Surface bending mode double-coupled monolithic high-sensitivity quartz tuning fork vacuum sensor

A technology of vacuum sensor and quartz tuning fork, applied in the direction of vacuum gauge by measuring the change of gas frictional resistance, can solve the problems of increasing process difficulty, affecting sensitive characteristics, not installing anti-oil pollution, etc., and achieving temperature stability and time stability Improve, improve vacuum measurement sensitivity, improve the effect of vacuum sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

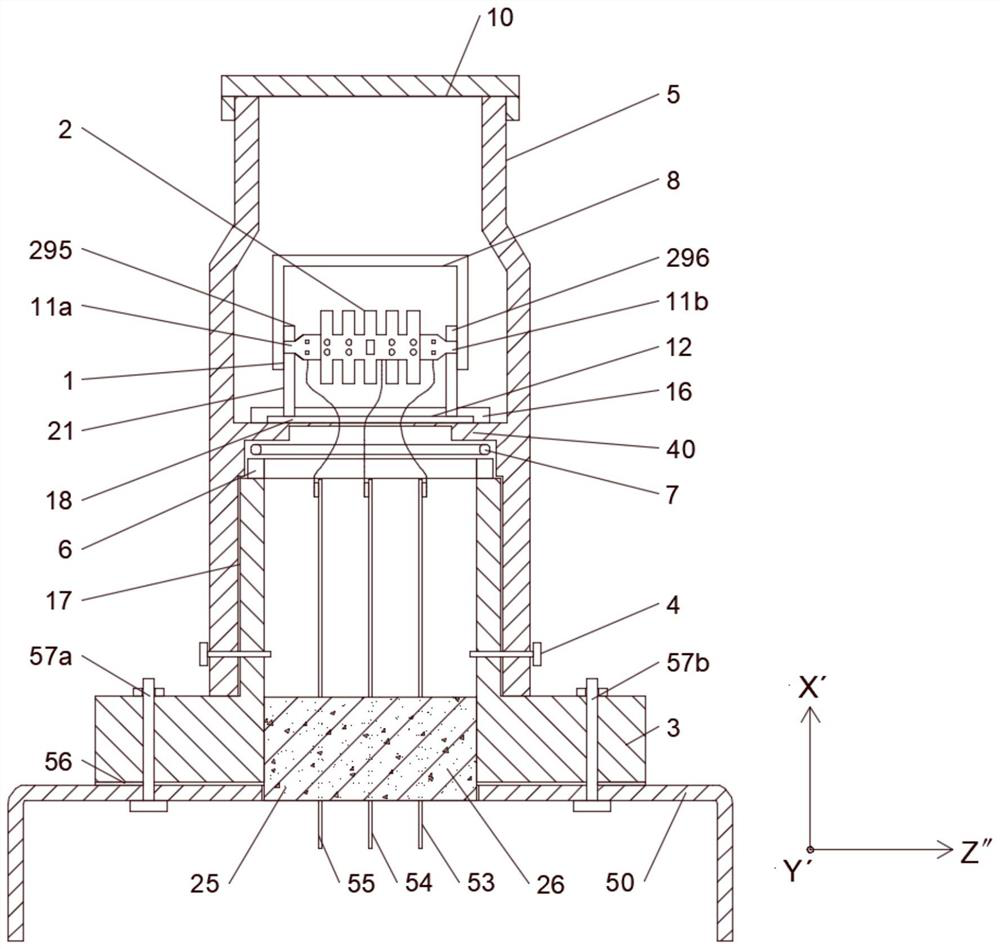

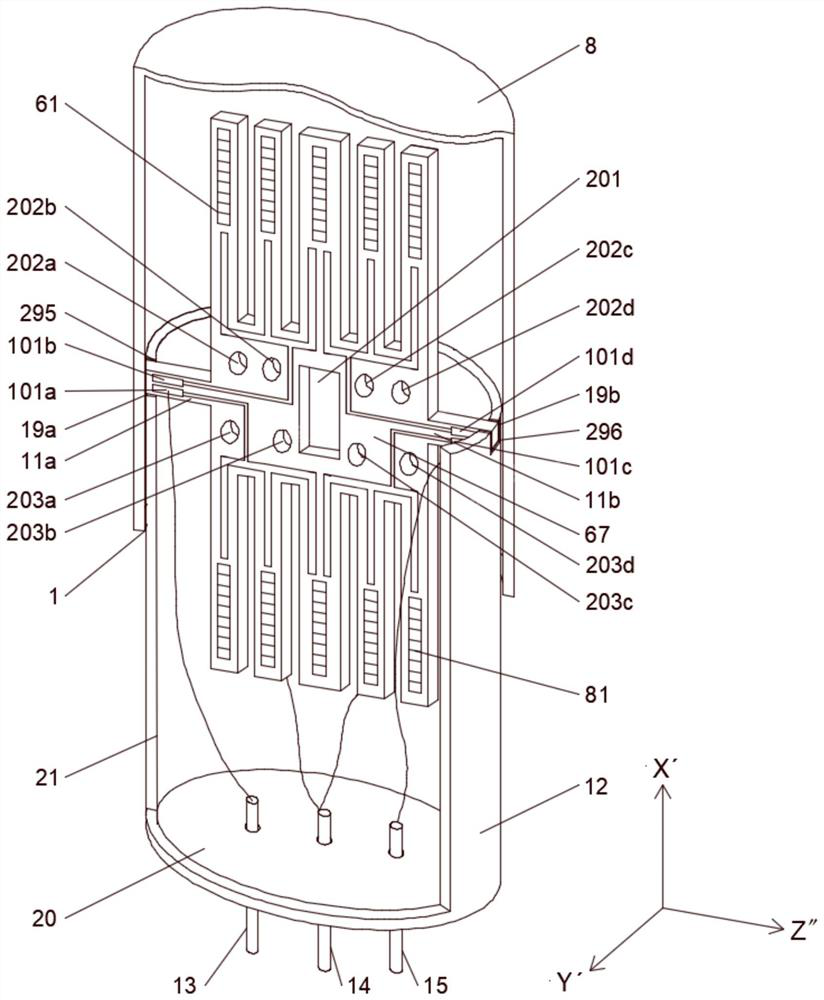

[0100] See figure 1 , figure 2 and Figure 4 As shown, a single-piece high-sensitive stone tunnel vacuum sensor, a single-chip double-open multi-open multi-cardiped aperture, a single-chip double-open multi-bage-based, bending mold, is characterized by a surface curved mold. Single-chip double-opening multi-made arm stone tunklow vacuum sensitive resonator 2 is a surface-bending mode type double-open quartz tonic type double-open quartz tunnel vacuum sensitive resonator;

[0101] Single-chip double-open multi-board arm of face curved molds, the vacuum sensitive resonator 2 includes a single closing stone 61 and a second set of multi-forkled arms each having a multi-fork arm Quartz tonic 81, the first set of multi-folded stone tunnel fork 61 and the second set of multi-bage-only stone tunnel fork 81 overlap or partially overlap each other, ie there is a public overlapping base 67. Double-opening tuning quartz resonators of the integrated single-chip structure of the integrated singl...

Embodiment 2

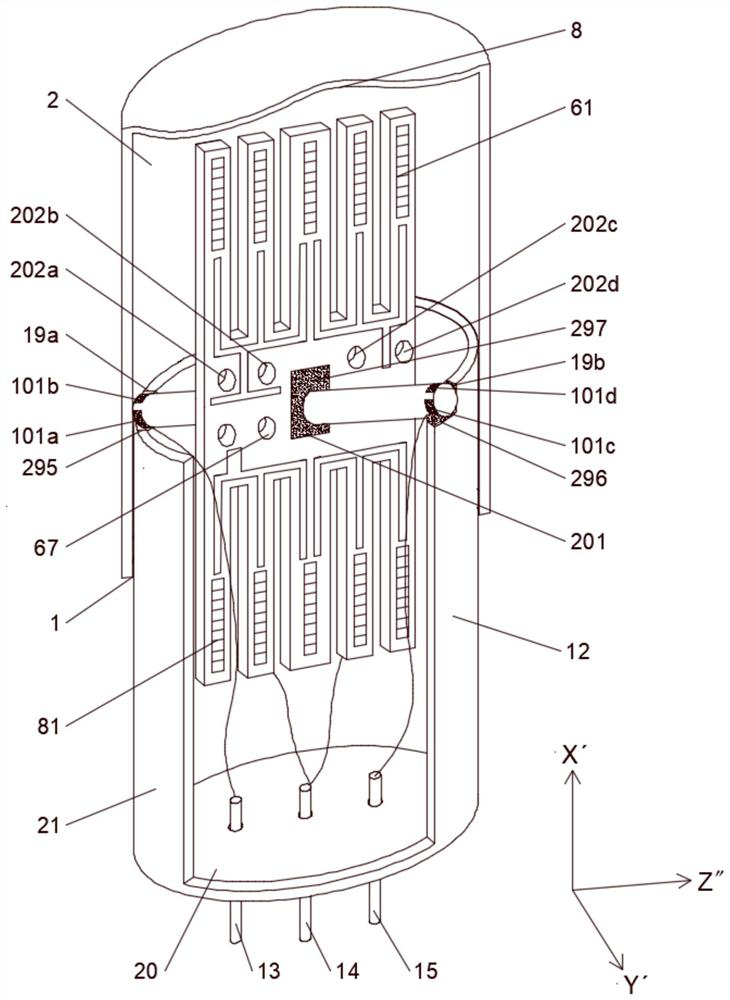

[0153]See image 3 Specifically, the present embodiment, the second embodiment, and the first embodiment, there are two:

[0154] 1. In the first opening of the single-closed stone tank fork 61 and the second set of multi-made stone tonic 81 located in the first set of forklons, the first opening rectangular slot 201 is loaded into the first The elliptical quartz crystal bar 293, the first elliptical quartz crystal bar 293 is equal, and the single-closed stone tuning fork 61 and the second set of multi-aircraft arm fork 61 and the second set of pusher The tunnel of the tone of the torch tunnel 81 is symmetrical. The crystal cutoform of the first elliptical quartz crystal bar 293 is (YXTL) - 32 ° / 15 ° quartz crystal bar; and in the first opening rectangular pass groove 201 and the first elliptical quartz crystal bar 293 The gap between the gap is filled with low melting glass, and the third low melting glass powder sealing area 297 is formed by the sintering process, and then the ...

Embodiment 3

[0158] See figure 1 and figure 2 Specifically, the present embodiment, the third embodiment, and the examples of the embodiments are as follows: the single-piece double-opening pork-projection of the surface curved mold is (YXTL) - 40 ° / 10 °. Sliced quartz crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com