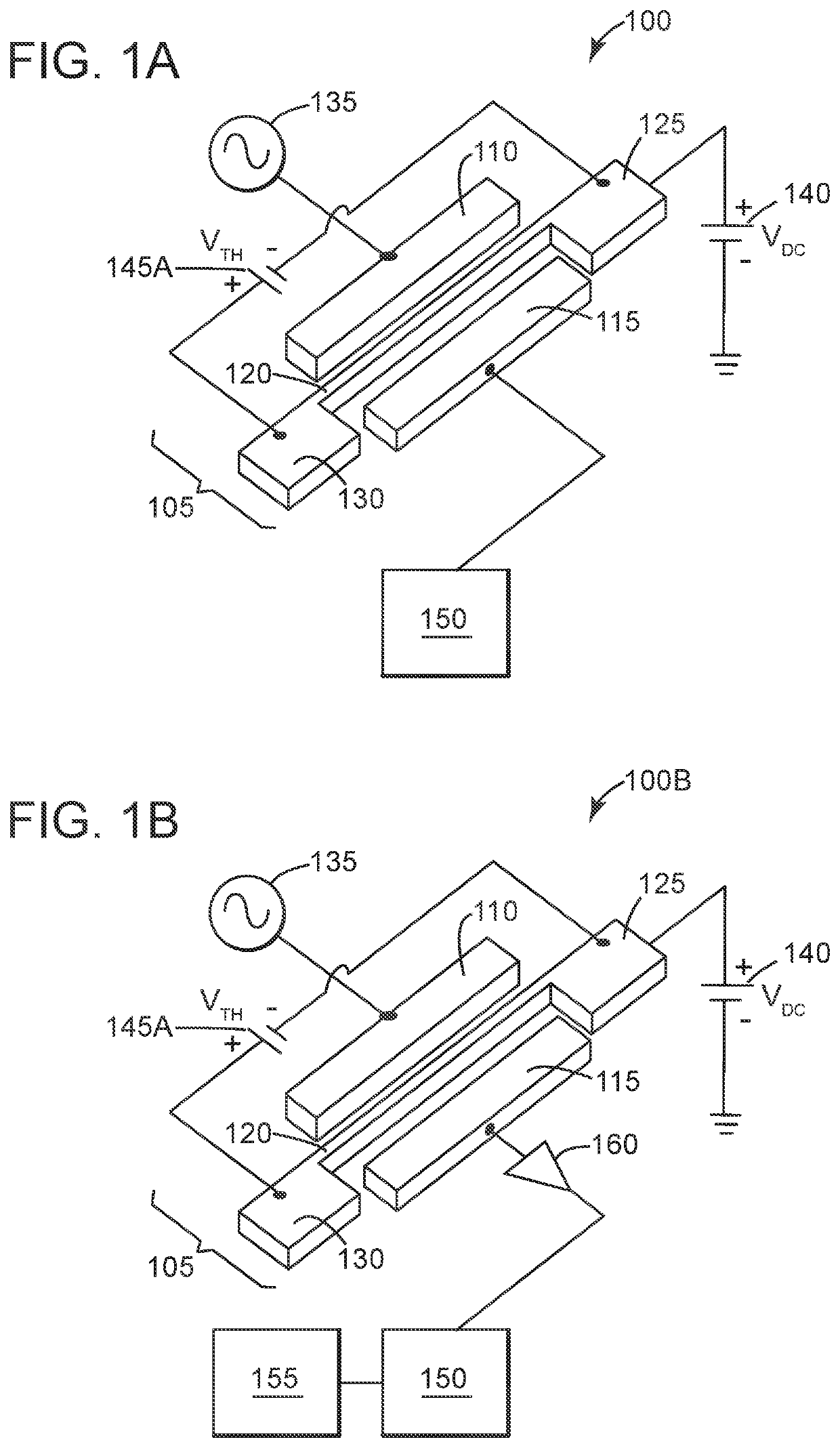

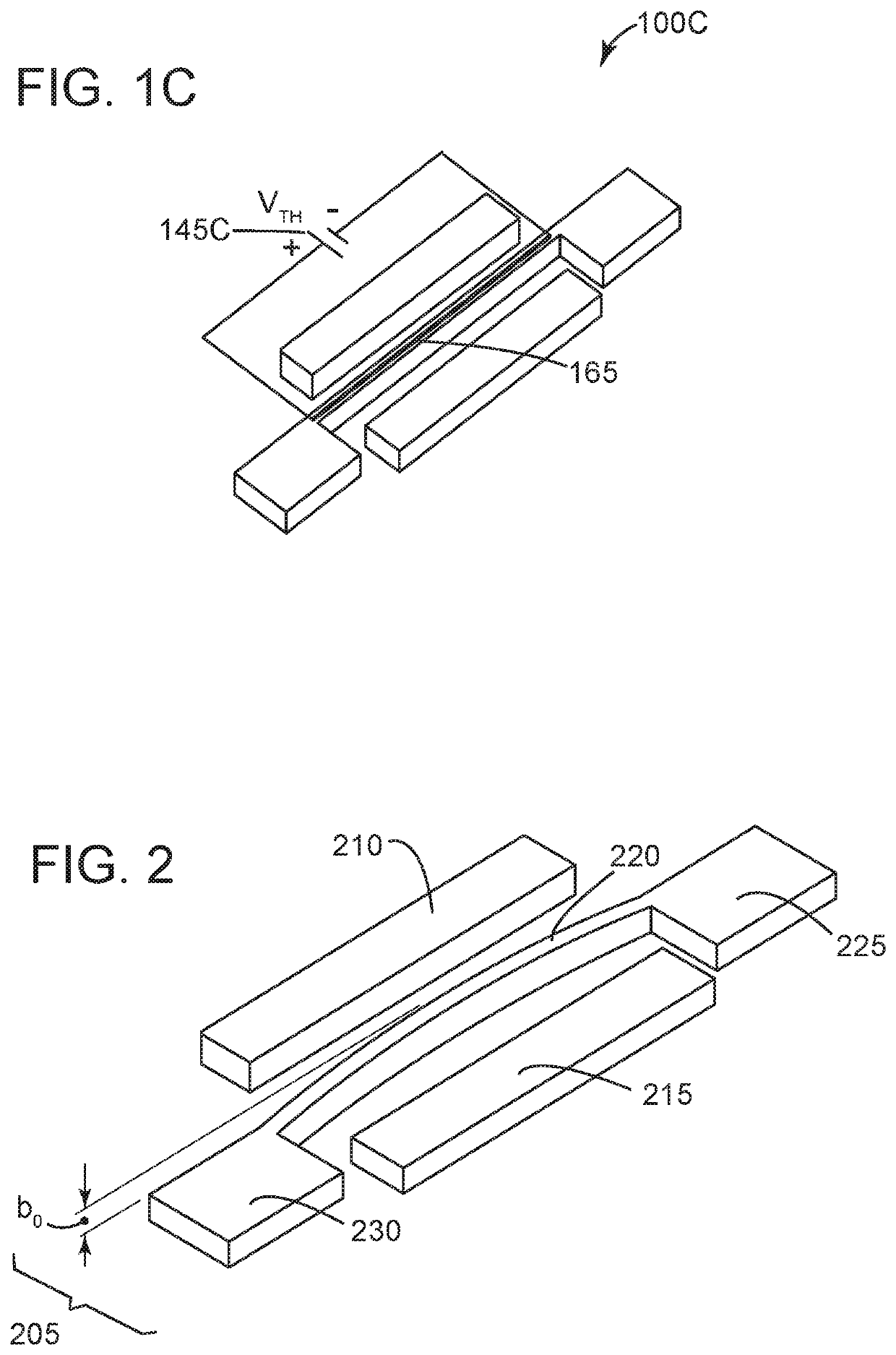

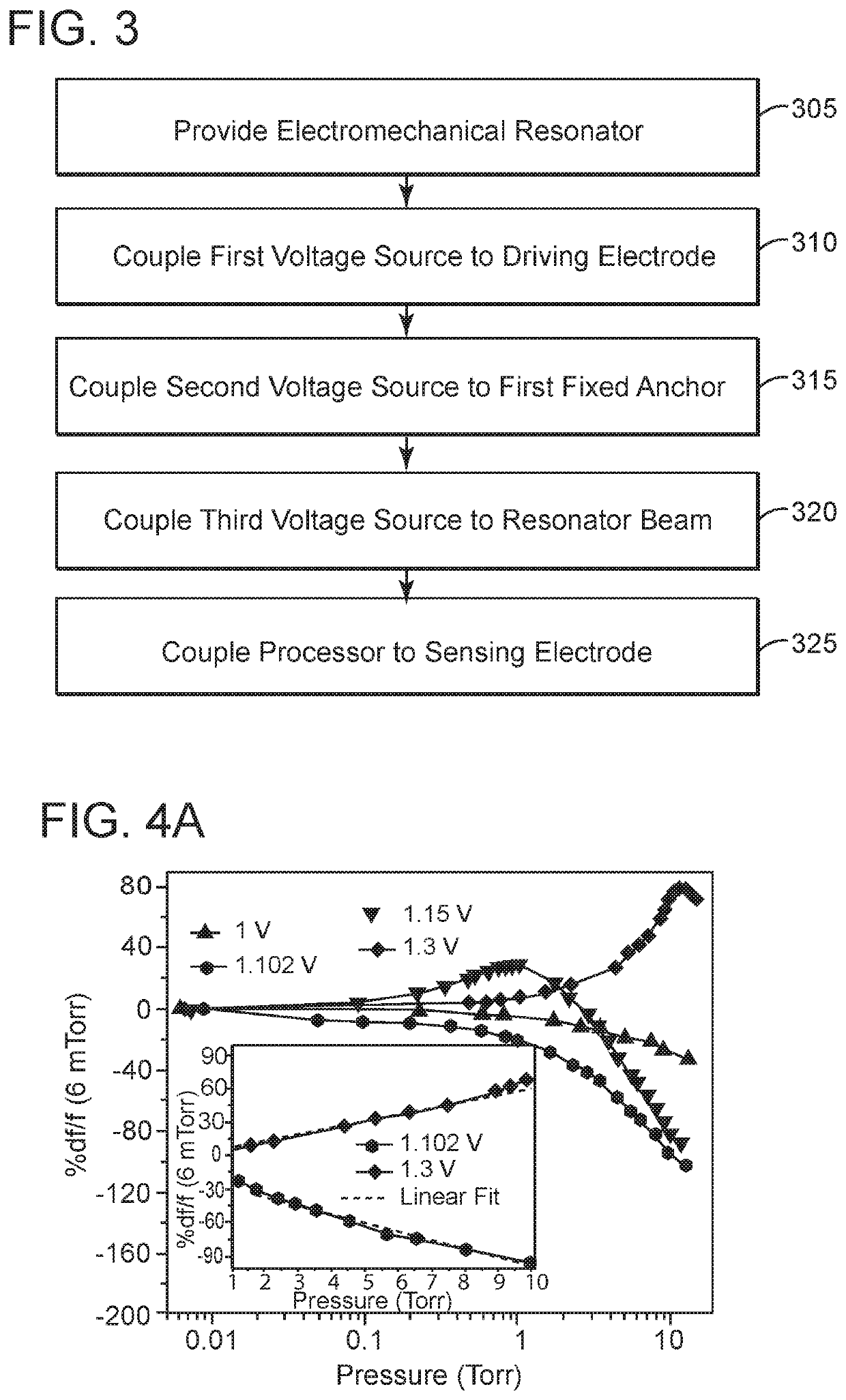

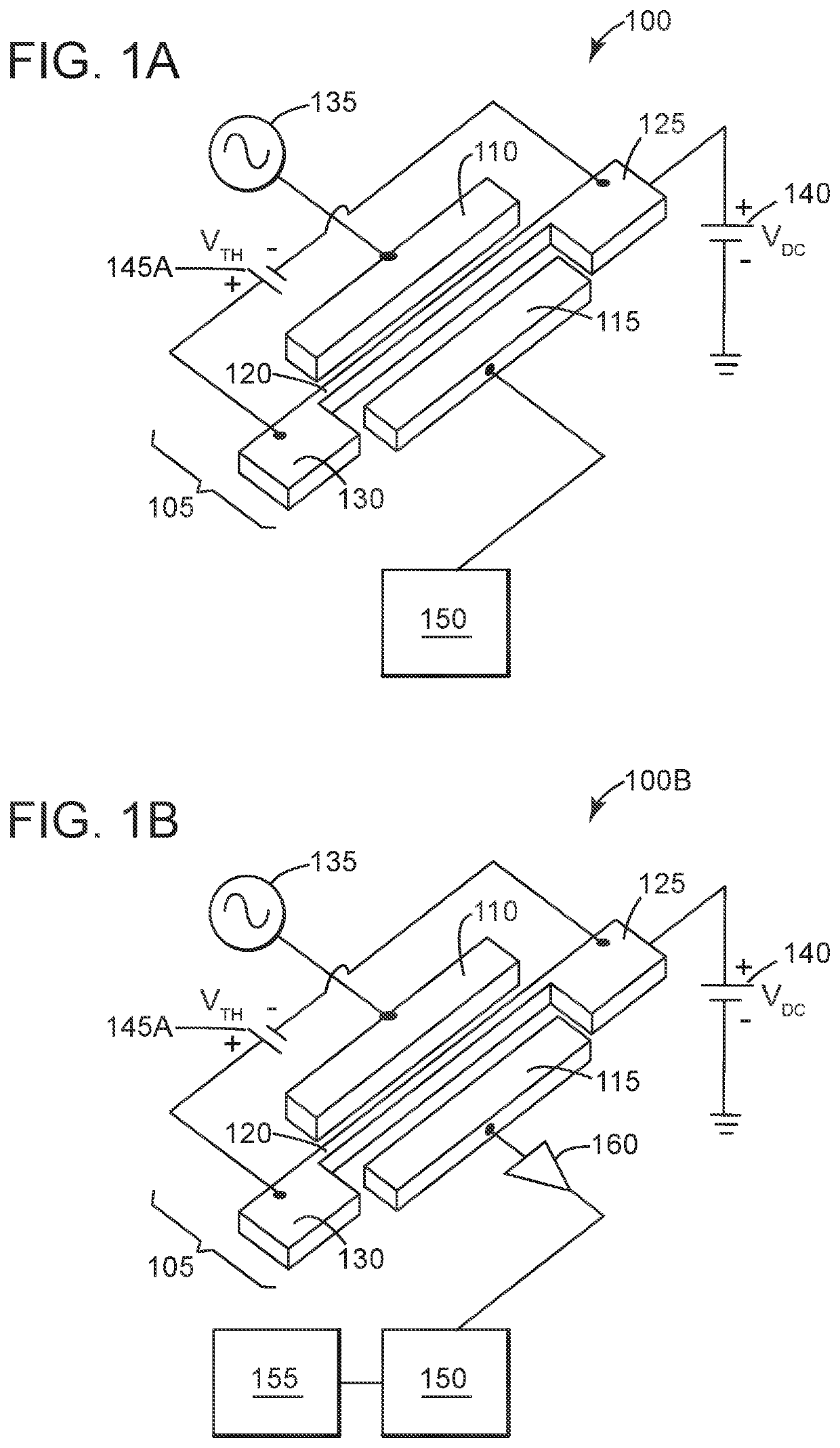

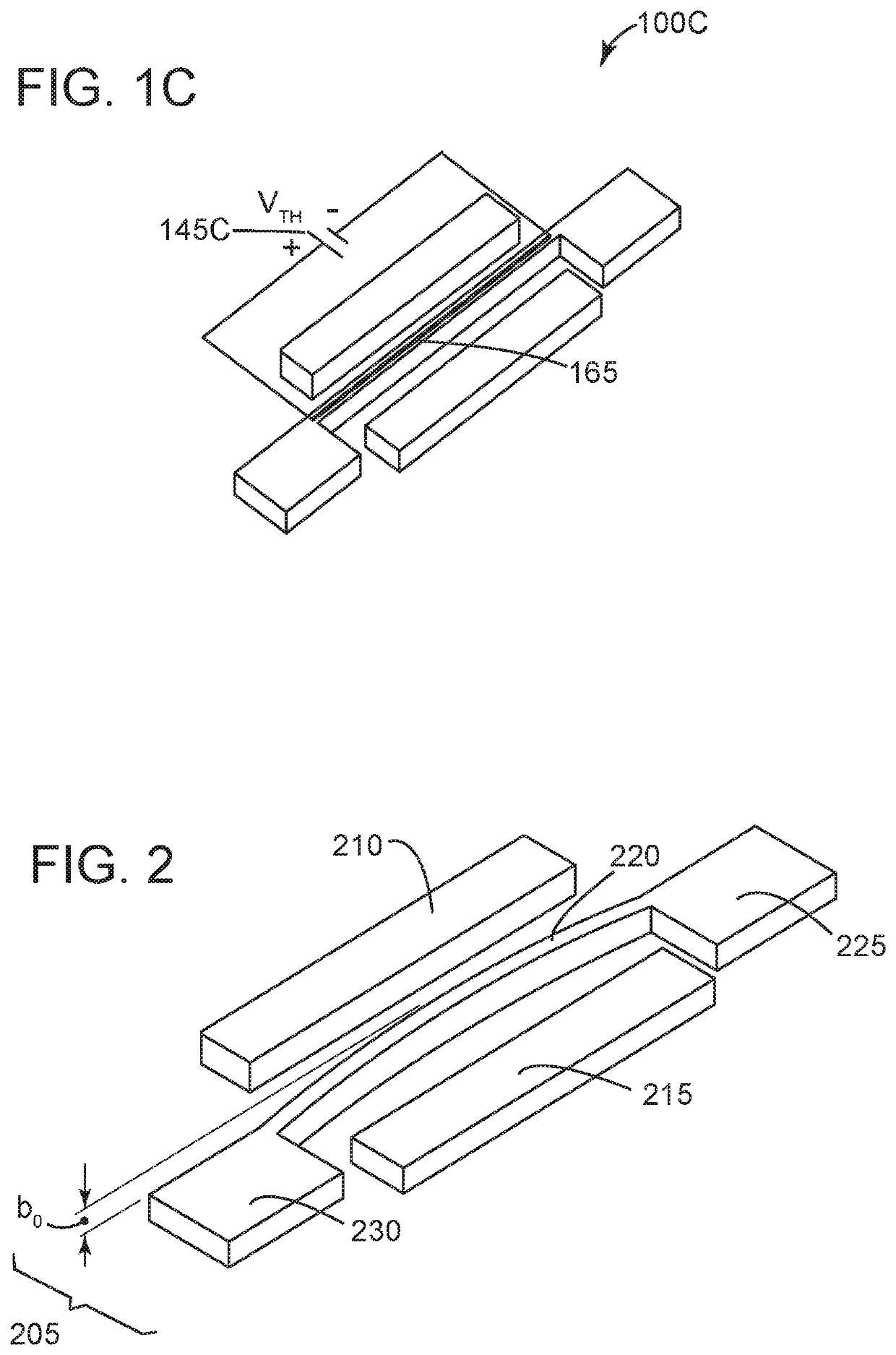

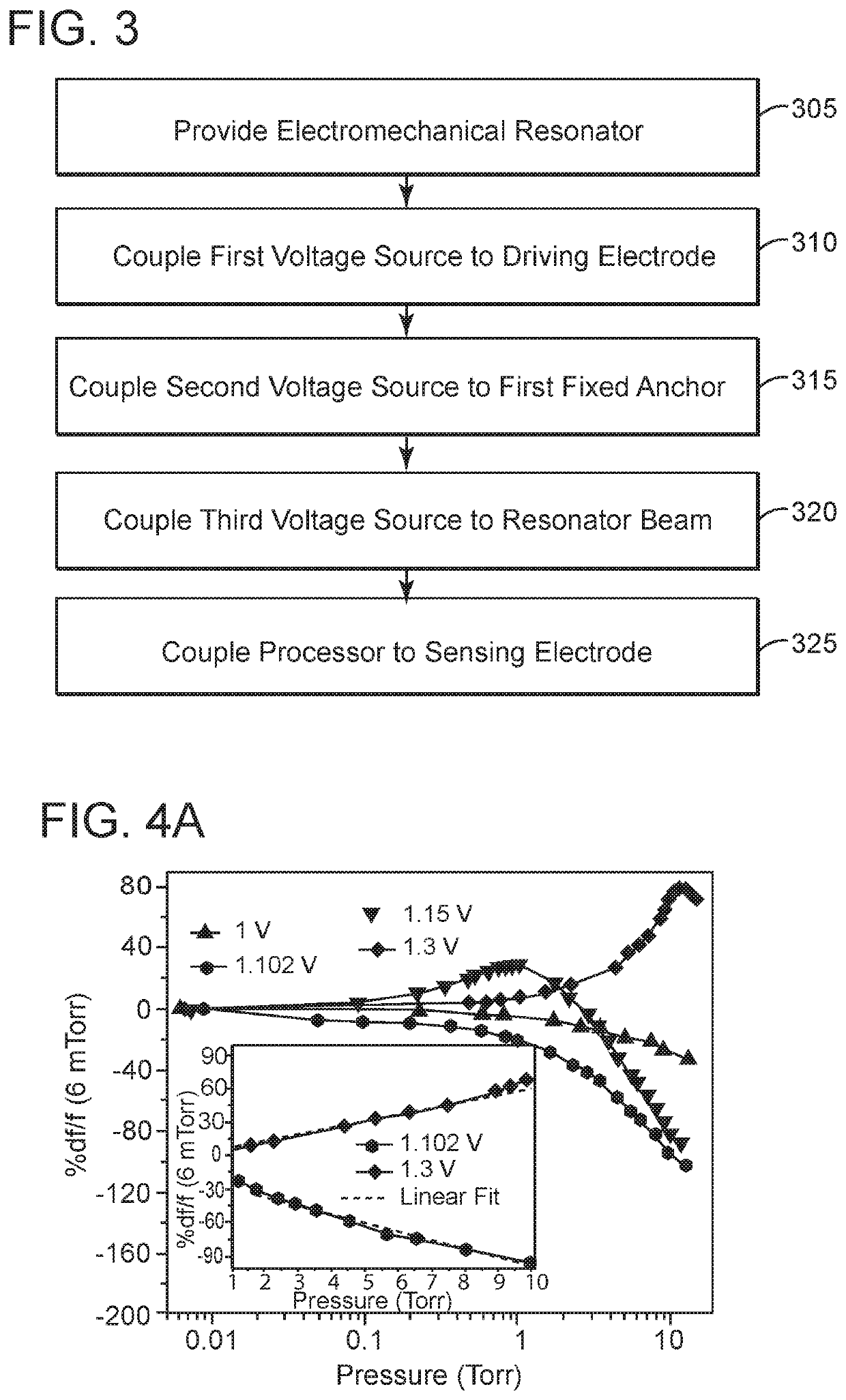

ActiveUS11274983B2Fluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationAC - Alternating currentVoltage source

An electromechanical pressure sensor includes an electromechanical resonator having a driving electrode, a sensing electrode, and a beam resonator arranged between the driving and sensing electrodes. The beam resonator includes a resonator beam coupled on a first end to a first fixed anchor and coupled on a second end to a fixed second fixed anchor. The electromechanical resonator also includes a first voltage source coupled to the driving electrode and configured to provide an alternating current to the driving electrode and a second voltage source coupled to the first fixed anchor. The second voltage source provides a DC bias to the resonator beam. The electromechanical resonator further includes a third voltage source coupled to the resonator beam via the first and second fixed anchors. The third voltage source is configured to supply a voltage to the resonator beam that results in a temperature differential between the resonator beam and the first and second fixed anchors. The electromechanical resonator also includes a processor coupled to the sensing electrode and configured to correlate a voltage on the sensing electrode with a pressure value.

Owner:KING ABDULLAH UNIV OF SCI & TECH

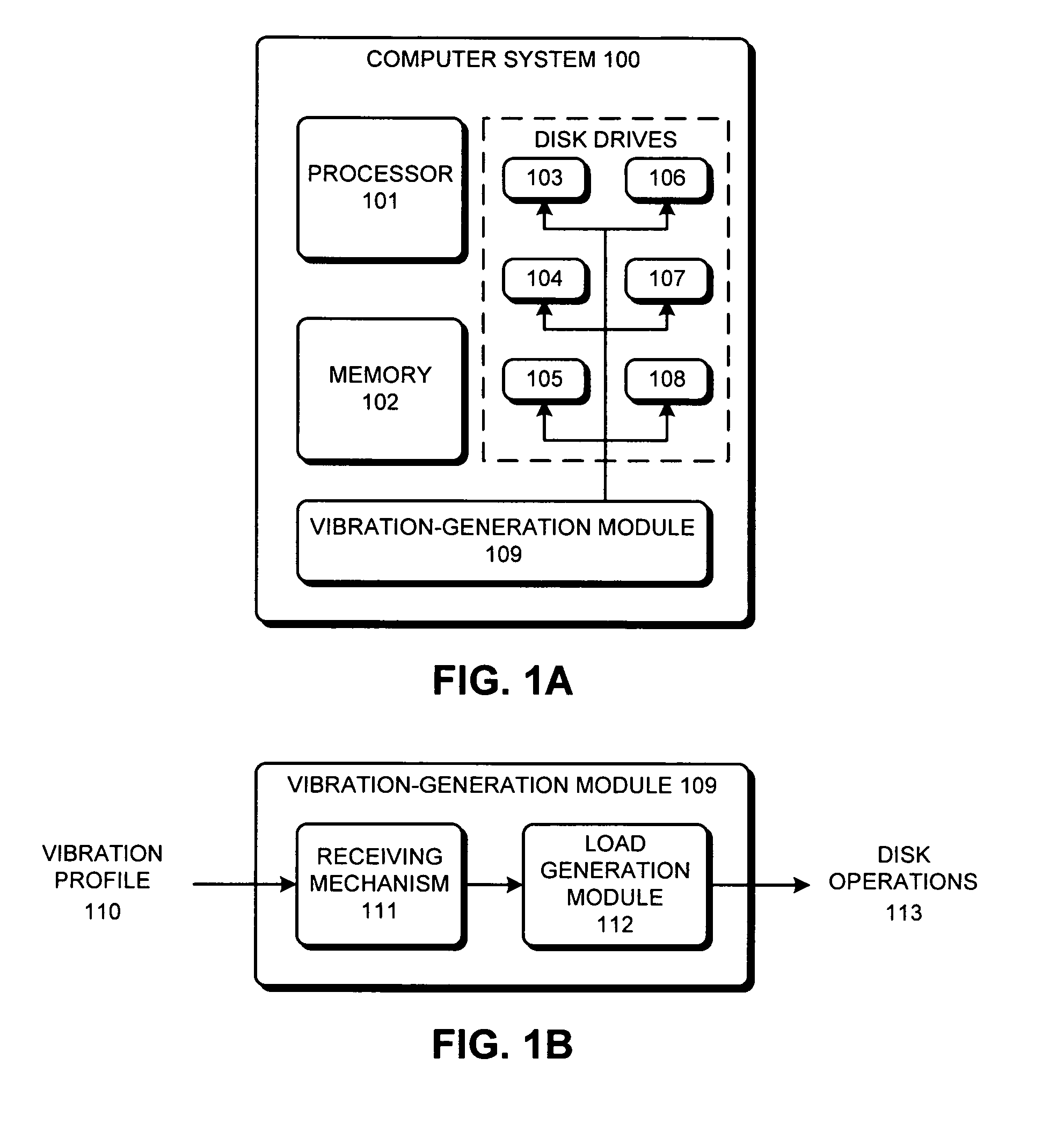

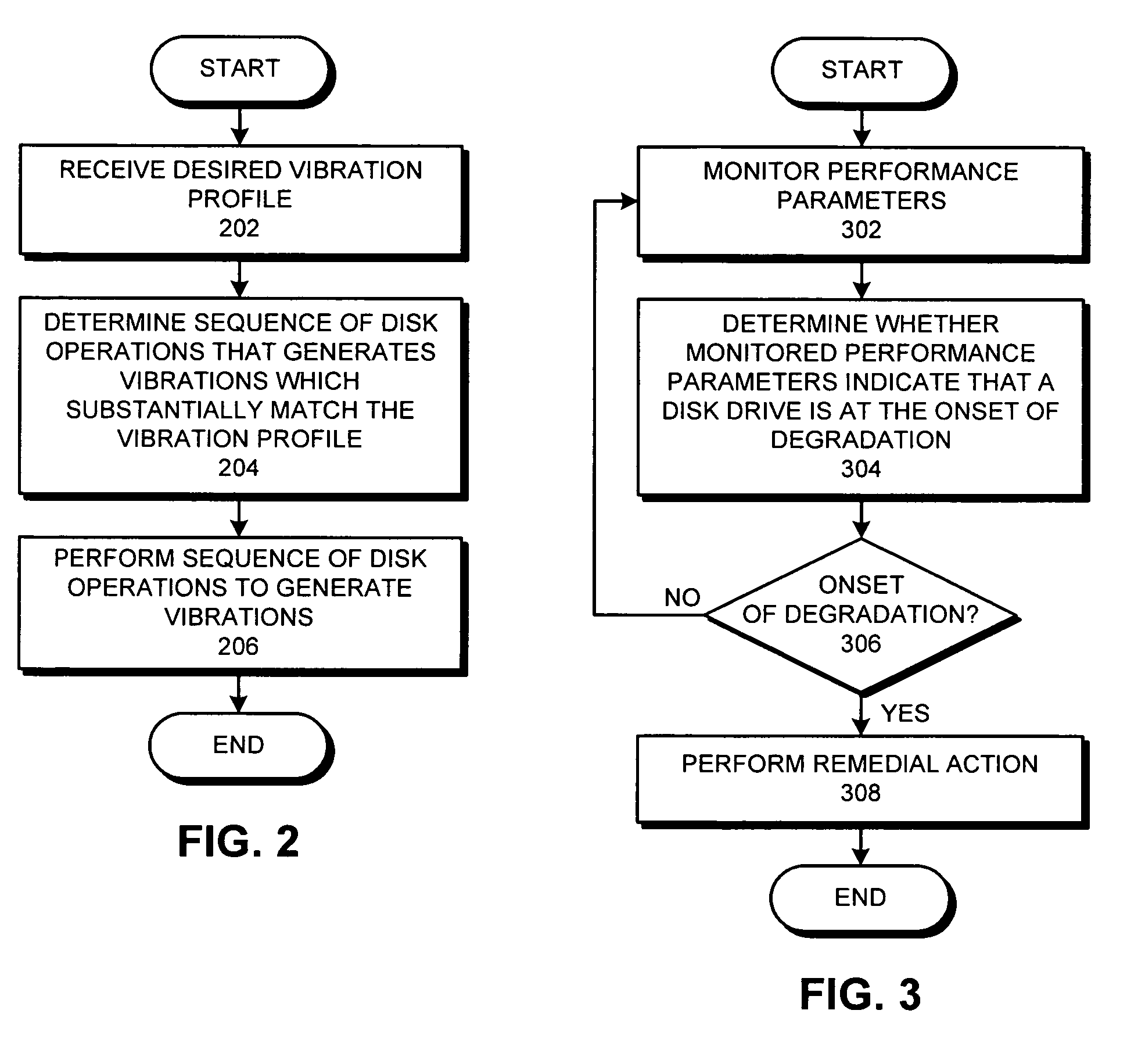

Method and apparatus for facilitating in-situ vibration testing of disk drives

A system that generates vibrations within a computer system. During operation, the system receives a desired vibration profile. Next, the system determines a sequence of disk operations for one or more disk drives within the computer system that generates vibrations which substantially matches the desired vibration profile. The system then performs the sequence of disk operations on the one or more disk drives to generate the vibrations.

Owner:ORACLE INT CORP

Vacuum monitor

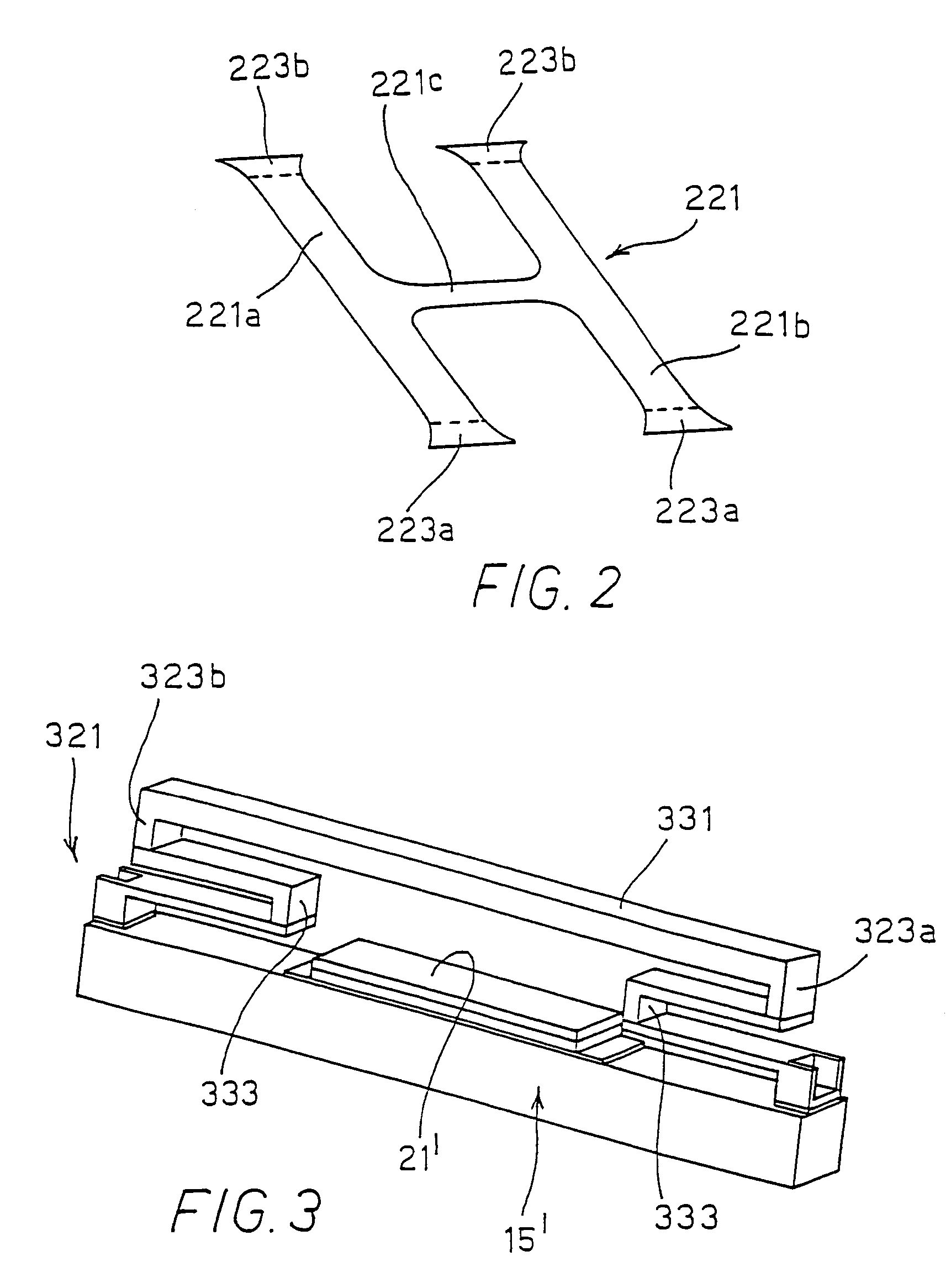

InactiveUS20190162618A1Reduce frequencySimple preparation processVacuum gauge using ionisation effectsVacuum gauge using heat conductivity variationEngineeringAtmosphere

In order to provide a vacuum monitor that, even if a sensing mechanism is exposed to an atmosphere into which various types of material gases are introduced, enables the deposition of matter on the sensing mechanism to be prevented, and enables the lifespan of the sensing mechanism to be extended, there are provided a sensing mechanism that is in contact with an atmosphere inside a measurement space, and outputs an output signal that corresponds to a pressure inside this measurement space, and a heater that adjusts a temperature of the sensing mechanism, wherein a set temperature of the heater is adjustable.

Owner:HORIBA STEC CO LTD

Resonator measurement device and method employing the device

ActiveUS7798005B2Broaden their knowledgeVibration measurement in solidsAcceleration measurement using interia forcesMeasurement deviceCondensed matter physics

The invention relates to a device and a method for detecting a fault in a measurement device comprising a resonator and means for measuring a resonant frequency of the resonator. According to the invention, the device further includes means delivering information (S3) representative of the quality factor of the resonator (3) at the resonant frequency.

Owner:THALES SA

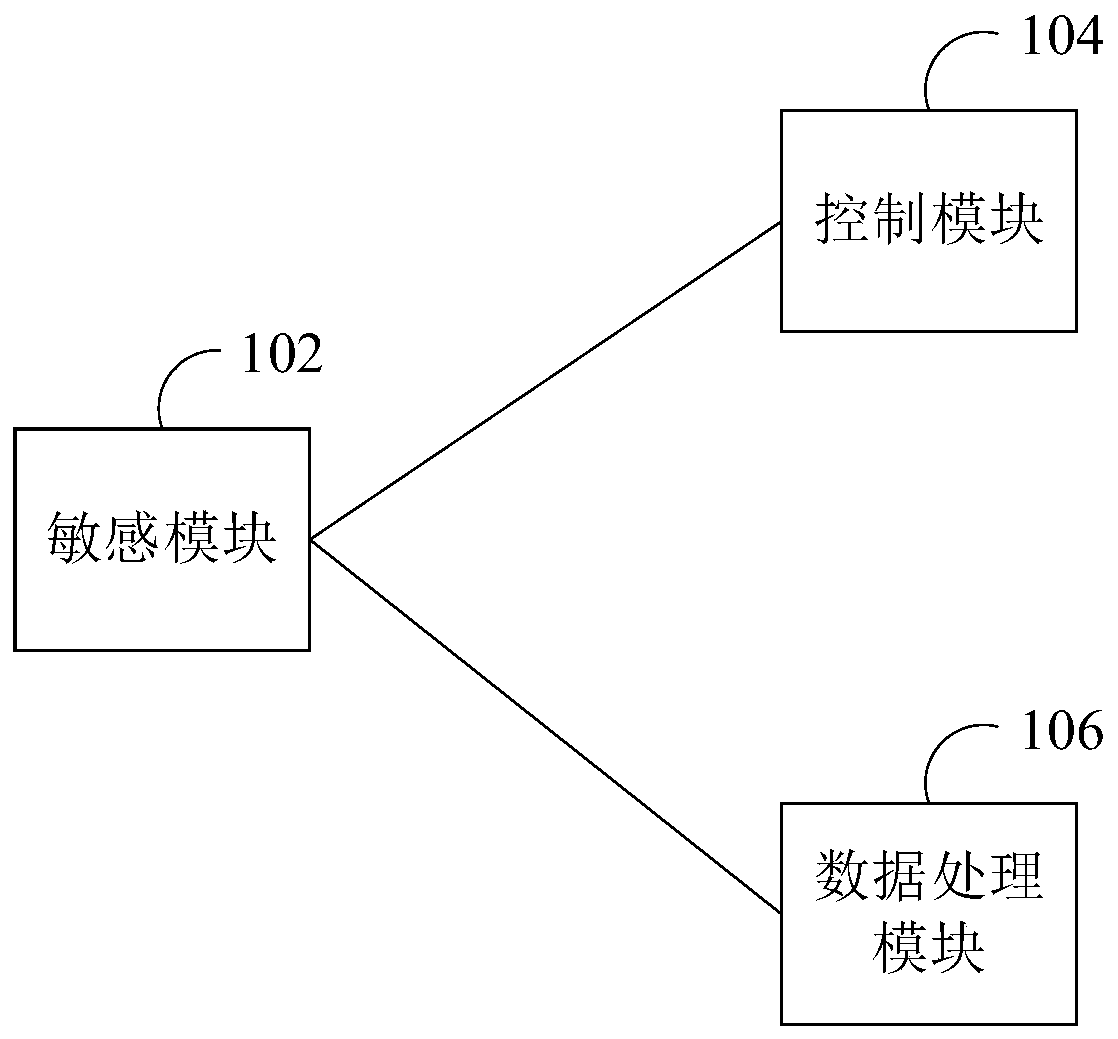

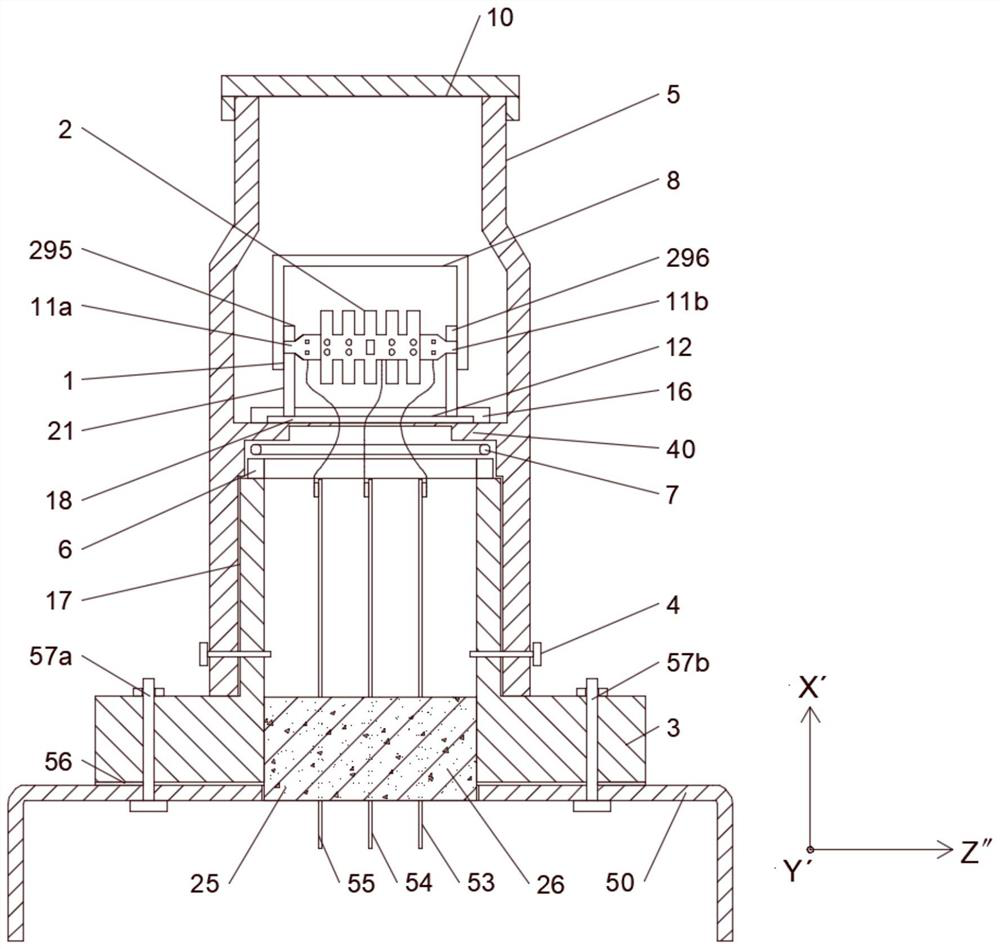

Full-measuring-range vacuum gauge and testing method thereof

PendingCN111595511AHigh precisionVacuum gauge using gaseous frictional resistance variationControl engineeringClassical mechanics

The invention relates to a full-measuring-range vacuum gauge and a testing method thereof. The full-measuring-range vacuum gauge comprises a sensitive module, a control module and a data processing module, wherein the sensitive module comprises a plurality of sensitive units with different sizes. Under the driving of different test modal output by the control module, a frequency response method and a frequency drift method are respectively used for measuring test intervals of low vacuum and medium vacuum by utilizing the sensitive units; the plurality of sensitive units with different sizes are utilized, and an attenuation method and a PID control method are adopted to measure a high-vacuum test interval; and the data processing module continuously collects output parameters of the sensitive units in different test modal, and an actual pressure value of a test environment is calculated according to the output parameters. By adopting the testing method, full-measuring-range measurementof the vacuum degree can be realized.

Owner:NAT UNIV OF DEFENSE TECH +1

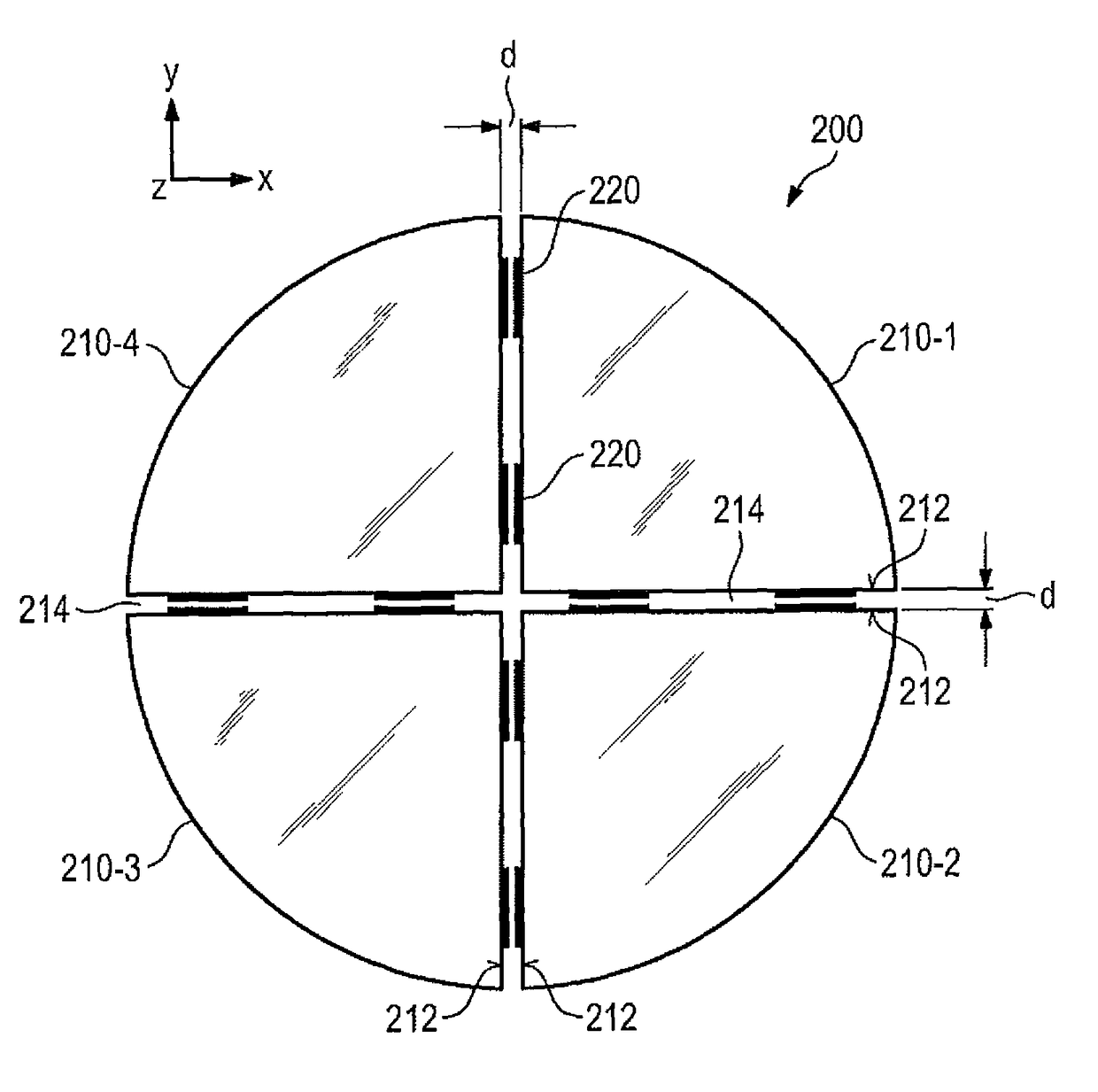

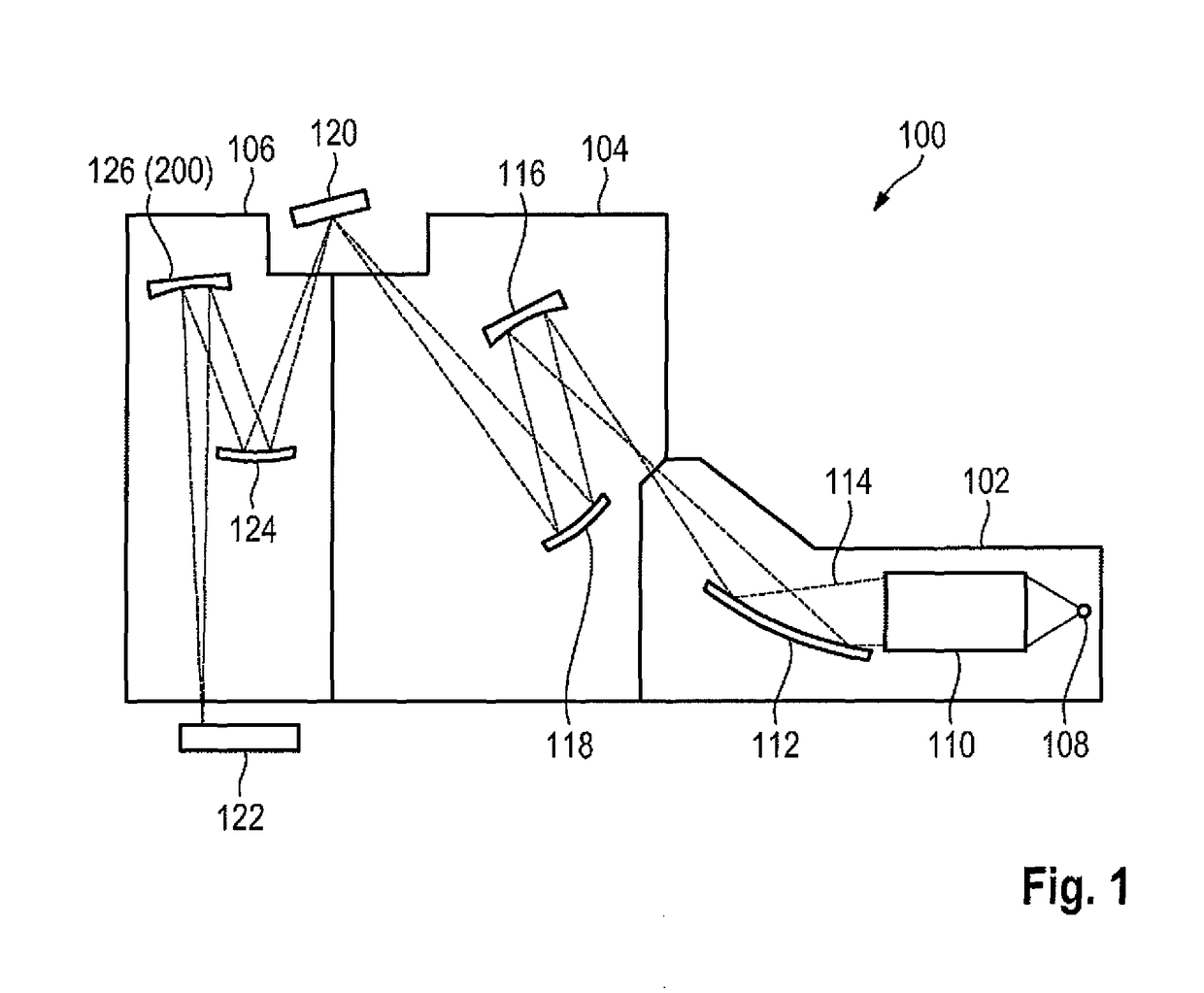

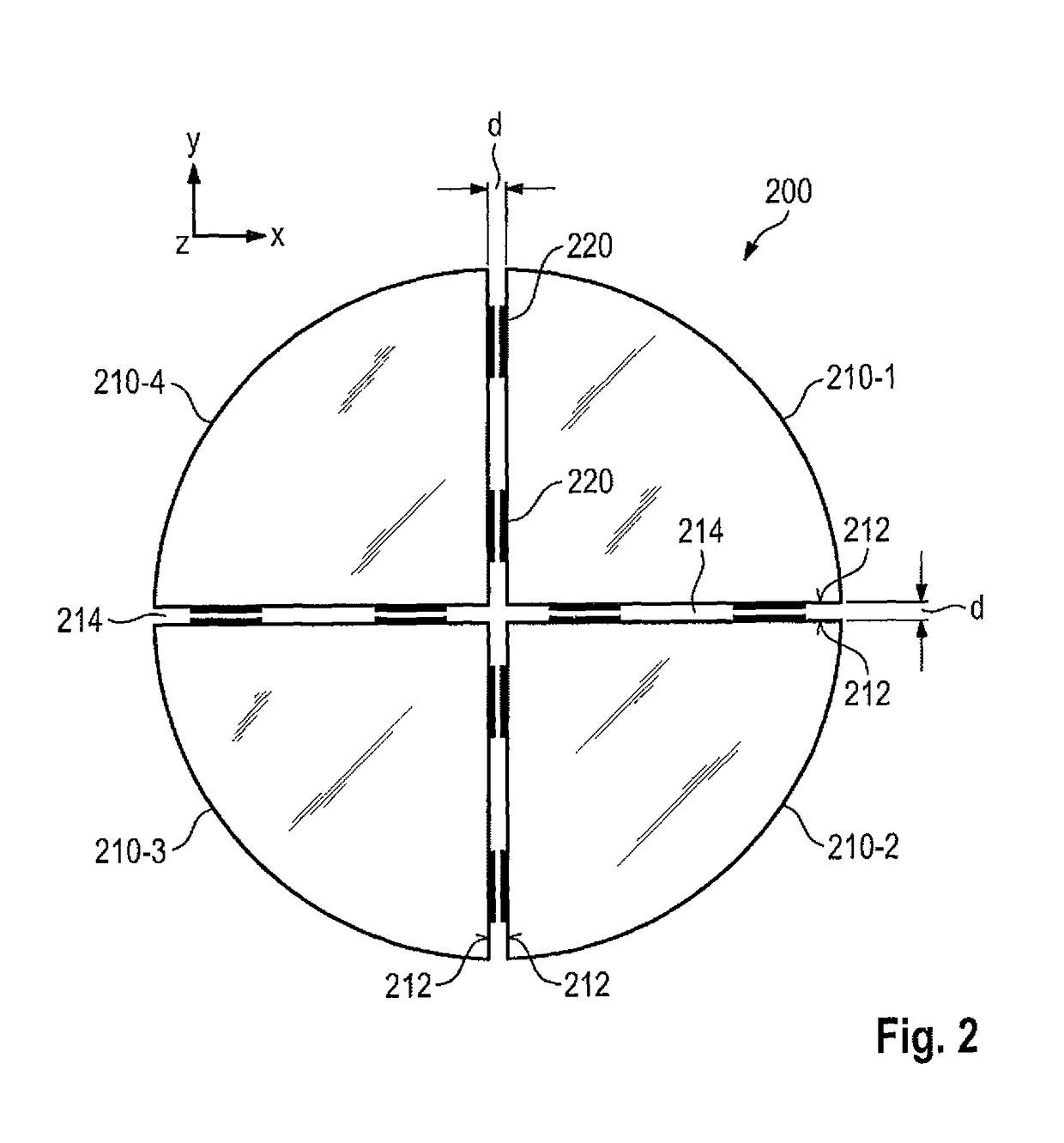

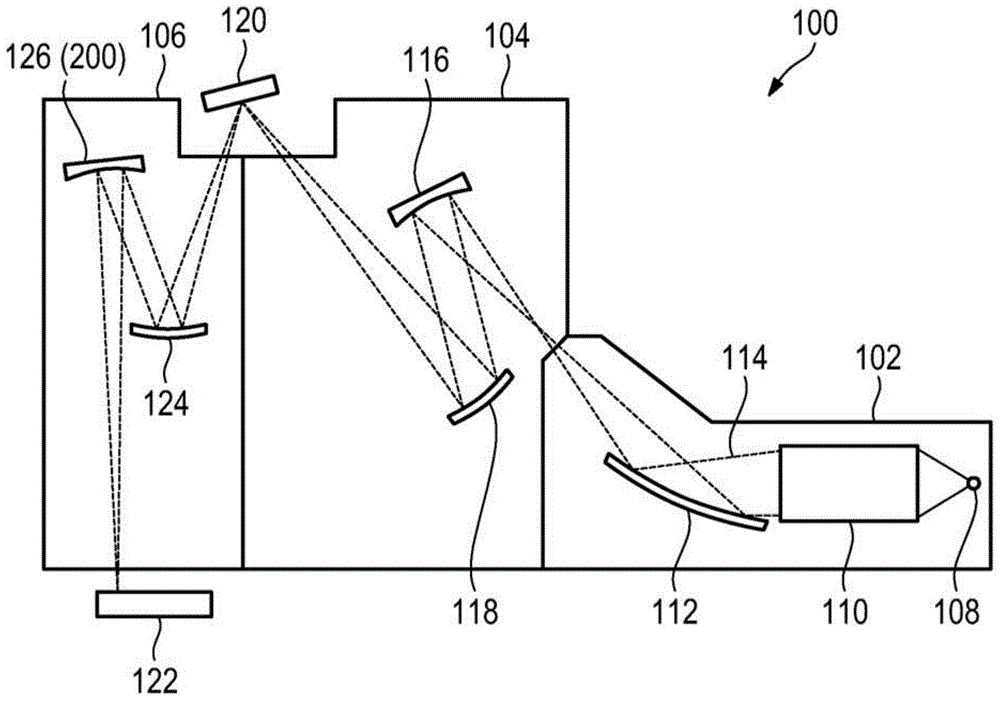

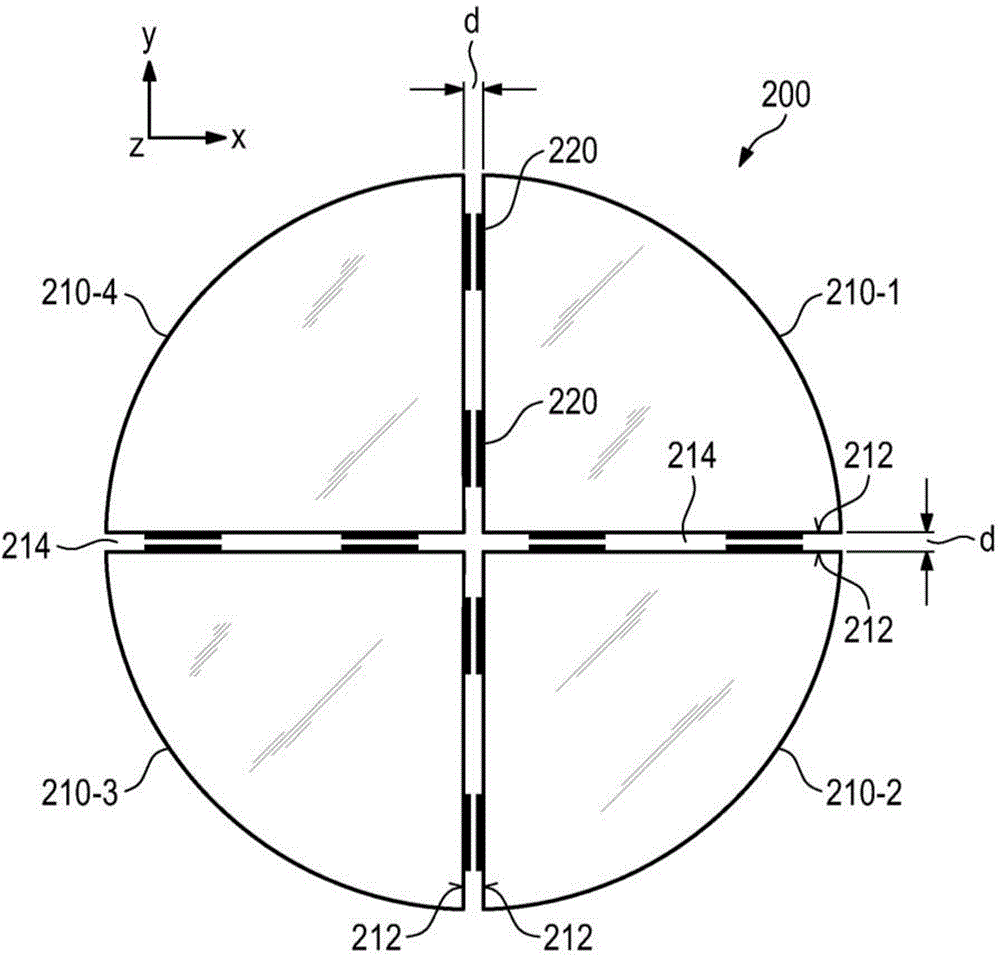

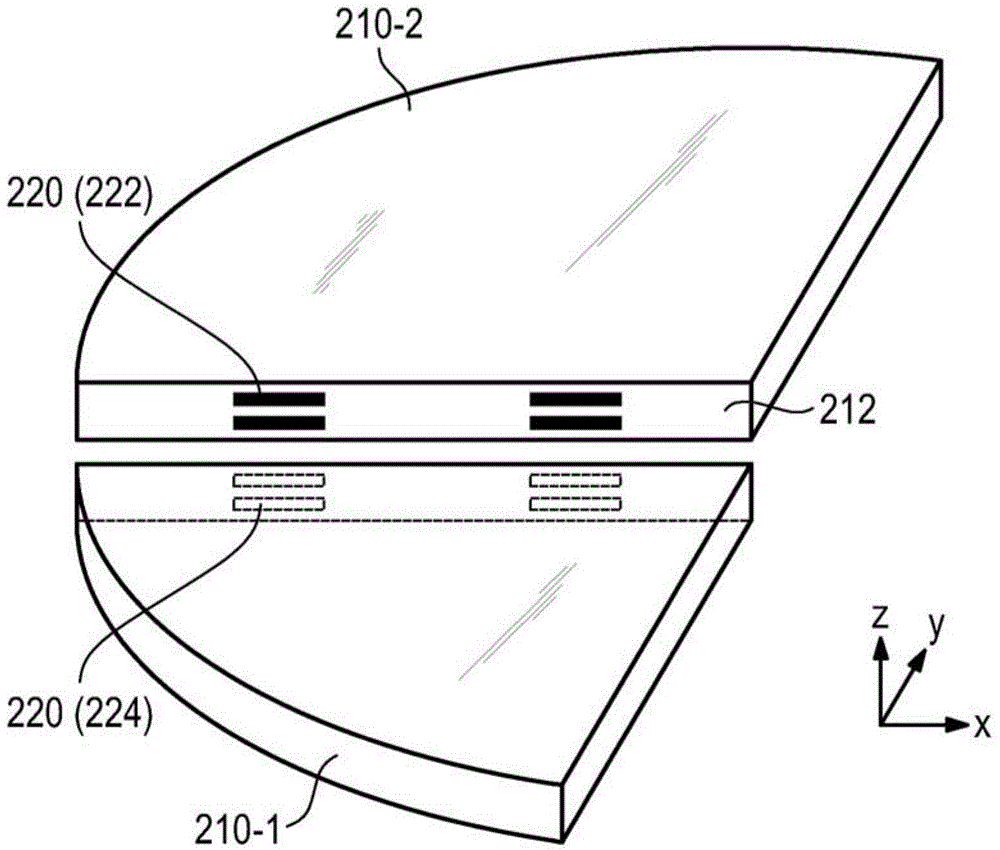

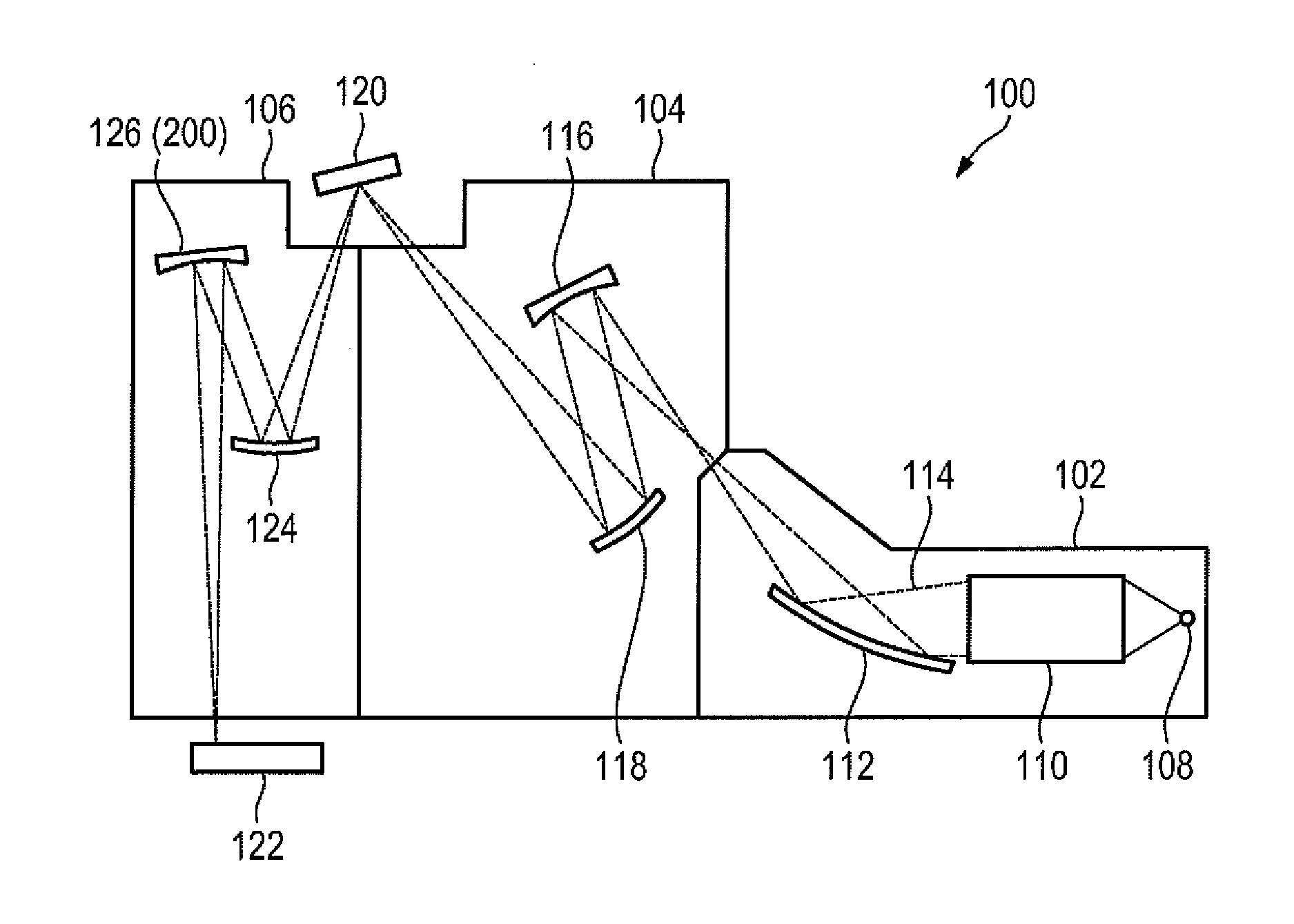

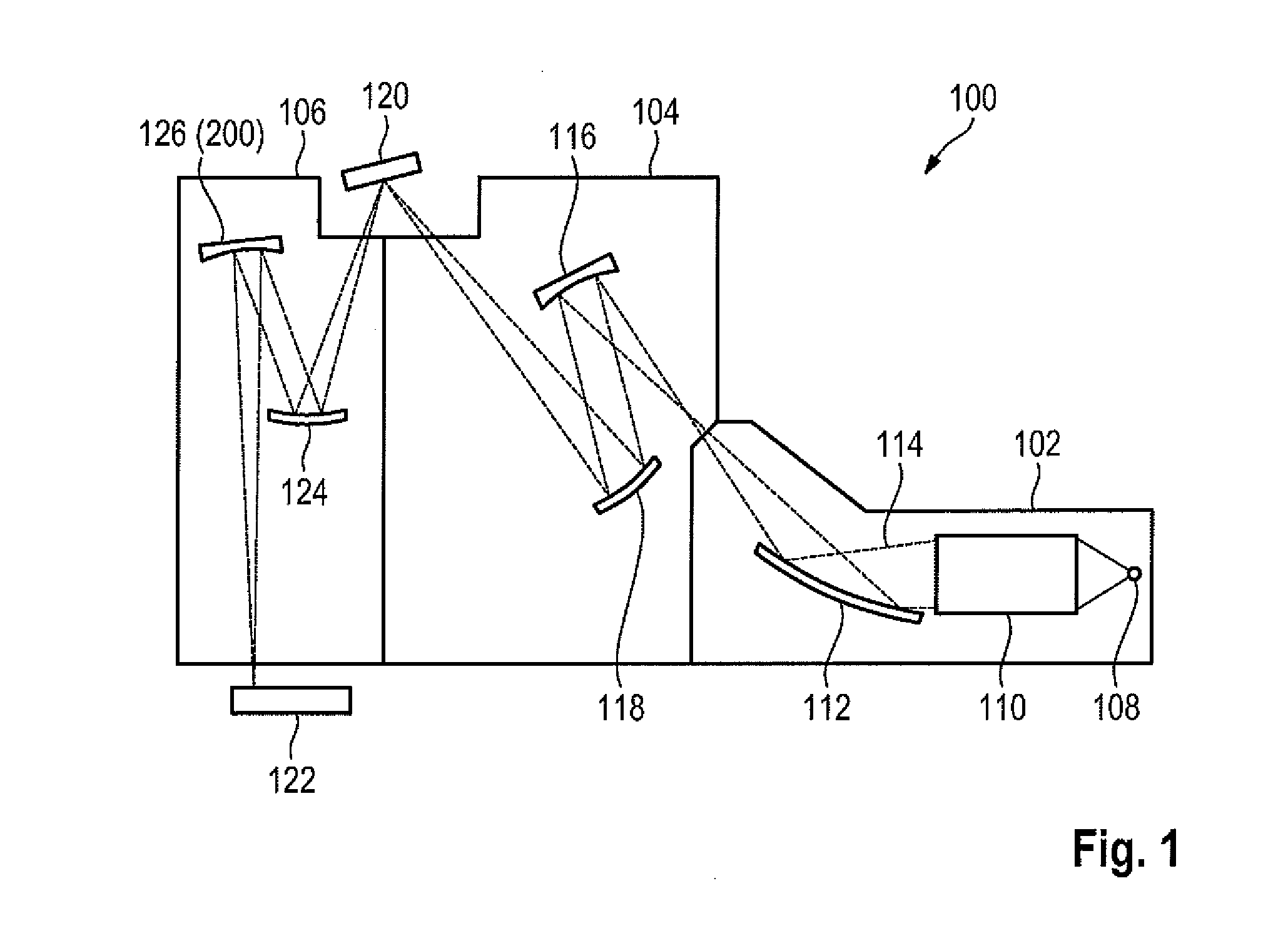

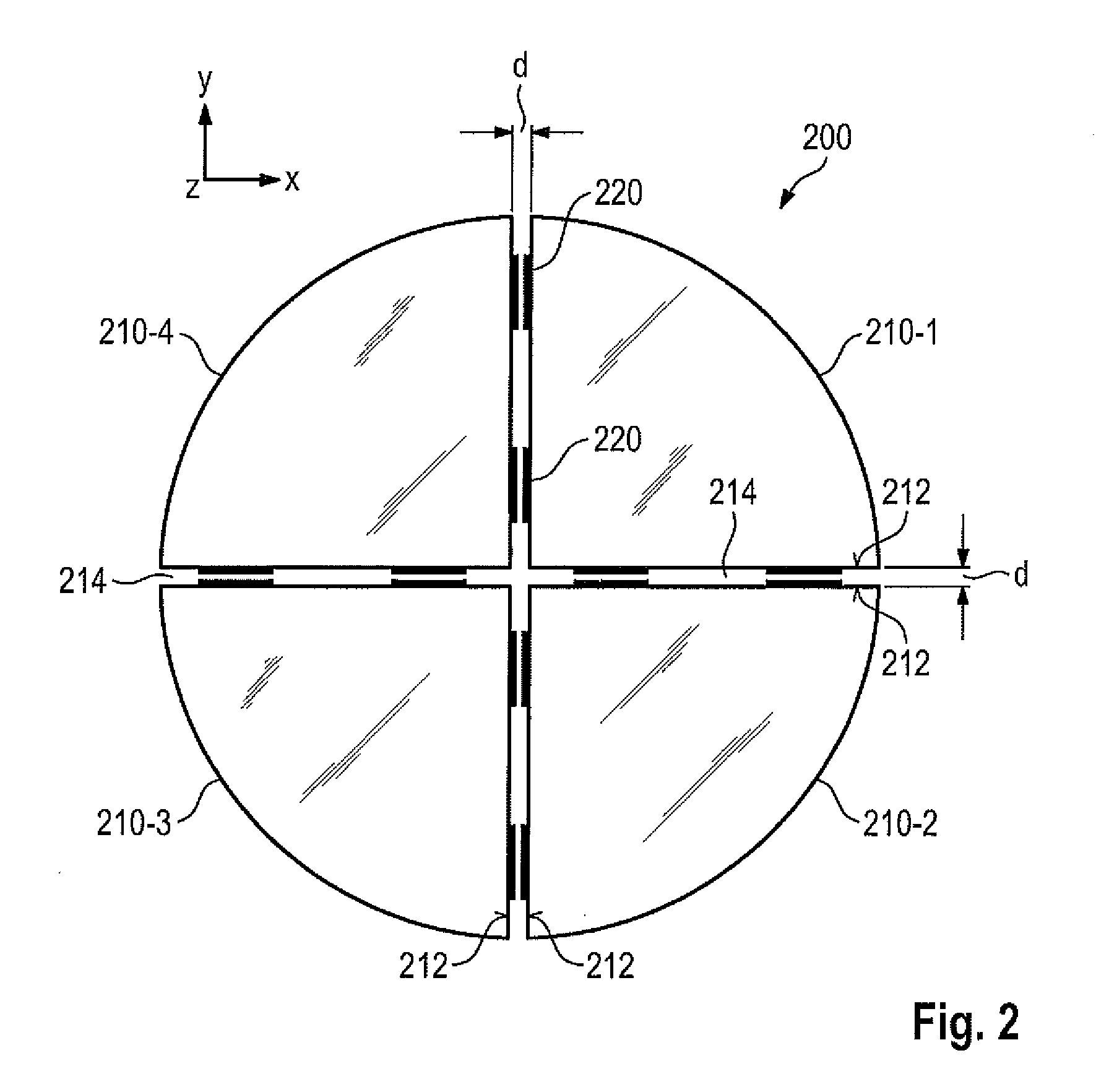

Lithography apparatus with segmented mirror

ActiveUS9846375B2Improve linearityVacuum gauge using gaseous frictional resistance variationUsing electrical meansLithographic artistPhotolithography

A lithography apparatus is disclosed, which comprises a mirror having at least two mirror segments which are joined together in such a way that an interspace is formed between the mirror segments, and a sensor for detecting the relative position of the mirror segments, wherein the sensor is arranged in the interspace between the mirror segments.

Owner:CARL ZEISS SMT GMBH

Lithography apparatus with segmented mirror

ActiveCN104428647APrecise position adjustmentSave spaceVacuum gauge using gaseous frictional resistance variationUsing electrical meansLithographic artistSegmented mirror

A lithography apparatus is disclosed, which comprises a mirror having at least two mirror segments which are joined together in such a way that an interspace is formed between the mirror segments, and a sensor for detecting the relative position of the mirror segments, wherein the sensor is arranged in the interspace between the mirror segments.

Owner:CARL ZEISS SMT GMBH

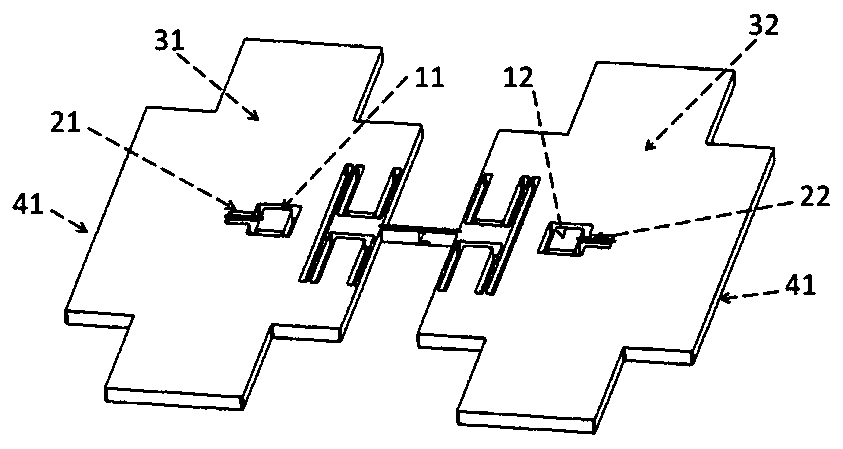

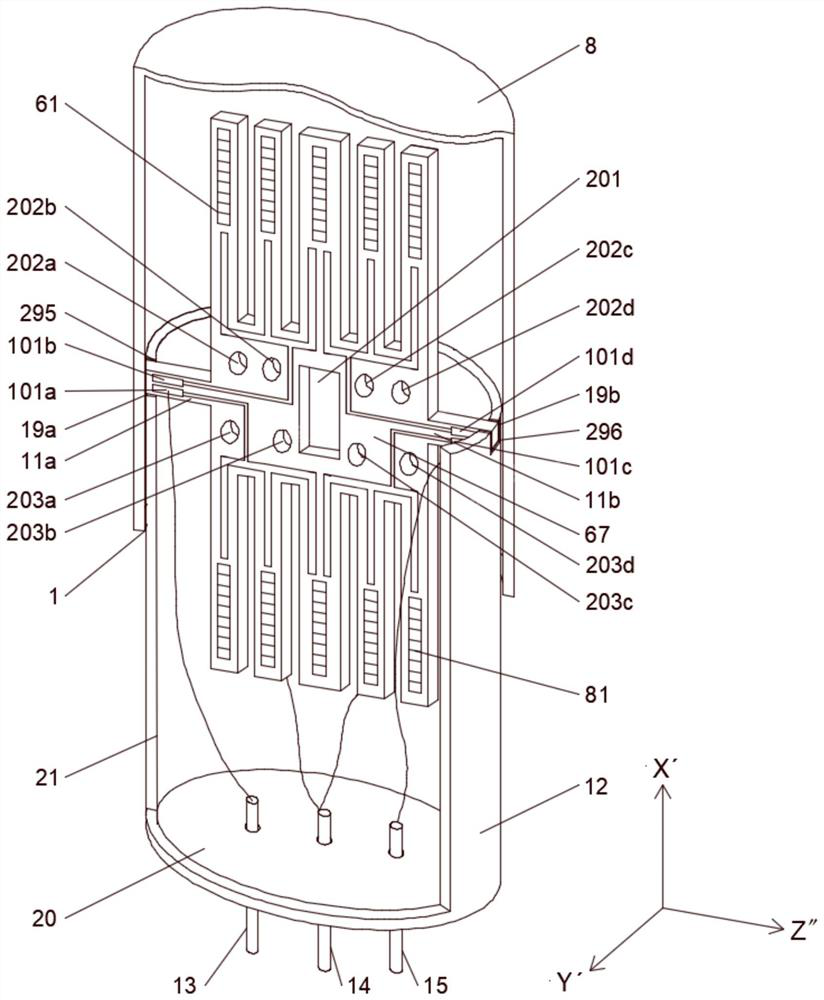

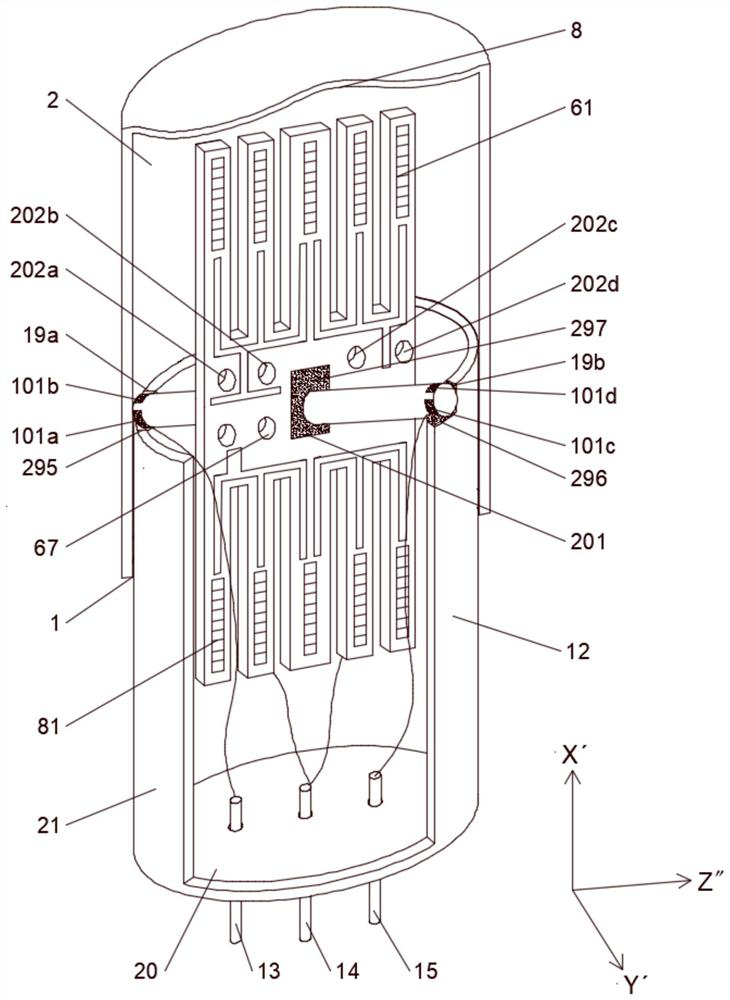

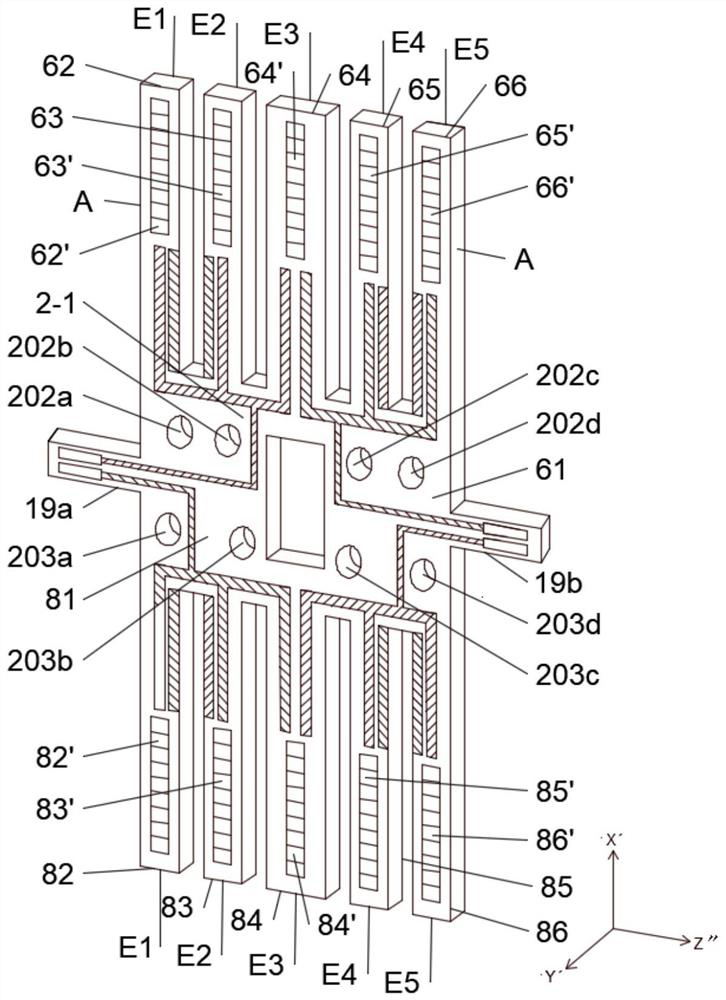

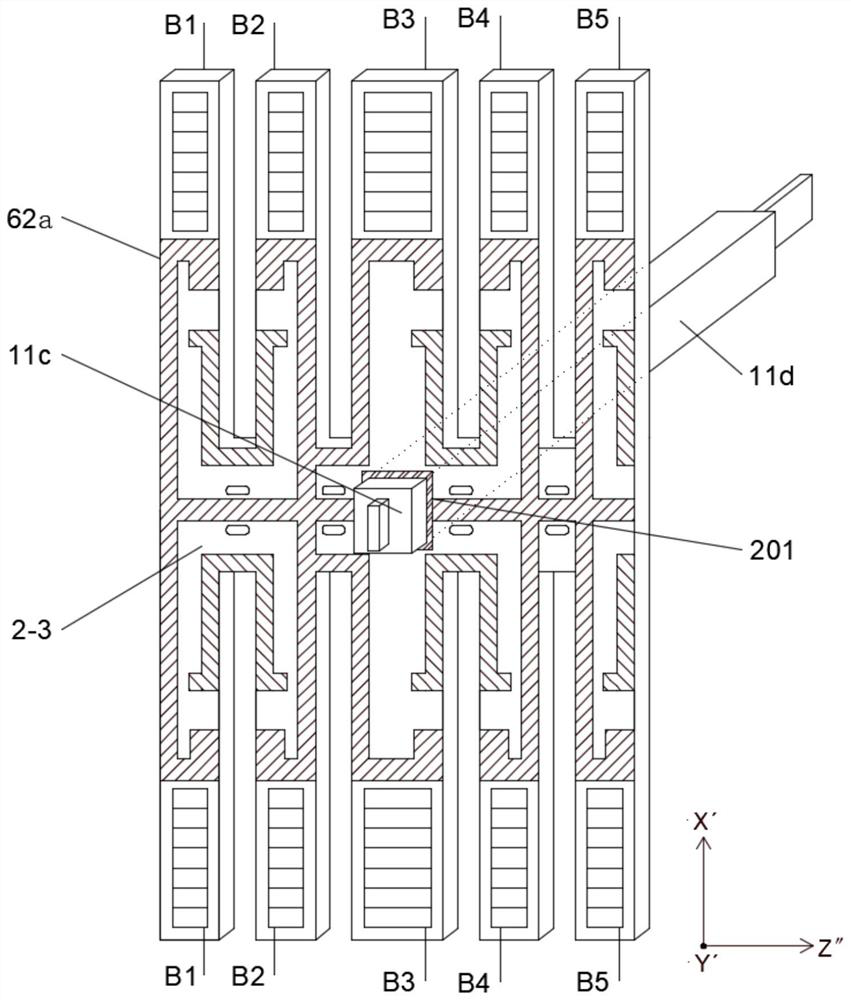

Surface bending mode double-coupled monolithic high-sensitivity quartz tuning fork vacuum sensor

PendingCN114112184AIncreased center of massLess stringent requirementsVacuum gauge using gaseous frictional resistance variationFiberGraphite

The invention relates to the technical field of quartz vacuum sensors, and discloses a surface bending mode double-coupled monolithic high-sensitivity quartz tuning fork vacuum sensor. The vacuum sensor comprises a single-piece type double-open-end multi-fork-arm quartz tuning fork vacuum sensitive resonator of a surface bending mode, a kovar alloy base, a vacuum sensor shell, an envelope-shaped inserting plate type fixing structure, a polytetrafluoroethylene-expanded graphite combined water-repellent sealing gasket, a ceramic fiber waterproof sealing ring and an anti-pollution and mildew-proof filtering cover, wherein the number n of fork arms of the quartz tuning fork vacuum sensitive resonator is larger than or equal to 3; and the dustproof and oil-stain-resistant ceramic filter cap can be self-recovered and self-purified at the temperature of-180 DEG C to + 350 DEG C. The surface bending mode monolithic double-open-end multi-fork-arm quartz tuning fork vacuum sensitive resonator adopts (yxtl)-24 degrees to-50 degrees / 5 degrees to 15 degrees cut-type double-rotation-angle quartz crystals, a fundamental wave-surface bending vibration mode is adopted, friction with residual gas in vacuum and mass loading are increased by increasing the arm width and carrying out Hamming weighting on the area of each fork arm electrode, and the surface bending mode of the single-sheet double-open-end multi-fork-arm quartz tuning fork vacuum sensitive resonator is obtained. The variable quantity of dynamic resistance is improved, and the vacuum sensitivity and stability are improved.

Owner:常州奇军苑电子科技有限公司

Electromechanical pressure sensor

ActiveUS20210140841A1Fluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationAC - Alternating currentEngineering

An electromechanical pressure sensor includes an electromechanical resonator having a driving electrode, a sensing electrode, and a beam resonator arranged between the driving and sensing electrodes. The beam resonator includes a resonator beam coupled on a first end to a first fixed anchor and coupled on a second end to a fixed second fixed anchor. The electromechanical resonator also includes a first voltage source coupled to the driving electrode and configured to provide an alternating current to the driving electrode and a second voltage source coupled to the first fixed anchor. The second voltage source provides a DC bias to the resonator beam. The electromechanical resonator further includes a third voltage source coupled to the resonator beam via the first and second fixed anchors. The third voltage source is configured to supply a voltage to the resonator beam that results in a temperature differential between the resonator beam and the first and second fixed anchors. The electromechanical resonator also includes a processor coupled to the sensing electrode and configured to correlate a voltage on the sensing electrode with a pressure value.

Owner:KING ABDULLAH UNIV OF SCI & TECH

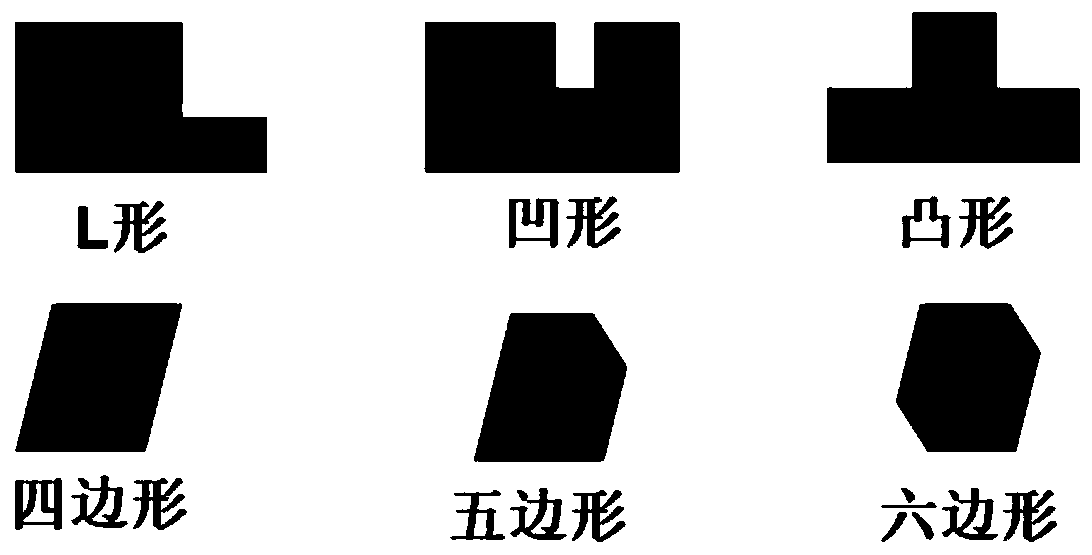

Monolithic surface bending mode double-coupling five-fork-arm quartz tuning fork vacuum sensitive resonator

PendingCN114421921ABoost energy trapHigh Q valueImpedence networksVacuum gauge using gaseous frictional resistance variationEngineeringMaterials science

The invention relates to the technical field of vacuum sensing, and discloses a monolithic surface bending mode double-coupling five-fork-arm quartz tuning fork vacuum sensitive resonator, which is composed of a five-fork-arm surface bending mode quartz tuning fork resonator plate, a quartz vacuum sensitive resonator tube socket and a quartz tuning fork vacuum sensitive resonator anti-pollution moisture-proof filter cap, the five-fork arm surface bending mode quartz tuning fork resonator piece is arranged in a vacuum sensitive resonator packaging part formed by the quartz vacuum sensitive resonator tube socket and the quartz tuning fork vacuum sensitive resonator anti-pollution moisture-proof filter cap; the (yxtl)-24 degrees to-50 degrees / 5 degrees to 15 degrees cut quartz crystal is suitable for a single-chip double-open-end five-fork-arm quartz tuning fork vacuum sensitive resonator of a surface bending mode and a single-chip double-group open-end and closed-end five-fork-arm quartz tuning fork vacuum sensitive resonator of the surface bending mode. And the temperature stability of the quartz tuning fork resonator is far better than that of the existing single-closed-end quartz tuning fork resonator and double-closed-end quartz tuning fork resonators.

Owner:常州奇军苑电子科技有限公司

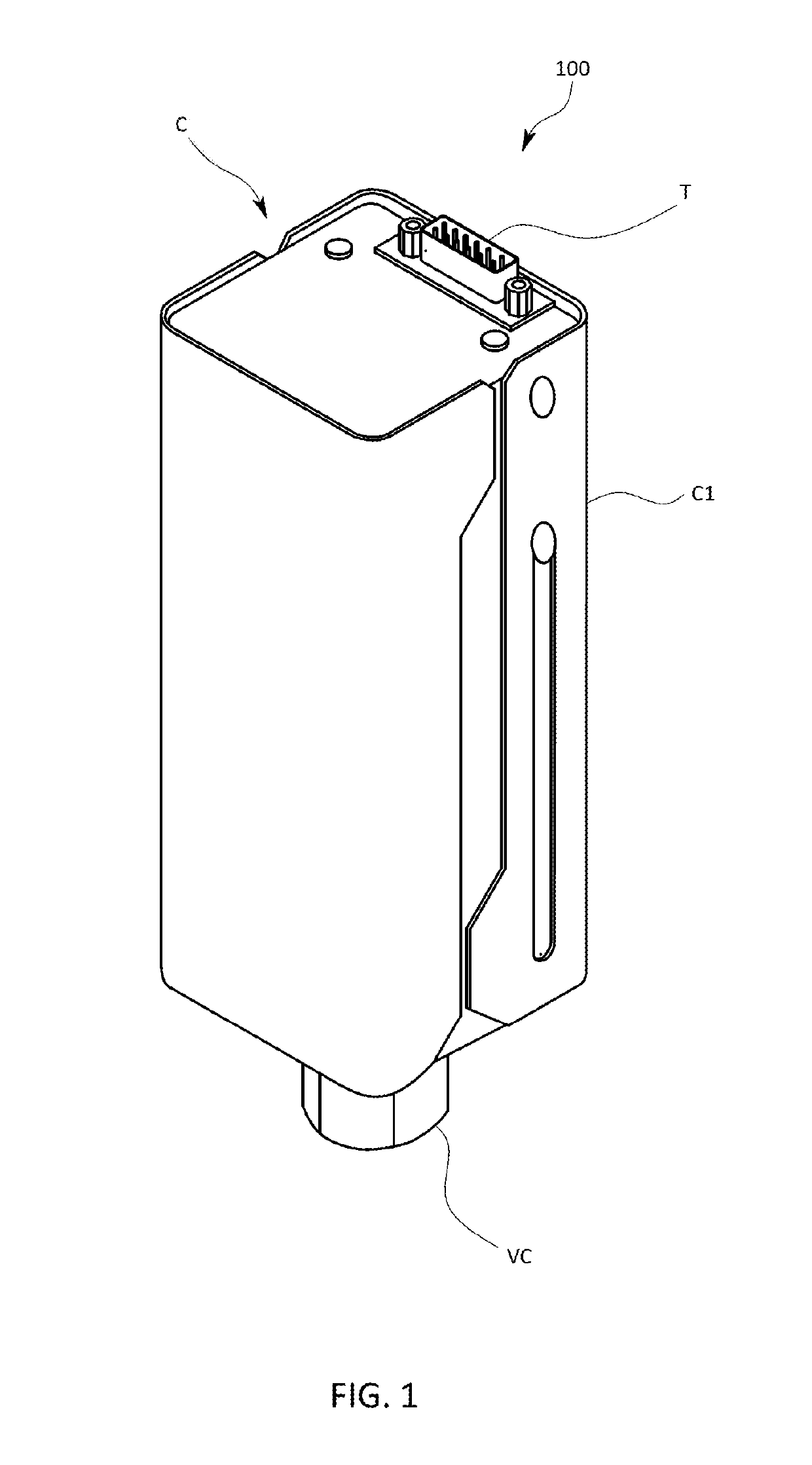

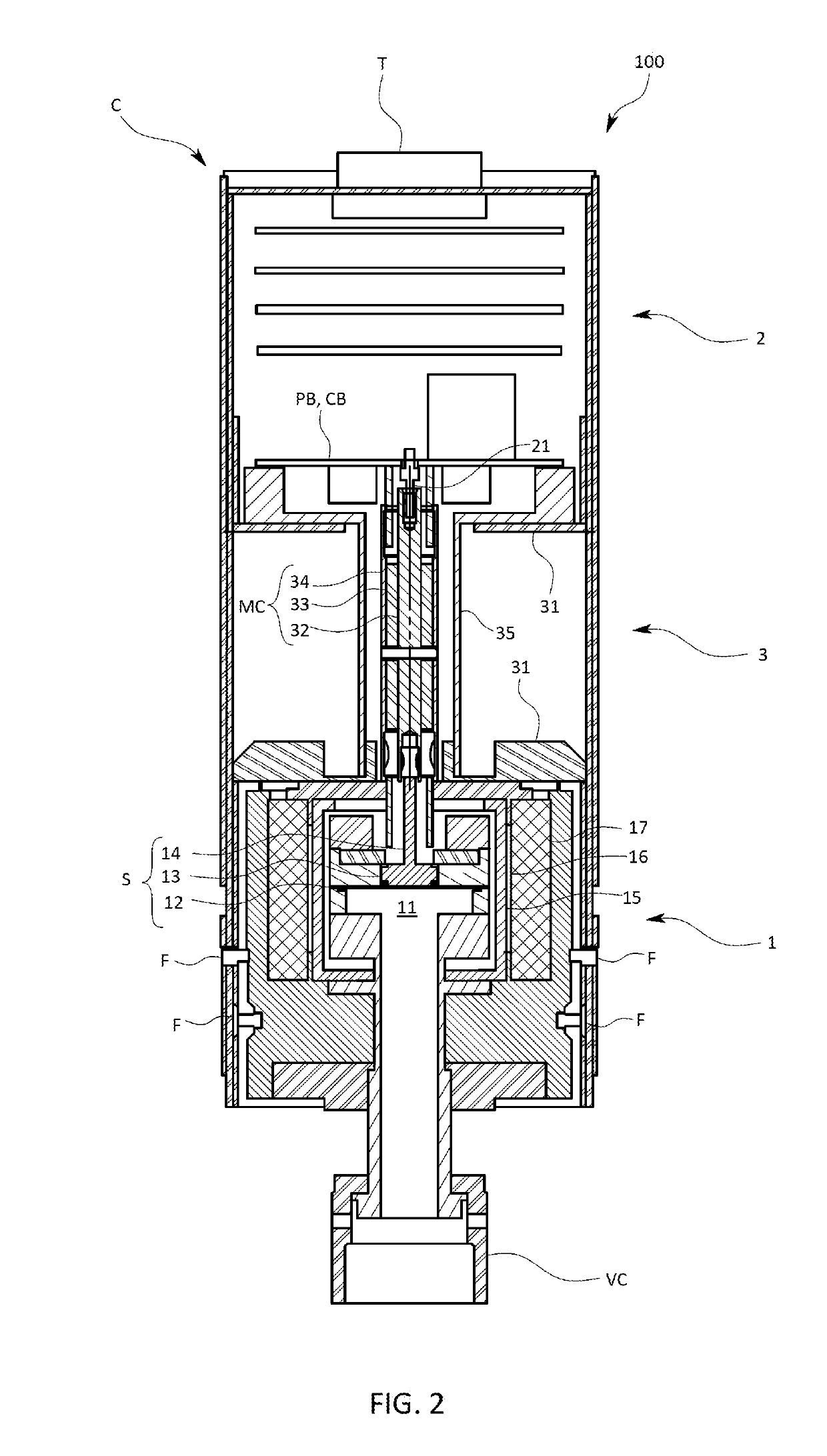

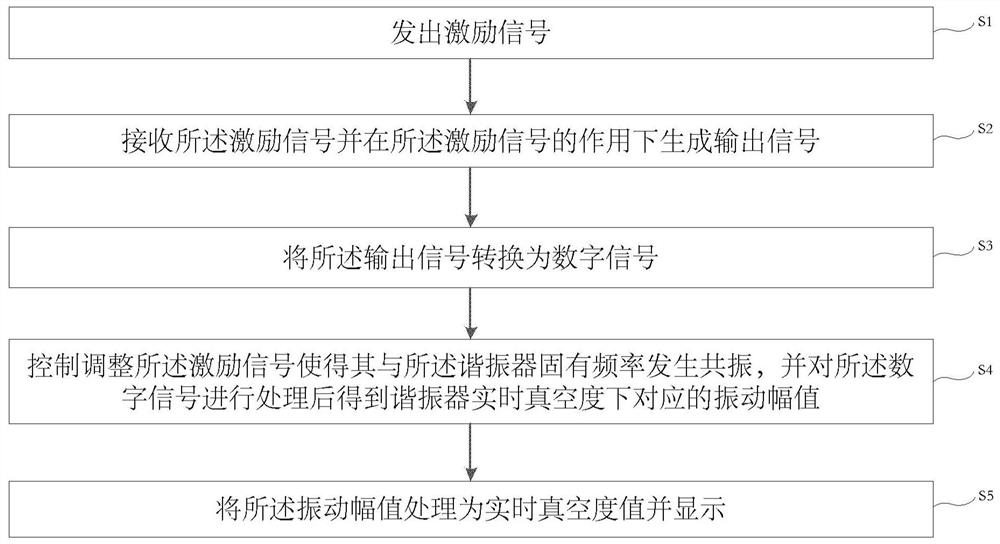

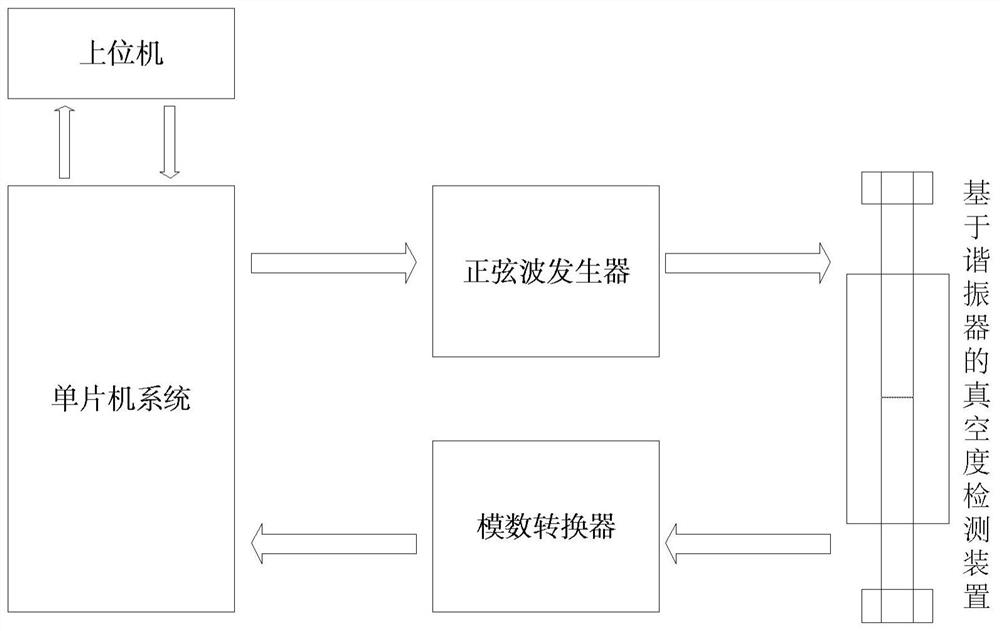

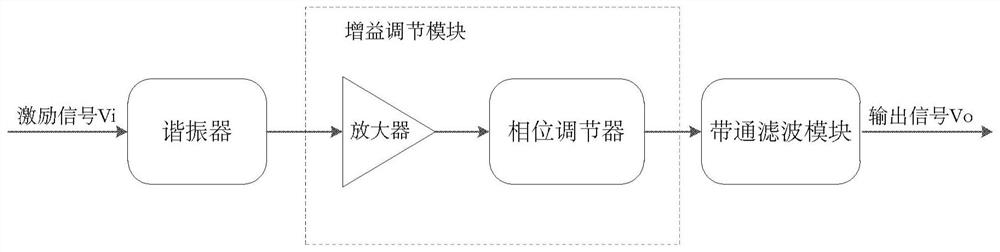

Resonator-based vacuum degree detection method, system and device

PendingCN113008453AAccurate detectionAdjust in timeVacuum gauge using gaseous frictional resistance variationSoftware engineeringExcitation signal

The invention provides a resonator-based vacuum degree detection method. The resonator-based vacuum degree detection method comprises the following steps: emitting an excitation signal; receiving the excitation signal and generating an output signal under the action of the excitation signal; converting the output signal into a digital signal; controlling and adjusting the excitation signal to enable the excitation signal to resonate with the inherent frequency of the resonator, and processing the digital signal to obtain a vibration amplitude corresponding to the real-time vacuum degree of the resonator; and processing the vibration amplitude into a real-time vacuum degree value and displaying the real-time vacuum degree value. The invention also provides a resonator-based vacuum degree detection system and a resonator-based vacuum degree detection device.

Owner:AEROSPACE INFORMATION RES INST CAS

Lithography apparatus with segmented mirror

ActiveUS20150103327A1Improve linearityVacuum gauge using gaseous frictional resistance variationUsing electrical meansLithographic artistPhotolithography

A lithography apparatus is disclosed, which comprises a mirror having at least two mirror segments which are joined together in such a way that an interspace is formed between the mirror segments, and a sensor for detecting the relative position of the mirror segments, wherein the sensor is arranged in the interspace between the mirror segments.

Owner:CARL ZEISS SMT GMBH

mems capacitive pressure sensor

ActiveCN103308239BFluid pressure measurement using elastically-deformable gaugesVacuum gauge using heat conductivity variationCapacitive pressure sensorCapacitive readout

Pressure sensors measure pressure by measuring the deflection of a MEMS membrane using a capacitive readout method. There are two ways of implementing the invention. One way involves the use of an integrated Pirani sensor and the other way involves the use of an integrated resonator used as a reference pressure sensor for measuring the internal cavity pressure.

Owner:希奥检测有限公司

Pressure Sensor

ActiveCN103630286BFluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationBiomedical engineeringMembrane configuration

The invention relates to a pressure sensor. According to one or more embodiments discussed, an integrated circuit device includes a membrane suspended from a cavity, the membrane and the cavity defining the chamber. The diaphragm has a plurality of openings in it that pass gas into and out of the chamber. When the diaphragm is actuated, the volume of the chamber changes to create a pressure inside the chamber that is different from the pressure outside the chamber. A sensor detects the frequency-based characteristic of the diaphragm in response to volume change and provides an indication of the gas pressure outside the chamber.

Owner:希奥检测有限公司

Popular searches

Pressure difference measurement between multiple valves Multiple fluid pressure valves simultaneous measurement Fluid pressure measurement using capacitance variation Piezoelectric/electrostrictive devices Flexible microstructural devices Fluid pressure measurement by acoustic means Fluid speed measurement using pressure difference Resonant frequency Material analysis by optical means Thermometers using physical/chemical changes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com