Slot type MOSFET and manufacturing method thereof

An oxide semiconductor and field effect transistor technology, which is applied in the field of trench metal oxide semiconductor field effect transistors and their manufacturing, can solve the problems of difficult processing and high cost, and achieves improved production efficiency, improved welding speed, and reduced usage quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

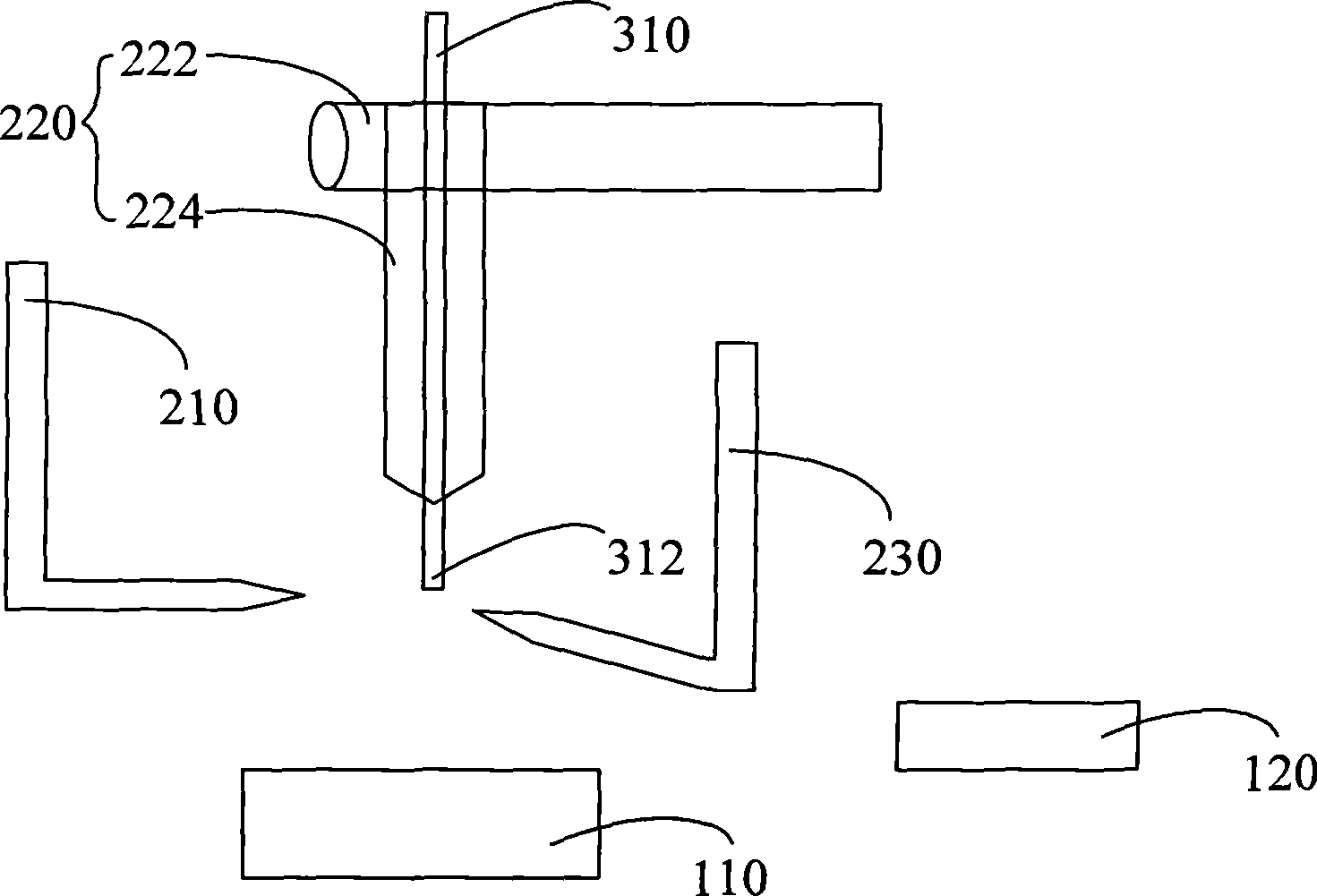

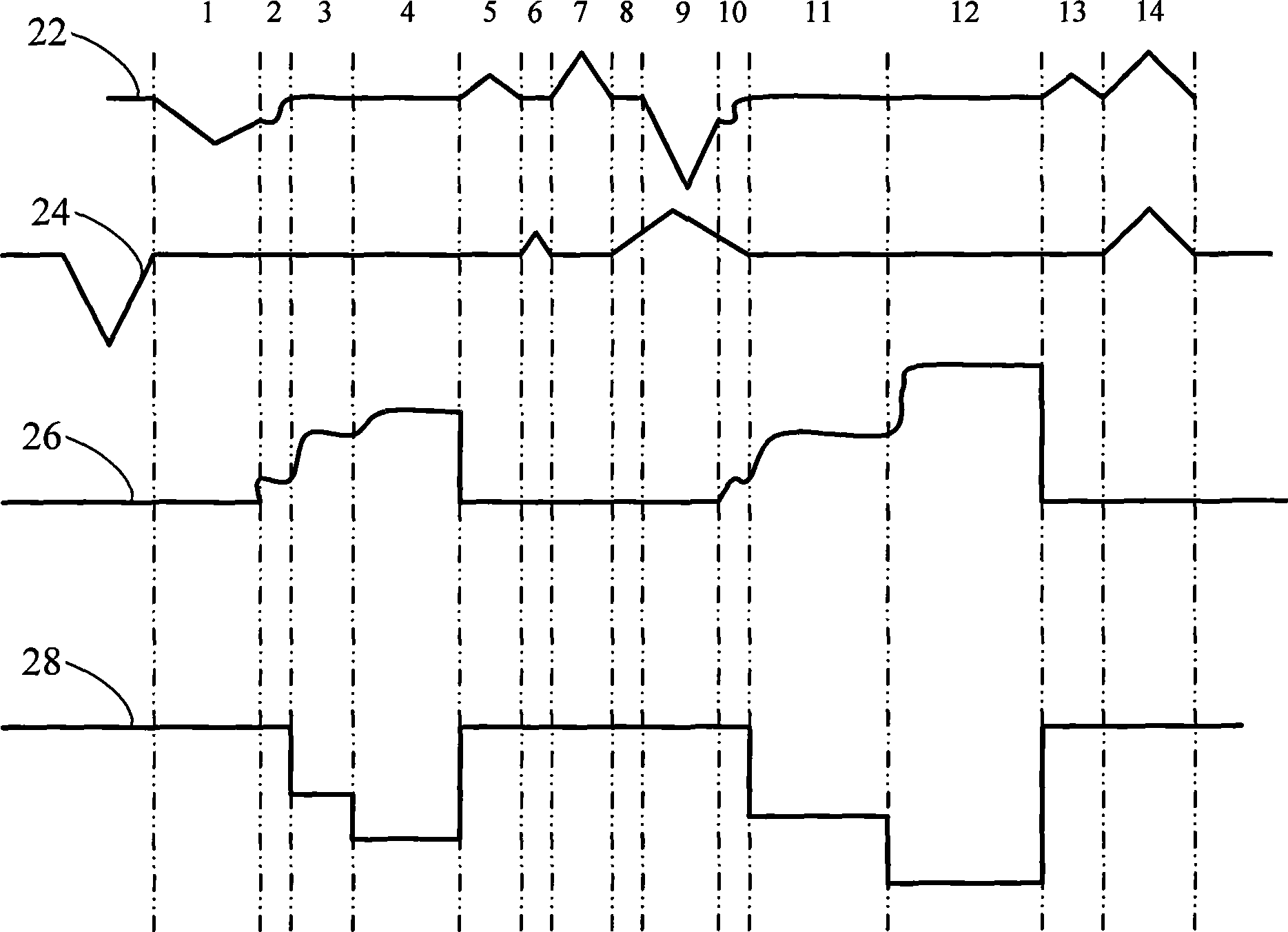

[0022] A detailed description will be given below in conjunction with specific embodiments. In the following embodiments, copper wires are used to replace traditional gold wires or aluminum wires to achieve the purpose of reducing cost and processing difficulty.

[0023] A significant advantage of copper is that its electrical conductivity is superior to that of gold and even higher than that of aluminum. Therefore, the amount of copper wire can be reduced to reduce the cost of raw materials. Since the Trench MOSFET is a power tube, the current is very large in practical applications, and due to technical limitations, the maximum wire diameter used for ball bonding should not exceed 3mil (1mil is one-thousandth of an inch, and gold wires can only be used for 2mil), so this The method actually needs to solder as many as 12 or more 2mil gold wires, so the cost is extremely high and the efficiency is very low. Based on the consideration of cost reduction and efficiency improvemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com