Monolithic surface bending mode double-coupling five-fork-arm quartz tuning fork vacuum sensitive resonator

A quartz tuning fork and resonator technology, applied in the field of vacuum sensing, to achieve long service life, strong ability to filter dust, and good heat insulation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

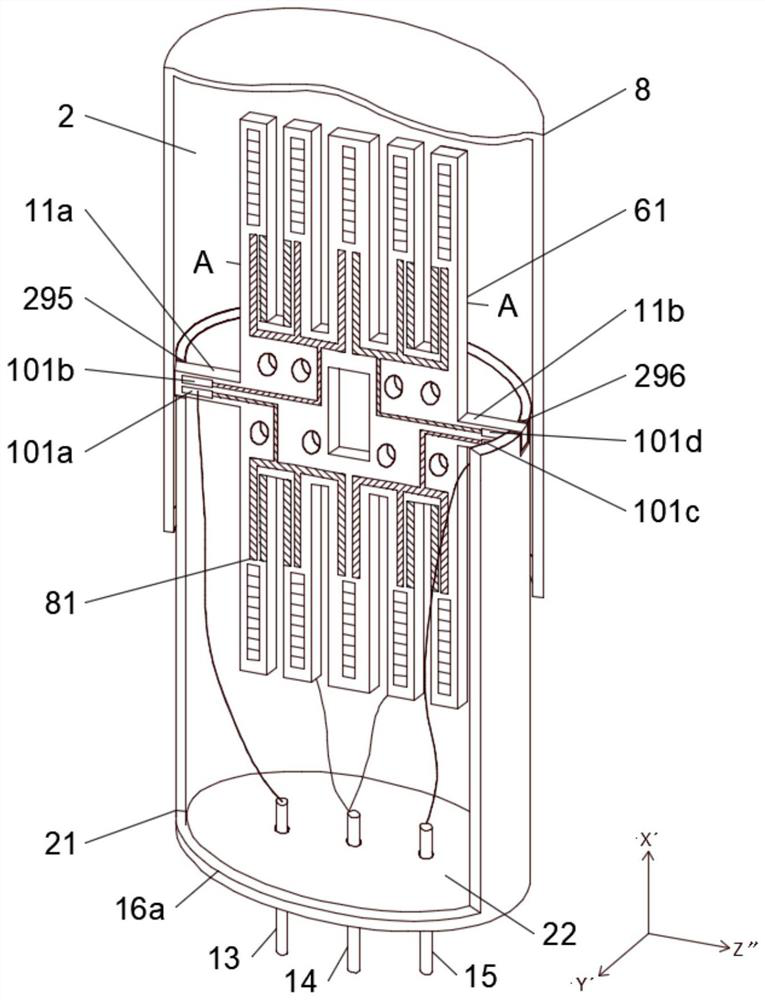

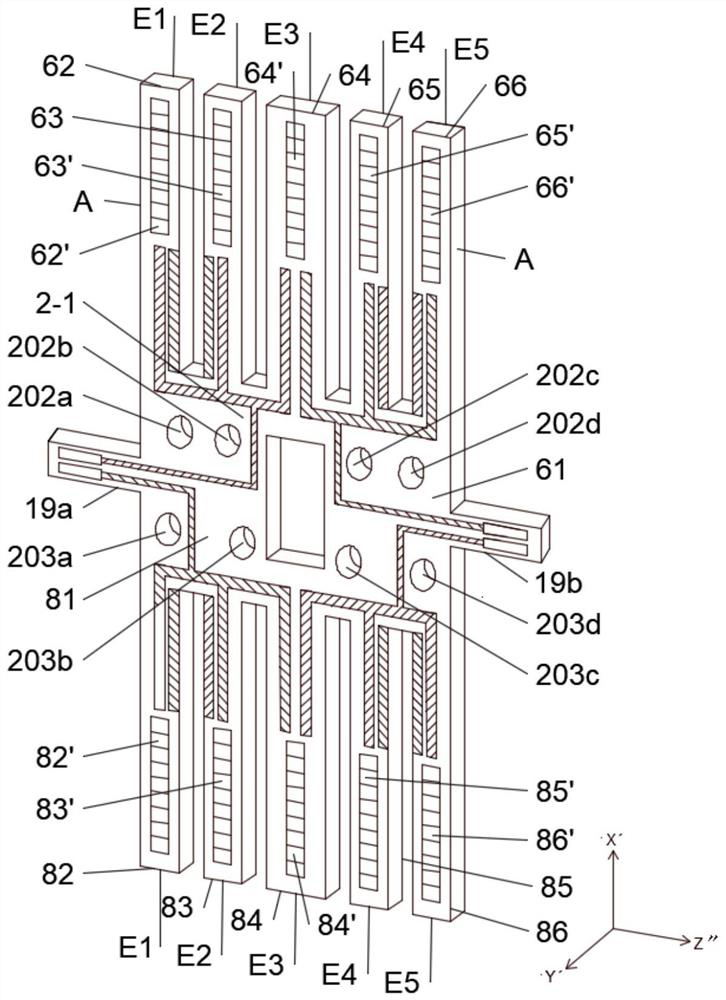

[0062] see figure 1 , figure 2 and Figure 5 As shown, the monolithic surface bending mode double-coupled five-arm quartz tuning fork vacuum sensitive resonator is composed of a five-arm surface bending mode quartz tuning fork resonator plate, a quartz vacuum sensitive resonator socket 12 and a quartz tuning fork vacuum sensitive resonator. Consisting of 8 anti-pollution and moisture-proof filter caps, the five-arm surface bending mode quartz tuning fork resonator piece 2 is placed on the tube base 12 of the quartz vacuum-sensitive resonator and the vacuum-sensitive resonator package composed of the anti-pollution and moisture-proof filter cap 8 of the quartz tuning fork vacuum-sensitive resonator inside part 3.

[0063] Quartz vacuum-sensitive resonator base 12 includes Kovar-glass base chassis 16a, Kovar base sidewall 21, insulating glass body 22, and first pins 13 and second tubes evenly distributed in insulating glass body 22. The pin 14 and the third pin 15, the Kovar...

Embodiment 2

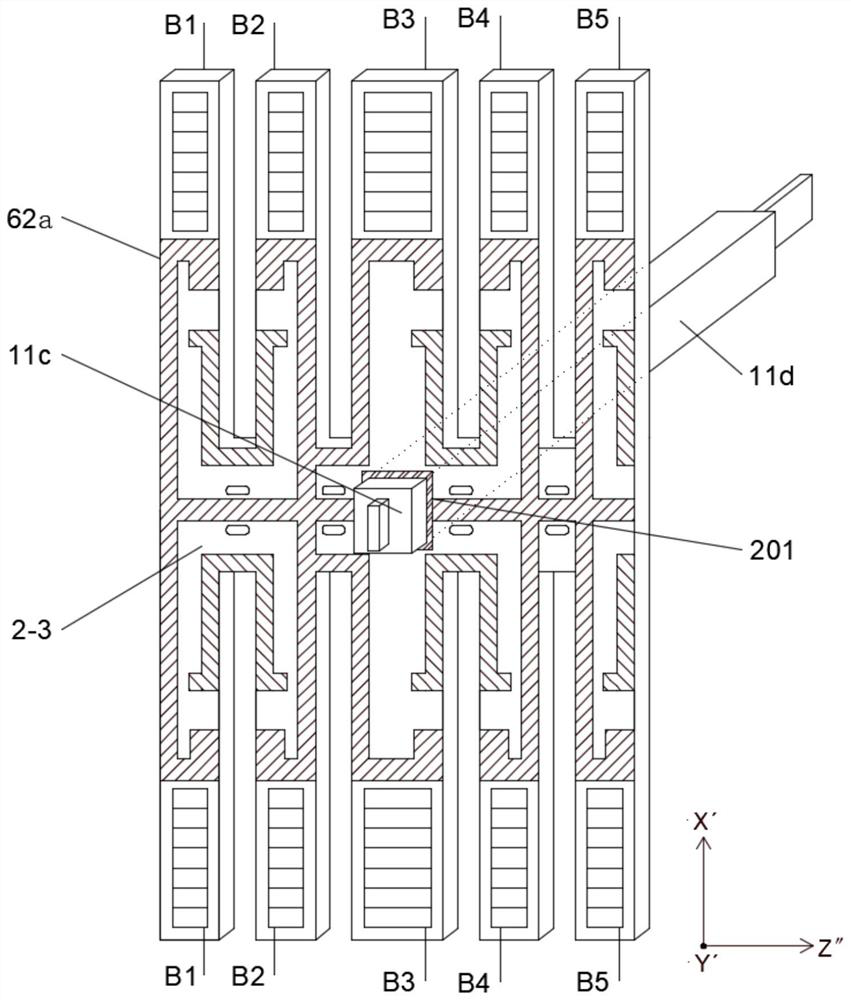

[0094] see image 3 and Figure 6 As shown, the monolithic double-opening five-pronged quartz tuning fork vacuum sensitive resonator piece 2 of the surface bending mode is the second monolithic surface bending mold double-opening five-pronged quartz tuning fork vacuum sensitive resonator piece 2-3, and the second The difference between the vacuum-sensitive resonator piece 2-3 with double-opening five-pronged quartz tuning fork of the monolithic surface bending mode and the vacuum-sensitive resonator piece 2-1 with double-opening five-pronged quartz tuning fork of the first monolithic surface bending mold is as follows:

[0095] 1. The two supporting beams of the second monolithic surface bending mold double-opening five-fork quartz tuning fork vacuum-sensitive resonator sheet 2-3—the third supporting beam 11c and the fourth supporting beam 11d are not arranged on the common overlapping base The left and right sides of the area are arranged on the front and rear of the second ...

Embodiment 3

[0101] see Figure 4 and Figure 6 As shown, the single-chip double-opening five-pronged quartz tuning fork vacuum sensitive resonator piece 2 of the surface bending mold is a double-opening-closed five-pronged quartz tuning fork vacuum sensitive resonator piece 2-2 of the single-piece surface bending mold , the double-opening-closed five-arm quartz tuning fork vacuum sensitive resonator piece 2-2 of the monolithic surface bending mold and the first monolithic surface bending mold double-opening five-arm quartz tuning fork vacuum sensitive resonator piece 2- 1 differs as follows:

[0102] 1. Two sets of opening-closed five-arm quartz tuning fork vacuum sensitive resonator plate 2-2 of the single-piece surface bending mold is composed of two groups of quartz tuning forks with five-arms, the first five-arm quartz tuning fork The tops of the first fork arm and the fifth fork arm and the tops of the second fork arm and the fourth fork arm on the outer edge of the outer edge are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com