Pressure gauge

A technology of pressure and pressure sense, which is applied in the field of pressure gauges to achieve the effects of high-efficiency manufacturing, low heating noise, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

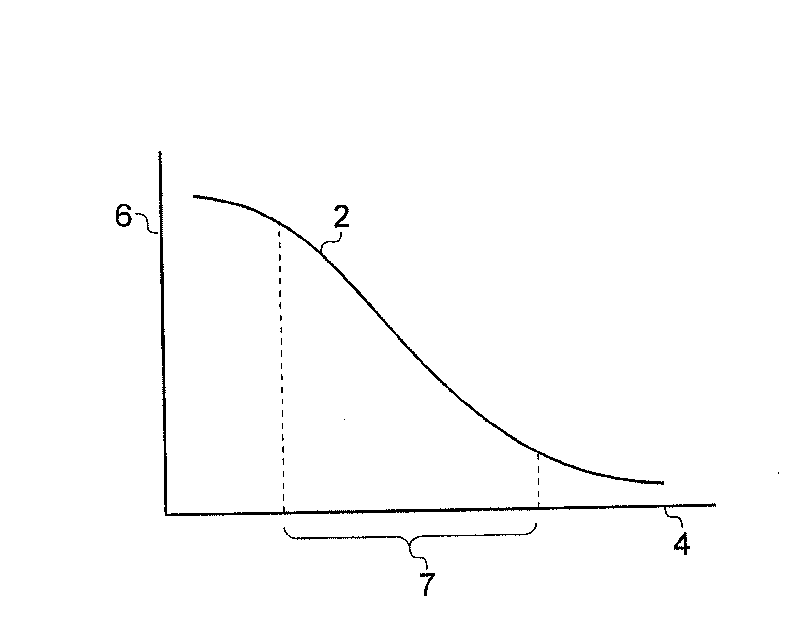

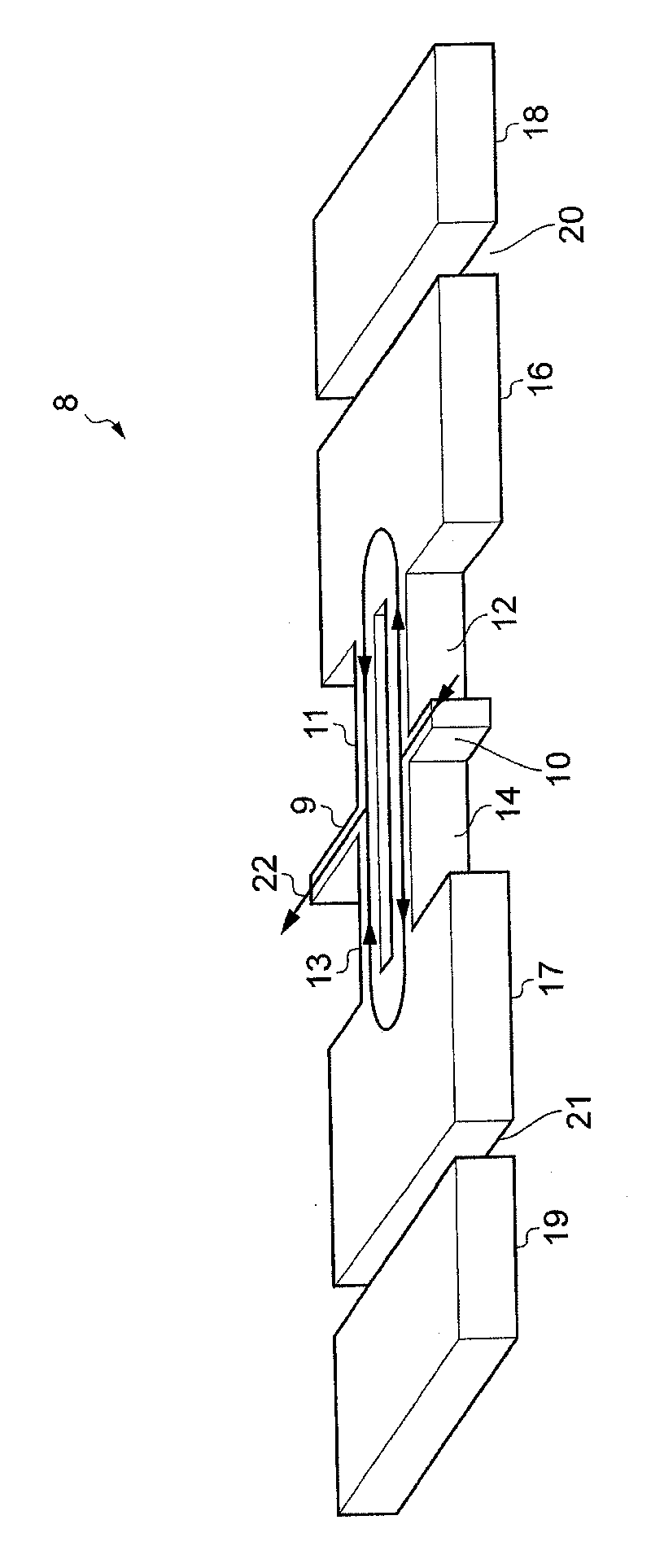

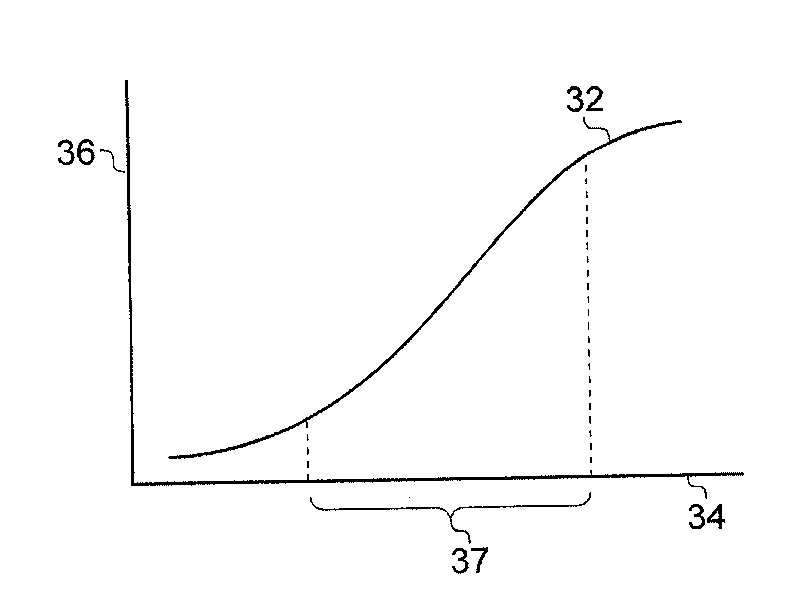

[0047] Certain aspects of the principles employed in the Pirani gauge will first be described, which will assist in understanding the embodiments of the invention which will be described below.

[0048] The general structure of a Pirani gauge consists of a heating element well thermally insulated from the environment (some air space must exist between the element and its environment), and means for sensing the temperature of the heating element. The thermal conductivity k from the heating element to the heat sink (ambient) depends on the air pressure p and can be written as:

[0049] k ( p ) = k solid + k gas ( ∞ ) ( p / p 0 1 + p ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com