TDLAS boiler gas two-dimensional concentration distribution detecting method and device based on automatic scanning system

An automatic scanning and concentration distribution technology, which is applied in the analysis of materials, color/spectral characteristic measurement, instruments, etc., can solve the problems affecting the reconstruction quality of the concentration distribution image, insufficient effective projection data, and difficulty in popularization and application, and achieves a reduction in the number of lasers, The effect of improving reconstruction accuracy and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below according to the embodiments shown in the accompanying drawings. It can be thought that embodiment disclosed this time is an illustration in every point, and is not restrictive. The scope of the present invention is not limited by the description of the following embodiments but only by the scope of the claims, and includes the same meaning as the scope of the claims and all modifications within the scope of the claims.

[0032] The structure of the present invention will be described below in conjunction with specific embodiments.

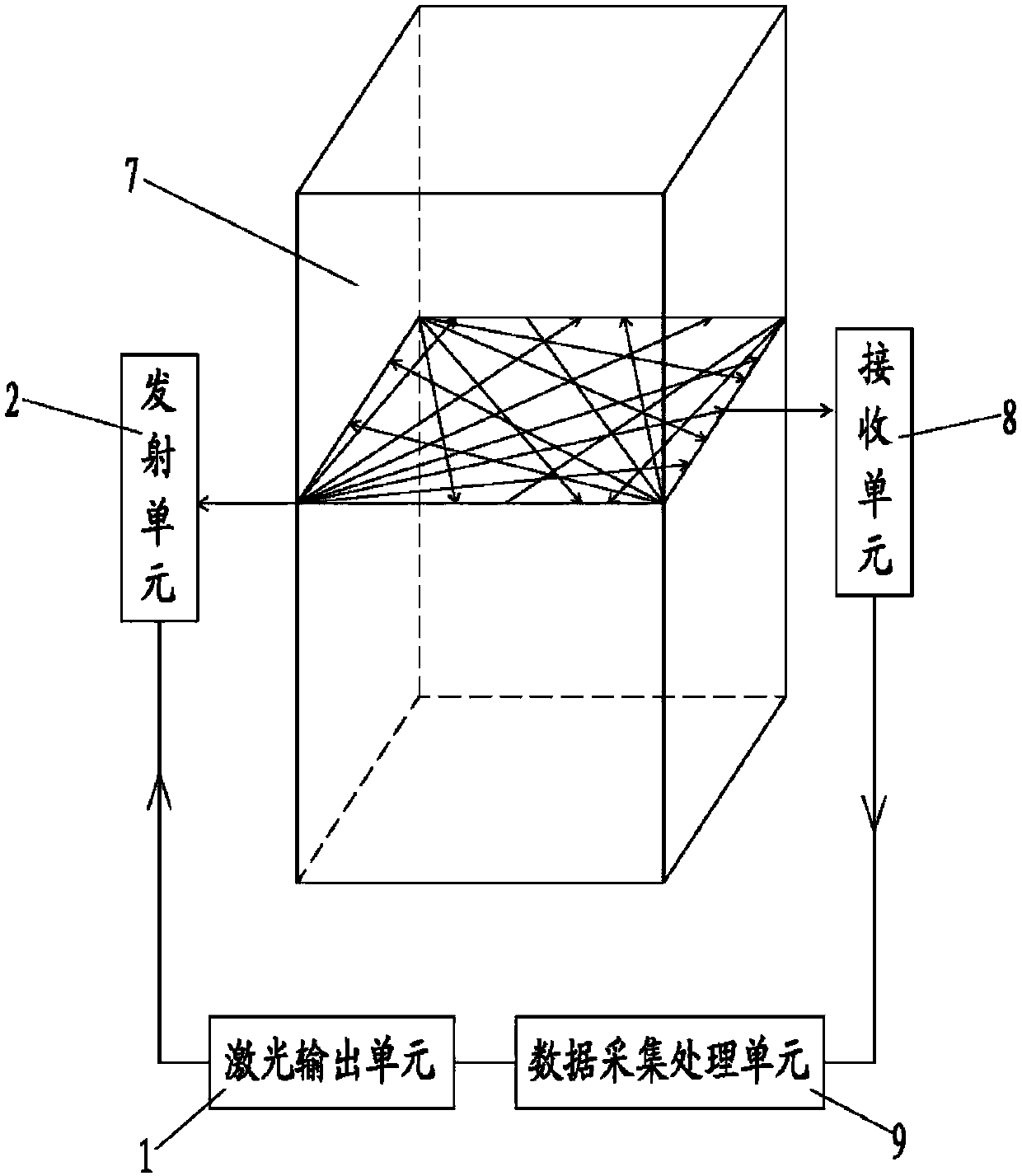

[0033] like figure 1 Shown is the structural schematic diagram of Embodiment 1 of the TDLAS boiler furnace gas two-dimensional concentration distribution detection device based on the automatic scanning system of the present invention, including:

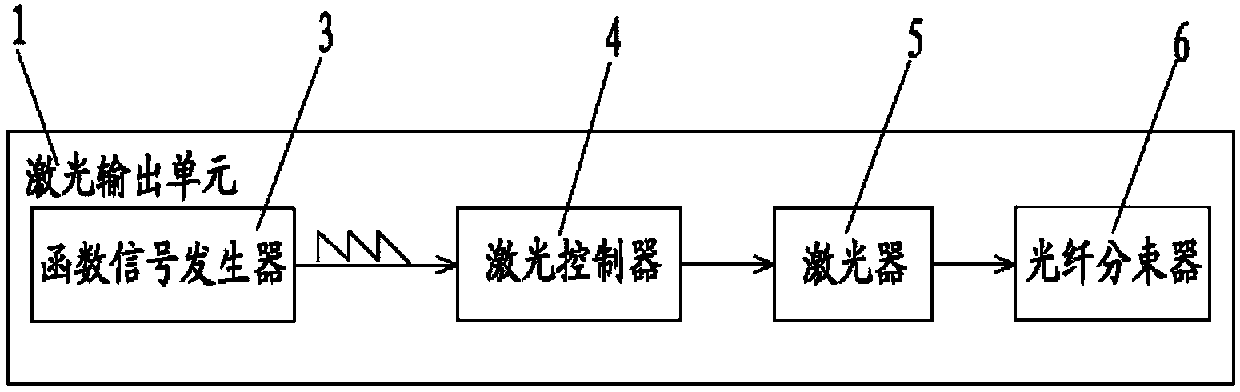

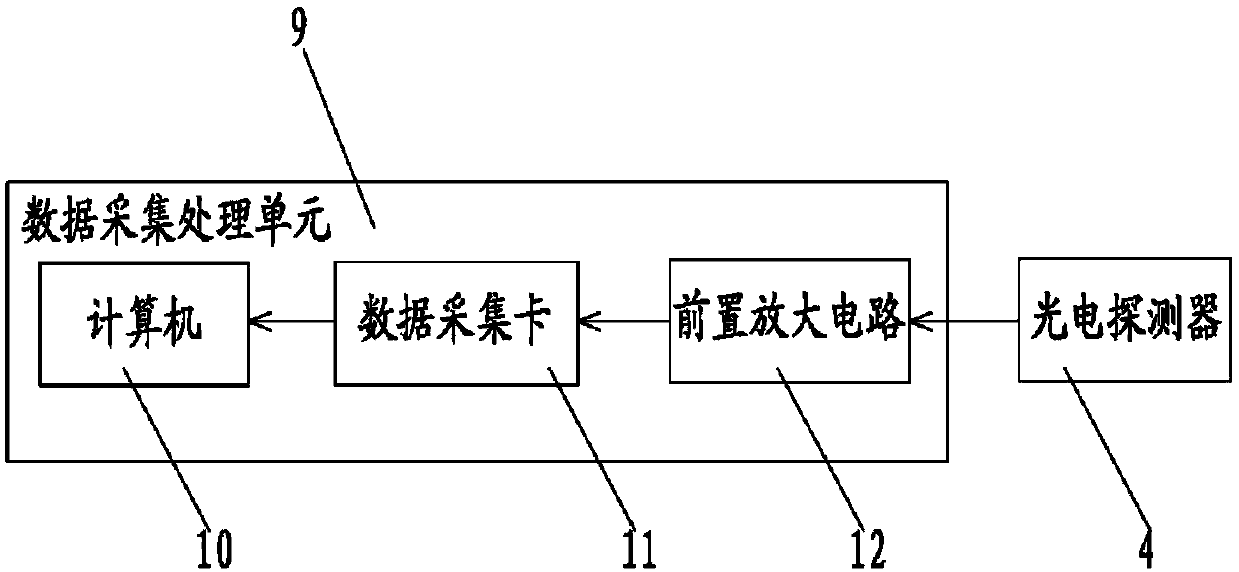

[0034] Laser output unit 1: used to output a beam of laser light to each emission unit 2, combined with figure 2 As shown, the laser output unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com