Vacuum monitor

A vacuum gauge, in-space technology, applied in vacuum gauges, vacuum gauges using ionization effects, vacuum gauges that measure changes in gas frictional resistance, etc. The effect of shortened life, increased productivity, and reduced frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

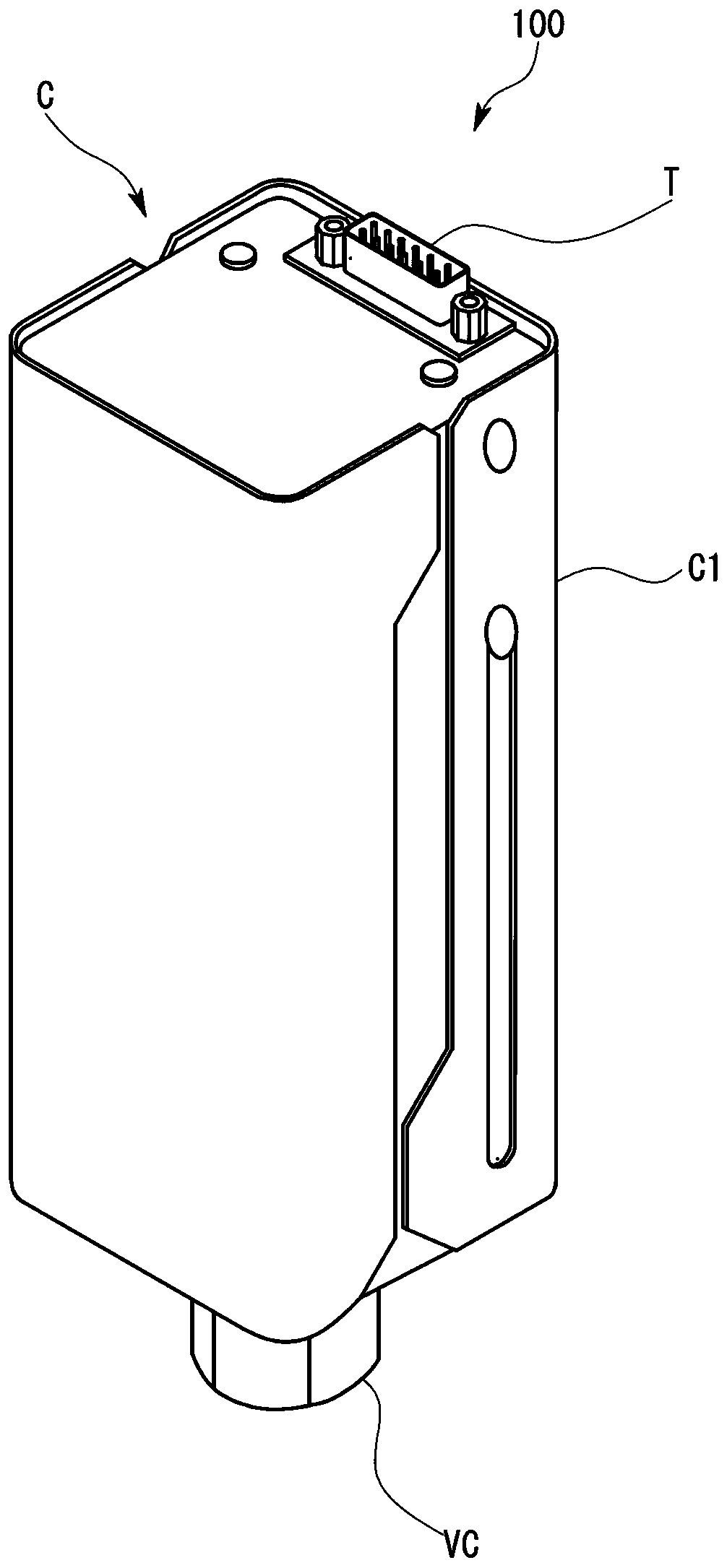

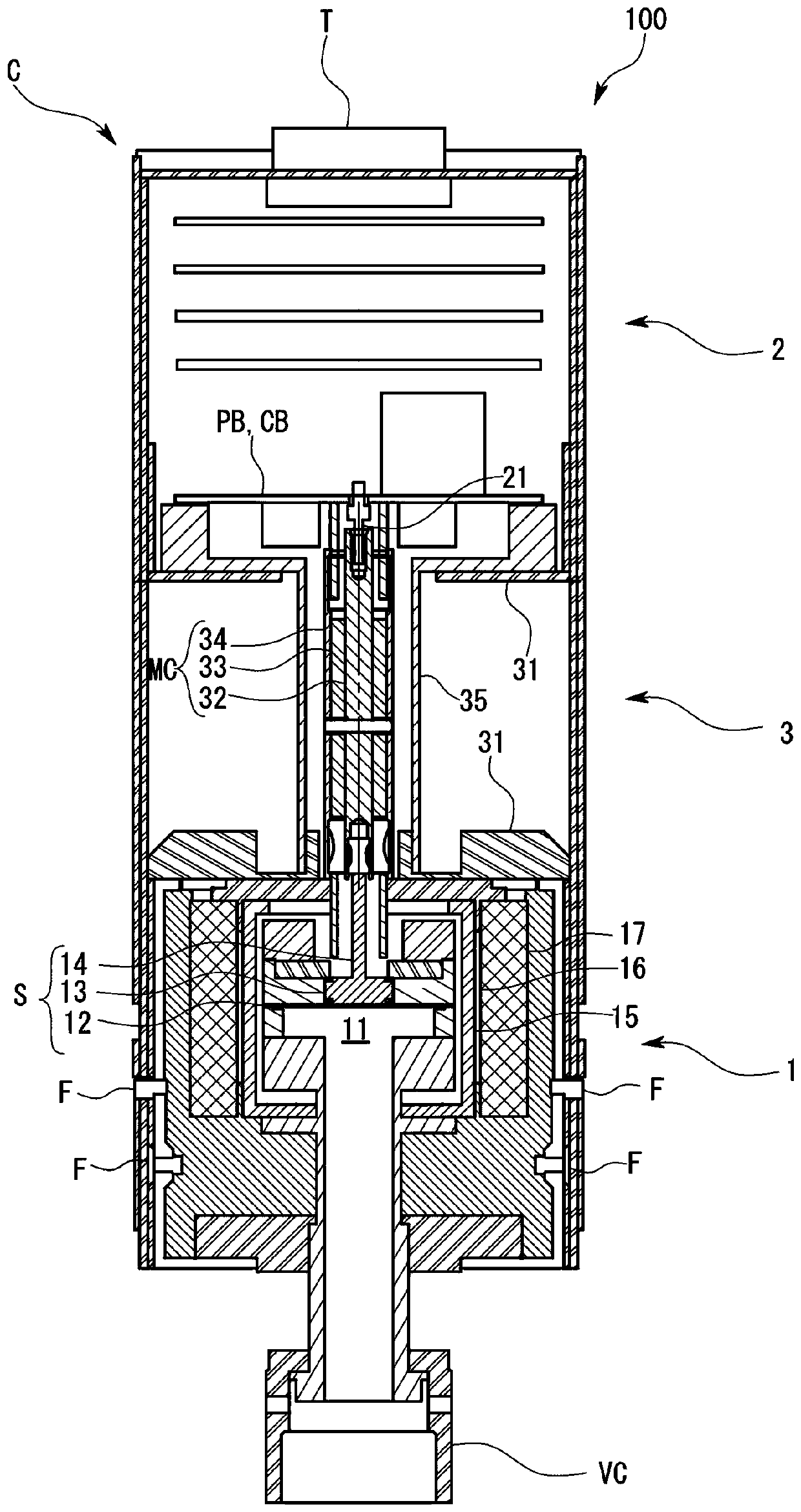

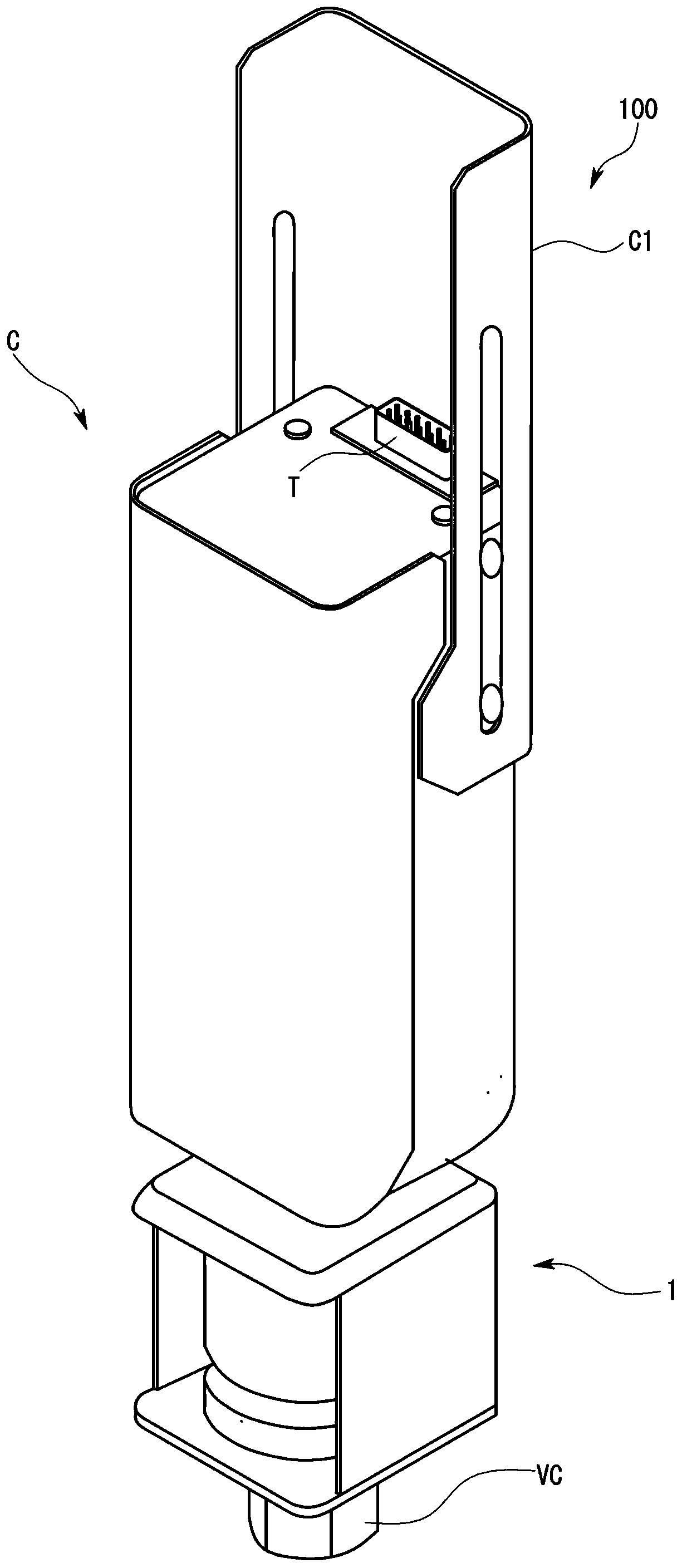

[0053] refer to Figure 1 to Figure 7 A vacuum gauge 100 according to one embodiment of the present invention will be described.

[0054] The vacuum gauge 100 of this embodiment is used, for example, to monitor the degree of vacuum in a vacuum chamber, which is a measurement space where film formation and the like are performed in semiconductor processing. The vacuum gauge 100 is installed outside the partition wall of the vacuum chamber, and connected so as to communicate with the inside of the vacuum chamber.

[0055] Such as figure 1As shown, the vacuum gauge 100 has a substantially rectangular parallelepiped shape, a vacuum connector VC is provided at its front end, and an output terminal T for outputting a measured pressure value to the outside is provided at its base end.

[0056] Such as figure 2 As shown in the cross-sectional view of the vacuum gauge 100, three modules are accommodated or formed in the casing C. That is, the three modules include: a sensor module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com