Process control system for mass production of polrvinyl chloride

A process control system, polyvinyl chloride technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of many steps, complex production process, and complicated polymerization kettle control, and achieve the effect of reducing the number of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

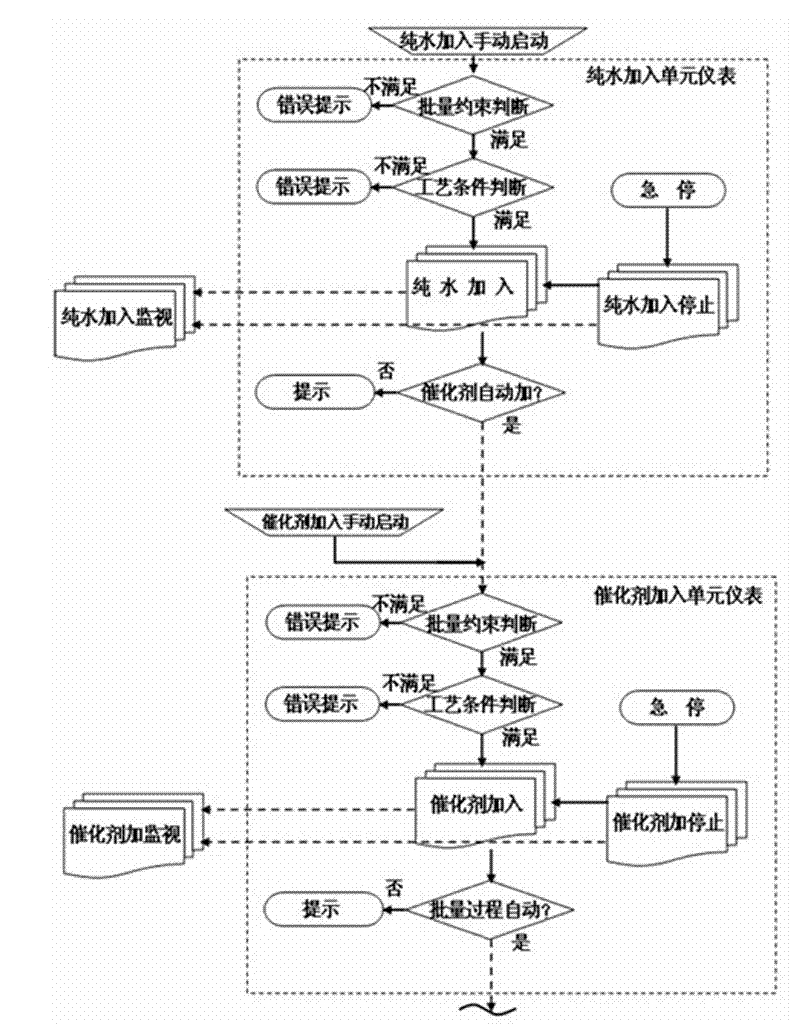

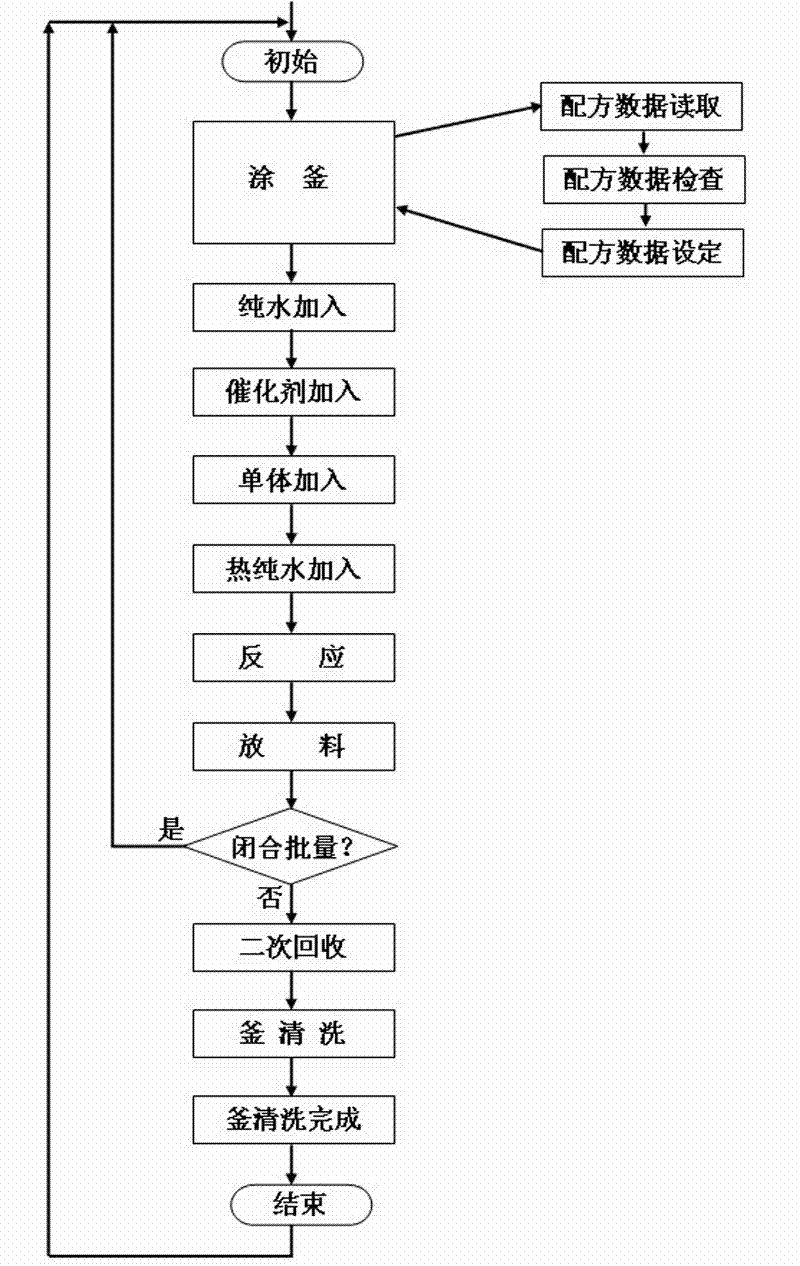

[0079] The polyvinyl chloride batch production process control system of the present invention includes two major parts of hardware and software.

[0080] Taking 6 kettles and an annual output of 250,000 tons of polyvinyl chloride plant as an example:

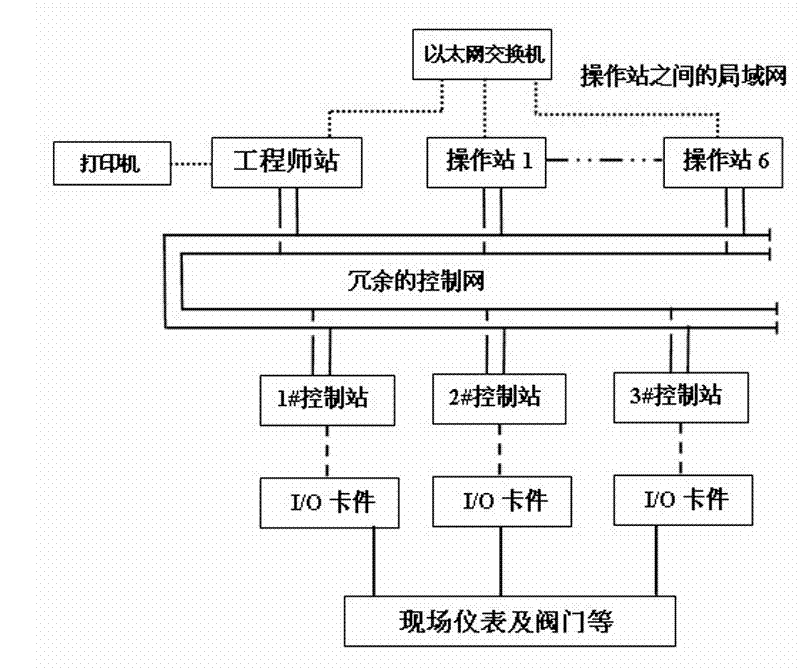

[0081] The hardware of the polyvinyl chloride batch production process control system of the present invention includes: an engineer station 1, six operator stations 2, three redundant control stations 3, a network switch 4 and a printer 5. Engineer station 1 is used for programming configuration, maintenance and debugging of the control system, and also serves as a recipe management server and an OPC data server.

[0082] Six operator stations 2 display various information and data of the entire production process, including flow chart screens, trend curve screens, alarm screens, etc., call recipe setting and report printing programs, and start or use the corresponding buttons in the operation screen Stop the polymerization b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com