Pressure sensor for micro electro-mechanical system and production method thereof

A technology of pressure sensor and micro-electromechanical system, which is applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc. It can solve the difficulty of controlling the uniformity of speed, affecting the sensitivity and linearity of sensitive resistors and pressure chambers, pressure sensors Influence and other issues to achieve the effect of ensuring uniformity, improving sensitivity and linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

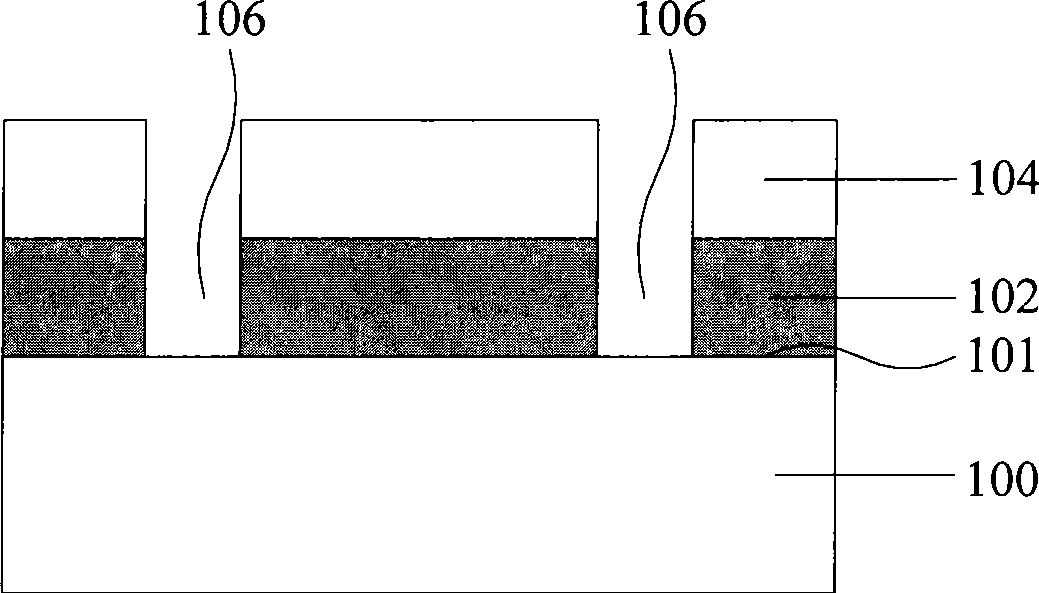

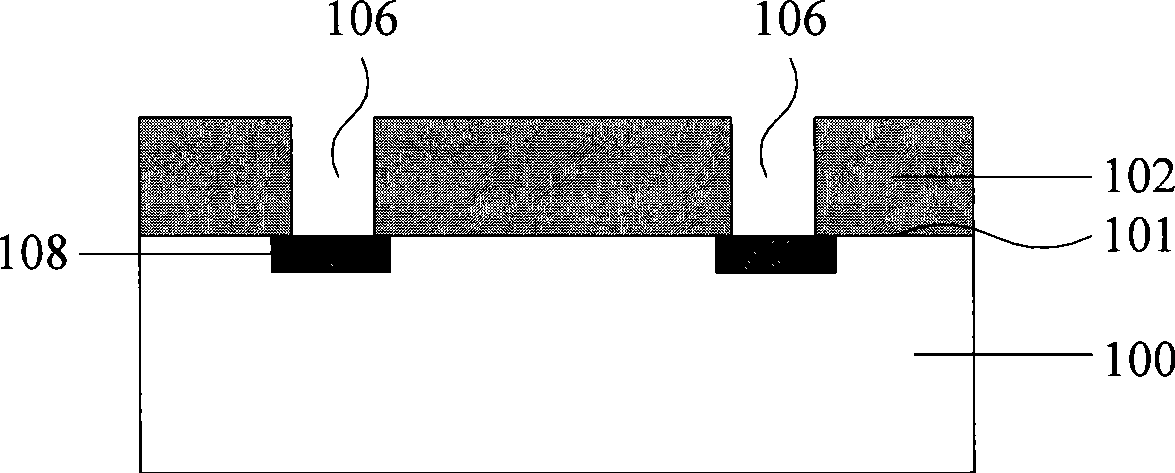

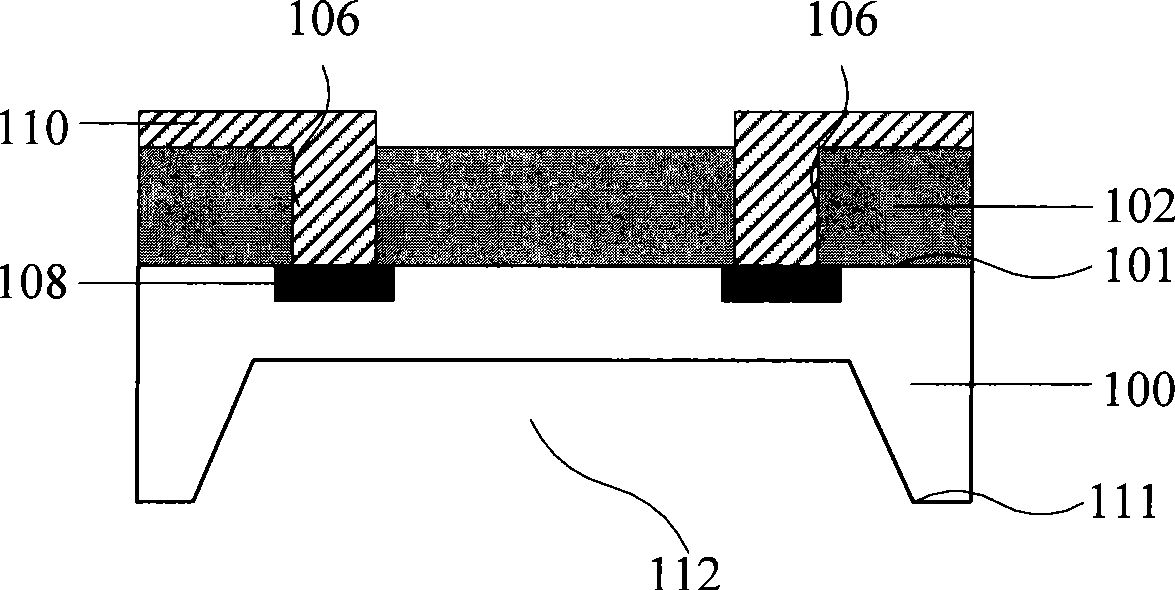

[0020] In the invention, after the opening of the pressure chamber is formed on the semiconductor substrate, the silicon-on-insulator substrate is bonded on the semiconductor substrate to form a pressure chamber; the silicon layer of the silicon-on-insulator substrate substrate is removed to expose the buried oxygen layer. Since the thickness of the top silicon layer as the sensitive film is already defined by the silicon-on-insulator substrate itself, the uniformity of the sensitive film is guaranteed. At the same time, the positions of the sensitive resistor and the pressure chamber are defined after the pressure chamber is formed, which avoids the change of the position of the sensitive resistor due to the change of the thickness of the sensitive film. Therefore, the thickness of the sensitive film and the position of the sensitive resistor in the above scheme can be precisely controlled, thereby improving the sensitivity and linearity of the pressure sensor.

[0021] In or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com