Hidden-type MEMS pressure sensor sensitive chip and manufacturing method thereof

A technology of pressure sensor and sensitive chip, which is applied in the measurement of the property force of the piezoelectric resistance material, fluid pressure measurement by changing the ohmic resistance, instruments, etc., can solve the problems of device performance and life, and solve the problem of device Reduced performance, improved service life, and reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

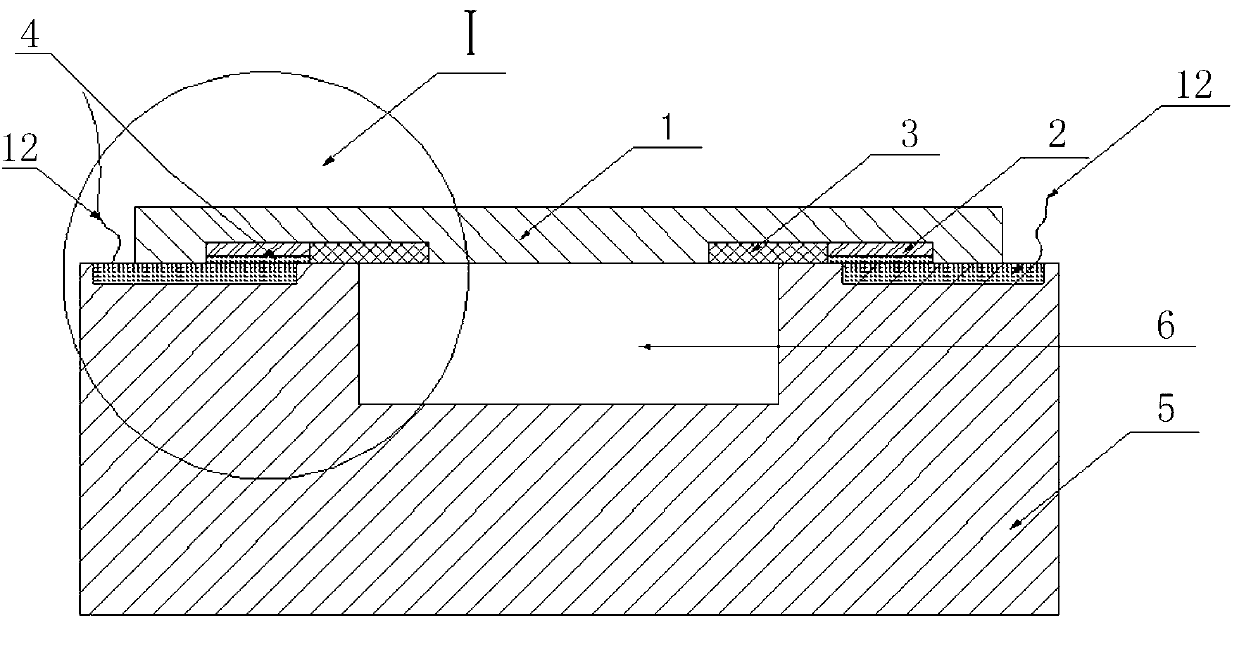

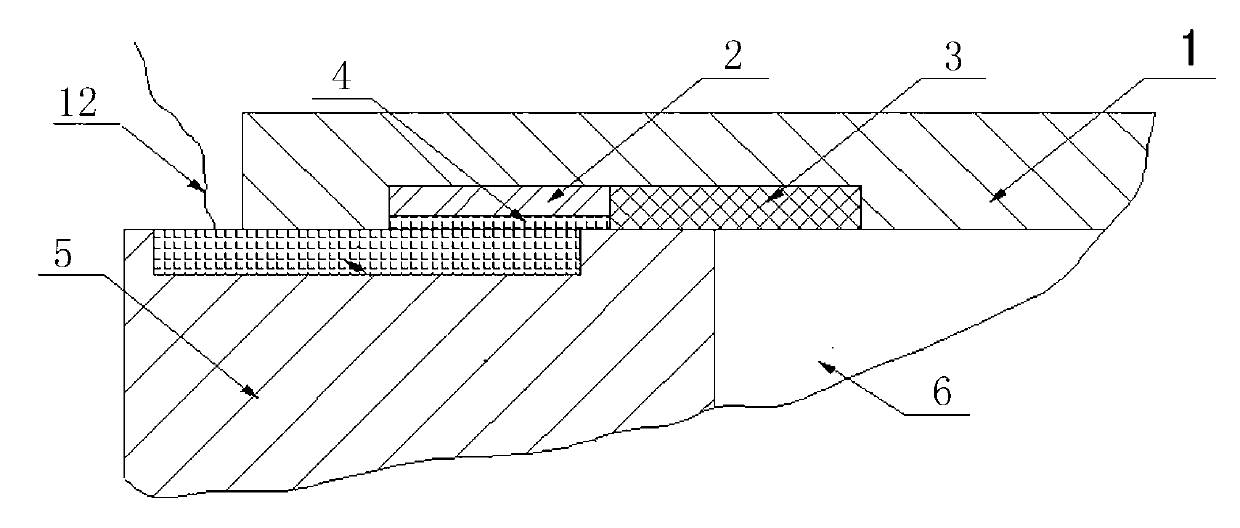

[0039] like figure 1 , 2 As shown, a sensitive chip of a hidden MEMS pressure sensor includes an SOI sheet device layer 1 (that is, as a sensitive film of a pressure sensor, and the SOI sheet is etched by a wet or dry etching process with the BOX layer of the SOI sheet as a stop layer. Formed after the substrate layer) and glass substrate 5.

[0040] Four piezoresistors R1, R2, R3, R4 of the Wheatstone bridge, eight doped wires 3 and eight connection anchor points 2 for connection are made on the SOI sheet device layer 1, and the Both ends of each varistor are connected to one end of a respective doped wire 3, and the other end of each doped wire 3 is overlapped with a respective connection anchor point 2; each connection anchor point 2 A layer of metal layer 4 forming an ohmic contact is formed on it.

[0041] The upper surface of the glass substrate 5 is corroded with a pressure chamber 6 with a depth of 5-200 μm and the first, second, third, fourth and fifth mosaic circu...

Embodiment 2

[0044] The manufacturing method of the hidden MEMS pressure sensor sensitive chip described in the above-mentioned embodiment 1 comprises the following steps:

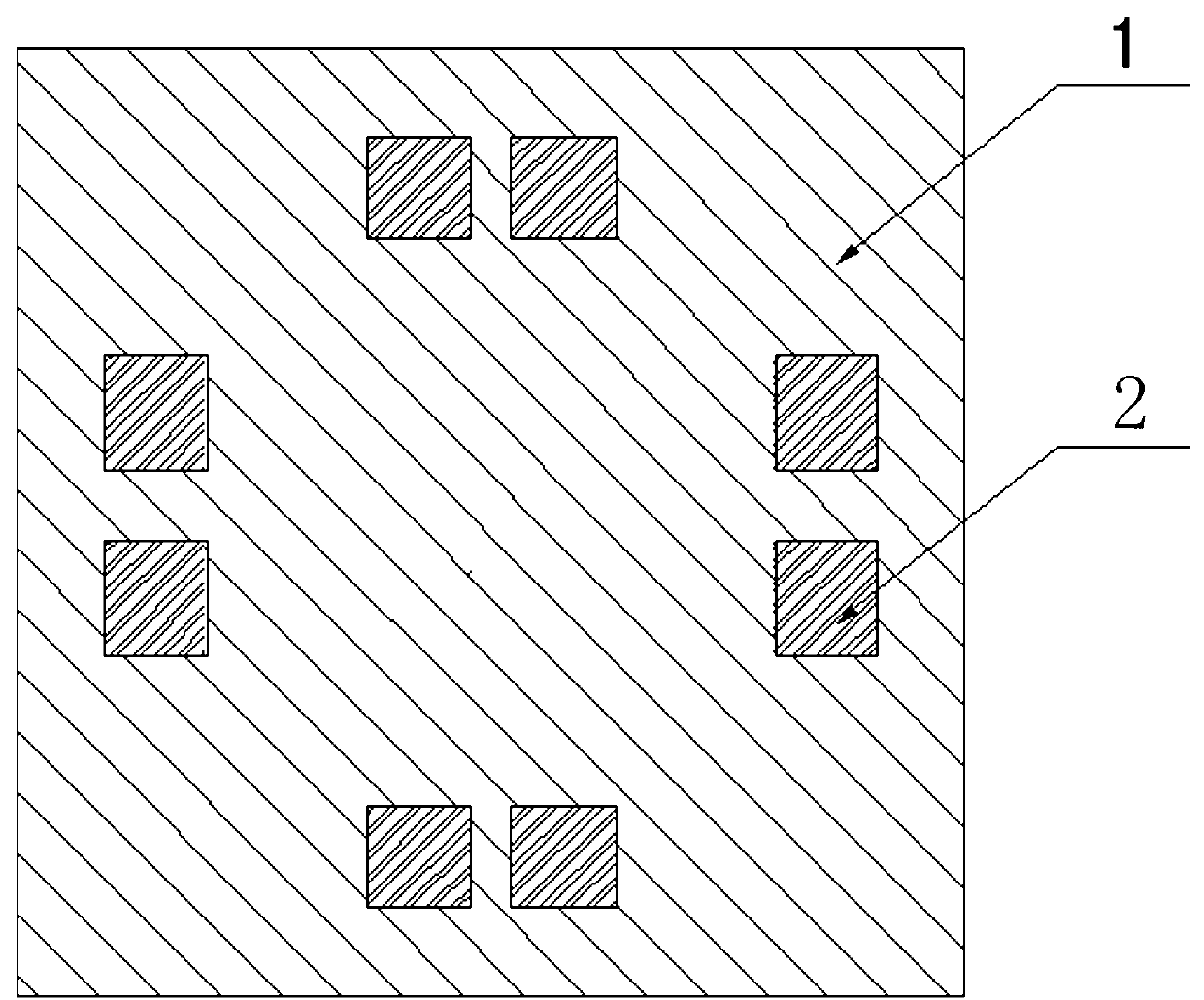

[0045] (1) Perform high-concentration diffusion, ion implantation process or growth of highly doped polysilicon on the SOI device layer 1 to form eight highly doped connection anchor points 2; as image 3 shown. For example, for P-type high doping, the concentration is required to be 10 19 cm -3 above.

[0046] (2) Perform ion implantation on the device layer 1 of the SOI sheet, and inject ion dose Φ=(4~8)×10 14 / cm 2 , the injection energy is 80~200KeV, making four piezoresistors R1, R2, R3, R4 of the Wheatstone bridge and eight doped wires 3 for connection; the two ends of each piezoresistor are all connected to one end of the respective doped wire 3, and the other end of each doped wire 3 is overlapped with the respective connection anchor point 2; as Figure 4 shown.

[0047] (3) Sputtering the metal layer 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com