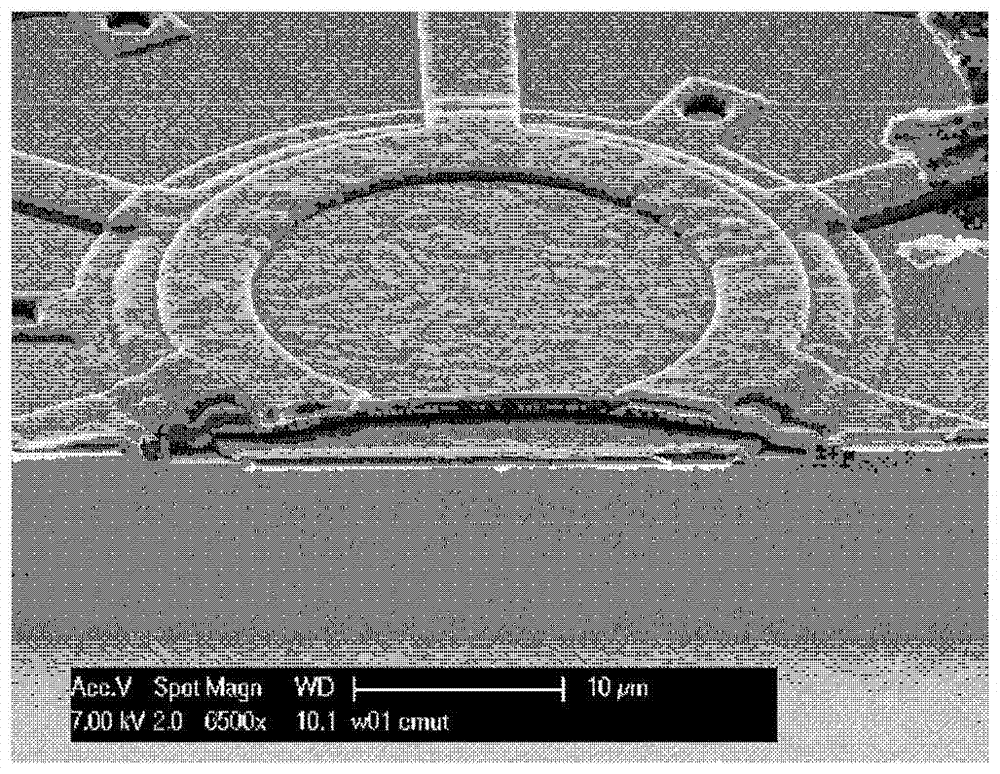

mems capacitive pressure sensor

A pressure sensor, capacitive technology, used in fluid pressure measurement using capacitance changes, fluid pressure measurement through electromagnetic components, elastic deformation gauge fluid pressure measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

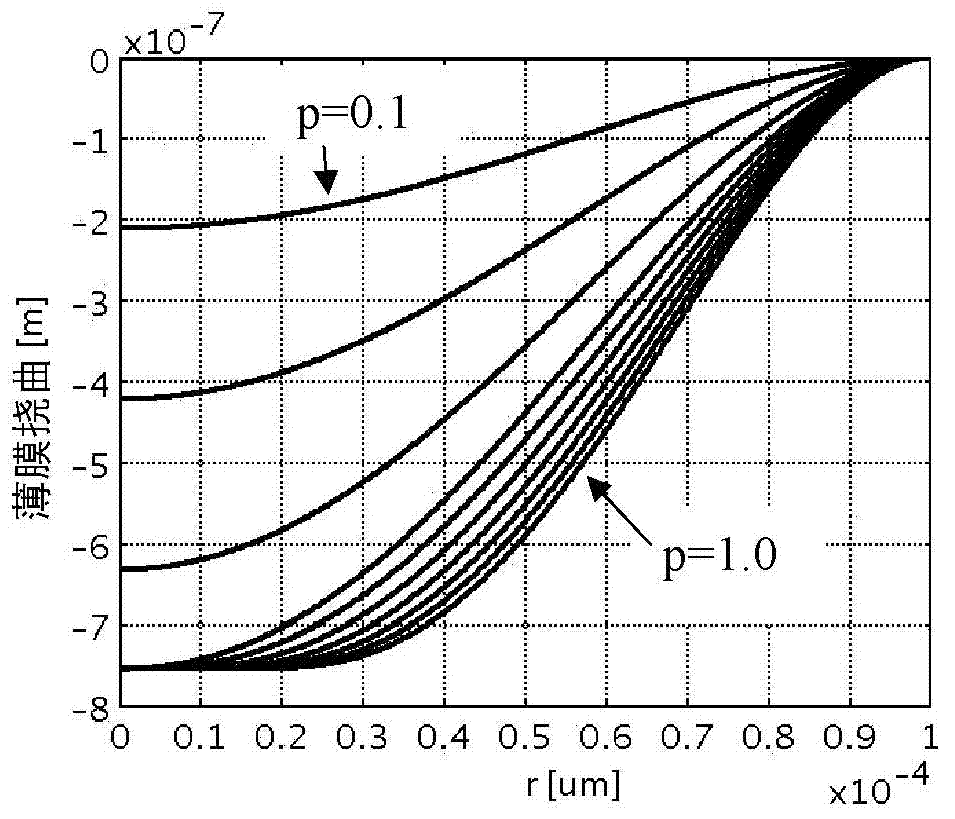

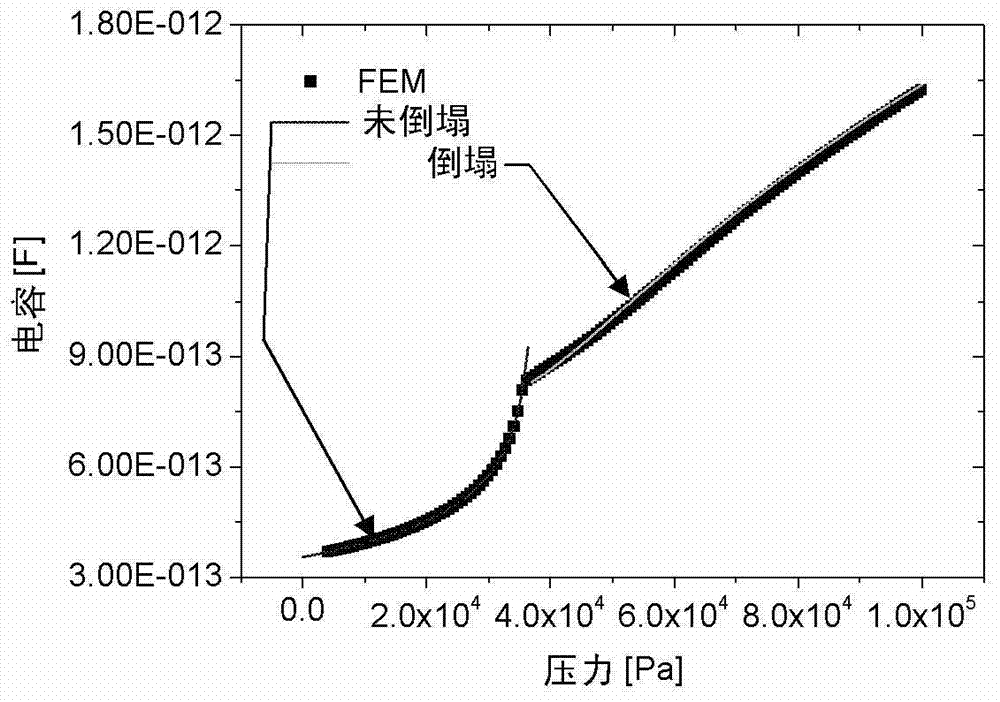

[0060] The present invention provides a pressure sensor capable of performing self-calibration and correcting for signal drift. The pressure difference between the external medium and the cavity is sensed by measuring the deflection of the membrane using a capacitive readout method. There are two ways of implementing the invention. One way involves the use of an integrated Pirani sensor and the other way involves the use of an integrated resonator, used as a reference pressure sensor.

[0061] Since its invention in 1906, the Pirani pressure gauge has been widely used for vacuum measurement. A heating wire with a high temperature coefficient of resistance is placed under vacuum. A wire (whose resistance is proportional to its temperature,) forms one arm of a balanced Wheatstone bridge. Gas molecules collide with the wire, transferring heat from the wire and unbalancing the bridge relative to a reference state. Since the frequency of molecular collisions is proportional to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com