Resonator-based vacuum degree detection method, system and device

A detection method and detection device technology, applied in the detection field, can solve the problems of low test accuracy, high cost, and low sensitivity, and achieve the effects of shortened detection time, high degree of automation, and reduced interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

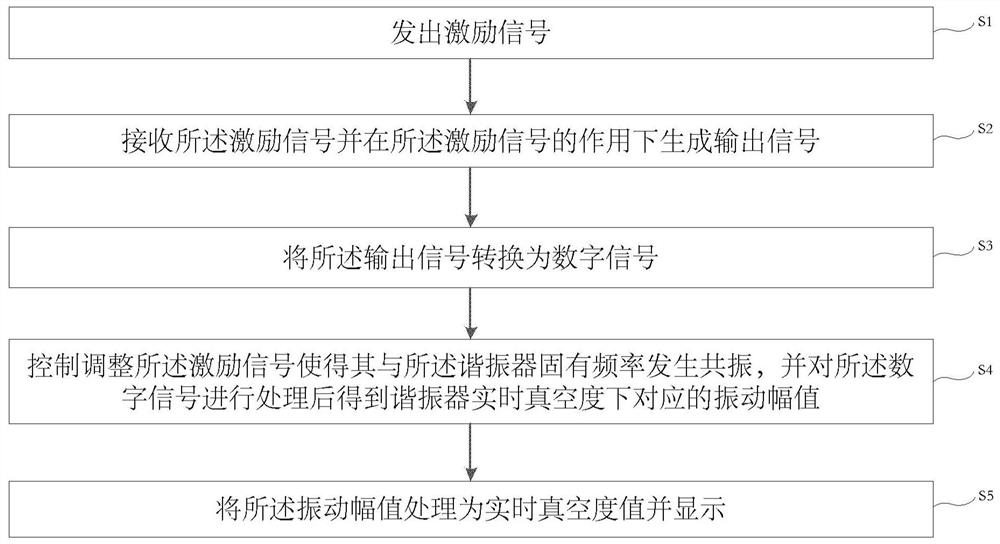

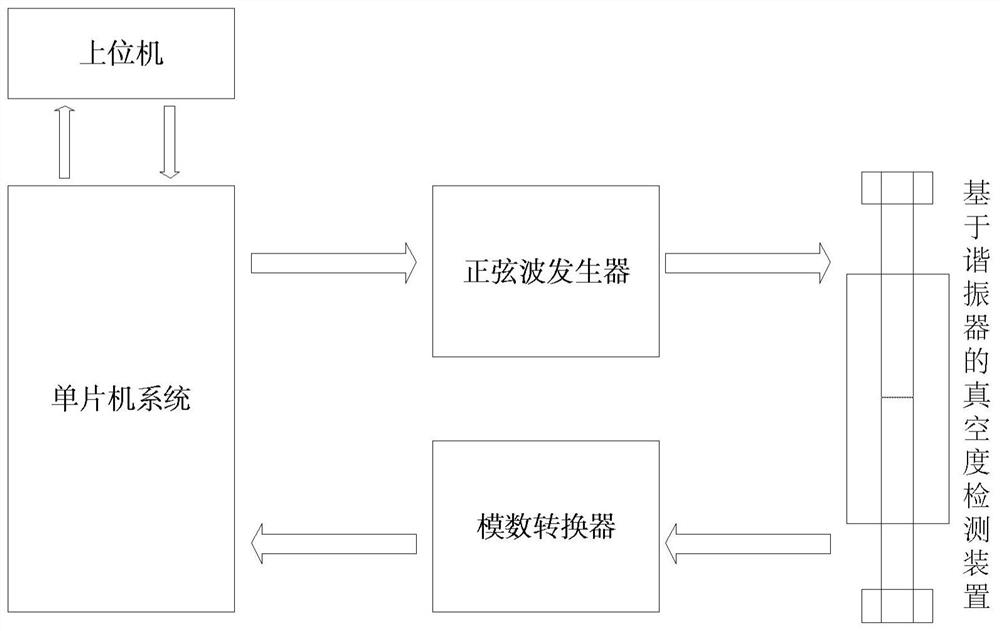

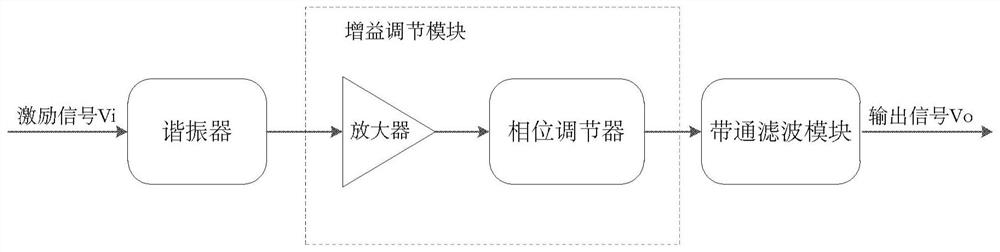

[0028] The present disclosure provides a method, system and device for detecting vacuum degree based on a resonator. By utilizing the characteristics of a resonator with small volume, stable performance, simple processing and easy integration, the resonator is built into the shell or cavity of a MEMS device. , based on the principle that the amplitude of the output signal of the resonator changes with the vacuum (pressure), and there is a relationship between the amplitude and the voltage, by detecting the change of the output signal amplitude of the MEMS resonator, the detection of the pressure of the vacuum cavity in the MEMS device is realized. In the case of constant excitation, the output voltage of the resonator is measured to indirectly obtain the amplitude of the output signal of the resonator in the vacuum package, and then the pressure in the cavity is converted according to the amplitude change, and the vacuum degree inside the cavity of the MEMS device is detected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com