Swing bolster and side frame integrated core preparation and core setting technology

An integral core and bolster technology, which is applied in the direction of manufacturing tools, cores, metal processing equipment, etc., can solve problems such as difficult wall thickness, draped seams, steps, sand holes, crack sources, etc., to reduce the number of uses and improve safety The effect of guaranteeing the accuracy of wall thickness and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

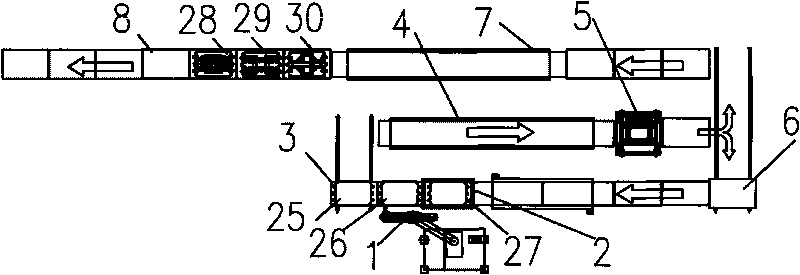

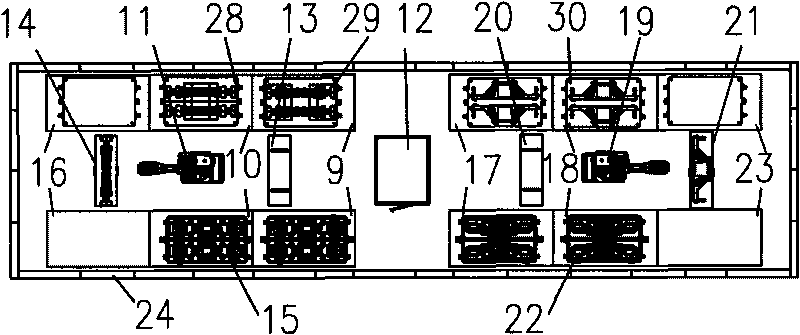

[0043] The manufacture of the bolster and side frame integral core sand core of the present invention and the core lowering process are as follows: Figure 13 As shown, the process includes as figure 1 A whole core production line of ester hardened sodium silicate sand as shown and such as figure 2 A robot lock cylinder and core lowering production line is shown.

[0044] Such as figure 1 As shown, the core-making production line is: sand mixer 1, vibrating table 2, primary transfer trolley 3, primary surface drying furnace 4, turning and lifting mold machine 5, secondary transfer trolley 6, secondary surface drying furnace 7, storage roller Road 8.

[0045] Such as figure 2 The robot lock cylinder and core lowering production line shown are: bolster core feeding station 9, bolster core working station 10, bolster robot 11, central control room 12, bolster transfer table 13, bolster lock cylinder Workbench 14, bolster sand mold 15, bolster core blanking station 16.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com